| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Amna Farrukh | + 2645 word(s) | 2645 | 2020-10-13 08:14:09 | | | |

| 2 | Bruce Ren | -1 word(s) | 2644 | 2020-10-21 08:10:11 | | |

Video Upload Options

Green lean six sigma (GLSS) is an emerging approach towards environmental sustainability in conjunction with operational achievements. The success of this approach is premised on an understanding of the different components of a GLSS program; being the determinants for its outcomes. The aim of this paper is to investigate the various constructs of GLSS that play an essential role in achieving environmental sustainability. For this purpose, a systematic review of available literature has been conducted to evaluate the drivers, enablers (tools), and outcomes of a GLSS strategy as well as its critical success factors and barriers. Findings reveal that these constructs of GLSS as a holistic approach can facilitate an organization to better accomplish environmental objectives such as waste minimization, emission reduction, and resource conservation as compared to constructs of only one or any two of these strategies. Based on the analysis, an integrated GLSS framework is developed for environmental sustainability in addition to identifying vital research gaps and future directions.

1. Introduction

In the past few decades, organizations have implemented various improvement strategies globally to increase operational performance and achieve customer satisfaction [1]. Nowadays, customer awareness towards eco-friendly products and services, and worldwide environmental legislations are forcing organizations to synchronize their environmental goals with operational performance requirements [2][3].

Organizations operating in different areas such as manufacturing, healthcare, service, and education are confronting several environmental problems including operational wastes. Environmental problems are identified as greenhouse gas (GHG) emissions such as carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) [4], generation of volatile organic compounds (VOCs), and water pollution [4][5]. These GHG emissions are not only generated during the manufacturing processes within the organization but also in supply chain activities while procuring material through logistics and transportation [6][7]. Along with these challenges, organizations also experience a global limitation of resources including energy, water, and raw material [8]. Additionally, sudden disruptions such as the current economic disturbance with a drastic increase in environmental awareness due to COVID-19 have emphasized the need for strategies that help organizations and governments in economic recovery together with environmental protection and resource conservation. A system is required that enhances the environmental performance of an organization without compromising the operational objectives [8].

Green lean six sigma (GLSS) has emerged as an approach towards achieving environmental objectives combined with operational performance [9]. It consists of tools and practices to achieve environmental performance by eliminating waste and conserving resources [10]. In the GLSS approach, green aims to reduce environmental wastes by executing environmental practices, lean decreases process wastes that helps in lowering environmental wastes, and six sigma contributes in minimizing defects and controlling process variation that leads to environmental waste reduction [11].

Literature regarding the green, lean, and six sigma strategies towards environmental problems include studies on linkages between lean and six sigma (LSS) [12], lean and green (LG) [13], and green lean six sigma [14]. Research also indicates the relationship of six sigma and green tools in gaining positive environmental effects [15]. There are numerous studies on the environmental performance achieved by utilizing these strategies separately [16][17][18]. However, there is a lack of literature on all three green, lean, and six sigma strategies as a combined holistic approach [19]. This gap is well highlighted in literature by several researchers such as Kumar et al. [20], Gaikwad and Sunnapwar [19], and Cherrafi et al. [21]. A combined GLSS approach is perceived as a potential strategy for the organizations towards environmental sustainability [22] as compared to the individual strategies or any of the two strategies. For example, lean six sigma lacks the ability of addressing life cycle impacts and managing environmental programs whereas green strategy can overcome this limitation by utilizing life cycle analysis (LCA) and environment management system (EMS) tools [11]. Similarly, if six sigma and green are combined, this approach is unable to highlight the lean process/production wastes that can have a major contribution on environmental performance [23].

Few studies have identified the theoretical constructs of a GLSS approach such as drivers, critical success factors (CSFs), tools and techniques, barriers, and outcomes individually [24][25]. However, there is little research that addresses the above GLSS constructs as a consolidated approach in reducing environmental impacts of organizations.

A systematic literature review has been conducted in this paper to investigate the existing studies on GLSS as an integrated concept. This paper investigates the drivers, enablers (tools), outcomes, CSFs, and barriers of a GLSS strategy which are the key components for realizing environmental benefits as well as identifies possible gaps and future research opportunities. The paper theoretically contributes to bridging the knowledge gap regarding the constructs of a holistic GLSS approach. Additionally, a holistic framework is developed that includes the GLSS constructs for achieving environmental sustainability. The research objectives of this paper are summarized as follows:

- To investigate the theoretical constructs (drivers, enablers, CSFs, barriers, and outcomes) of a holistic GLSS approach.

- To develop an integrated framework combining the above GLSS constructs as a holistic approach.

- To highlight the possible gaps and future research directions of a holistic GLSS approach.

The rest of the paper is structured as follows. Section two presents a literature review on green, lean, and six sigma strategies. Section three highlights the systematic literature review methodology used for this study. Section four represents the descriptive analysis of the selected articles and related findings. Section five entails a critical analysis of the green lean six sigma findings from literature. Section six highlights the gaps identified and future directions. Finally, conclusions and limitations of the study are presented in section seven.

2. A Review of Green, Lean, and Six Sigma Approaches towards Environmental Sustainability

2.1. Green Approach

Green manufacturing as a philosophy determines, measures, evaluates, and controls the environmental wastes by solving problems associated with the products and processes. The green concept has gained importance as it facilitates more and more organizations in minimizing their environmental impacts. A plethora of literature has emphasized the impact of green methods such as LCA, EMS, design for environment (DFE), energy management system (EnMS), and 3R (reducing, reusing, and recycling) on environmental performance [26][27][28][29]. These practices have positive outcomes in the form of conforming regulatory requirements, meeting customers’ demands of environmental-friendly products, and achieving environmental certification [30]. The core objective of green approach is to minimize environmental impacts such as hazardous wastes, air emissions, health and safety risks to people and environment, and energy and resource conservation. Green wastes include pollution, unnecessary water consumption, air emissions, excessive energy and material utilization, eutrophication, and garbage [31]. Green manufacturing comprises various environmental initiatives in the form of green marketing, green packaging, green purchasing, green innovation, and green design [32]. The environmental initiatives in the form of EMS, eco-labelling, and environmental legislation have created a demand for green manufacturing in organizations [30].

2.2. Lean Approach

Lean manufacturing originated from Toyota Production System and gained recognition after the book entitled The Machine That Changed the World was published [33]. The lean philosophy works on “to do more with less” and minimizes waste in almost every area of an organization [30] (p. 410). Lean as a concept is based on the elimination of non-value added activities and can be described as a group of tools aimed to achieve the objectives of waste minimization and value addition [34]. Organizations implement lean strategy to create value for customers by minimizing lead time, reducing wastes, and improving flow of the process [14]. Moreover, value addition in lean manufacturing also includes providing value in products and services that reflect the environmental requirements from customers and initiatives taken by the organization [14].

Lean paradigm offers a variety of tools which can be utilized to reduce environmental impacts of manufacturing organizations [35]. These methods not only help organizations in achieving operational performance and gaining competitive advantage but also in accomplishing environmental targets [17]. Several studies have recognized the environmental advantages of lean practices by saving resources and energy [17][36][37]. In this regard, different examples of the lean tools are: total productive maintenance (TPM), Kaizen, 5S (seiri, seiton, seiso, seiketsu, shitsuke), value stream mapping (VSM), cellular manufacturing (CM), just-in-time (JIT), single minute exchange of die (SMED), visual management, and work standardization which have been utilized to enhance the environmental performance [17][38].

2.3. Six Sigma Approach

Six sigma methodology was first introduced by Motorola, in 1987, in the manufacturing sector. The concept is based on the statistical process control (SPC) technique, which is used to reduce defects up to 3.4 parts per million opportunities and the term sigma is used to describe variation. It provides a systematic and structured approach of problem solving through the DMAIC process that includes define (D), measure (M), analyze (A), improve (I), and control (C) phases [39]. Six sigma not only helps in removing manufacturing defects in the production processes but also brings about improvements throughout the organization [40]. The core objectives of six sigma are to control process variation and defect reduction [41][42].

Although reducing environmental waste is not the primary objective of a six sigma approach, it is capable of achieving environmental performance such as reducing air emissions, energy consumption, and wastewater [43][44]. Process variation has a negative impact on overall environmental performance of an organization as deviating from the specifications results in defective products as well as resource and energy consumption [45]. Thus, the environmental impacts of six sigma are viewed as a “by-product” [36] (p. 10). By utilizing its tools in reducing defects, six sigma gains the objectives of resource conservation, air pollution, and waste minimization [36]. Literature also indicates the environmental benefits of six sigma methodology such as through use of pareto analysis, gage repeatability and reproducibility (gage R&R), control charts, design of experiment (DOE), histogram, failure mode effect analysis (FMEA), DMAIC methodology, and supplier-input-process-output-control (SIPOC) diagram [46][47][48].

2.4. Lean-Green Approach

The difference between lean and green wastes is that the first is about non-value added activities and the second is about unnecessary usage of water, energy, and natural resources [49]. However, US Environmental Protection Agency (EPA) [50] presented a relationship between lean mudas and green wastes after an analysis of American firms which showed the simultaneous occurrence of the environmental wastes along with the lean wastes. Furthermore, the non-value-added activities could be regarded as a segment of wastage of power and natural resources. For instance, unnecessary movement of raw materials, work-in-process, and finished products are regarded as wastes from both lean and green perspective in terms of power consumption, gaseous emissions, and immoderate use of resources [51]. Based on the mutual objective of waste minimization, lean and green have been integrated into a joint strategy . This synergistic relationship between lean and green not only achieves the environmental benefits but also reduces costs through waste minimization.

2.5. Lean-Six Sigma Approach

The integration of lean and six sigma is an established concept (i.e., LSS) and well acknowledged in literature. The major common aspects of lean six sigma are waste minimization, continuous improvement, and customer satisfaction [52]. Since waste also includes rework and scrap which are often produced as a result of process variability, thereby, lean and six sigma are also connected [53]. Several organizations are developing a concurrent lean six sigma (LSS) approach, which integrates lean with six sigma as they contribute to a common objective of waste minimization [54].

2.6. Limitations of Lean, Green, and Six Sigma Approaches

Although, lean application has a positive and strong effect on environmental impact, research studies have emphasized that lean cannot fully remove the root causes of operational and environmental wastes, as it lacks a systematic and scientific approach in controlling manufacturing processes [55]. Further, lean individually cannot overcome problems of defect detection and reduction in the process to address environmental concerns [56]. On the other hand, green is incapable of addressing the variability issues in the process which leads to the environmental wastes [56]. While green manufacturing includes application of a decision support system and expert system [9], these techniques lack effective problem-solving approach [57]. Further, green manufacturing has limitations regarding the strategic concerns of an organization and decision making towards investment opportunities, for example, how to implement green practices in a manner that achieves the organizational goal towards environmental sustainability and profitability [58]. Similarly, six sigma alone cannot achieve the optimal environmental performance since it lacks the ability of addressing lean wastes in an organization and life cycle impact assessment related to products [59].

2.7. Limitations of Lean-Green, Lean-Six Sigma, and Green-Six Sigma Approaches

Due to the inherent limitations of the lean, green, and six sigma strategies, combinations of these strategies such as lean-green, lean-six sigma, and green-six sigma also experience limitations. For example, in the case of lean-green, although lean and green have the ability to identify wastes for environmental impacts, they usually do not present a structured problem-solving approach to waste reduction [60] nor are they able to control process variation [43]. Despite lean and green being closely related, they do not address root causes of a problem which is critical from a waste minimization aspect. Therefore, studies have focused on combining six sigma with lean and green to resolve the above limitations of these strategies and enhance environmental sustainability [11,43]. Although, lean six sigma can enhance the environmental performance indirectly, environmental waste reduction is not the primary objective of LSS. This combination also lacks the ability of addressing life cycle impacts and deploying environmental improvement programs whereas green strategy can overcome this limitation by utilizing tools such as LCA, EMS, and DOE. Similarly, if six sigma and green are combined then this combination may not be able to highlight lean wastes that have an indirect impact on environmental performance (as lean process/production wastes have a contribution on environmental wastes). Lean can overcome this limitation through its waste analysis and management tools.

Garza-Reyes has explained the relationship between green, lean, and six sigma by highlighting lean’s role as an intermediate strategy for connecting green and six sigma. These three approaches are interrelated, adaptable, share common features, and overcome limitations of each other. Due to these characteristics, green, lean, and six sigma strategies as a unified approach can address the aims of waste minimization, resource savings, and environmental impacts.

2.8. Green Lean Six Sigma Approach

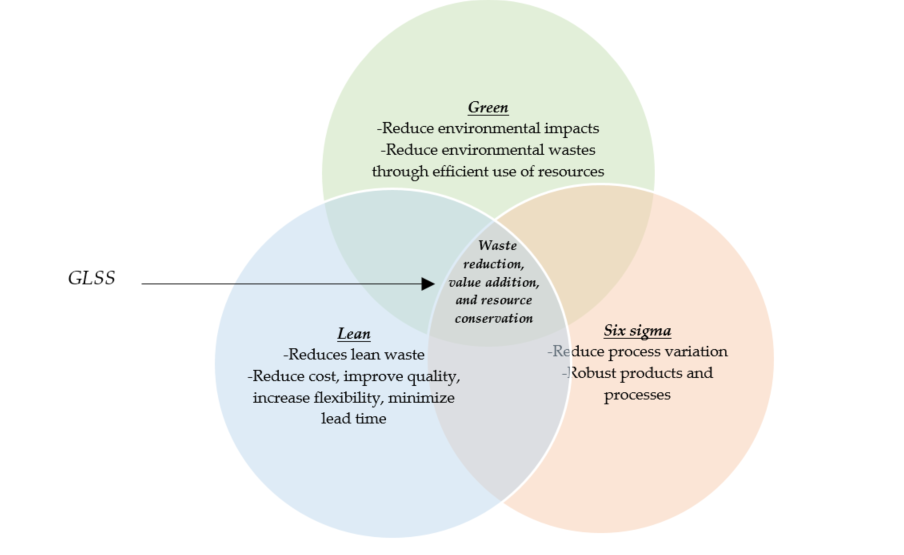

The relationship among these three strategies can be better understood by their inherent characteristics of customer satisfaction achieved through waste reduction and value addition. Each strategy in GLSS approach overcomes limitations of the other strategy to provide value by identifying and removing wastes resulting in environmental sustainability. Waste has a different meaning within the green, lean, and six sigma strategies. In green manufacturing, waste is defined as environmental wastes and the green practices aim to remove these in order to fulfil customers’ requirements of an environmentally safe product. Green strategy also includes the concept of green value addition (GVA) which adds value for the organization, stakeholders, and eventually for the environment [61]. Lean refers to the elimination of non-value added activities to satisfy customers and attempts to minimize various lean wastes. On the other hand, six sigma enhances customer satisfaction by reducing defects (waste) which can result in a high-quality product. It generates value in the products and services through stable and reliable processes by reducing variation. Although waste has different meanings in these strategies, the effect of waste is similar from “resource consumption” point of view, which is the ultimate impact of all these three strategies. In terms of environmental impacts of these strategies, green manufacturing clearly focuses on the environmental performance and resource conservation as one of its main dimensions [62]. Lean also saves resources by reducing waste, thus is recognized as an “environmental friendly method". Similarly, six sigma signifies defect as material waste, space occupied, safety issue, and energy consumed [63]. The relationship between these three strategies is evident from Figure 1.

Figure 1. Objectives of green, lean, and six sigma and common aspects of GLSS, adapted from Snee [64], Dues et al. [65], and Kaswan and Rathi [22].

From the above discussion, the environmental performance can be improved if the green, lean, and six sigma strategies are combined to support each other as each of these has limitations. Although the practices associated with the green, lean, and six sigma strategies have positive environmental impacts, their combined effect is more significant as compared to individual practices [66].

References

- Shokri, A.; Li, G. Green implementation of Lean Six Sigma projects in the manufacturing sector. Int. J. Lean Six Sigma 2020, doi:10.1108/ijlss-12-2018-0138.

- Garza-Reyes, J.A.; Yu, M.; Kumar, V.; Upadhyay, A. Total quality environmental management: Adoption status in the Chinese manufacturing sector. TQM J. 2018, 30, 2–19, doi:10.1108/tqm-05-2017-0052.

- Parmar, P.S.; Desai, T.N. A systematic literature review on Sustainable Lean Six Sigma. Int. J. Lean Six Sigma 2019, doi:10.1108/ijlss-08-2018-0092.

- Galli, A.; Wiedmann, T.; Ercin, E.; Knoblauch, D.; Ewing, B.; Giljum, S. Integrating Ecological, Carbon and Water footprint into a “Footprint Family” of indicators: Definition and role in tracking human pressure on the planet. Ecol. Indic. 2012, 16, 100–112, doi:10.1016/j.ecolind.2011.06.017.

- Bai, X.; Ren, X.; Khanna, N.Z.; Zhou, N.; Hu, M. Comprehensive water footprint assessment of the dairy industry chain based on ISO 14046: A case study in China. Resour. Conserv. Recycl. 2018, 132, 369–375, doi:10.1016/j.resconrec.2017.07.021.

- Sreedharan, R.; Sandhya, G.; Raju, R. Development of a Green Lean Six Sigma model for public sectors. Int. J. Lean Six Sigma 2018, 9, 238–255, doi:10.1108/ijlss-02-2017-0020.

- Tseng, M.L.; Islam, M.S.; Karia, N.; Fauzi, F.A.; Afrin, S. A literature review on green supply chain management: Trends and future challenges. Resour. Conserv. Recycl. 2019, 141, 145–162, doi:10.1016/j.resconrec.2018.10.009.

- Mangla, S.K.; Luthra, S.; Mishra, N.; Singh, A.; Rana, N.P.; Dora, M.; Dwivedi, Y. Barriers to effective circular supply chain management in a developing country context. Prod. Plan. Control 2018, 29, 551–569, doi:10.1080/09537287.2018.1449265.

- Garza-Reyes, J.A. Green lean and the need for Six Sigma. Int. J. Lean Six Sigma 2015, 6, 226–248, doi:10.1108/ijlss-04-2014-0010.

- Cherrafi, A.; Elfezazi, S.; Chiarini, A.; Mokhlis, A.; Benhida, K. The integration of lean manufacturing, Six Sigma and sustainability: A literature review and future research directions for developing a specific model. J. Clean. Prod. 2016, 139, 828–846, doi:10.1016/j.jclepro.2016.08.101.

- Banawi, A.; Bilec, M.M. A framework to improve construction processes: Integrating Lean, Green and Six Sigma. Int. J. Constr. Manag. 2014, 14, 45–55, doi:10.1080/15623599.2013.875266.

- De Freitas, J.G.; Costa, H.G.; Ferraz, F.T. Impacts of Lean Six Sigma over organizational sustainability: A survey study. J. Clean. Prod. 2017, 156, 262–275, doi:10.1016/j.jclepro.2017.04.054.

- Farias, L.M.S.; Santos, L.C.; Gohr, C.F.; de Oliveira, L.C.; da Silva Amorim, M.H. Criteria and practices for lean and green performance assessment: Systematic review and conceptual framework. J. Clean. Prod. 2019, 218, 746–762.

- Sony, M.; Naik, S. Green Lean Six Sigma implementation framework: A case of reducing graphite and dust pollution. Int. J. Sustain. Eng. 2019, doi:10.1080/19397038.2019.1695015.

- Cagno, E.; Trucco, P. Integrated green and quality function deployment. Int. J. Prod. Lifecycle Manag. 2007, 2, doi:10.1504/ijplm.2007.012875.

- Shih, C.W.; Wang, C.H. Integrating wireless sensor networks with statistical quality control to develop a cold chain system in food industries. Comput. Stand. Interfaces 2016, 45, 62–78, doi:10.1016/j.csi.2015.12.004.

- Garza-Reyes, J.A.; Kumar, V.; Chaikittisilp, S.; Tan, K.H. The effect of lean methods and tools on the environmental performance of manufacturing organisations. Int. J. Prod. Econ. 2018, 200, 170–180, doi:10.1016/j.ijpe.2018.03.030.

- Al-Sheyadi, A.; Muyldermans, L.; Kauppi, K. The complementarity of green supply chain management practices and the impact on environmental performance. J. Environ. Manag. 2019, 242, 186–198, doi:10.1016/j.jenvman.2019.04.078.

- Gaikwad, L.; Sunnapwar, V. An integrated Lean, Green and Six Sigma strategies. TQM J. 2020, 32, 201–225, doi:10.1108/tqm-08-2018-0114.

- Kumar, S.; Luthra, S.; Govindan, K.; Kumar, N.; Haleem, A. Barriers in green lean six sigma product development process: An ISM approach. Prod. Plan. Control 2016, doi:10.1080/09537287.2016.1165307.

- Cherrafi, A.; Elfezazi, S.; Govindan, K.; Garza-Reyes, J.A.; Benhida, K.; Mokhlis, A. A framework for the integration of Green and Lean Six Sigma for superior sustainability performance. Int. J. Prod. Res. 2016, 55, 4481–4515, doi:10.1080/00207543.2016.1266406.

- Kaswan, M.S.; Rathi, R. Green Lean Six Sigma for sustainable development: Integration and framework. Environ. Impact Assess. Rev. 2020, 83, doi:10.1016/j.eiar.2020.106396.

- Arroyo, P.; Gonzalez, V. Rethinking waste definition to account for environmental and social impacts. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24 July 2016; pp. 20–22.

- Hussain, K.; He, Z.; Ahmad, N.; Iqbal, M.; Taskheer Mumtaz, S.M. Green, lean, Six Sigma barriers at a glance: A case from the construction sector of Pakistan. Build. Environ. 2019, 161, doi:10.1016/j.buildenv.2019.106225.

- Mishra. Identify critical success factors to implement integrated green and Lean Six Sigma. Int. J. Lean Six Sigma 2018, doi:10.1108/ijlss-07-2017-0076.

- Guo, C.; Xu, J.; Yang, L.; Guo, X.; Liao, J.; Zheng, X.; Zhang, Z.; Chen, X.; Yang, K.; Wang, M. Life cycle evaluation of greenhouse gas emissions of a highway tunnel: A case study in China. J. Clean. Prod. 2019, 211, 972–980, doi:10.1016/j.jclepro.2018.11.249.

- Canellada, F.; Laca, A.; Laca, A.; Diaz, M. Environmental impact of cheese production: A case study of a small-scale factory in southern Europe and global overview of carbon footprint. Sci. Total Environ. 2018, 635, 167–177, doi:10.1016/j.scitotenv.2018.04.045.

- Nguyen, Q.A.; Hens, L. Environmental performance of the cement industry in Vietnam: The influence of ISO 14001 certification. J. Clean. Prod. 2015, 96, 362–378, doi:10.1016/j.jclepro.2013.09.032.

- De Sousa Jabbour, A.B.L.; Verdério Júnior, S.A.; Jabbour, C.J.C.; Leal Filho, W.; Campos, L.S.; De Castro, R. Toward greener supply chains: Is there a role for the new ISO 50001 approach to energy and carbon management? Energy Effic. 2016, 10, 777–785, doi:10.1007/s12053-016-9478-z.

- Prasad, S.; Khanduja, D.; Sharma, S.K. An empirical study on applicability of lean and green practices in the foundry industry. J. Manuf. Technol. Manag. 2016, 27, 408–426, doi:10.1108/jmtm-08-2015-0058.

- Hines, P. Lean and green. In Source Magazine the Home of Lean Thinking; 3rd ed.; SA Partners, Caerphilly, UK, 2009.

- Kazancoglu, Y.; Kazancoglu, I.; Sagnak, M. A new holistic conceptual framework for green supply chain management performance assessment based on circular economy. J. Clean. Prod. 2018, 195, 1282–1299, doi:10.1016/j.jclepro.2018.06.015.

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World: The Story of Lean Production—Toyota’s Secret Weapon in the Global Car Wars That is Now Revolutionizing World Industry; Simon and Schuster: New York, USA, 2007.

- Panwar, A.; Jain, R.; Rathore, A.P.S.; Nepal, B.; Lyons, A.C. The impact of lean practices on operational performance – an empirical investigation of Indian process industries. Prod. Plan. Control 2017, 29, 158–169, doi:10.1080/09537287.2017.1397788.

- Alhuraish, I.; Robledo, C.; Kobi, A. A comparative exploration of lean manufacturing and six sigma in terms of their critical success factors. J. Clean. Prod. 2017, 164, 325–337, doi:10.1016/j.jclepro.2017.06.146.

- Chugani, N.; Kumar, V.; Garza-Reyes, J.A.; Rocha-Lona, L.; Upadhyay, A. Investigating the green impact of Lean, Six Sigma and Lean Six Sigma. Int. J. Lean Six Sigma 2017, 8, 7–32, doi:10.1108/ijlss-11-2015-0043.

- Dieste, M.; Panizzolo, R.; Garza-Reyes, J.A.; Anosike, A. The relationship between lean and environmental performance: Practices and measures. J. Clean. Prod. 2019, 224, 120–131, doi:10.1016/j.jclepro.2019.03.243.

- Ramos, A.R.; Ferreira, J.C.E.; Kumar, V.; Garza-Reyes, J.A.; Cherrafi, A. A lean and cleaner production benchmarking method for sustainability assessment: A study of manufacturing companies in Brazil. J. Clean. Prod. 2018, 177, 218–231, doi:10.1016/j.jclepro.2017.12.145.

- Hilton, R.J.; Antony, J.; Sohal, A. A conceptual model for the successful deployment of Lean Six Sigma. Int. J. Qual. Reliab. Manag. 2012, 29, 54–70, doi:10.1108/02656711211190873.

- Singh, M.; Rathi, R. A structured review of Lean Six Sigma in various industrial sectors. Int. J. Lean Six Sigma 2018, doi:10.1108/ijlss-03-2018-0018.

- Pacheco, D.; Pergher, I.; Vaccaro, G.L.R.; Jung, C.F.; ten Caten, C. 18 comparative aspects between lean and Six Sigma: Complementarity and implications. Int. J. Lean Six Sigma 2015, 6, 161–175.

- Andersson, R.; Mi Dahlgaard‐Park, S.; Eriksson, H.; Torstensson, H. Similarities and differences between TQM, six sigma and lean. TQM Mag. 2006, 18, 282–296, doi:10.1108/09544780610660004.

- Sagnak, M.; Kazancoglu, Y. Integration of green lean approach with six sigma: An application for flue gas emissions. J. Clean. Prod. 2016, 127, 112–118, doi:10.1016/j.jclepro.2016.04.016.

- Powell, D.; Lundeby, S.; Chabada, L.; Dreyer, H. Lean Six Sigma and environmental sustainability: The case of a Norwegian dairy producer. Int. J. Lean Six Sigma 2017, 8, 53–64, doi:10.1108/ijlss-06-2015-0024.

- Ben Ruben, R.; Vinodh, S.; Asokan, P. Implementation of Lean Six Sigma framework with environmental considerations in an Indian automotive component manufacturing firm: A case study. Prod. Plan. Control 2017, 28, 1193–1211, doi:10.1080/09537287.2017.1357215.

- Sony, M. Lean Six Sigma in the power sector: Frog into prince. Benchmarking Int. J. 2019, 26, 356–370, doi:10.1108/bij-10-2017-0276.

- Kaushik, P.; Khanduja, D.; Mittal, K.; Jaglan, P. A case study. TQM J. 2012, 24, 4–16, doi:10.1108/17542731211191186.

- Rimantho, D.; Hanantya, M.W. Enhancing the management of the noise level using six sigma method: A case study on the machining industry. IOP Conf. Ser. Mat. Sci. Eng. 2017, 277, doi:10.1088/1757-899x/277/1/012055.

- Duarte, S.; Cruz‐Machado, V. Modelling lean and green: A review from business models. Int. J. Lean Six Sigma 2013, 4, 228–250.

- EPA. The Lean and Environmental Toolkit; United States Environmental Protection Agency: Washington, DC, USA, 2007.

- Carvalho, H.; Duarte, S.; Machado, V.C. Lean, agile, resilient and green: Divergencies and synergies. Int. J. Lean Six Sigma 2011, 2, 151–179.

- Maleyeff, J.; Arnheiter, E.A.; Venkateswaran, V. The continuing evolution of Lean Six Sigma. TQM J. 2012, 24, 542–555, doi:10.1108/17542731211270106.

- Klochkov, Y.; Gazizulina, A.; Muralidharan, K. Lean Six Sigma for Sustainable Business Practices: A Case Study and Standardisation. Int. J. Qual. Res. 2019, 13, 47–74, doi:10.24874/ijqr13.01-04.

- Salah, S.; Rahim, A.; Carretero, J.A. The integration of Six Sigma and lean management. Int. J. Lean Six Sigma 2010, 1, 249–274, doi:10.1108/20401461011075035.

- Assarlind, M.; Gremyr, I.; Bäckman, K. Multi-faceted views on a Lean Six Sigma application. Int. J. Qual. Reliab. Manag. 2013, 30, 387–402.

- Kaswan, M.S.; Rathi, R. Analysis and modeling the enablers of Green Lean Six Sigma implementation using Interpretive Structural Modeling. J. Clean. Prod. 2019, 231, 1182–1191, doi:10.1016/j.jclepro.2019.05.253.

- Chan, C.C.; Yu, K.; Yung, K. Green manufacturing using integrated decision tools. In Proceedings of the 2010 IEEE International Conference on Industrial Engineering and Engineering Management, Macao, China, 7–10 December 2010; pp. 2287–2291.

- Nunes, B.; Bennett, D. Green operations initiatives in the automotive industry: An environmental reports analysis and benchmarking study. Benchmarking Int. J. 2010, 17, 396–420.

- Zhang, Y. Green QFD-II: A life cycle approach for environmentally conscious manufacturing by integrating LCA and LCC into QFD matrices. Int. J. Prod. Res. 1999, 37, 1075–1091, doi:10.1080/002075499191418.

- Han, S.H.; Chae, M.J.; Im, K.S.; Ryu, H.D. Six sigma-based approach to improve performance in construction operations. J. Manag. Eng. 2008, 24, 21–31.

- Ndubisi, N.O.; Nair, S.R. Green entrepreneurship (GE) and green value added (GVA): A conceptual framework. Int. J. Entrep. 2009, 13, 21.

- Thanki, S.; Thakkar, J. Interdependence analysis of lean-green implementation challenges: A case of Indian SMEs. J. Manuf. Technol. Manag. 2018, doi:10.1108/jmtm-04-2017-0067.

- Goyal, A.; Agrawal, R.; Saha, C.R. Quality management for sustainable manufacturing: Moving from number to impact of defects. J. Clean. Prod. 2019, 241, doi:10.1016/j.jclepro.2019.118348.

- Snee, R.D. Lean Six Sigma—Getting better all the time. Int. J. Lean Six Sigma 2010, 1, 9–29, doi:10.1108/20401461011033130.

- Dües, C.M.; Tan, K.H.; Lim, M. Green as the new Lean: How to use Lean practices as a catalyst to greening your supply chain. J. Clean. Prod. 2013, 40, 93–100, doi:10.1016/j.jclepro.2011.12.023.

- Green, K.W.; Inman, R.A.; Sower, V.E.; Zelbst, P.J. Impact of JIT, TQM and green supply chain practices on environmental sustainability. J. Manuf. Technol. Manag. 2019, 30, 26–47, doi:10.1108/jmtm-01-2018-0015.