Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Yanping Xu | -- | 1044 | 2022-08-17 09:43:31 | | | |

| 2 | Camila Xu | Meta information modification | 1044 | 2022-08-17 10:05:31 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Xu, Y.; Ma, S.; Pang, Y. Fluorescence-Based Sensors for High-Temperature Monitoring. Encyclopedia. Available online: https://encyclopedia.pub/entry/26237 (accessed on 05 March 2026).

Xu Y, Ma S, Pang Y. Fluorescence-Based Sensors for High-Temperature Monitoring. Encyclopedia. Available at: https://encyclopedia.pub/entry/26237. Accessed March 05, 2026.

Xu, Yanping, Shaonian Ma, Yuxi Pang. "Fluorescence-Based Sensors for High-Temperature Monitoring" Encyclopedia, https://encyclopedia.pub/entry/26237 (accessed March 05, 2026).

Xu, Y., Ma, S., & Pang, Y. (2022, August 17). Fluorescence-Based Sensors for High-Temperature Monitoring. In Encyclopedia. https://encyclopedia.pub/entry/26237

Xu, Yanping, et al. "Fluorescence-Based Sensors for High-Temperature Monitoring." Encyclopedia. Web. 17 August, 2022.

Copy Citation

Fiber-optic high-temperature sensors are gradually replacing traditional electronic sensors due to their small size, resistance to electromagnetic interference, remote detection, multiplexing, and distributed measurement advantages.

high-temperature measurement

fiber-optic sensors

Fluorescence-Based Sensors

1. Introduction

The reliable measurement of high temperatures plays a significant role in the aerospace field, metallurgical industry, and nuclear energy production [1][2][3][4][5]. For example, the application of long-range distributed high-temperature sensors guarantees the long-term safe operation of deep underground wells [6][7]. In the metallurgical industry, real-time measurement of the internal temperature of high-temperature boilers is key to monitoring combustion efficiency and safety prevention [1][8][9]. Temperature monitoring inside the combustion chambers and turbines of an aircraft or aero-engine can help extend its service life [2][10][11][12]. Extremely harsh environments with high temperatures, high pressures, and strong electromagnetic radiation present a challenge to traditional temperature sensors.

According to the installation and detection methods, high-temperature measurement technology can be mainly divided into contact measurement and non-contact measurement [3][13]. Thermocouple sensors made of precious metals are commonly used for contact temperature measurements thanks to their mature preparation process, ease of operation, wide temperature measurement range, and the capability for absolute measurements [14][15][16]. However, the thermocouple sensors have disadvantages of poor corrosion resistance, short service life, low measurement accuracy, and susceptibility to electromagnetic interference. Precious metal materials or alloys used to form thermocouple sensors are easily damaged at high temperatures, strong oxidation, or strong corrosion environments, affecting the service life and temperature measurement accuracy of thermocouples [17][18]. Infrared thermography (IRT) is representative of non-contact temperature measurement technology, which can avoid direct contact between temperature measurement equipment and high-temperature areas to achieve non-destructive testing [19][20][21]. Unfortunately, radiation temperature measurement technology is only suitable for surface measurements, such as explosion flame, and cannot detect the temperature of the internal structure of the closure device. Moreover, complex background noise is also a limiting factor in accurate temperature measurement [22].

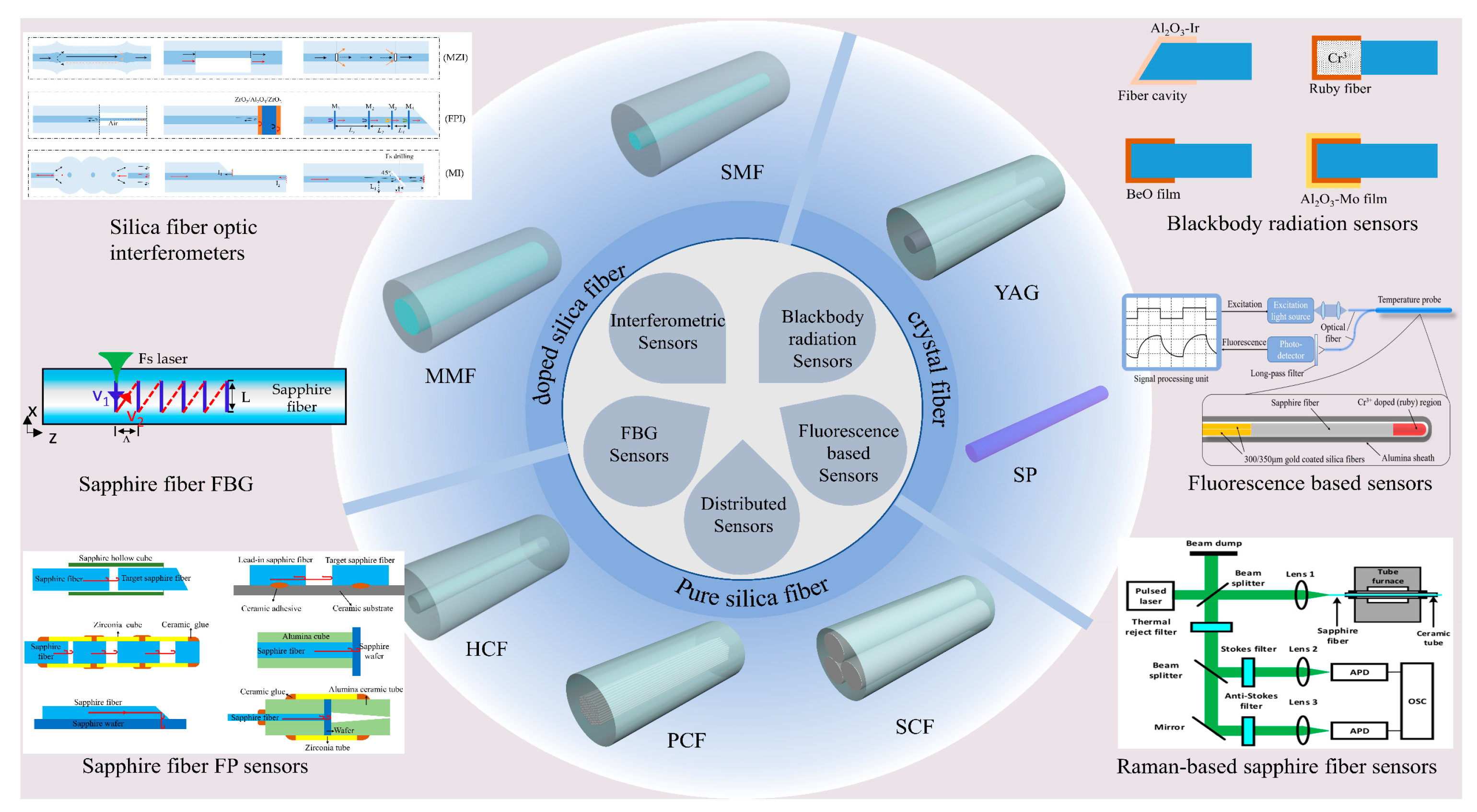

Compared to traditional electronic sensors [2], fiber-optic sensors have attracted intensive attention during the past decades due to their inherent advantages such as compact size, flexible structure, high sensitivity, high resolution, ability to multiplex, and immunity to electromagnetic interference [23][24][25][26]. In fiber-optic high-temperature sensing systems, various optical fibers are used as the sensor transducer, as the medium for data transmission, or both [27][28]. According to the temperature measurement principle, fiber-optic sensors can be divided into blackbody radiation sensors, fluorescence-based sensors, interferometric sensors, fiber Bragg grating (FBG) sensors, and distributed temperature sensors (DTS). The commonly employed high-temperature sensing fibers mainly include silica fibers and crystal fibers. Theoretically, the maximum temperature that a temperature sensor can withstand depends primarily on the fiber material rather than the sensing mechanism. Generally, silica-fiber-based temperature sensors are limited to operating within 1000 °C due to the diffusion of germanium dopant. In addition, temperature sensors based on pure silicon fibers (e.g., photonic crystal fibers, hollow-core fibers, suspended-core fibers) can operate at 1300 °C (near the melting point of silicon), and temperature sensors based on single-crystal fibers can operate stably below 1900 °C. Figure 1 shows the temperature sensor classification, fiber type, and sensor mechanism from the inside to the outside.

Figure 1. The temperature sensor classification, fiber type, and sensor mechanism from the inside to the outside. SP: sapphire, YAG: Yttrium aluminum garnet, SMF: single-mode fiber, MMF: multi-mode fiber, HCF: hollow-core fiber, PCF: photonic crystal fiber, SSCF: suspended-core fiber.

2. Fluorescence-Based Sensors

Fluorescence-based high-temperature sensors are generally realized by attaching various photoluminescent materials to a silica fiber or a single-crystal fiber tip such as yttrium aluminum garnet (YAG), sapphire, and MgAl2O4 by the LHPG method or co-precipitation method. When a strong laser pulse hits the fluorescent material at the probe, it generates fluorescence, which gradually decays over time (also named fluorescence lifetime). The fluorescence lifetime and fluorescence intensity of the material depends on the external temperature and generally have a linear relationship [29]. At present, two commonly used fluorescence high-temperature sensing schemes are available: one is the fluorescence lifetime (FL) method [29][30][31][32][33][34][35][36][37] and the other is the fluorescence intensity ratio (FIR) method [38][39][40][41].

The FIR method achieves temperature testing by detecting the fluorescence intensity ratio of two wavelengths at different excited states. Compared to single wavelength fluorescence intensity testing, the FIR method avoids the effects of light source intensity fluctuations. However, it suffers from some limitations in terms of performance, such as poor linearity between temperature and intensity [32]. On the other hand, the FL method does not require precise measurement of output light intensity and is not affected by fluctuations in light source intensity or external background noise, so it is widely used in commercial sensors.

Fluorescence lifetime methods have been used for sensing measurements since the 1980s, but not in fiber form [42]. With the development of optical fiber technology, optical-fiber-based fluorescent temperature sensors have been widely studied. When silicon is used as the sensor waveguide, the sensor usually operates below 400 °C. The sensor can reach a measurement value of approximately 600 °C by using a metal-coated optical fiber [43]. Later, single-crystal optical fibers were widely used in fluorescent sensors due to their higher melting point (>2000 °C), excellent mechanical properties, and extreme resistance to oxidation. In addition to the waveguide, the temperature measurement range of the sensor is also affected by the fluorescent material. Table 1 summarizes the temperature sensing performance of fluorescence-based sensors with different doping materials in recent years. It can be found that the fluorescent material not only determines the upper limit of the measurable temperature of the sensor but also determines the sensitivity, stability, and strength of the signal under detection. For example, the burst effect of Er3+-doped YAG above 600 °C causes rapid decay of fluorescence intensity and fluorescence lifetime, resulting in different sensitivity of the sensor in different temperature intervals [44]. Tm-doped Y2O3 has a weak fluorescence intensity, so the signal-to-noise ratio of the detected signal is poor and not suitable for high-precision measurements [45]. Therefore, the development of fluorescent sensors with high luminescence intensity and good linearity is a challenge to be faced in the future.

Table 1. Performances comparison of fluorescence-based sensors.

| Test Method |

Sensing Materials Doped with Rare Earths | Temperature Range |

Sensing Performance |

Ref. |

|---|---|---|---|---|

| FL | YAG: Tm3+ | 0–1400 °C | ±5 °C | 2003 [29] |

| YAG: Cr3+ | −20–500 °C | 1 μs/°C @500 °C | 2006 [32] | |

| YAG: Cr3+ | −25–50 °C | 0.1 °C | 1995 [33] | |

| YAG/KGW/YVO4: Nd3+ | 0–1000 °C | ±2 °C | 1997 [34] | |

| YAG: Yb3+ | 1600 °C | 3 °C | 2002 [35] | |

| YSZ/YAG: Dy3+ | 0–1200 °C | - | 2009 [36] | |

| YAG: Dy3+, Er3+ | 24–1700 °C | 10 °C | 2020 [37] | |

| FIR | SiO2/YAG: Tb3+ | 300–1200 K | - | 2006 [38] |

| YAG: Pr3+ | 293–573 K | 0.0025 K−1 | 2016 [39] | |

| YAG: Yb3+ | 500–1000 K | 0.3% K−1 | 2018 [40] | |

| YAG: Sm3+ | 303–1028 K | 3.046 × 10−4 K−1 | 2022 [41] |

References

- Yang, S.; Homa, D.; Heyl, H.; Theis, L.; Beach, J.; Dudding, B.; Acord, G.; Taylor, D.; Pickrell, G.; Wang, A. Application of sapphire-fiber-bragg-grating-based multi-point temperature sensor in boilers at a commercial power plant. Sensors 2019, 19, 3211.

- Watson, J.; Castro, G. A review of high-temperature electronics technology and applications. J. Mater. Sci. Mater. Electron. 2015, 26, 9226–9235.

- Childs, P.R.N.; Greenwood, J.R.; Long, C.A. Review of temperature measurement. Rev. Sci. Instrum. 2000, 71, 2959–2978.

- Rizzolo, S.; Périsse, J.; Boukenter, A.; Ouerdane, Y.; Marin, E.; Macé, J.-R.; Cannas, M.; Girard, S. Real time monitoring of water level and temperature in storage fuel pools through optical fibre sensors. Sci. Rep. 2017, 7, 8766.

- Sang, A.K.; Froggatt, M.E.; Gifford, D.K.; Kreger, S.T.; Dickerson, B.D. One centimeter spatial resolution temperature measurements in a nuclear reactor using rayleigh scatter in optical fiber. IEEE Sens. J. 2008, 8, 1375–1380.

- Reinsch, T.; Henninges, J. Temperature-dependent characterization of optical fibres for distributed temperature sensing in hot geothermal wells. Meas. Sci. Technol. 2010, 21, 94022.

- Lu, P.; Lalam, N.; Badar, M.; Liu, B.; Chorpening, B.T.; Buric, M.P.; Ohodnicki, P.R. Distributed Optical Fiber Sensing: Review and Perspective. Appl. Phys. Rev. 2019, 6, 041302.

- Willsch, M.; Bosselmann, T.; Flohr, P.; Kull, R.; Ecke, W.; Latka, I.; Fischer, D.; Thiel, T. Design of Fiber Optical High Temperature Sensors for Gas Turbine Monitoring; Jones, J.D.C., Ed.; SPIE: Bellingham, WA, USA, 2009; p. 75037R.

- Mekhrengin, M.V.; Meshkovskii, I.K.; Tashkinov, V.A.; Guryev, V.I.; Sukhinets, A.V.; Smirnov, D.S. Multispectral pyrometer for high temperature measurements inside combustion chamber of gas turbine engines. Measurement 2019, 139, 355–360.

- García, I.; Zubia, J.; Durana, G.; Aldabaldetreku, G.; Illarramendi, M.; Villatoro, J. Optical fiber sensors for aircraft structural health monitoring. Sensors 2015, 15, 15494–15519.

- Gao, S.; Wang, L.; Feng, C. Multi-Spectral Pyrometer for Gas Turbine Blade Temperature Measurement; Kazemi, A.A., Kress, B.C., Mendoza, E.A., Eds.; SPIE: Bellingham, WA, USA, 2014; p. 920217.

- Liang, M.; Sun, B.; Sun, X.; Xie, J. Development of a new fiber-optic multi-target multispectral pyrometer for achievable true temperature measurement of the solid rocket motor plume. Measurement 2017, 95, 239–245.

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F. Infrared thermography for temperature measurement and non-destructive testing. Sensors 2014, 14, 12305–12348.

- Bradley, D.; Matthews, K.J. Measurement of high gas temperatures with fine wire thermocouples. J. Mech. Eng. Sci. 1968, 10, 299–305.

- Heitor, M.V.; Moreira, A.L.N. Thermocouples and sample probes for combustion studies. Prog. Energy Combust. Sci. 1993, 19, 259–278.

- Kus, A.; Isik, Y.; Cakir, M.C.; Co, S. Thermocouple and infrared sensor-based measurement of temperature distribution in metal cutting. Sensors 2015, 15, 1274.

- Jun, S.; Kochan, O. Investigations of Thermocouple drift irregularity impact on error of their inhomogeneity correction. Meas. Sci. Rev. 2014, 14, 29–34.

- Holmsten, M.; Ivarsson, J.; Falk, R.; Lidbeck, M.; Josefson, L.-E. Inhomogeneity measurements of long thermocouples using a short movable heating zone. Int. J. Thermophys. 2008, 29, 915–925.

- Nie, B.; He, X.; Zhang, C.; Li, X.; Li, H. Temperature measurement of gas explosion flame based on the radiation thermometry. Int. J. Therm. Sci. 2014, 78, 132–144.

- Meriaudeau, F. Real time multispectral high temperature measurement: Application to control in the industry. Image Vis. Comput. 2007, 25, 1124–1133.

- Hartmann, J. High-temperature measurement techniques for the application in photometry, radiometry and thermometry. Phys. Rep. 2009, 469, 205–269.

- Lou, C.; Li, W.-H.; Zhou, H.-C.; Salinas, C.T. Experimental investigation on simultaneous measurement of temperature distributions and radiative properties in an oil-fired tunnel furnace by radiation analysis. Int. J. Heat Mass Transf. 2011, 54, 1–8.

- Roriz, P.; Silva, S.; Frazão, O.; Novais, S. Optical fiber temperature sensors and their biomedical applications. Sensors 2020, 20, 2113.

- Mihailov, S.J. Fiber bragg grating sensors for harsh environments. Sensors 2012, 12, 1898–1918.

- Joe, H.-E.; Yun, H.; Jo, S.-H.; Jun, M.B.G.; Min, B.-K. A Review on Optical Fiber Sensors for Environmental Monitoring. Int. J. Precis. Eng. Manuf.-Green Tech. 2018, 5, 173–191.

- Xu, Y.; Lu, P.; Chen, L.; Bao, X. Recent developments in micro-structured fiber optic sensors. Fibers 2017, 5, 3.

- Yu, Y.B.; Chow, W.K. Review on an advanced high-temperature measurement technology: The optical fiber thermometry. J. Thermodyn. 2009, 2009, 823482.

- Wang, B.; Niu, Y.; Qin, X.; Yin, Y.; Ding, M. Review of high temperature measurement technology based on sapphire optical fiber. Measurement 2021, 184, 109868.

- Shen, Y.; Zhao, W.; He, J.; Sun, T.; Grattan, K.T.V. Fluorescence decay characteristic of Tm-Doped YAG crystal fiber for sensor applications, investigated from room temperature to 1400 °C. IEEE Sens. J. 2003, 3, 507–512.

- Wade, S.A.; Collins, S.F.; Baxter, G.W. Fluorescence intensity ratio technique for optical fiber point temperature sensing. J. Appl. Phys. 2003, 94, 4743.

- Rai, V.K. Temperature sensors and optical sensors. Appl. Phys. B 2007, 88, 297–303.

- Ye, L.; Zhang, J.; Shi, Y. Growth and characteristics of Cr3+:YAG crystal fiber for fluorescence decay temperature sensor. Rev. Sci. Instrum. 2006, 77, 054901.

- Fernicola, V.; Crovini, L. Digital optical fiber point sensor for high-temperature measurement. J. Lightwave Technol. 1995, 13, 1331–1334.

- Zhang, Z.Y.; Grattan, K.T.V.; Palmer, A.W.; Meggitt, B.T. Potential for temperature sensor applications of highly neodymium-doped crystals and fiber at up to approximately 1000 °C. Rev. Sci. Instrum. 1997, 68, 2759–2763.

- Kennedy, J.L.; Djeu, N. Operation of Yb: YAG fiber-optic temperature sensor up to 1600 °C. Sens. Actuators A Phys. 2002, 100, 187–191.

- Skinner, S.J.; Feist, J.P.; Brooks, I.J.E.; Seefeldt, S.; Heyes, A.L. YAG: YSZ composites as potential thermographic phosphors for high temperature sensor applications. Sens. Actuators B Chem. 2009, 136, 52–59.

- Allison, S.W.; Beshears, D.L.; Cates, M.R.; Scudiere, M.B.; Shaw, D.W.; Ellis, A.D. Luminescence of YAG:Dy and YAG:Dy,Er crystals to 1700 °C. Meas. Sci. Technol. 2020, 31, 044001.

- Aizawa, H.; Katsumata, T.; Komuro, S.; Morikawa, T.; Ishizawa, H.; Toba, E. Fluorescence thermometer based on the photoluminescence intensity ratio in Tb doped phosphor materials. Sens. Actuators A Phys. 2006, 126, 78–82.

- Hu, S.; Lu, C.; Liu, X.; Xu, Z. Optical temperature sensing based on the luminescence from YAG:Pr transparent ceramics. Opt. Mater. 2016, 60, 394–397.

- Demirkhanyan, H.G.; Demirkhanyan, G.G.; Kostanyan, R.B. YAG:Yb 3+ Crystal as a potential material for optical temperature sensors. Laser Phys. 2018, 28, 025701.

- Zhu, K.; Zhou, H.; Qiu, J.; Wang, L.-G.; Ye, L. Optical temperature sensing characteristics of Sm3+ doped YAG single crystal fiber based on luminescence emission. J. Alloy. Compd. 2022, 890, 161844.

- Sholes, R.R.; Small, J.G. Fluorescent decay thermometer with biological applications. Rev. Sci. Instrum. 1980, 51, 882–884.

- Zhang, Z.; Grattan, K.T.V.; Palmer, A.W. Fiber optic temperature sensor based on the cross referencing between blackbody radiation and fluorescence lifetime. Rev. Sci. Instrum. 1992, 63, 3177–3181.

- Zhang, Z.Y.; Grattan, K.T.V.; Palmer, A.W.; Meggitt, B.T.; Sun, T. Fluorescence decay-time characteristics of erbium-doped optical fiber at elevated temperatures. Rev. Sci. Instrum. 1997, 68, 2764–2766.

- Zhang, Z.Y. Optical fiber temperature sensor scheme using Tm-doped yttrium oxide powder-based probe. In Proceedings of the 13th International Conference on Optical Fiber Sensors; SPIE: Kyongju, Korea, 1999; p. 76.

More

Information

Subjects:

Optics

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.5K

Revisions:

2 times

(View History)

Update Date:

17 Aug 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No