| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Sushanta Kumar Saha | + 3460 word(s) | 3460 | 2020-09-21 04:38:25 | | | |

| 2 | Catherine Yang | Meta information modification | 3460 | 2020-10-20 05:56:12 | | |

Video Upload Options

Marine microalgae are a group of microscopic photosynthetic organisms with a much faster growth rate compared to land plants. They represent a significant reservoir of bioactive compounds, nutritional ingredients, and commercial commodities for the benefit of mankind. One such bioactive compound is the carotenoid lutein, which marine microalgae biosynthesises as their accessory light-harvesting pigment. Lutein is one of the dietary requirements for humans that provides several health benefits including aiding in the prevention of macular degenerative disease, reducing the risk of stroke, heart attack, and mitigation against other metabolic syndromes. Lutein is particularly known to help to maintain the normal visual function by absorbing and attenuating the blue lights that strike the retina in our eyes. Therefore, lutein is becoming a popular bioactive compound as a dietary supplement especially nowadays due to the excessive use of electronic devices and also due to insufficient dietary lutein consumption through our normal diet. Marigold flowers are currently the predominant natural source of lutein, while marine microalgae can be a competitive sustainable alternative. Moreover, microalgae have more free lutein than marigold flowers, which is preferable since it is easily absorbed compared to the esterified forms found in marigold. Although carotenoids astaxanthin and β-carotene are currently commercially produced from specific microalgae, marine microalgae are still waiting for their commercial exploration for the production of lutein.

1. Introduction

Microalgae are photosynthetic microscopic organisms that possess several accessory light-harvesting carotenoid pigment molecules such as astaxanthin, canthaxanthin, lutein, zeaxanthin, and β-carotene, which have commercial value. Lutein is a xanthophyll and one of 1178 known naturally occurring carotenoids [1]. It is an oxygenated carotenoid found primarily in plants such as spinach, kale, and marigold as well as certain microalgal species such as Scenedesmus almeriensis, Chlorella zofingiensis, and Muriellopsis sp. [2]. Lutein is a lipid-soluble primary carotenoid that humans obtain from their diet and has several known health benefits including aiding in the prevention of macular degenerative disease, reducing the risk of stroke and heart attack, and mitigation against other debilitating metabolic syndromes. In photosynthetic species, xanthophylls act to modulate light energy and free radical quenching agents which are produced during photosynthesis under high light intensity. Lutein is found to accumulate in the macula of the eye, acting as a light filter protecting cells against free radical damage, and has also been implicated in ameliorating the damaging effects of macular degenerative disease in ageing adults [3]. These health-promoting effects of lutein as well as its potential as a natural food colourant have led to increased investigations on the potential of lutein as a high-value nutraceutical functional food ingredient. The growth of the global nutraceutical market is driven by an increase in demand for healthy and organic food products and a surge in awareness of dietary health-promoting supplements. Furthermore, the rise in disposable income allows consumers to purchase healthy alternatives to regular food products. The global lutein market is expected to reach EUR 409 million by 2027 at a Compound Annual Growth Rate (CAGR) of 6.10% over the predicted period 2020–2027 [4].

Primarily, commercial natural lutein production has been reliant on extraction from marigold flower oleoresin. However, marigold flower harvesting and extraction is seasonal and labour intensive and recent data have suggested that microalgal species under controlled cultivation conditions can have much higher lutein productivity rates when compared to marigold cultivars [5]. There is, therefore, the strong potential for these organisms to be an alternative production route for natural lutein. Microalgae are attractive lutein producers; concomitantly, they function as a carbon dioxide capturing system reducing greenhouse gases, they can be cultivated all year round depending on the selected reactor cultivation conditions chosen, and environmentally friendly solvent-free extraction strategies can be tailored to enriched-lutein extraction e.g., supercritical fluid extraction methodologies [6].

The use of microalgae as human food is not unusual as it can be traced back many years in indigenous populations from China, Japan, and the Republic of Korea [7]. The traditional knowledge of microalgae use by these indigenous people has now disseminated throughout the world population through migration. Further, growth in microalgal consumption has been due to the significant amount of research on the health and nutritional benefits of microalgae and these health benefits are especially relevant for our modern-day lifestyle [8]. As a result, presently, several microalgae are commercially cultivated for various nutraceutical products that are available in the market. Arthrospira (Spirulina) maxima, Arthrospira (Spirulina) platensis, and Aphanizomenon flos-aquae are used as “whole cells biomass” in supplement products as well as for extraction of blue food colourant phycocyanin, Chlorella vulgaris biomass for health supplement products, and Dunaliella salina and Haematococcus pluvialis for commercial production of natural carotenoids such as β-carotene and astaxanthin [9].

2. Putative Biosynthetic Pathway of Lutein in Microalgae

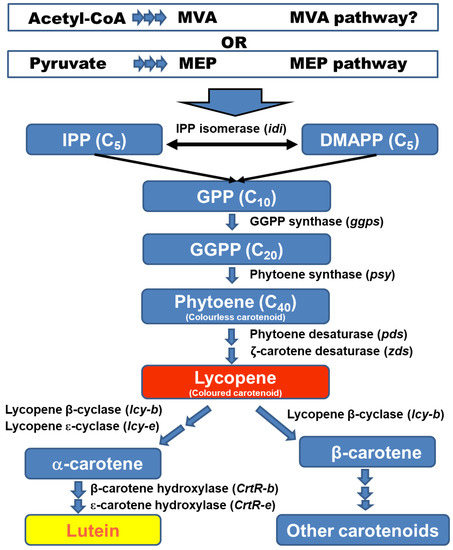

Lutein is found within the members of Chlorophyta, Chlorarachniophyta, Cryptophyta, Euglenophyta, and Rhodophyta algal species [10]. Knowledge of the biosynthetic pathways for lutein biosynthesis in microalgae is limited. The current understanding is based on identified chemical structures of carotenoids found in microalgae. It is now believed that all types of carotenoids, including lutein, are obtained from common five-carbon (C5) starting molecules isopentenyl diphosphate (IPP) and dimethylallyl diphosphate (DMAPP). These common metabolic precursors (IPP and DMAPP) might be derived from either of the two independent pathways: (i) the cytosolic mevalonate (MVA) pathway starting from Acetyl-CoA, or (ii) the plastidic (chloroplast in microalgae) methylerythritol 4-phosphate (MEP) pathway starting from pyruvate [11]. However, there is evidence to suggest that the precursors for microalgal carotenoids including lutein biosynthesis proceed from the MEP pathway in Dunaliella salina, Chlorella vulgaris, Scenedesmus sp. [11], and Haematococcus pluvialis [12] species.

Lutein biosynthesis in microalgae begins in the MEP pathway (Figure 2) through the 5-carbon building block molecule isopentenyl pyrophosphate (IPP), which isomerises to dimethylallyl pyrophosphate (DMAPP) by the action of the enzyme IPP isomerase. Elongation of the carbon chain then takes place through continuous head-to-tail condensation of IPP to DMAPP followed by growing of the polyprenyl pyrophosphate chain by the action of the enzyme prenyltransferase [13][14][15]. As a result, geranylgeranyl PP (GGPP, C20), the first immediate precursor of lutein, is synthesised following a condensation reaction of GPP (C10) by the action of GGPP synthase. Next, the colourless C40 carotenoid phytoene is formed through condensation of two GGPP (C20) molecules by the action of phytoene synthase (PSY). Next, lycopene (a coloured carotenoid with 13 double bonds and a chromophore of 11 conjugated double bonds) is formed by the conversion of phytoene (nine double bonds molecule) through stepwise desaturation reactions (or dehydrogenation reactions) catalysed by phytoene desaturase (PDS) and zeta-carotene desaturase (ZDS) enzymes. Lycopene is the precursor to the formation of both α-carotene and β-carotene after two cyclisation reactions. The enzyme lycopene β-cyclase (lcy-b) catalyses the cyclisation of both ends of lycopene to make β-carotene with two β-rings. Meanwhile, the action of lycopene β-cyclase (lcy-b) and lycopene ε-cyclase (lcy-e) enzymes catalyse the cyclisation of both ends of lycopene to make α-carotene with a β-ring and an ε-ring. This is an important branching point of the carotenoid biosynthesis pathway in microalgae, where one branch leads to the biosynthesis of α-carotene and the other branch leads to the biosynthesis of β-carotene. The former is then converted to lutein in two hydroxylation steps, while the latter is converted to zeaxanthin and subsequently, to other carotenoids. The hydroxylation of α-carotene at the C-3 and C-3′ positions results in the formation of lutein and the enzymes involved in these processes are β-carotene hydroxylase and ε-carotene hydroxylase, respectively [16].

Figure 2. Schematic overview of lutein biosynthesis in microalgae. Enzymes involved in each biochemical conversion step are listed and their corresponding genes are indicated in parenthesis.

From the biotechnological perspective, a number of chemical inhibitors have been tested to regulate the carotenoid biosynthetic pathway in microalgae. For examples, Yildirim et al. [17] studied the effect of the addition of 2-methylimidazole in Dunaliella salina and found an increase of 1.7-fold lutein content and a related decline in β-carotene content. This study suggested that 2-methylimidazole preferentially alters lycopene β-cyclase (lcy-b) activity and thus, shifts the carotenogenic pathway from β-carotene to the α-carotene branch. Liang et al. [18] tested triethylamine, which triggered lycopene production in Dunaliella bardawil as a lycopene cyclase inhibitor that inhibited the expression levels of lcy-b and lcy-e, and upregulated the upstream carotenogenic genes. Likewise, nicotine was also tested as a possible lycopene cyclase inhibitor. A low concentration of nicotine resulted in a significant decrease in β-carotene, while triggering the accumulation of lycopene in Chlorella regularis Y-21 and Dunaliella salina CCAP 19/18 [19][20].

3. Extraction of Lutein from Microalgae and Challenges

The extraction of intracellular microalgae products is most commonly conducted by conventional means. This involves using dry biomass coupled with maceration and thermal extraction employing either organic or aqueous solvents (Table 1), depending on the polarity of the desired compound to be extracted. Compounds, such as carotenoids, display varying polarities and chemical natures. Hence, an appropriate solvent must be chosen with regards to extracting target carotenoids based on the selectivity, efficiency, and purity required. The extraction of carotenoids is typically conducted using non-polar solvents such as n-hexane, dichloromethane, and dimethyl ether, with other solvents such as acetone and octane also used for extraction [21].

Table 1. List of lutein-producing microalgae and their lutein yield associated with tested cultivation and stress conditions.

|

Microalgae |

Biomass |

Cultivation Conditions |

Lutein Yield |

Stress Conditions |

Extraction Methodologies |

References |

|

Marine cultures |

||||||

|

Chlamydomonas sp. JSC4 |

1271 mg L−1 d−1 |

1-L glass photobioreactor |

3.27 mg L−1 d−1 |

Temperature |

Solvent extraction |

[22] |

|

Chlamydomonas sp. |

1500 mg L−1 d−1 |

1-L glass photobioreactor |

5.08 mg L−1 d−1 |

Light intensity |

Solvent extraction |

[23] |

|

Chlamydomonas sp. JSC4 |

560 mg L−1 d−1 |

1-L glass photobioreactor |

3.42 mg g−1 |

Salinity gradient |

Solvent extraction |

[24] |

|

Chlamydomonas sp. JSC4 |

490 mg L−1 d−1 |

1-L glass photobioreactor |

2.95 mg g−1 |

Light wavelengths |

Solvent extraction |

[23] |

|

Chlamydomonas acidophila |

- |

Batch growth |

20 mg L−1 |

UV-A radiation (10 μmol photons m−2 s−1), or heated at 40 °C. |

Solvent extraction |

[25] |

|

Chlorella salina |

- |

3-L glass flask |

2.92 mg g−1 |

- |

Microextraction coupled with ultrasonication |

[26] |

|

Dunaliella salina |

2.2 g m−2 d−1 |

Tubular photobioreactor |

15.4 mg m−2 d−1 |

None |

Solvent extraction |

[27] |

|

Muriellopsis sp. |

40 g m−2 d−1 |

Outdoor tubular photobioreactor |

6 mg g−1 |

None |

Solvent extraction |

[28] |

|

Muriellopsis sp. |

12.9 g m−2 d−1 |

Open ponds |

100 mg m−2 d−1 |

None |

Solvent extraction |

[29] |

|

Tetraselmis sp. CTP4 |

- |

5-L reactors |

3.17 mg g−1 |

Light intensity (170 and 280 μmol photons m−2 s −1) and temperature (35 °C) |

Solvent extraction |

[30] |

|

Freshwater cultures |

||||||

|

Chlorella minutissima |

0.117 g L−1 d−1 |

2-L airlift photobioreactor |

5.58 mg g−1 |

None |

Solvent extraction |

[31] |

|

C. vulgaris, C. zofingiensis and C. protothecoides |

0.131, 0.122, 0.103 g L−1 d−1 (respectively) |

In indoor vertical alveolar panel photobioreactor |

3.86, 4.38 and 3.59 mg g−1 (respectively) |

None |

Glass bead vortexing and ball mill grinding |

[32] |

|

Chlorella protothecoides |

31.2 g L−1 |

Heterotrophic growth in a 3.7-L fermenter |

1·90 mg g−1 |

80 g L−1 glucose addition |

Solvent extraction |

[33] |

|

Chlorella pyrenoidosa |

- |

- |

1.24 mg g−1 |

None |

Ultrasound-enhanced subcritical CO2 extraction |

[16] |

|

Chlorella sorokiniana |

1.98 g L−1 d−1 |

Two-stage mixotrophic cultivation |

7.62 mg L−1 d−1 |

None |

Solvent extraction |

[34] |

|

Chlorella vulgaris |

- |

Batch |

3.36 mg g−1 |

None |

Ultrasound extraction with enzymatic pretreatment |

[35] |

|

Chlorella sorokiniana |

2.4 g L−1 |

Semi-batch mixotrophic cultivation. |

5.21 mg g−1 |

None |

Reduced pressure extraction method. |

[36] |

|

Chlorella protothecoides |

28.4 g L−1 |

Heterotrophic batch growth in a 3.7-L fermenter |

0.27 mg g−1 |

Nitrogen limitation and high temperature |

Mechanical method |

[37] |

|

Chlorella zofingiensis |

7 g L−1 |

Batch growth |

4 mg g−1 |

None |

Solvent extraction |

[38] |

|

Desmodesmus sp. |

939 mg L−1 d−1 |

1-L glass vessel |

5.22 mg L−1 d−1 |

Different C/N ratios |

Solvent extraction |

[39] |

|

Muriellopsis sp. |

5.37 g L−1 |

Batch growth |

29.8 mg L−1 |

None |

Solvent extraction |

[40] |

|

Scenedesmus incrassatulus |

17.98 g L−1 |

Two-stage heterotrophy photoinduction culture |

1.49 mg g−1 |

Glucose concentration increase (30.3 g L−1) |

Solvent extraction |

[41] |

|

Scenedesmus sp. CCNM 1028 |

0.47 g L−1 |

Batch growth (1L) |

2.12 mg g−1 |

Two-stage nitrogen starvation |

Solvent extraction |

[42] |

|

Scenedesmus obliquus CWL-1 |

9.88 g L−1 |

Mixotrophic cultivation |

1.78 mg g−1 |

Light-related strategies (12/12 L/D, blue to red light) |

Solvent extraction |

[43] |

|

Scenedesmus almeriensis |

0.95 g L−1 |

Vertical bubble column photo-bioreactor |

8.54 mg g−1 |

Different CO2 Content (3.0% v/v) |

Accelerated solvent extraction |

[44] |

|

Scenedesmus sp. |

1.1 g L−1 |

20 L photobioreactor |

1.794 mg g−1 |

Different pressure and temperature in the SFE operation (400 bar, 70 °C and ethanol as the co-solvent) |

Supercritical CO2 extraction |

[45] |

|

Scenedesmus almeriensis |

0.63 g L−1 |

Bubble column photobioreactors (2.0 L) |

3.6 mg L−1 |

Salinity (5 g L−1) |

Solvent extraction |

[46] |

|

Scenedesmus obliquus |

2.44 g L−1 |

1-L glass vessel |

3.63 mg g−1 |

Light-related strategies |

Solvent extraction |

[47] |

The use of these non-polar solvents is due to the high hydrophobicity of carotenoids. Recently, green solvents such as ethanol and biphasic water solvent mixtures have also been researched for the extraction of carotenoids from microalgae [48]. The conventional extraction process of microalgae products still bears limitations such as extraction efficiency, selectivity, and high solvent consumption. Lin et al. [5] discussed that the energy consumption for microalgal cell disruption ranged from 30 to 500 MJ kg−1. This energy consumption was reliant on the disruption process, where the energy demand is determined by factors such as cell wall compositions, cell wall thickness, and cell size. This value is 1000 times higher than the crushing energy for marigold flower (800 kJ kg−1). To overcome this problem, the development and application of a multistage extraction process, combined with varying physical and chemical methods, may prove useful in selectively targeting the carotenoids of interest [21]. Microalgal biomass consists of a rich cellular composition and much thicker cell wall than marigold flowers. Dry-milled marigold petals are usually processed using solvent extraction to produce oleoresin-containing carotenoids in their ester form. This is followed by a multistep purification process which frees the hydroxylated carotenoids from the accompanying fatty acids and finally, a recrystallisation process occurs which results in pure lutein/zeaxanthin. Lutein is sold in oily extracts ranging from 5% to 60% as its crystalline form poses management and stability problems, where microalgal biomass can be extracted into an oleoresin-like extract with 25% lutein in free form that could be used directly for the commercial products [49].

Araya et al. [32] applied two cell disruption methods, glass bead vortexing and ball mill grinding, on Chlorella vulgaris, Chlorella zofingiensis, and Chlorella protothecoides to improve the extraction yield of lutein, where the yield of C. vulgaris (0.51 mg L−1 d−1) and C. zofingiensis (0.53 mg L−1 d−1) was higher compared to C. protothecoides (0.37 mg L−1 d−1). Chen et al. [50] also applied two different cell disruption methods (bead-beating and high pressure) on Chlorella sorokiniana MB-1 and the lutein was extracted by a reduced pressure extraction method. High-pressure pretreatment extracted with tetrahydrofuran (THF) as the solvent resulted in high lutein recovery efficiencies of 87.0% (at 20 min incubation) and 99.5% (at 40 min incubation) at 850 mbar pressure and at temperature 25 °C.

Solvents such as hexane and/or ethanol are the most commonly employed methods for lutein extraction due to the easy removal of the solvent from the extract while also retrieving a high content of lutein. In contrast, direct extraction with vegetable oil was described by Nonomura [51] and does not allow for solvent removal. This patent involves direct extraction on wet biomass using the addition of vegetable oil, followed by emulsification and a resting period. However, in regard to microalgae with thick cell walls, such as Murielopsis sp. or Scenedesmus sp., it is unlikely this methodology would be efficient.

Low et al. [52] described a microwave-assisted binary phase solvent extraction method (MABS) for the recovery of lutein from microalgae. The method was established and optimised to specifically attain the highest lutein recovery from microalgae Scenedesmus sp. biomass, with a total of 11.92 mg g−1 lutein recovered. The optimal binary phase solvent composition was a 60% potassium hydroxide solution with acetone in the ratio of 0.1 (mL/mL). The highest lutein content was at 55 °C treatment temperature, 36 min extraction time, 0.7 (mg mL−1) biomass:solvent ratio, 250 Watt microwave power, and 250 rpm stirring speed. This optimised novel procedure can increase lutein recovery by approximately 130%, along with also shortening the overall extraction time by 3-fold.

In conclusion, in regard to the large-scale production of lutein, only solvent extraction has, to date, achieved high degrees of efficiency and purity. However, new advances in methods and techniques such as selective precipitation with supercritical CO2 and new advantageous solvents, such as ethyl lactate, which have been proposed for the extraction of other plant matter [53], may also be applied to microalgae and prove beneficial.

4. Current Market Demand, Value and Sources

Currently, the global lutein market is valued at EUR 255 million and is expected to reach EUR 409 million by 2027 [4]. Lutein appears as a slightly lower value carotenoid compared to the market price for astaxanthin. As per ICIS market research, the price for 100% pure lutein may range from EUR 1688.00 to EUR 2532.00 per kg, while the available products with dry forms of lutein may range from EUR 126.00 to EUR 253.00 per kg, and the products with the liquid forms of lutein may range from EUR 422.00 to EUR 590.00 per kg (https://www.icis.com/explore/resources/news/2003/05/16/195956/lutein-eyes-robust-growth-in-food-and-nutraceuticals/ accessed on 12 September 2020). The growth of the global lutein market is driven by an increase in demand for healthy and organic food products and a surge in awareness towards dietary supplements. Furthermore, the rise in disposable income allows consumers to purchase healthy alternatives to regular food products.

Asia Pacific is projected to account for 23.2% of the global market. Developing nations such as China and India are expected to observe high growth. High occurrence of eye disorders coupled with the growing demand for dietary supplements is expected to accelerate the need [54]. Dietary supplements held 29% of the overall market share in 2019 and are expected to keep their dominance over the forecast period. Europe held 36.2% of the industry in 2018 and is projected to grow significantly in the coming years [54].

5. Overall Discussion and Future Prospects

Although marigold meets the global demand for lutein to some extent, there is still a huge opportunity to contribute to the global demand for natural lutein. This is where microalgae can play a significant role because there are several microalgae that produce 0.5–1.2% lutein of their cell dry weight [5]. Moreover, microalgae have more free lutein than marigold, which is preferable since it is easily absorbed compared to the esterified forms found in marigold flowers. In addition, there are several microalgal commercial technologies for cultivation, and optimum extraction of carotenoids is available. Importantly, microalgae are considered as one of the most promising biofactories, with 5–10 times higher growth rate than land plants, high-potential CO2 scavenging, and their commercial cultivation technologies can be based on all types of water sources such as freshwater, brackish water, and seawater, and do not require arable land. Microalgae as commercial lutein producers are still waiting for the involvement of enthusiast entrepreneur biotechnologists who would be willing to adopt existing microalgal cultivation technologies. It is good that there are already a number of marine as well as freshwater microalgal strains identified as lutein producers through various research studies (Table 1), which can serve as a starting point.

The commercially optimum method and the safety of chemically synthesised lutein for human consumption are still questionable; therefore, the natural lutein market is gaining interest. Even though there is no commercial production of lutein, microalgae are an attractive source for the mass production of lutein due to their high growth rates and high pigment content. However; there are some challenges to be focused on that are mostly related to the cost [55]. Particularly, these are due to the current market price for lutein as well as the lutein yield in known microalgae being lower compared to the market price and yield of astaxanthin, which is currently produced economically and reliably from Haematococcus pluvialis. Although heterotrophic cultivation improves cell growth and lutein content, the cost of glucose and other carbon sources prevent microalgal lutein production from being commercially profitable [56]. Not only the carbon addition cost, but also the downstream processes such as harvesting and drying increase the cost, where energy-saving approaches are essential for both processes. Moreover, to improve the growth capacity of the selected culture, high-efficiency photobioreactors should be designed, where optimal growth conditions such as temperature or light can be applied. Based on the current cultivation technologies for Dunaliella sp. and Haematococcus sp. that were also found suitable at experimental-scale for Muriellopsis sp. and Scenedesmus sp., it appears that tubular photobioreactors can also be the choice for lutein production from these microalgae.

In addition, advanced metabolic engineering approaches may be applied to improve the lutein synthesis pathways in microalgae and increase its cellular accumulation to be commercially competitive. In summary, microalgal lutein has a great potential to be commercially produced with some challenges mentioned above to be overcome. In the future, better engineering reactor designs should be created for higher culture growth, new innovations should be applied for low-cost harvesting/drying processes, and selected cultures should be metabolically engineered (by chemical mutagenesis or targeted genetic engineering) to produce higher lutein without decreasing the culture biomass yield.

Overall, considering the growing demand for natural lutein, available potential microalgal strains, and their cultivation technologies available, it is high time to initiate industrial involvement along with some research and development activities for microalgal lutein production, along with other value-added bioproducts, using a biorefinery approach. The approach would at least need to achieve, through the rapid cultivation of selected microalgal strains by tweaking their abiotic growth factors to enhance lutein content followed by simple harvesting of biomass, extraction of lutein at affordable costs and valorisation of lutein-extracted biomass for additional bioproducts development.

References

- Fernandes, A.S.; do Nascimento, T.C.; Jacob-Lopes, E.; De Rosso, V.V.; Zepka, L.Q. Introductory Chapter: Carotenoids—A Brief Overview on Its Structure, Biosynthesis, Synthesis, and Applications. Prog. Carotenoid Res. 2018, 1–16.

- Guedes, A.C.; Amaro, H.M.; Malcata, F.X. Microalgae as sources of carotenoids. Mar. Drugs 2011, 9, 625–644.

- Roberts, J.E.; Dennison, J. The Photobiology of Lutein and Zeaxanthin in the Eye. J. Ophthalmol. 2015, 2015, 687173.

- Marino, T.; Casella, P.; Sangiorgio, P.; Verardi, A.; Ferraro, A.; Hristoforou, E.; Molino, A.; Musmarra, D. Natural beta-carotene: A microalgae derivate for nutraceutical applications. Chem. Eng. Trans. 2020, 79, 103–108.

- Lin, J.H.; Lee, D.J.; Chang, J.S. Lutein production from biomass: Marigold flowers versus microalgae. Bioresour. Technol. 2015, 184, 421–428.

- Khan, M.I.; Shin, J.H.; Kim, J.D. The promising future of microalgae: Current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb. Cell Fact. 2018, 17, 1–21.

- Saha, S.K.; Murray, P. Exploitation of microalgae species for nutraceutical purposes: Cultivation aspects. Fermentation 2018, 4, 46.

- Bilal, M.; Rasheed, T.; Ahmed, I.; Iqbal, H.M.N. High-value compounds from microalgae with industrial exploitability—A review. Front. Biosci. Sch. 2017, 9, 319–342.

- Saha, S.K.; Mchugh, E.; Murray, P.; Walsh, D.J. Microalgae as a source of nutraceuticals. In Phycotoxins: Chemistry and Biochemistry, 2nd ed.; Botana, L.M., Alfonso, A., Eds.; JohnWiley & Sons Ltd.: Chichester, UK, 2015; pp. 255–292.

- Takaichi, S. Carotenoids in algae: Distributions, biosyntheses and functions. Mar. Drugs 2011, 9, 1101–1118.

- Barredo, J.-L. Microbial Carotenoids from Bacteria and Microalgae. Methods and Protocols. Methods Mol. Biol. 2012, 892, 133–141.

- Gwak, Y.; Hwang, Y.S.; Wang, B.; Kim, M.; Jeong, J.; Lee, C.G.; Hu, Q.; Han, D.; Jin, E. Comparative analyses of lipidomes and transcriptomes reveal a concerted action of multiple defensive systems against photooxidative stress in Haematococcus pluvialis. J. Exp. Bot. 2014, 65, 4317–4334.

- Hunter, W.N. The non-mevalonate pathway of isoprenoid precursor biosynthesis. J. Biol. Chem. 2007, 282, 21573–21577.

- Kim, J.; Kim, M.; Lee, S.; Jin, E.S. Development of a Chlorella vulgaris mutant by chemical mutagenesis as a producer for natural violaxanthin. Algal Res. 2020, 46, 101790.

- Lee, P.C.; Schmidt-Dannert, C. Metabolic engineering towards biotechnological production of carotenoids in microorganisms. Appl. Microbiol. Biotechnol. 2002, 60, 1–11.

- Fan, X.D.; Hou, Y.; Huang, X.X.; Qiu, T.Q.; Jiang, J.G. Ultrasound-enhanced subcritical CO2 extraction of lutein from Chlorella pyrenoidosa. J. Agric. Food Chem. 2015, 63, 4597–4605.

- Yildirim, A.; Akgün, İ.H.; Conk Dalay, M. Converted carotenoid production in Dunaliella salina by using cyclization inhibitors 2-methylimidazole and 3-amino-1,2,4-triazole. Turkish J. Biol. 2017, 41, 213–219.

- Liang, M.H.; Hao, Y.F.; Li, Y.M.; Liang, Y.J.; Jiang, J.G. Inhibiting Lycopene Cyclases to Accumulate Lycopene in High β-Carotene-Accumulating Dunaliella bardawil. Food Bioprocess Technol. 2016, 9, 1002–1009.

- Ishikawa, E.; Abe, H. Lycopene accumulation and cyclic carotenoid deficiency in heterotrophic Chlorella treated with nicotine. J. Ind. Microbiol. Biotechnol. 2004, 31, 585–589.

- Fazeli, M.R.; Tofighi, H.; Madadkar-Sobhani, A.; Shahverdi, A.R.; Nejad-Sattari, T.; Sako, M.; Jamalifar, H. Nicotine inhibition of lycopene cyclase enhances accumulation of carotenoid intermediates by Dunaliella salina CCAP 19/18. Eur. J. Phycol. 2009, 44, 215–220.

- Poojary, M.M.; Barba, F.J.; Aliakbarian, B.; Donsì, F.; Pataro, G.; Dias, D.A.; Juliano, P. Innovative alternative technologies to extract carotenoids from microalgae and seaweeds. Mar. Drugs 2016, 14, 214.

- Ma, R.; Zhao, X.; Ho, S.H.; Shi, X.; Liu, L.; Xie, Y.; Chen, J.; Lu, Y. Co-production of lutein and fatty acid in microalga Chlamydomonas sp. JSC4 in response to different temperatures with gene expression profiles. Algal Res. 2020, 47, 101821.

- Ma, R.; Zhao, X.; Xie, Y.; Ho, S.H.; Chen, J. Enhancing lutein productivity of Chlamydomonas sp. via high-intensity light exposure with corresponding carotenogenic genes expression profiles. Bioresour. Technol. 2019, 275, 416–420.

- Xie, Y.; Lu, K.; Zhao, X.; Ma, R.; Chen, J.; Ho, S.H. Manipulating Nutritional Conditions and Salinity-Gradient Stress for Enhanced Lutein Production in Marine Microalga Chlamydomonas sp. Biotechnol. J. 2019, 14, 1–28.

- Garbayo, I.; Cuaresma, M.; Vílchez, C.; Vega, J.M. Effect of abiotic stress on the production of lutein and β-carotene by Chlamydomonas acidophila. Process Biochem. 2008, 43, 1158–1161.

- Gayathri, S.; Radhika, S.R.R.; Suman, T.Y.; Aranganathan, L. Ultrasound-assisted microextraction of β, ε-carotene-3, 3′-diol (lutein) from marine microalgae Chlorella salina: Effect of different extraction parameters. Biomass Convers. Biorefinery 2018, 8, 791–797.

- Serejo, M.L.; Posadas, E.; Boncz, M.A.; Blanco, S.; García-Encina, P.; Muñoz, R. Influence of biogas flow rate on biomass composition during the optimization of biogas upgrading in microalgal-bacterial processes. Environ. Sci. Technol. 2015, 49, 3228–3236.

- Del Campo, J.A.; Rodríguez, H.; Moreno, J.; Vargas, M.Á.; Rivas, J.; Guerrero, M.G. Lutein production by Muriellopsis sp. in an outdoor tubular photobioreactor. J. Biotechnol. 2001, 85, 289–295.

- Blanco, A.M.; Moreno, J.; Del Campo, J.A.; Rivas, J.; Guerrero, M.G. Outdoor cultivation of lutein-rich cells of Muriellopsis sp. in open ponds. Appl. Microbiol. Biotechnol. 2007, 73, 1259–1266.

- Schüler, L.M.; Santos, T.; Pereira, H.; Duarte, P.; Katkam, N.G.; Florindo, C.; Schulze, P.S.C.; Barreira, L.; Varela, J.C.S. Improved production of lutein and β-carotene by thermal and light intensity upshifts in the marine microalga Tetraselmis sp. CTP4. Algal Res. 2020, 45, 101732.

- Dineshkumar, R.; Dhanarajan, G.; Dash, S.K.; Sen, R. An advanced hybrid medium optimization strategy for the enhanced productivity of lutein in Chlorella minutissima. Algal Res. 2015, 7, 24–32.

- Araya, B.; Gouveia, L.; Nobre, B.; Reis, A.; Chamy, R.; Poirrier, P. Evaluation of the simultaneous production of lutein and lipids using a vertical alveolar panel bioreactor for three Chlorella species. Algal Res. 2014, 6, 218–222.

- Shi, X.M.; Liu, H.J.; Zhang, X.W.; Chen, F. Production of biomass and lutein by Chlorella protothecoides at various glucose concentrations in heterotrophic cultures. Process Biochem. 1999, 34, 341–347.

- Chen, C.Y.; Liu, C.C. Optimization of lutein production with a two-stage mixotrophic cultivation system with Chlorella sorokiniana MB-1. Bioresour. Technol. 2018, 262, 74–79.

- Deenu, A.; Naruenartwongsakul, S.; Kim, S.M. Optimization and economic evaluation of ultrasound extraction of lutein from Chlorella vulgaris. Biotechnol. Bioprocess Eng. 2013, 18, 1151–1162.

- Xin, C.; Addy, M.M.; Zhao, J.; Cheng, Y.; Cheng, S.; Mu, D.; Liu, Y.; Ding, R.; Chen, P.; Ruan, R. Comprehensive techno-economic analysis of wastewater-based algal biofuel production: A case study. Bioresour. Technol. 2016, 211, 584–593.

- Shi, X.M.; Jiang, Y.; Chen, F. High-yield production of lutein by the green microalga Chlorella protothecoides in heterotrophic fed-batch culture. Biotechnol. Prog. 2002, 18, 723–727.

- Del Campo, J.A.; Rodríguez, H.; Moreno, J.; Vargas, M.Á.; Rivas, J.; Guerrero, M.G. Accumulation of astaxanthin and lutein in Chlorella zofingiensis (Chlorophyta). Appl. Microbiol. Biotechnol. 2004, 64, 848–854.

- Xie, Y.; Zhao, X.; Chen, J.; Yang, X.; Ho, S.H.; Wang, B.; Chang, J.S.; Shen, Y. Enhancing cell growth and lutein productivity of Desmodesmus sp. F51 by optimal utilization of inorganic carbon sources and ammonium salt. Bioresour. Technol. 2017, 244, 664–671.

- Del Campo, J.A.; Moreno, J.; Rodríguez, H.; Angeles Vargas, M.; Rivas, J.; Guerrero, M.G. Carotenoid content of chlorophycean microalgae: Factors determining lutein accumulation in Muriellopsis sp. (Chlorophyta). J. Biotechnol. 2000, 76, 51–59.

- Flórez-Miranda, L.; Cañizares-Villanueva, R.O.; Melchy-Antonio, O.; Martínez-Jerónimo, F.; Flores-Ortíz, C.M. Two stage heterotrophy/photoinduction culture of Scenedesmus incrassatulus: Potential for lutein production. J. Biotechnol. 2017, 262, 67–74.

- Ram, S.; Paliwal, C.; Mishra, S. Growth medium and nitrogen stress sparked biochemical and carotenogenic alterations in Scenedesmus sp. CCNM 1028. Bioresour. Technol. Rep. 2019, 7, 100194.

- Chen, W.C.; Hsu, Y.C.; Chang, J.S.; Ho, S.H.; Wang, L.F.; Wei, Y.H. Enhancing production of lutein by a mixotrophic cultivation system using microalga Scenedesmus obliquus CWL-1. Bioresour. Technol. 2019, 291, 121891.

- Molino, A.; Mehariya, S.; Karatza, D.; Chianese, S.; Iovine, A.; Casella, P.; Marino, T.; Musmarra, D. Bench-scale cultivation of microalgae Scenedesmus almeriensis for CO2 capture and lutein production. Energies 2019, 12, 2806.

- Yen, H.W.; Chiang, W.C.; Sun, C.H. Supercritical fluid extraction of lutein from Scenedesmus cultured in an autotrophical photobioreactor. J. Taiwan Inst. Chem. Eng. 2012, 43, 53–57.

- Sánchez, J.F.; Fernández, J.M.; Acién, F.G.; Rueda, A.; Pérez-Parra, J.; Molina, E. Influence of culture conditions on the productivity and lutein content of the new strain Scenedesmus almeriensis. Process Biochem. 2008, 43, 398–405.

- Ho, S.H.; Chan, M.C.; Liu, C.C.; Chen, C.Y.; Lee, W.L.; Lee, D.J.; Chang, J.S. Enhancing lutein productivity of an indigenous microalga Scenedesmus obliquus FSP-3 using light-related strategies. Bioresour. Technol. 2014, 152, 275–282.

- Kumar, S.P.J.; Kumar, G.V.; Dash, A.; Scholz, P.; Banerjee, R. Sustainable green solvents and techniques for lipid extraction from microalgae: A review. Algal Res. 2017, 21, 138–147.

- Macías-Sánchez, M.D.; Fernandez-Sevilla, J.M.; Fernández, F.G.A.; García, M.C.C.; Grima, E.M. Supercritical fluid extraction of carotenoids from Scenedesmus almeriensis. Food Chem. 2010, 123, 928–935.

- Chen, C.Y.; Jesisca; Hsieh, C.; Lee, D.J.; Chang, C.H.; Chang, J.S. Production, extraction and stabilization of lutein from microalga Chlorella sorokiniana MB-1. Bioresour. Technol. 2016, 200, 500–505.

- Nonomura, A.M. Process for Producing a Naturally-Derived Carotene/Oil Composition by Direct Extraction from Algae. U.S. Patent 4,680,314A, 14 July 1987.

- Low, K.L.; Idris, A.; Mohd Yusof, N. Novel protocol optimized for microalgae lutein used as food additives. Food Chem. 2020, 307, 125631.

- Ishida, B.K.; Chapman, M.H. Carotenoid Extraction from Plants Using a Novel, Environmentally Friendly Solvent. J. Agric. Food Chem. 2009, 57, 1051–1059.

- Lutein Market to Reach USD 454.8 Million by 2026|Reports And Data. Available online: https://www.prnewswire.com/news-releases/lutein-market-to-reach-usd-454-8-million-by-2026--reports-and-data-300941985.html (accessed on 4 September 2020).

- Ambati, R.R.; Gogisetty, D.; Aswathanarayana, R.G.; Ravi, S.; Bikkina, P.N.; Bo, L.; Yuepeng, S. Industrial potential of carotenoid pigments from microalgae: Current trends and future prospects. Crit. Rev. Food Sci. Nutr. 2019, 59, 1880–1902.

- Gong, M.; Bassi, A. Carotenoids from microalgae: A review of recent developments. Biotechnol. Adv. 2016, 34, 1396–1412.