Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Din Bandhu | -- | 3737 | 2022-08-31 18:30:08 | | | |

| 2 | Rita Xu | -14 word(s) | 3723 | 2022-09-01 02:58:39 | | | | |

| 3 | Rita Xu | + 20 word(s) | 3743 | 2022-09-02 11:25:02 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kumari, S.; Shah, M.; Modi, Y.; Bandhu, D.; Zadafiya, K.; Abhishek, K.; Saxena, K.K.; Msomi, V.; Mohammed, K.A. Minimum Quantity Lubrication Machining of Titanium Alloys. Encyclopedia. Available online: https://encyclopedia.pub/entry/26752 (accessed on 07 February 2026).

Kumari S, Shah M, Modi Y, Bandhu D, Zadafiya K, Abhishek K, et al. Minimum Quantity Lubrication Machining of Titanium Alloys. Encyclopedia. Available at: https://encyclopedia.pub/entry/26752. Accessed February 07, 2026.

Kumari, Soni, Meet Shah, Yug Modi, Din Bandhu, Kishan Zadafiya, Kumar Abhishek, Kuldeep K. Saxena, Velaphi Msomi, Kahtan A. Mohammed. "Minimum Quantity Lubrication Machining of Titanium Alloys" Encyclopedia, https://encyclopedia.pub/entry/26752 (accessed February 07, 2026).

Kumari, S., Shah, M., Modi, Y., Bandhu, D., Zadafiya, K., Abhishek, K., Saxena, K.K., Msomi, V., & Mohammed, K.A. (2022, August 31). Minimum Quantity Lubrication Machining of Titanium Alloys. In Encyclopedia. https://encyclopedia.pub/entry/26752

Kumari, Soni, et al. "Minimum Quantity Lubrication Machining of Titanium Alloys." Encyclopedia. Web. 31 August, 2022.

Copy Citation

Titanium alloys offer a variety of unique qualities, including high strength, resistance to chemical deterioration, and excellent corrosion resistance, particularly stress corrosion. These alloys are utilized in aircraft, power plants, heat exchangers, water heaters, pressure vessels, and orthopedic implants because of their characteristics. Minimum quantity lubrication (MQL) is one method in which just a small amount of fluid is required during machining operations.

titanium alloy

MQL

wet machining

1. Introduction

The ability of this alloy to maintain these qualities at elevated temperatures severely hinders machinability during machining, and hence, this alloy is classified as difficult to cut. The increased temperature at the point of contact between the tool and the workpiece promotes quick tool wear and, as a result, a poor surface finish [1][2]. To address this issue, coolant/lubricant oils and liquids are delivered to the cutting zone.

The use of these fluids in machining operations produces aerosols and mists that can endanger the environment and have an impact on worker health [3]. Furthermore, the cost of these coolants is 7–17% of the entire machining cost, which is greater than the cost of tooling (i.e., 7%) [4][5]. As a result, reducing the use of these fluids is essential here [6]. Dry machining is used for economic and environmental reasons, but it has some limitations in that it is not suitable for sticky and difficult-to-cut materials such as titanium alloys because it causes the material to stick to the tool face, produces a poor surface finish, requires a high cutting force, and has a high wear rate [7]. Titanium alloy machining is confined to lower cutting speed operations, resulting in a reduced production rate [8]. Minimum quantity lubrication (MQL) is one method in which just a small amount of fluid is required during machining operations [9]. Cooling in a deformation zone is critical, hence a fluid with high thermal conductivity must be used [10]. Given the aforementioned limitations, unique cutting fluid and long-term cooling methods are critical for achieving high-performance cooling.

Coolants/lubricants are crucial in machining and cannot be overlooked when evaluating machining performance. If coolants/lubricants are not used during machining, high tool wear, high energy consumption, and shorter tool life will be the results, besides other machining outcomes. It is also critical to select a cutting fluid (CF) composition that does not hurt the environment or emit high levels of emissions. To address these environmental issues, various eco-friendly cutting fluids are now available. The following characteristics are used to select cutting fluids: heat transmission, lubrication, flushing action, fluid mist formation, and corrosion inhibition. Aside from that, the expense of the cutting fluid should be kept to a minimum. The fluid should provide high machining performance while also being environmentally friendly. As a result, because cutting fluids have a bigger impact on the company’s sustainability, cutting fluids should be chosen properly to be profitable while emitting as little as possible.

2. Minimum Quantity Lubrication (MQL) Machining Strategy

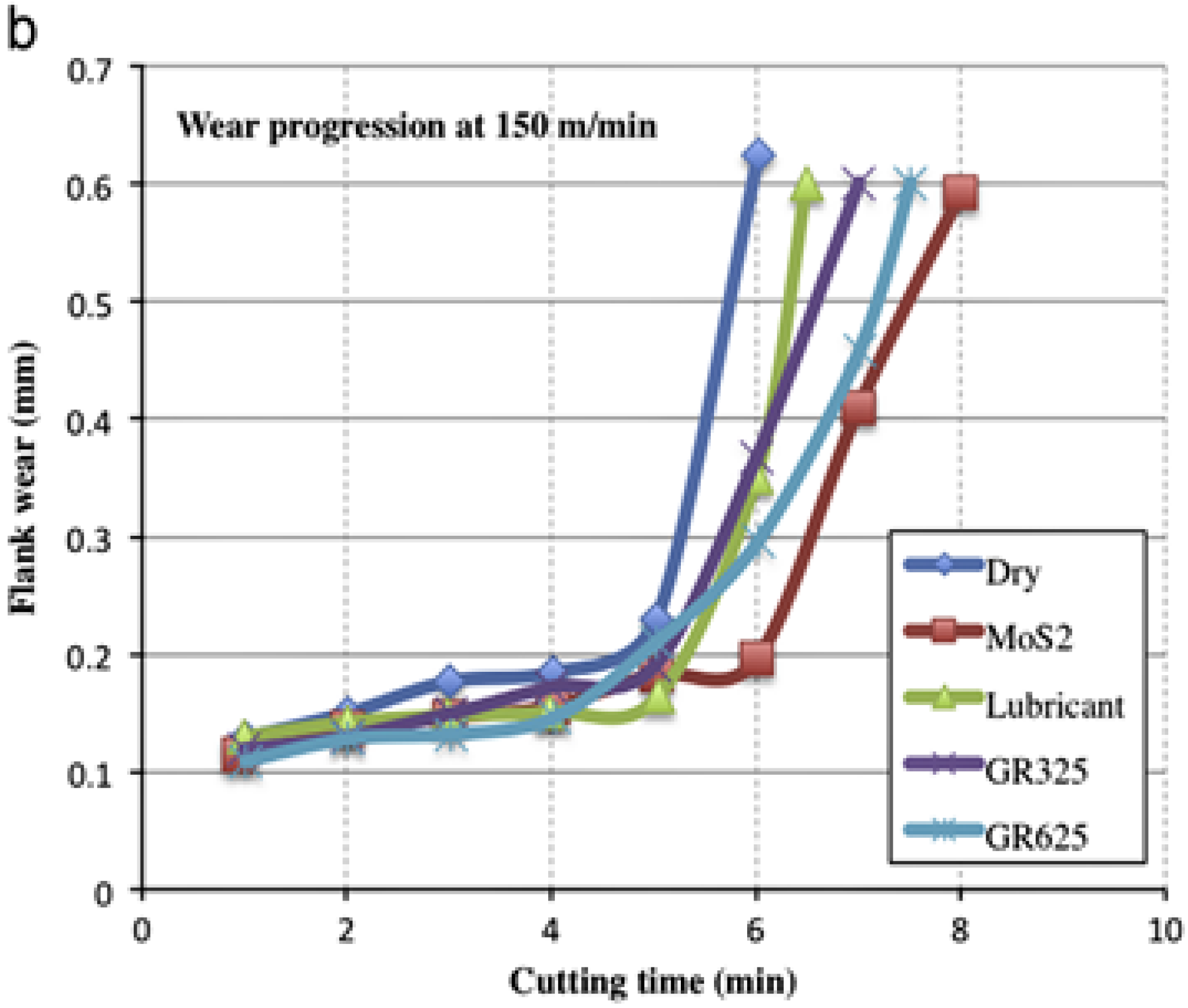

Yan et al. [11] investigated the performance of dry machining, micro lubrication in ultrasonic-assisted machining (UAM), and continuous MQL with ultrasonic vibration (U-CMQL) on turning Ti-6Al-4V. Tool wear, surface roughness, chip morphology, and cutting force were the parameters that were analyzed. When MQL with ultrasonic vibration was used, the tool rake face and workpiece contact were intermittent, due to which lubricant accessed the cutting interface. The cutting force was reduced by UAM, but due to the better lubrication in U-CMQL, the lowest cutting force was registered by U-CMQL at different cutting speeds (Figure 1). Moreover, tool wear was reduced by U-CMQL, and thus better surface roughness and favorable chip morphology were obtained (Figure 1).

Figure 1. Effect of different cutting environments on (a) cutting force versus cutting speed and (b) surface roughness [11].

Pervaiz [12] et al. perform the minimum quantity lubrication (MQL) method that offers a feasible substitute to the MWF-based conventional flood cooling method. A vegetable oil-based MQL system was mixed with sub-zero temperature air to design a new minimum quantity cooling lubrication (MQCL) system. The machinability of Ti-6Al-4V using an MQCL system under various oil flow rates and compared its machining performance with both dry cutting and conventional flood cooling, the surface roughness, flank wear, and associated wear mechanisms. The viscous nature was increased, and the penetration was decreased on adding low temperature (−4 °C) It was found that in the MQCL system (60–70 mL/h), oil supply rates provided reliable machining performance at higher feed levels. Rao et al. [13] experimented by setting cutting inserts in two different designs and comparing relative criteria further. They observed that as the cutting velocity increases, cutting temperature and flank wear increase, respectively, under all the machining environments. In this experiment of surface roughness and cutting vibration, a decreasing trend was observed as cutting velocity increased. The cutting vibration while doing machining operations was reduced by 35% and 20% when compared to normal and Design 1 cutting insert machining. The maximum tool flank wear reductions observed in Design 2 modified inserts were 62% and 40%, respectively, over normal and Design 1 cutting insert machining. Kishawy et al. [14] carried out a turning operation on Ti-6Al-4V and assessed sustainability by employing MQL and MQL-nanofluid. The fluid used in MQL and MQL-nanofluid was ECOLUBRIC E200 (flow rate of 40 mL/h, air pressure 0.5 Mpa). In this they have chosen three-level parameters cutting speed (120, 170, 220 m/min), feed (0.1, 0.15, 0.2 mm/rev) and nanoparticle concentration (Al2O3 wt.%-0, 2, 4). Overall, the best results based on machinability and sustainability were obtained at a cutting speed of 170 m/min, a feed rate of 0.1 mm/rev, and an Al2O3 concentration of 2 wt.%. There was a decrease in the induced friction on increasing nanoparticle concentration as they act as a spacer between tool and workpiece. This significantly affects power consumption. Singh et al. [15] investigated the tool wear behavior during turning Ti-6Al-4V under dry, MQL, and NMQL conditions, and the fluid used in that was canola oil. In MQL, additional lubrication is provided at the chip-tool contact area due to the high viscosity of oil, and thus heat is generated in the machining zone, and the coefficient of friction is reduced. At a lower cutting speed of 80 m/min, lubrication was good at the rake-face compared to higher speeds due to the tool life deteriorating at higher speeds. NMQL graphene has high thermal conductivity, easy-to-shear property, and high durability. It also helps in reducing friction and improving wettability; thus, it gives better tool life and a lower rate of tool wear, even at the higher cutting speed of 180 m/min. The lower Ra value was obtained in NMQL, followed by MQL and the dry environment.

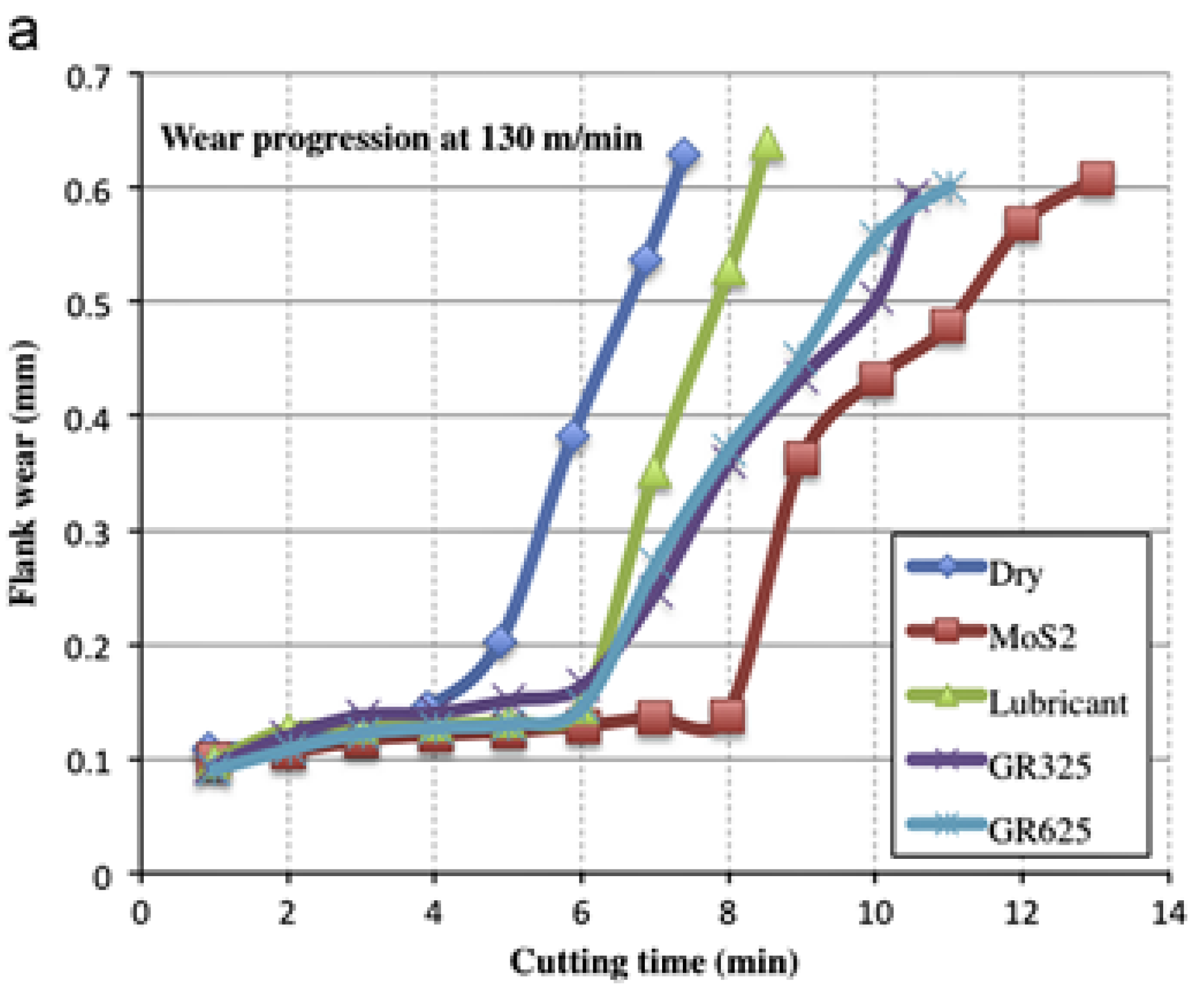

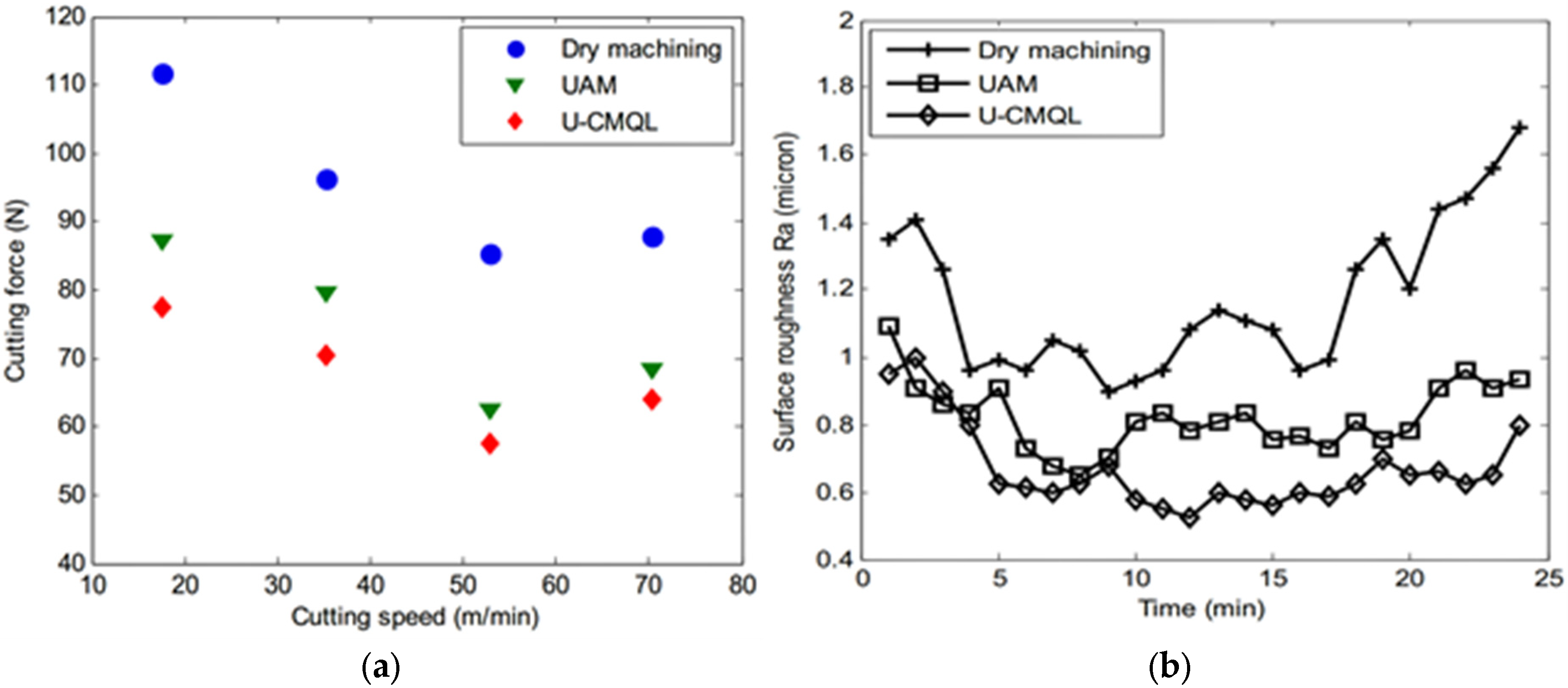

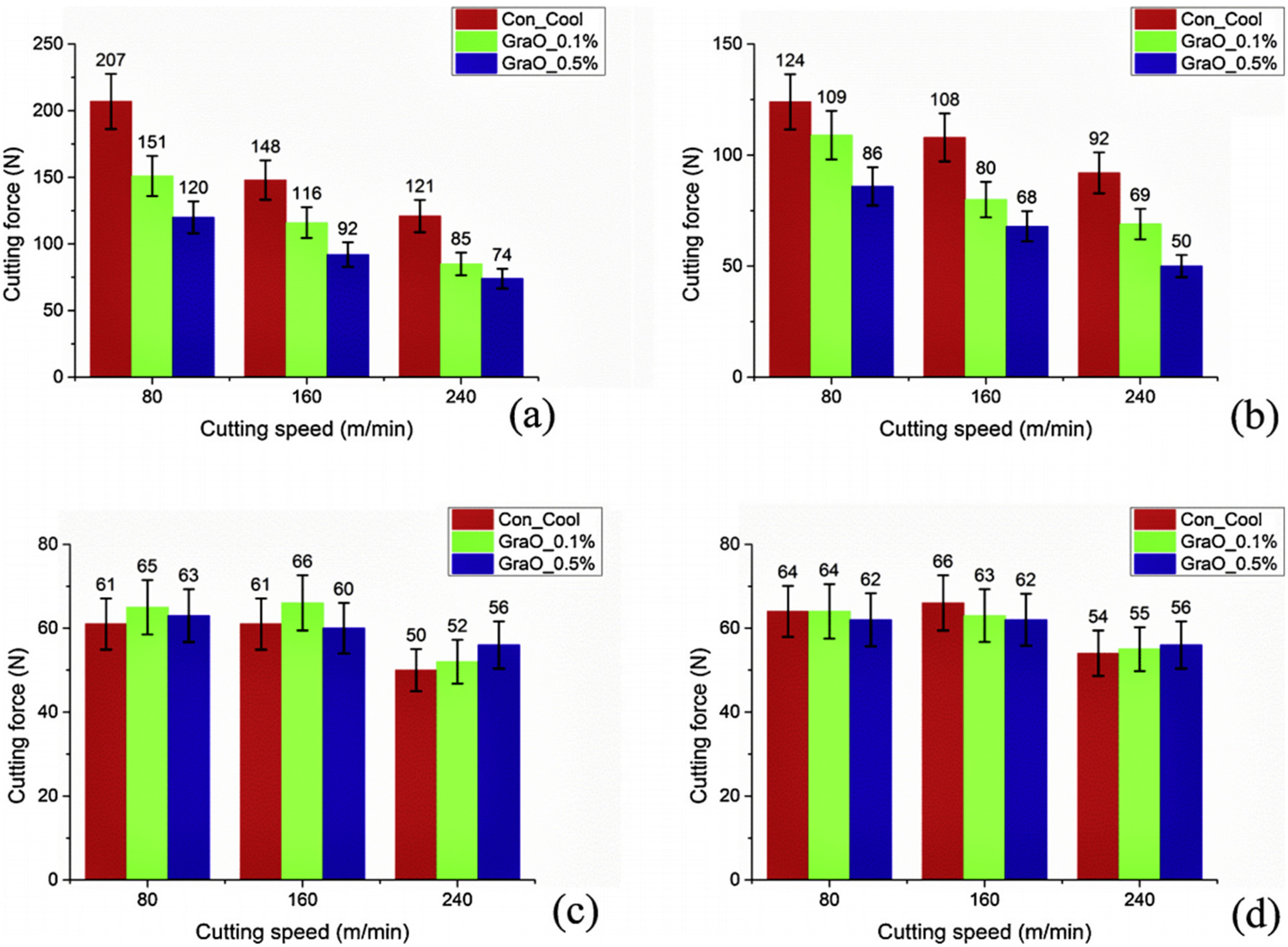

Li et al. [16] carried out a turning operation on Ti-6Al-4V under a conventional cooling environment. The base fluid used was ROCOL Ultracut Clear. Moreover, in this 0.1% and 0.5% weight percentage, a graphene nanosheet was added to the base fluid. The lubrication effect was analyzed by considering friction force and friction coefficient at the tool-chip and tool-workpiece interface. The cooling and lubrication effects were analyzed by examining the wired tool surface area. It was found that the temperature at the tool/chip interface was reduced significantly on adding graphene oxide nanosheet. The friction force and friction coefficient were reduced at the flank face. It was observed that there was an improvement in the lubrication ability and cooling effect by using graphene oxide sheet in the cutting fluid, which was shown by the reduced flank wear and crater. Figure 2 shows the measured values of cutting forces at each level of cutting speed. From Figure 2a,b it was identified that the main cutting force decreases with the increase in the concentration of graphene oxide Nanosheets in a fluid. From Figure 2c,d it was observed that there was no significant effect of the increase in pressure and concentration of graphene nanosheets on feed force. Moura et al. [17] investigated the effect of solid lubricant on Ti-6Al-4V by out carrying turning operation, and the parameters that are taken into consideration in this investigation are surface roughness, tool life, cutting force, and temperature rise. The base oil used in MQL is synthetic oil, and graphite mesh 625, graphite mesh 325, and molybdenum disulfide (MoS2) solid particles were added to the base oil. There was a reduction in surface roughness by implementing solid lubricant even at high temperatures. Satisfactory cooling and lubrication were obtained at the chip/tool interface, which increased tool life (Figure 3). There was a reduction in friction at the tool/workpiece interface due to solid lubricants, which resulted in a cutting force reduction. It was observed that the lowest machining temperature is attained when MoS2 is used. Hegab et al. [18] researched to see the influence of dispersed MWCNTs on vegetable oil by using it with the MQL technique during the turning of Ti-6Al-4V. The whole experiment lies in enhancing the MQL heat capacity using different concentrations of nanofluid to improve Ti-6Al-4V machinability. The parameters were power consumption and flank wear. The incrementation of adding nanoparticles to the lubricant showed a significant positive effect. When MWCNT was added, there was an improvement in rank and flank regions, wetting, and lubricating properties, which resulted in smooth cutting. Anand et al. [19] investigated the effect of MQCL with Al2O3 nanofluid, hBN nanofluid, and soluble oil on machining Ti-6Al-4V at constant cutting parameters. It was observed that when MQCL with soluble oil was carried out, it showed better cutting force, tool wear, and adhesion of material over the rake face. MQCL with Al2O3 nanofluid and hBN nanofluid had not given acceptable performance in machining. Thus, MQCL with soluble oil is a better alternative to flood cooling.

Figure 2. Measurement of cutting forces at different cutting levels (a,b) main cutting forces under 1 bar and 10 bar coolant pressure, respectively, (c,d) feed forces under 1 bar and 10 bar coolant pressure, respectively [16].

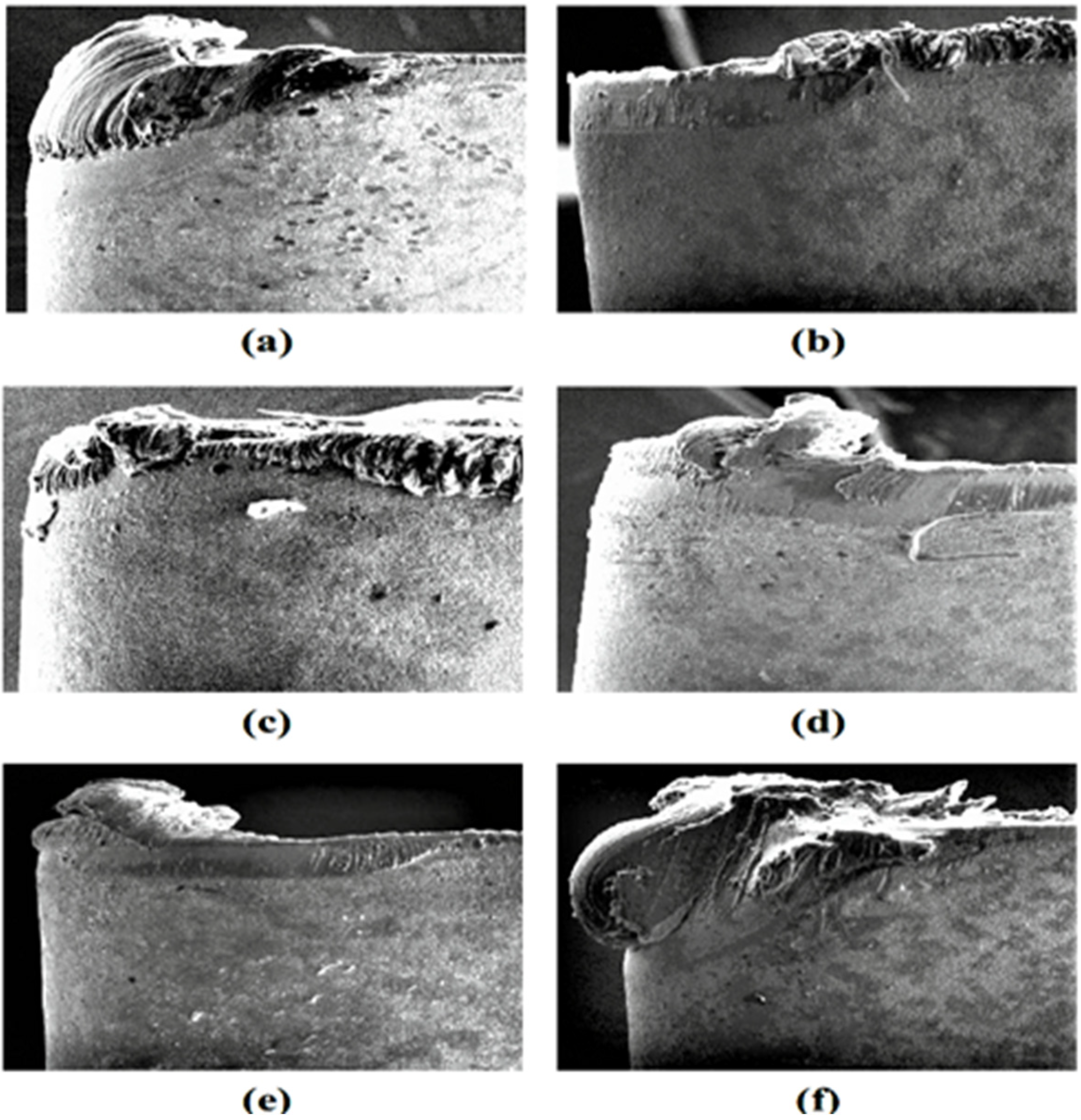

The experiment performed by Srikant et al. [20] used sustainable lubricants in turning Ti-6Al-4V. Soybean oil-based lubricants were used with/without the addition of micro-graphite particles in a minimum quantity of lubrication at a rate of 40 mL/h. The PVD-coated carbide tools were used for machining under different cutting conditions. Among the considered combinations, it was found that a cutting speed of 90 m/min, a feed of 0.3 mm/rev, and a depth of cut of 0.5 mm were optimal for overall machining performance. By using a different type of coolant, it was observed that the cutting conditions under those situations Tool wear is significantly affected by the type of coolant used (Figure 4).

Figure 4. SEM image of tool wear (a) dry, (b) cutting fluid, (c) cutting fluid with graphite, (d) oil, (e) oil with graphite, and (f) dry in run 6 [20].

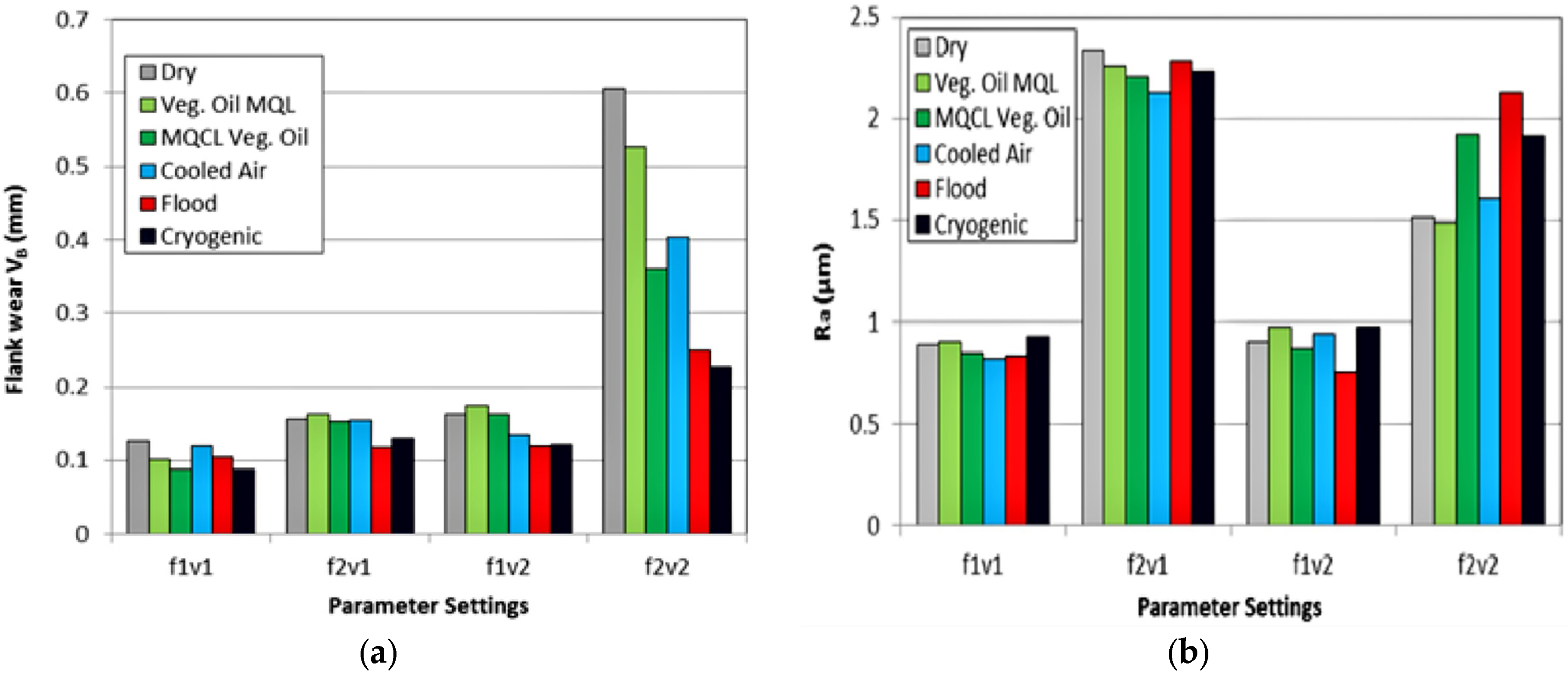

Under all the cutting conditions, dry machining showed the highest tool wear. Cutting fluids give the least tool wear due to effective cooling. However, under severe conditions, oil + powder gave better results due to the combined lubricating effect of oil and graphite. While machining at high feeds and speeds, oil with graphite inclusions gave about 85% less tool wear compared to dry machining and about 20% less tool wear compared to cutting fluid. Raza et al. [21] have used six different strategies that include dry, cooled air, flood, cryogenic, MQL, and MQCL and investigated flank tools during the turning of Ti-6Al-4V. The tool used was uncoated carbide. Rapeseed vegetable oil was used in MQL and MQCL. The cutting parameters were a depth of cut of 0.8 mm, a cutting speed of 90, 120 m/min, and a feed rate of 0.1, 0.2 mm/rev. It was observed that MQL and MQCL could be the alternatives to dry machining at low feed and a speed of 0.1 mm/rev and 90 m/min, respectively, as they had given lower flank wear compared to dry. For higher feed and cutting speed, cryogenic was giving lower flank wear. At lower speeds, feed surface roughness was close to each other under all lubricating conditions. At higher feed, the surface roughness is higher. At a feed of 0.2 mm/rev and a speed of 90 m/min, the surface roughness is high; thus, at a higher feed high, the cutting speed gives better surface roughness values (Figure 5).

Figure 5. Effect of different lubrication techniques on (a) flank wear and (b) surface roughness [21].

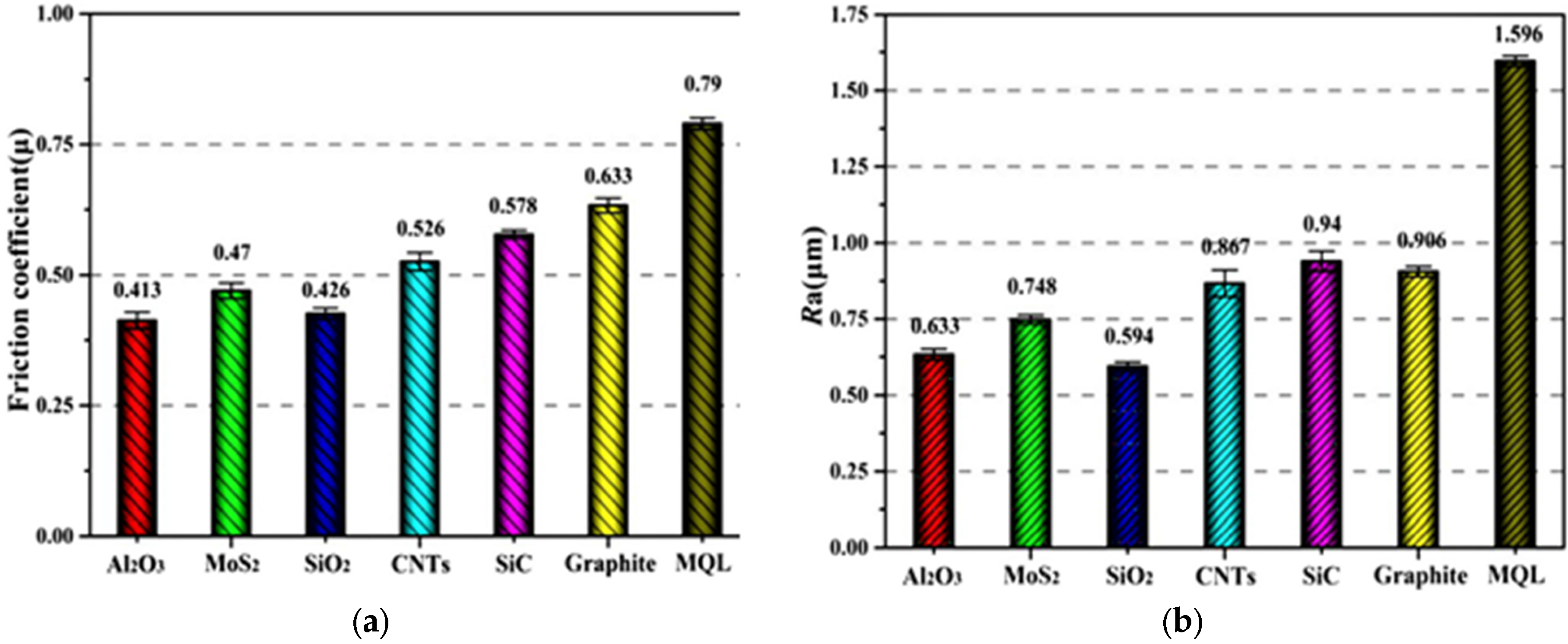

Ramana [22] investigate the effect of cutting fluid and optimization of process parameters to reduce surface roughness under dry, minimum quantity lubrication (MQL), and flooded conditions using Taguchi’s robust design methodology. The fluid used in flood and MQL is sunflower-based vegetable oil. For MQL, the optimum parameters are the following: a cutting speed of 63 m/min, a feed rate of 0.206 mm/rev, and a depth of cut of 1 mm. The CVD-coated tool showed a good result as it is tough and wear-resistant. In minimizing the surface roughness, the feed rate contributes 92.01%. A better surface roughness reduction was obtained in MQL compared to dry and flood conditions. Gupta et al. [23] performed the turning of titanium (Grade-2) alloy to assess the life cycle model with MQL (commercially available cutting fluid). The results showed that the Ranque–Hilsch vortex tube-assisted minimum quantity cutting fluids (RHVT-MQCF) was less energy-hungry compared to MQCF. Besides, the higher machining temperature that was generated during the MQCF compared to the RHVT-MQCF and RHVT-MQCF resulted in a regular chip and a smoother surface, which led to the better machining performance of the RHVT-MQCF technique. Faga et al. [24] compared the effects of various cutting strategies on machinability during the turning of Ti-6Al-4V. The best tool life was achieved with Emulsion Mist Cooling/Lubrication (EMCL) compared to MQL, wet, and dry. The lubricant type, delivery strategy, and supplied amount are the most important parameters that control the overall process. Khan et al. [25] investigated the effects of cooling strategy and cutting speed on the machinability during the turning of titanium grade-II. The better penetration of MQL resulted in the lowest cutting temperature compared to flood and dry cutting methods. The lower cutting force was observed with MQL than in dry and flood conditions, which further confirmed the lower power consumption. The MQL with vegetable oil provided better surface smoothness in contrast with another cutting environment. Sartori and Bruschi [26] performed a turning of Ti-6Al-4V to investigate the enhancements in tool life and surface quality of the final product with MQL and minimum quantity cooling (MQC). The solid lubricant aided MQC and provided the best results in terms of both nose and crater wear. However, in contrast with the MQC, the MQL exhibited lower cooling capacity, which led to the involvement of a cratering phenomenon. Gupta et al. [27] evaluated the machining performance of grade II Ti alloy in terms of cutting force, surface roughness, and cutting performance using Al2O3, MoS2, and graphite immersed nanofluid. The lower cutting temperature, cutting force, and surface roughness were observed using graphite NF compared to Al2O3 and MoS2 NFs. Additionally, the scanning electron microscopic evaluation of the tool divulged that the graphite NFs can provide a better tool profile and machined surface. Limin et al. [28] compared the surface roughness and tool wear in different cooling/lubrication conditions, i.e., dry, wet, and MQL, in the turning of Ti-6Al-4V. The rake wear was not found to be improved when using MQL compared to dry and wet machining strategies. However, better surface roughness was observed using MQL compared to dry machining. Singh et al. [29] studied the effects of different cooling conditions such as dry, MQL, and NMQL on tool life, cutting force, and temperature while turning Ti-6Al-4V alloy. The thermal conductivity was significantly enhanced by mixing graphene (1 wt.%) with canola oil. The friction between chip/workpiece and tool was reduced, and NMQL provided better cooling and lower cutting force compared to vegetable-based MQL. At a cutting speed of 180 m/min, catastrophic tool failures have taken place under dry cutting. The tool life was improved by 178–190%, the cutting force was reduced by 36–40%, and the temperature was reduced by 31–42% in NMQL compared to dry cutting conditions. Singh et al. [30] carried out a turning operation on Ti-3Al-2.5V alloy and investigated the effects of the different cooling environments such as dry, compressed air assisted wet cooling, Ranque–Hilsch vortex tube (RHVT), MQL, and wet oil cooling on workers’ health, surface roughness, power consumption, tool wear, and chip morphology. The large chip curl was causing poor surface roughness, while in MQL and RHVT, it had given proper cooling effect and thus improved the tool life. Moreover, in this, the chip curl diameter was small, which resulted in a better surface finish. The power consumption and carbon emissions were also less under MQL and RHVT conditions compared to other conditions. The air quality was degrading in MQL, so vortex tubes (RHVT) were found profitable as a tool-related cost, and workers’ health was saved with this. Yi et al. [31] investigated the performance of graphene oxide (GO) suspended fluid under MQL turning of Ti-6AL-4V alloy. In this, they have analyzed cutting temperature and cutting forces using a finite element analysis model. With this, it was seen that GO nanofluid provides better lubrication and reduced friction compared to conventional cooling conditions. With 0.1 wt.%, 0.3 wt.% and 0.5 wt.% of GO nanoparticles, the reduction in friction was 4.01%, 5.36% and 3.37%, respectively. The cutting force was lower with 0.3 wt.% of GO nanoparticles than with 0.5 wt.% of GO nanoparticles. Yi et al. [32] investigated the effect of new graphene oxide (GO) suspended fluid on drilling Ti-6Al-4V at different cutting parameters. The parameters that were considered in the result are thrust force, surface roughness, tool wear, and chip morphology. It was observed that when the feed rate is high, the thrust force is high, and when the spindle speed is increased, the thrust force reduces. The reduction in thrust force was up to 17.21%, and the reduction in surface roughness was 15.1% in the GO fluid compared to the conventional coolant. Excellent chip morphology was obtained when feed was below 0.12 mm/rev, and spindle speed was below 1600 rpm, while in conventional coolants, a discontinuous chip was formed. The tool wear was insignificant after 32 drills under suspended coolants, while under conventional coolants, chip abrasion was observed on the tool. Nam et al. [33] evaluated the micro-drilling process on Ti-6Al-4V under NMQL conditions. The base fluid used here was palm oil in MQL, and the nanodiamond particles (0.2 wt.%, 0.4 wt.%) were added to it in NMQL. The spherical shape of the nanoparticle could effectively penetrate the area of drilling. The machinability was enhanced in terms of torque, force, tool wear, and quality of hole at small particle size (35 mm), high concentration of nanoparticles (0.4 wt.%), and low feed rate (10 mm/min). Niketh et al. [34] analyzed the effect of micro-textures on the sliding friction in the drilling of Ti-6Al-4V. The non-textured, margin-textured, and flute-textured drills were used in experimentation. The margin-textured drill resulted in a reduction of thrust force (10.68%) and torque (12.33%) compared to the margin-textured drill. The chip evacuation force was decreased by using a flute-textured drill. Overall, the texturing of the tool can significantly reduce energy consumption by reducing the friction between two sliding surfaces. Li et al. [35] have carried out milling on titanium alloy TC4, in which they have used LB2000 oil as a base fluid for MQL, and they have checked the feasibility of graphene MQL. Moreover, they compared it with pure MQL, gas, and dry conditions. The cutting tool was TiAlN coated with a 6 mm diameter, four flutes, a helix angle of 45°, a rake angle of 8°, and a relief angle of 14°. In their experiment to evaluate force and tool wear, they performed slot milling by taking machining parameters N = 796 rpm, feed = 0.016 mm/tooth, and axial depth = 0.1 mm. In addition, for evaluating temperature and surface integrity, they have performed side milling by taking machining parameters of speed of 796 rpm, feed of 0.04 mm/tooth, axial depth of 0.2 mm, and radial depth of 0.2 mm. Firstly, they found the lubricating oil film showed good antiwear and load-bearing capacity, due to which milling force was smaller in pure MQL and graphene MQL. Secondly, they found that the lubricating oil film was giving a good cooling effect in MQL, especially in graphene MQL, due to which tool wear was also less in these conditions. Surface roughness with pure and graphene MQL is 0.425—0.311 μm, respectively. Yin et al. [36] performed a milling operation on Ti-6Al-4V, taking cottonseed oil as the base fluid. The milling parameters were kept the same; only nanoparticles were changed in the fluid, and their effect on milling force and surface roughness was observed. It was observed that after incorporating Al2O3 NMQL, the lubricating effect on the workpiece surface was improved, and the lowest force (Fx of 312 N, Fy of 96 N, and the friction coefficient of 0.413) was noted. Thus, Al2O3 NMQL consumes less energy and is efficient. The best surface roughness was achieved under SiO2 NMQL conditions as it exhibits high viscosity (Figure 6).

Figure 6. Effect of different working conditions on (a) friction coefficient and (b) surface roughness [36].

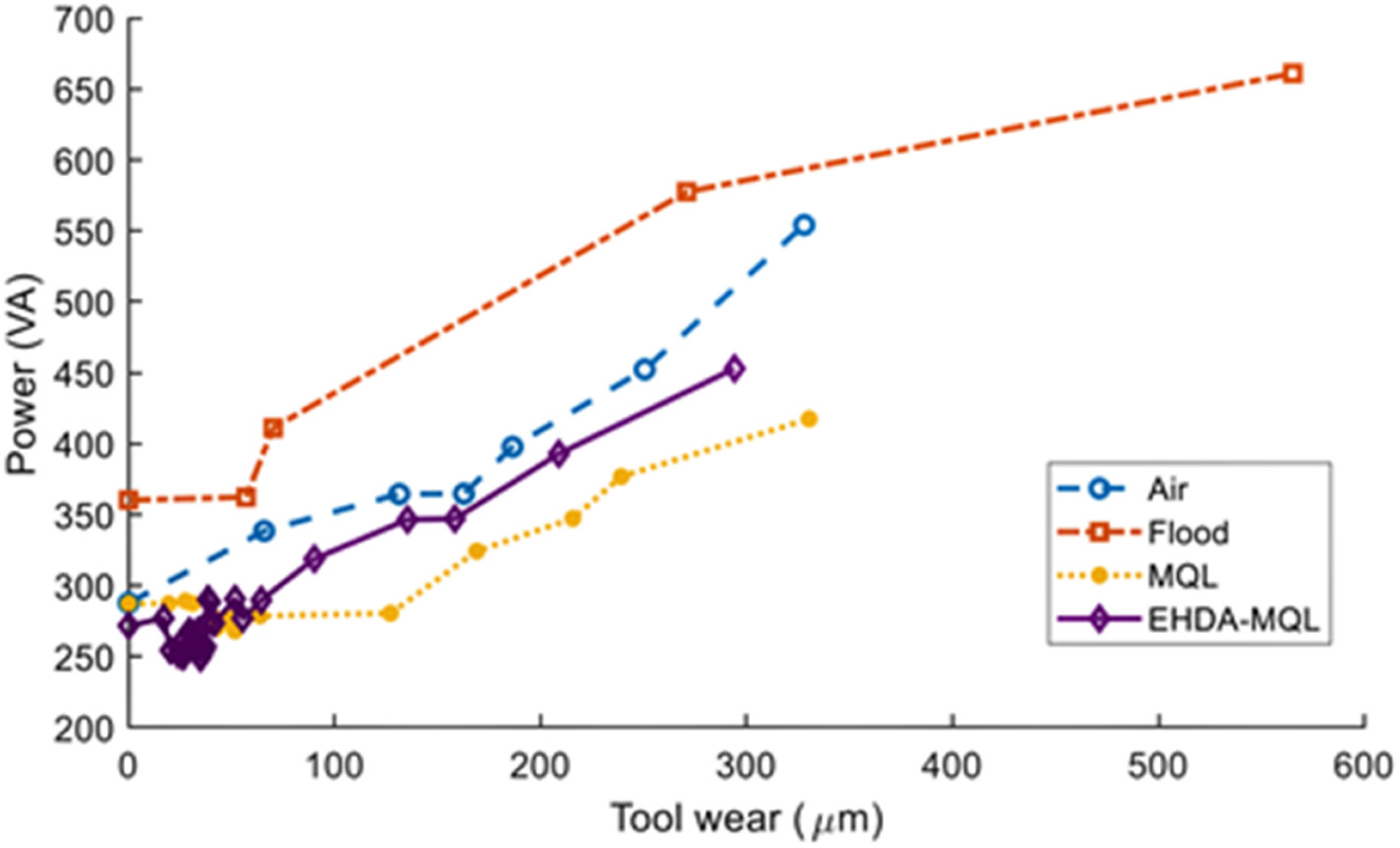

Priarone et al. [37] have used LB2000 vegetable-based oil as MQL fluid for the milling of titanium alloy Ti-48Al-2Cr-2Nb. They have compared MQL against dry and flood cooling environments. They have kept milling parameters such as axial and radial depth of cut, feed, and cutting speed equal to 0.3 mm, 0.08 mm/tooth, and 50 m/min, respectively. The tool used for milling was TiAlN coated (diameter of 8 mm), and the LB2000 vegetable-based oil was conveyed by air at 5.5 bar pressure, with a 0.3 mL/min quantity as the rate of consumption. They have obtained results in the form of tool wear and surface roughness. Moreover, better lubrication was obtained in MQL, due to which there was friction reduction, and hence tool wear was lowest in MQL, while in surface roughness, dry cutting was found to be slightly better than in MQL and flood cooling. Bartolomeis et al. [38] proposed an electrohydrodynamic atomization cooling-lubrication system for MQL (EHDA-MQL) during milling of Ti-6Al-4V. The EHDA-MQL was proficient at generating a micron-sized fine droplet. The tool life was enhanced 6 times compared to MQL and 22 times compared to flood cooling. The emergence of fine particles significantly improved the heat removal rate, ultimately resulting in a reduction in tool wear. Figure 7 exhibits the change in power consumption for tool wear under different machining conditions. It can be seen that EHDA-MQL consumed the least power up to 60 µm, and afterward, MQL exhibited the lowest power consumption compared to other machining environments.

Figure 7. The variation in power consumption against tool wear under different machining conditions [38].

References

- Gupta, M.K.; Sood, P.K. Machining comparison of aerospace materials considering minimum quantity cutting fluid: A clean and green approach. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 231, 1445–1464.

- Deng, J.; Zhou, J.; Zhang, H.; Yan, P. Wear mechanisms of cemented carbide tools in dry cutting of precipitation hardening semi-austenitic stainless steels. Wear 2011, 270, 520–527.

- Sujova, E. Contamination of the working air via metalworking fluids aerosols. In Engineering Review: Međunarodni Časopis Namijenjen Publiciranju Originalnih Istraživanja s Aspekta Analize Konstrukcija, Materijala i Novih Tehnologija u Području Strojarstva, Brodogradnje, Temeljnih Tehničkih Znanosti, Elektrotehnike, Računarstva i Građevinarstva; Faculty of Engineering/Faculty of Civil Engineering, University of Rijeka: Rijeka, Croatia, 2012; Volume 32, pp. 9–15.

- Sanchez, J.A.; Pombo, I.; Alberdi, R.; Izquierdo, B.; Ortega, N.; Plaza, S.; Martinez-Toledano, J. Machining evaluation of a hybrid MQL-CO2 grinding technology. J. Clean. Prod. 2010, 18, 1840–1849.

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. A critical assessment of lubrication techniques in machining processes: A case for minimum quantity lubrication using vegetable oil-based lubricant. J. Clean. Prod. 2013, 41, 210–221.

- Astkhov, V.P.; Joksch, S. Metal Working Fluids for Cutting and Grinding—Fundamentals and Recent Advances; Woodhead Publishing: Cambridge, UK, 2012.

- Dureja, J.S.; Singh, R.; Singh, T.; Singh, P.; Dogra, M.; Bhatti, M.S. Performance evaluation of coated carbide tool in machining of stainless steel (AISI 202) under minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf. Technol. 2015, 2, 123–129.

- da Silva, R.B.; Machado, Á.R.; Ezugwu, E.O.; Bonney, J.; Sales, W.F. Tool life and wear mechanisms in high speed machining of Ti-6Al-4V alloy with PCD tools under various coolant pressures. J. Mater. Process. Technol. 2013, 213, 1459–1464.

- Sharma, V.S.; Dogra, M.; Suri, N.M. Cooling techniques for improved productivity in turning. Int. J. Mach. Tools Manuf. 2009, 49, 435–453.

- Srikanth, K.S.; Jaisankar, V.; Vasisht, J.S. Evaluation of tool wear and surface finish of AISI 316l stainless steel using nano cutting environment. Int. J. Mech. Prod. Eng. 2014, 2, 73–76.

- Yan, L.; Zhang, Q.; Yu, J. Effects of continuous minimum quantity lubrication with ultrasonic vibration in turning of titanium alloy. Int. J. Adv. Manuf. Technol. 2018, 98, 827–837.

- Pervaiz, S.; Rashid, A.; Deiab, I.; Nicolescu, C.M. An experimental investigation on effect of minimum quantity cooling lubrication (MQCL) in machining titanium alloy (Ti6Al4V). Int. J. Adv. Manuf. Technol. 2016, 87, 1371–1386.

- Rao, C.M.; Rao, S.S.; Herbert, M.A. Development of novel cutting tool with a micro-hole pattern on PCD insert in machining of titanium alloy. J. Manuf. Process. 2018, 36, 93–103.

- Kishawy, H.A.; Hegab, H.; Deiab, I.; Eltaggaz, A. Sustainability Assessment during Machining Ti-6Al-4V with Nano-Additives-Based Minimum Quantity Lubrication. J. Manuf. Mater. Process. 2019, 3, 61.

- Singh, R.; Dureja, J.S.; Dogra, M.; Gupta, M.K.; Mia, M.; Song, Q. Wear behavior of textured tools under graphene-assisted minimum quantity lubrication system in machining Ti-6Al-4V alloy. Tribol. Int. 2020, 145, 106183.

- Li, G.; Yi, S.; Li, N.; Pan, W.; Wen, C.; Ding, S. Quantitative analysis of cooling and lubricating effects of graphene oxide nanofluids in machining titanium alloy Ti6Al4V. J. Mater. Process. Technol. 2019, 271, 584–598.

- Moura, R.R.; Da Silva, M.B.; Machado, Á.R.; Sales, W.F. The effect of application of cutting fluid with solid lubricant in suspension during cutting of Ti-6Al-4V alloy. Wear 2015, 332–333, 762–771.

- Hegab, H.; Umer, U.; Deiab, I.; Kishawy, H. Performance evaluation of Ti-6Al-4V machining using nano-cutting fluids under minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2018, 95, 4229–4241.

- Anand, N.; Kumar, A.S.; Paul, S. Effect of cutting fluids applied in MQCL mode on machinability of Ti-6Al-4V. J. Manuf. Process. 2019, 43, 154–163.

- Revuru, R.S.; Zhang, J.Z.; Posinasetti, N.R.; Kidd, T. Optimization of titanium alloys turning operation in varied cutting fluid conditions with multiple machining performance characteristics. Int. J. Adv. Manuf. Technol. 2017, 95, 1451–1463.

- Raza, S.W.; Pervaiz, S.; Deiab, I. Tool wear patterns when turning of titanium alloy using sustainable lubrication strategies. Int. J. Precis. Eng. Manuf. 2014, 15, 1979–1985.

- Ramana, M.V. Optimization and Influence of Process Parameters on Surface Roughness in Turning of Titanium Alloy under Different Lubricant Conditions. Mater. Today Proc. 2017, 4, 8328–8335.

- Gupta, M.K.; Song, Q.; Liu, Z.; Pruncu, C.I.; Mia, M.; Singh, G.; Lozano, J.A.; Carou, D.; Khan, A.M.; Jamil, M.; et al. Machining characteristics based life cycle assessment in eco-benign turning of pure titanium alloy. J. Clean. Prod. 2019, 251, 119598.

- Faga, M.G.; Priarone, P.C.; Robiglio, M.; Settineri, L.; Tebaldo, V. Technological and sustainability implications of dry, near-dry, and wet turning of Ti-6Al-4V alloy. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 129–139.

- Khan, A.; Maity, K. Influence of cutting speed and cooling method on the machinability of commercially pure titanium (CP-Ti) grade II. J. Manuf. Process. 2018, 31, 650–661.

- Sartori, S.; Ghiotti, A.; Bruschi, S. Solid Lubricant-assisted Minimum Quantity Lubrication and Cooling strategies to improve Ti6Al4V machinability in finishing turning. Tribol. Int. 2018, 118, 287–294.

- Gupta, M.K.; Mia, M.; Iulian Pruncu, C.; Khan, A.M.; Rahman, M.A.; Jamil, M.; Sharma, V.S. Modeling and performance evaluation of Al2O3, MoS2 and graphite nanoparticle-assisted MQL in turning titanium alloy: An intelligent approach. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 207.

- Limin, S. Investigation of tool wear and surface roughness when turning titanium alloy (Ti6Al4V) under different cooling and lubrication conditions. Ferroelectrics 2018, 526, 199–205.

- Singh, R.; Dureja, J.S.; Dogra, M.; Gupta, M.K.; Mia, M. Influence of graphene-enriched nanofluids and textured tool on machining behavior of Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2019, 105, 1685–1697.

- Singh, R.; Dureja, J.; Dogra, M.; Gupta, M.K.; Jamil, M.; Mia, M. Evaluating the sustainability pillars of energy and environment considering carbon emissions under machining ofTi-3Al-2.5 V. Sustain. Energy Technol. Assess. 2020, 42, 100806.

- Yi, S.; Li, N.; Solanki, S.; Mo, J.; Ding, S. Effects of graphene oxide nanofluids on cutting temperature and force in machining Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 103, 1481–1495.

- Yi, S.; Li, G.; Ding, S.; Mo, J.P. Performance and mechanisms of graphene oxide suspended cutting fluid in the drilling of titanium alloy Ti-6Al-4V. J. Manuf. Process. 2017, 29, 182–193.

- Nam, J.; Lee, S.W. Machinability of titanium alloy (Ti-6Al-4V) in environmentally-friendly micro-drilling process with nanofluid minimum quantity lubrication using nanodiamond particles. Int. J. Precis. Eng. Manuf. Technol. 2018, 5, 29–35.

- Niketh, S.; Samuel, G. Surface texturing for tribology enhancement and its application on drill tool for the sustainable machining of titanium alloy. J. Clean. Prod. 2017, 167, 253–270.

- Li, M.; Yu, T.; Zhang, R.; Yang, L.; Li, H.; Wang, W. MQL milling of TC4 alloy by dispersing graphene into vegetable oil-based cutting fluid. Int. J. Adv. Manuf. Technol. 2018, 99, 1735–1753.

- Yin, Q.; Li, C.; Dong, L.; Bai, X.; Zhang, Y.; Yang, M.; Jia, D.; Hou, Y.; Liu, Y.; Li, R. Effects of the physicochemical properties of different nanoparticles on lubrication performance and experimental evaluation in the NMQL milling of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2018, 99, 3091–3109.

- Priarone, P.C.; Robiglio, M.; Settineri, L.; Tebaldo, V. Milling and Turning of Titanium Aluminides by Using Minimum Quantity Lubrication. Procedia CIRP 2014, 24, 62–67.

- De Bartolomeis, A.; Shokrani, A. Electrohydrodynamic Atomization for Minimum Quantity Lubrication (EHDA-MQL) in End Milling Ti6Al4V Titanium Alloy. J. Manuf. Mater. Process. 2020, 4, 70.

More

Information

Subjects:

Engineering, Aerospace

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.7K

Revisions:

3 times

(View History)

Update Date:

02 Sep 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No