2. Geothermal Technologies

In the geothermal business, the vast majority of currently available power generation methods have been developed, taking advantage of typical convective geothermal systems (also referred to as hydrothermal systems). The features of the geothermal resource (fluid and reservoir) to be exploited have a significant impact on the selection process for the best geothermal power generation technology (i.e., geological, chemical, physical and thermodynamic properties). In particular, there are three types of geothermal fields:

- 1.

-

Vapor dominated systems with temperatures greater than 240 °C;

- 2.

-

Liquid (or hot water) dominated systems with temperatures up to 350 °C;

- 3.

-

Petro-thermal or solidified hot dry rock resources with temperatures up to 650 °C.

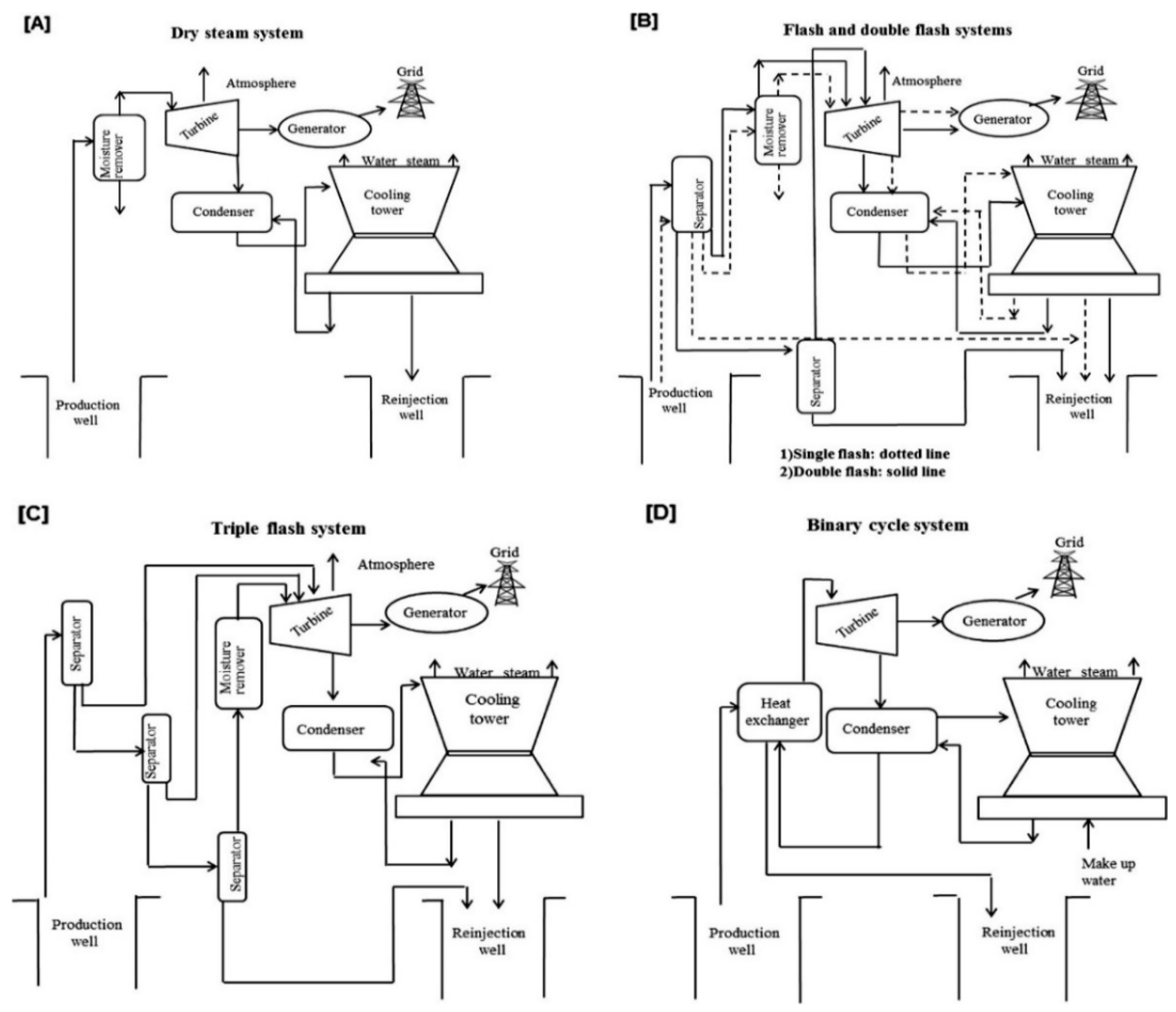

Convective hydrothermal systems (groups (1) and (2)) are commercially exploited around the world, while group (3) refers to the exploitation of the Hot Dry Rock (HDR) or Enhanced Geothermal Systems (EGS). The geothermal systems can be exploited using a variety of technologies, depending on the reservoir’s characteristics (e.g., geological, geophysical, geochemical, physicochemical, thermodynamic among others). This has been accomplished through the commercial and successful application of three types of mature technologies: dry steam, flash (single, double and triple) and binary cycle power plants (

Figure 1). A quick rundown of several emerging technologies follows

[1].

Figure 1. Simplified flow diagram for dry steam systems (

A), single and double flash systems (

B), triple flash system (

C) and binary-cycle (

D) geothermal power plant

[1].

2.1. Dry Steam Systems

The earth’s gradient temperature leads to reservoirs of high temperatures (>240 °C) in certain privileged locations, such as the geysers in California and Larderello in Italy. The steam turbine is used in alternating the reservoir vapor into mechanical energy, then sending it to a generator, where it is converted into electricity and transmitted to the grid (

Figure 2A). Because of its simple plant design, dry steam is the cheapest method of generating geothermal energy. In addition, a gas extraction system can be included in the plant setup if the chemical composition of the steam is water steam (>90% wt. of steam) and Non-Condensable Gases (NCG) (10% wt. of steam). Many other gases can be removed with this technique, such as H

2S, CO

2, H

2S-nitrogen trioxide, NH

3 and other trace gases (e.g., He, H

2, Ar, N

2, CH

4 and CO). Due to the potential corrosive effects of the NCG in the steam stream, additional changes are occasionally necessary to avoid a decrease in the turbine’s efficiency in geothermal power generation. As a result of these two causes, the power plant’s output is expected to fall, which could result in lower profits

[1].

2.2. Single and Multi-Stage (Double and Triple) Flash Systems

When the geothermal fluid in the reservoir is a mixture of liquid and vapor, the power generating process is known as flash. Single-, double- and triple-flash systems can be used in the separation process, depending on the thermodynamic mixture’s characteristics. A single-flash setup is commonly utilized when the mixture temperature exceeds 210 °C (dotted lines in

Figure 1B). By applying a cyclonic separator (Webre type), the geothermal fluid is recovered from the production well and delivered to separate the liquid and vapor phases of the combination. An expansion steam turbine and a generator complete the process of removing the primary vapor from the separator. Condensed cooling water from the expansion turbine’s steam condenser flows into an injection well, where the leftover liquid phase mixture (known as brine) can be reined in

[1].

Adding a second separation stage (known as double-flash) to this technique improves its efficiency (solid lines in

Figure 1B). A single-flash cycle of low-pressure steam is separated using this method. A low-pressure turbine or an appropriate stage of the main turbine are the two possible destinations for the secondary low-pressure steam (with dual-pressure and dual-admission specifications). In case the amount of NCG in the geothermal fluid is very high, an integration of an NCG abatement device may be necessary, despite the fact that this is merely an overview of the process in general. Both process efficiency and power generation can be increased by 35 and 20%, respectively, by using double-flash power plants

[1].

Triple-flash power plants are possible in this context, where a third separation step can be incorporated into the plant setup (

Figure 1C). Brine from the double-flash cycle, as well as NCG from the geothermal fluid, is used in this procedure to extract the maximum amount of energy possible from the brine. Some geothermal fields in the United States, New Zealand and Turkey currently make use of this technology

[1]. Concluding, 63% of the world’s installed geothermal power capacity comes from single- and double-flash conversion technology, while 2% comes from triple-flash power plants.

2.3. Binary Cycle Systems

Referring to temperatures lower than 200 °C, a binary-cycle power production system is applied, which accounts for 12% of the world’s capacity. The geo fluid cannot be utilized directly in this system as it can in the other power generation technologies that have been discussed so far. This is due to the inadequate vapor generation caused by the geo fluid’s low temperature. A thermodynamic Organic Rankine Cycle (ORC) or a Kalina cycle can be used to evaporate working fluids with lower boiling points such as isobutane, n-isopropyl and pentane, which can then be used to generate electricity. In a heat exchanger, an organic vapor is generated and transferred to a turbo generator system for generating power (

Figure 1D). Flowing steam from the turbine is condensed in a condenser and the brine is returned to the heat exchanger

[1].

2.4. Engineered or Enhanced Geothermal Systems (EGS)

As with binary cycle plants, it is theoretically possible to generate electricity by utilizing EGS. Deep subsurface reservoirs with low permeability and/or insufficient water supply can be exploited using these technologies (specifically, hot dry rock, hot wet rock and hot fractured rock resources)

[1].

An artificial reservoir must be created by either opening existing fractures in the rock or developing new ones in order to take advantage of such geothermal systems’ greater rock permeability. For the most part, heat energy is extracted from heated fractured rock (or artificial reservoirs) by injecting water (or another appropriate fluid such as CO

2) into the rock to drive a vigorous heat exchange and extract as much of the rock’s available energy as possible. Geothermal fluid loops are sometimes created by circulating fluid that is already present in the rock formations. Hot fluid from the well is retrieved and pumped to a power plant on the surface to create electricity. Despite the potential of the EGS, it is not widely used in the commercial market. This can be explained by the fact that this technology is still in its infancy. Several pilot projects in Australia, the United States, Italy, France, Germany, Switzerland, Japan and El Salvador have proved the viability of using these systems at depths ranging from 3 to 10 km, thanks to recent technological developments

[1].

3. Applications of Geothermal Systems

3.1. Combination of Geothermic and Biomass Systems

The potential benefits of the combination of deep geothermal energy and woody biomass for the heat production, electricity and biofuels were investigated, as energy consumption and energy-related GHG emissions of urban systems are increased. According to the LCA approach employed in the case study, the overall yearly cost of running the city was a primary target, while also measuring the environmental effect. Initially, all pathways were evaluated individually for each of the two technological options. When all conceivable combinations between geothermal and biomass solutions were studied, hybrid systems with fewer costs and environmental consequences were found. Furthermore, new hybrid systems that utilize excess geothermal heat to improve biomass conversion processes were discovered

[2].

Another application of the combination of geothermal and biomass scheme was accomplished in Italy. This case study conducted a life cycle analysis of a commercially available 150 kW co generative ORC system attached with a biomass boiler to assess its environmental impacts. While the used software was SimaPro, the data were gathered from the five years’ activity of the plant. The ORC module was a commercially available Combined Heat and Power (CHP) unit, adopting as working means a mix of hydrocarbons. In addition, the plant was driven by woodchip with values: 40%, 24%, 20%, 14% and 2% of birch, spruce, pine, beech and oak wood, respectively. Lastly, the obtained findings showed that the biomass production and the leaks of the organic liquid impacted by 71% and 19% of the total environmental impact, respectively

[3].

3.2. District Heating Systems

In this section, different studies examine all possible ways to heat a very large number of households using geothermal energy. The problem of heating a large residential area, more specifically a town center with a population of 25,000 habitants, has been examined. An energy and exergy analysis combined with LCC coupled with Net Present Value (NPV) analysis were applied by comparing different methods and ways to address the problem. According to the designing parameters of temperature and the pressure of twelve alternative working fluids, 4686 designs were performed, obtaining the optimum scenario

[4].

An exergoenvironmental analysis of the Afyon Geothermal District Heating System (GDHS) has been conducted, examining its environmental impact. An estimated 10,000 residencies may be heated by the Afyon GDHS’ total heating capability of 102 MW. Exergy losses of 12%, exergy destruction of 18% and approximately 0.0004% of the environmental effect were found to be attributable to system components, according to the study results. Priority should be directed to improving heat exchangers and reducing their thermodynamic inefficiencies, according to the findings

[5].

On a more theoretical perspective, an effort focusing on the life cycle design of a district energy system for a new residential development in Finland has been accomplished. By combining LCC and LCA, a Life Cycle Management (LCM) perspective is portrayed to support decision making on a long-term basis. Several energy design options were compared: (a) district heating (reference design), (b) district heating with building integrated PhotoVoltaic (PV) panels, (c) Ground Source Heat Pump (GSHP) and (d) GSHP with building-integrated photovoltaic panels. The authors identified that the design option with the highest initial investment was (d), being the most viable from a life cycle perspective by further strengthening the connection between cost savings and carbon emissions reduction in a life cycle context. Furthermore, their study was aiming to portray the mutual support between economic and environmental benefits in urban residential development, rather than evaluating the sustainability of a technical energy design solution in the long run. They concluded that geothermal energy is a rather viable option for applications such as district heating, even though the initial investment costs and improvements should be considered

[6].

Under investigation was the scenario where a plant was running in CHP mode for 3000 h/yr, corresponding to a heat generation of 33,750 MWh in its lifetime. Particularly, the ORC was assumed to work with a regenerative sub-critical cycle, where the valuable heat was provided as hot water at around 80 °C

[3].

On the other hand, Douziech et al.,

[7] conducted a comparative LCA on the production of 1 kWhth among the Rittershoffen geothermal heat plant in France and the produced heat from natural gas in Europe. Their article showed that, in climate change and resource-use fossil categories, the Rittershoffen plant impacted less than the average heat production. Moreover, LCA results highlighted that in the operation and maintenance phases, the hot spot was the electricity production for numerous impact categories.

3.3. Domestic Heating Systems

In this part, different aspects of domestic heating are investigated. Domestic heating is referred to a building, regardless of its use and size. Although geothermal energy is a renewable source, it is not free of GHG emissions, where this factor can be vastly attributed to the construction phase of the plant.

A major aspect is the comparison of different technologies in terms of environmental impacts and economic criteria, targeting the most appropriate. When combined with LCA, the prospective energy, exergetic and environmental performance of three regularly used residential building heating systems was investigated in Turkey. In more detail, a conventional coal boiler, a condensing natural gas boiler and a Ground Source Heat Pump (GSHP) were compared. From a thermodynamic perspective, the GSHP was an efficient heating system for the given application in terms of the coefficient of performance and exergy efficiency. No matter how it is compared with other systems, LCA results showed that the greatest impacts came from GSHP’s environmental effect: (a) borehole drilling, polyethylene pipes and copper pipelines, all of which are used during installation, and (b) the refrigerant top-up in the maintenance stage. According to the study, condensing gas boilers were the most cost-effective and ecologically friendly option for heating applications in Turkish buildings at that time

[8].

Geothermal energy-based heating systems require indispensable connection and utilization of the existing power grid. This is of main concern, since in many countries (e.g., Greece, USA) the leading resource used for electricity production is coal. That means that a geothermal system will not only have GHG emissions in its construction phase but also in its operational phase. An interesting study comparing the life cycle implications of three heating plant systems that differ in their energy source and system type has been implemented. An electric heat pump, an absorption water–water heat pump and a natural gas-fired boiler were studied in further depth using Eco-indicator ′99 as the LCA approach. The Ecoinvent 2.0 LCI database was applied to gather data on the extraction of raw materials and fuels, the fabrication of heating equipment and their transportation. Single score, damage category and effect category indicators were studied by the researchers. All calculations for characterization, normalization and weighting phases were simulated by SimaPro 7.3.2 throughout the complete system’s life cycle. In that investigation, it was obvious that heating plants employing a low temperature geothermal source had a lower eco-indicator than a gas boiler unit did; because of this, the comparison between absorption and electrical heat pumps revealed that the former had a lesser environmental effect. Accordingly, despite a high eco-indicator, it was revealed that the gas boiler was the least harmful to human health as Coefficient of Performance (COP) and power generation profiles dictated the environmental effect of the electrical heat pump. The greater the COP, the lower the power used and the emissions. Human health suffered significantly in Poland, where about 90% of the country’s power is generated from coal

[9].

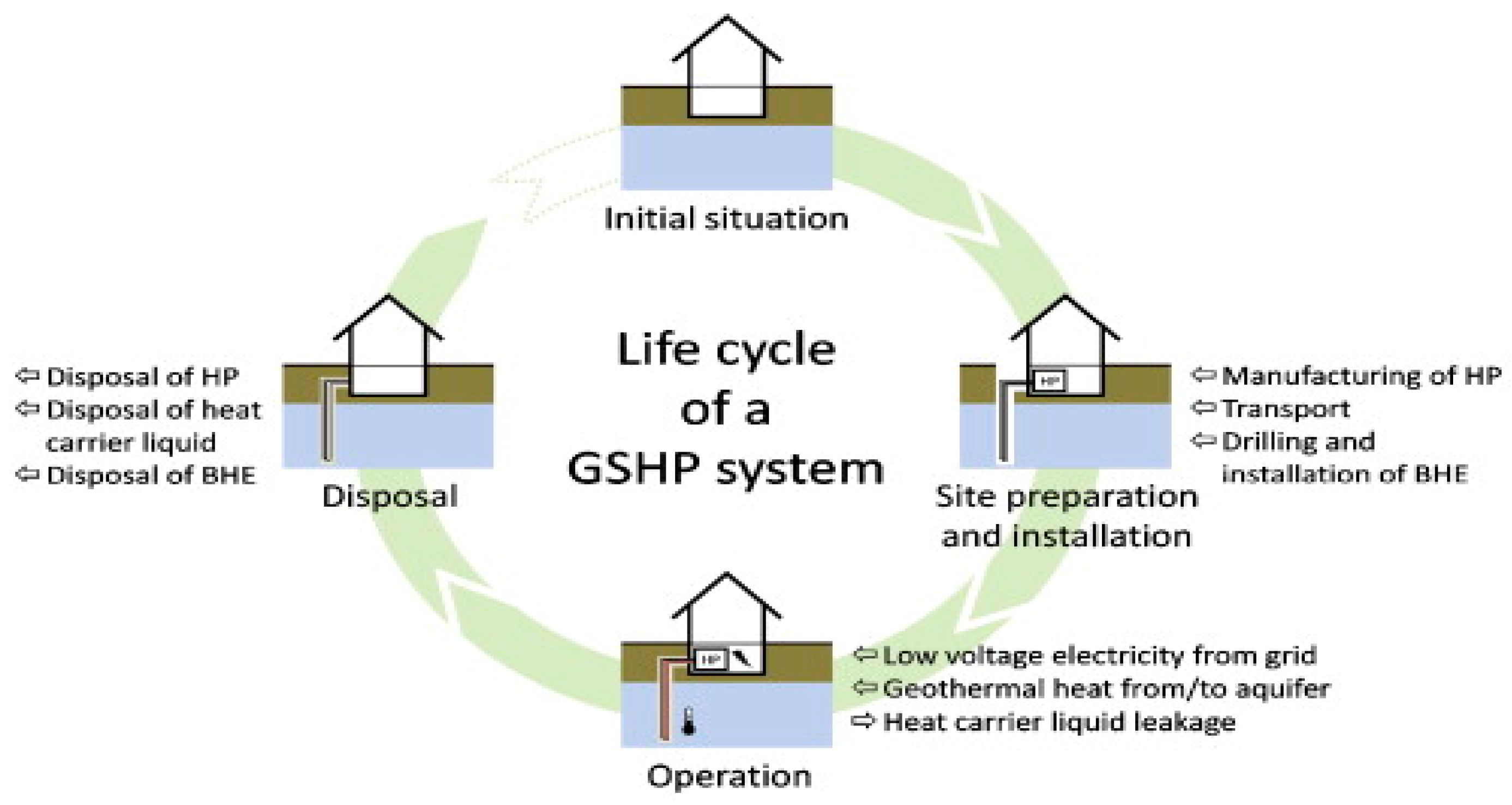

Research into shallow geothermal systems, such as open and closed Geothermal Heat Pump (GHP) systems, had resulted in an efficient and renewable energy technology for cooling and heating buildings and other structures. By utilizing a cutting-edge LCA, the researchers were able to comprehensively assess the environmental costs and advantages of using shallow geothermal systems, including net energy consumption and GHG reductions due to GHP operation.

Figure 2 shows the relative contributions of such GSHP systems to environmental degradation in terms of resource depletion (34%), human health (43%) and ecosystem quality (23%), as shown by the LCIA technique (ReCiPe 2008). Out of the overall number of environmental damages, 55.4% may be attributed to climate change. Additionally, LCIA found that the heat pump refrigerant, heat pump manufacturing, transport, heat carrier liquid and the borehole and Borehole Heat Exchanger (BHE) were all major contributors to the environmental burden of GSHP systems. When utilizing the continental European power mix of 0.599 kgCO

2eq/kWh, an average life cycle of 20 years was determined to have an average of 63 tCO

2eq. However, the CO2eq reductions for Europe range from 31% to 88 % when compared with traditional heating systems such as oil-fired boilers and gas furnaces

[10].

Figure 2. Life cycle stages of a GSHP system and the main flows of unit processes contributing to the whole life cycle

[10].

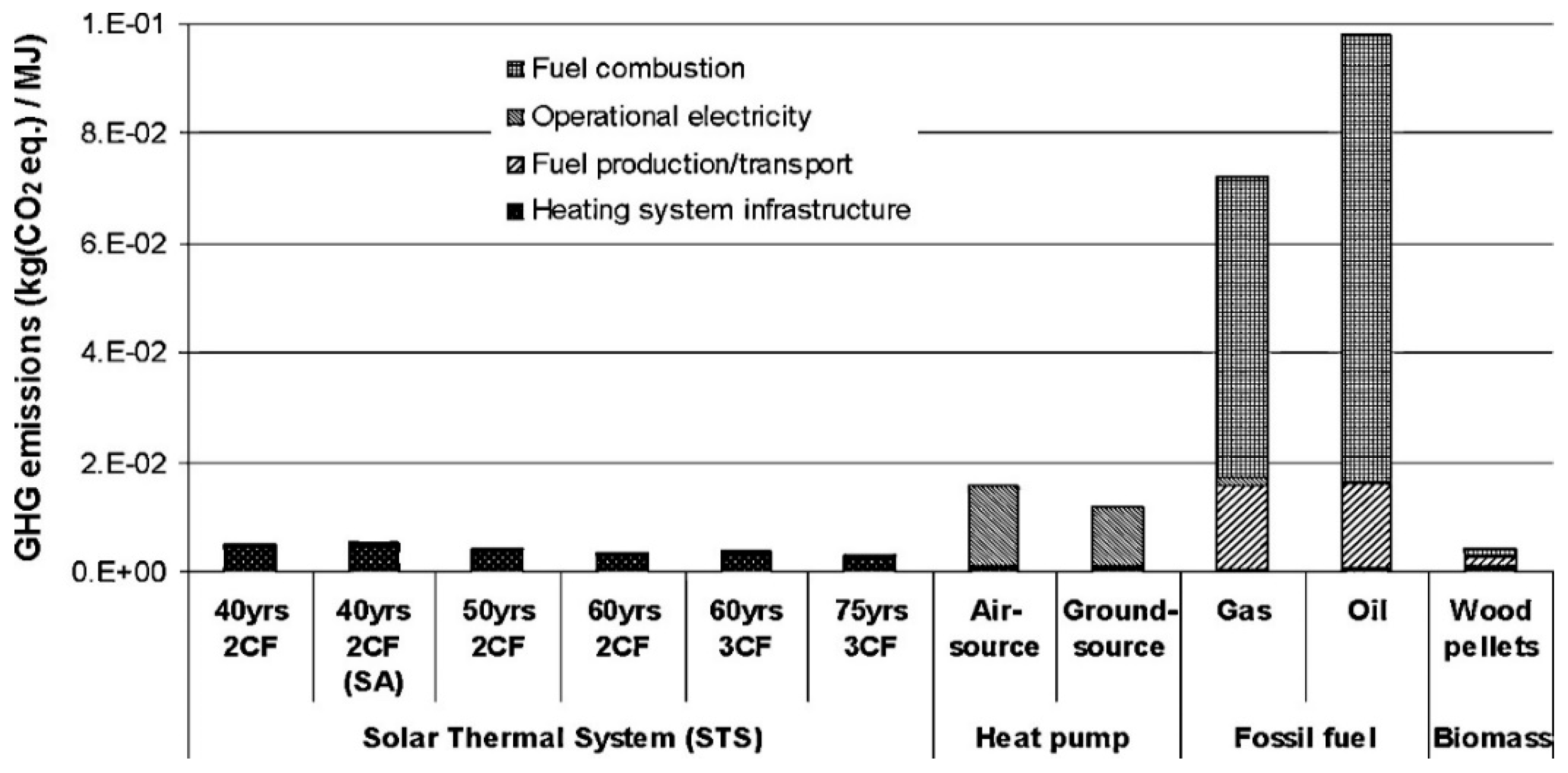

A new apartment building in Switzerland performed a comparative LCA between a solar thermal system, an Air-Source Heat Pump (ASHP), a natural gas furnace, an oil furnace and a wood-pellet stove. The solar thermal system showed potential benefits over all other systems in terms of reductions in bought primary energy (from 84% to 93%) and reductions in GHG emissions, according to a variety of life cycle scenarios (from 59% to 97%). Due to intensive industrial operations and the specific metals used in production, the solar thermal system was found to have a larger demand for resources, which in proportion to the natural gas system, may be almost 38. Although the heat pump systems had similar potential human health implications, they were more advantageous than the fossil and biomass driven systems in this regard. In

Figure 3, it is evident that most GHG emissions, related to GSHP, were from electricity required for the system operation. Additionally, the GSHP’s infrastructure impacts were lower compared with the solar systems’ and greater than those of the conventional ones. This verifies the electricity mix problem: a cleaner electricity mix means a cleaner operation phase of GSHP systems

[11].

Figure 3. Life cycle GHG emissions of each heating system

[11].

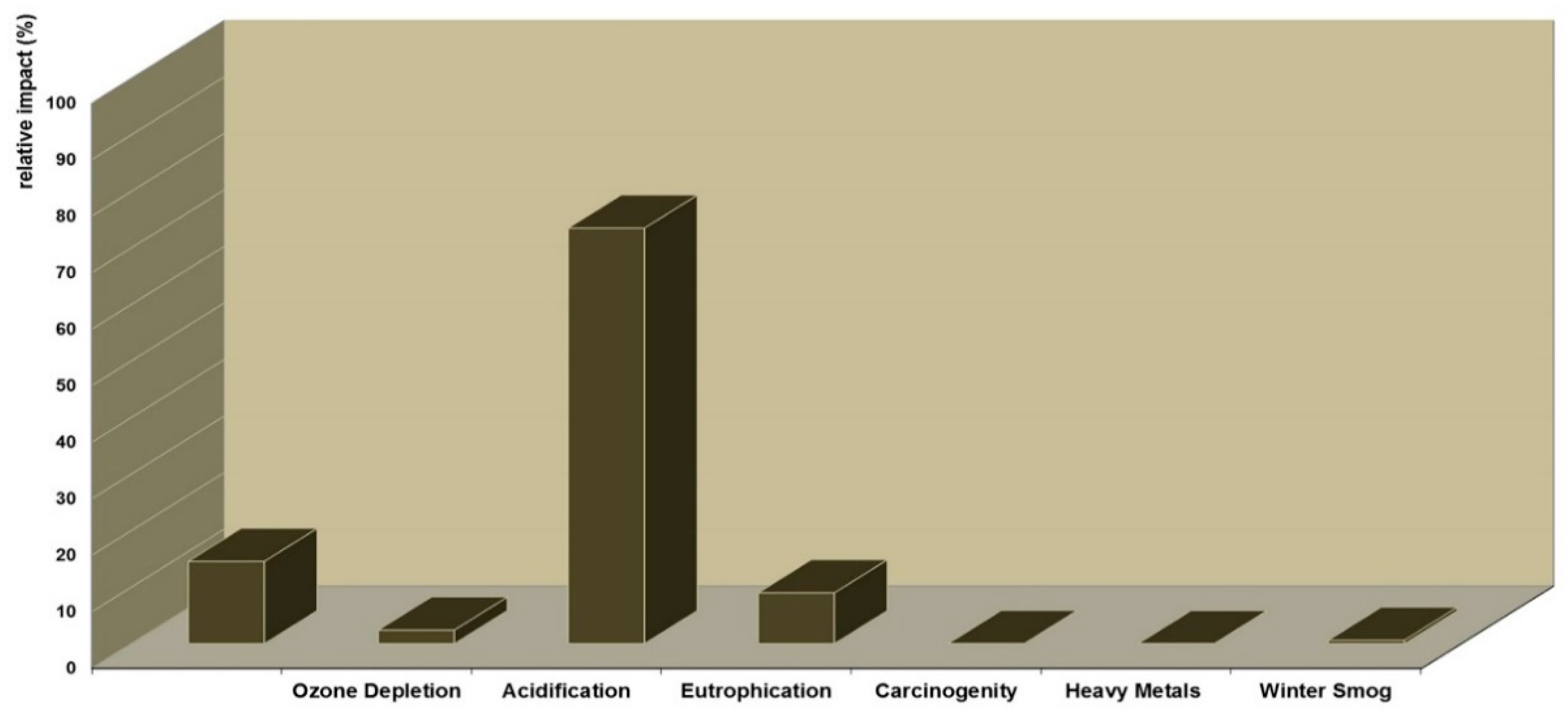

The technical and environmental performance of a GSHP using LCA was investigated for the Pylaia Town Hall in Thessaloniki, Greece. A ground heat exchanger installation was assessed for its impact on the environment using an LCA study. The researchers focused on the GSHP system throughout its life cycle, from manufacturing and transportation to installation and operation, and recorded energy consumption and air emissions. The manufacturing of raw materials including copper, plastic, steel, aluminum and rubber was part of the system’s border. Heat pumps and pipes were transported as well as the GSHP system was operated, and ultimately the assembly was completed. Moreover, the environmental impact categories considered were those of greenhouse effect, ozone depletion, acidification, eutrophication, carcinogenesis, winter smog and heavy metals. The system analysis indicated that 73% and 14.54% of the emissions were attributed to acidification and greenhouse effect, respectively, while SO2 was produced by the use of lignite (coal) in the Hellenic electric power production, resulting as the main cause for the acidification (Figure 4).

Figure 4. Environmental impact assessment of each category during GSHP’s system lifespan

[12].

In this view, the authors assumed that when increasing the renewable energy fraction in the electricity power mix of Greece, the environmental impacts of the geothermal systems would definitely improve

[12].

The mitigation of the effects of the existing power grid on the environmental efficiency of geothermal systems can be achieved by combining them with other renewable energy sources such as PV panels or solar heating systems. The European Centre for Public Law in Legraina, Greece used a hybrid solar and geothermal heating and cooling system, according to the results of research. A saline groundwater well, a water storage tank for 6 hours’ autonomy, an inverter that regulated geothermal flow, a heat exchanger, two electrical water source heat pumps set in cascade, fan coils, air handling units and solar air collectors for air preheating in winter were considered. Moreover, the building hostel’s hot water supply was achieved by solar water heaters. Solar energy’s ability to contribute to the building’s energy balance was demonstrated during winter measurements, boosting the overall proportion of renewable energy consumption

[13].

By examining small-scale multi-generation systems, CHP, Combined Cooling, Heating, and Power (CCHP) as well as traditional systems with sixteen Heating/Cooling Energy Generation Systems (H/C-EGSs), the case of technological combination was further strengthened. A comparison approach for evaluating the energy performance of buildings under the European Building Performance Directive (EBPD) was utilized. Local and global cost optimums for an office building in Helsinki, Finland were calculated for each of the H/C-EGS. A total of 144 building combinations and 2304 examples of H/C-EGSs were included in the proposed energy-saving measures. According to the findings, the GSHP with free ground cooling was the most cost-effective option available globally. Only with great overall efficiency and a low power-to-heat ratio might biomass-based CHPs be economically viable due to low investment and operational costs. There were no economic or environmental advantages to biomass-based CCHPs over biomass-based CHPs due to the considerable rise in both investment and operational expenses. Using coal-fired CHPs, which had significant operating costs, was the most inefficient and ecologically damaging option. The net zero energy office building was created by extending the cost-optimal solutions with a PV solar panel system

[14].

An alternative way for the reduction of the energy consumption of large public buildings in Beijing by comparing three different air-conditioning systems has been examined. ASHP coupled with GSHP and GSHPs with solar assistance were all considered. Using DeST modeling software, the building load was calculated and economic indicators such as initial investment, LCC, operating cost, payback period, energy saving rate and cooling and heating costs per hour were evaluated. Results implied that a solar-assisted GSHP coupled with an air-source heat pump system had better economic results than the other two, especially the air-source heat pump system and, although the initial investment was higher, it had a payback period of less than 3 years compared with the air-source heat pump system

[15].

On the other hand, Bartolini et al.,

[16] presented a techno-economic and environmental analysis of four different weight concentration fluids: propylene glycol at 25% and 33%, calcium chloride at 20% and pure water. The outcomes revealed that the use of pure water as a heat carrier fluid was appropriate for cooling buildings (i.e., in Seville, Lisbon and well-insulated buildings in Bologna), but, for heating-dominated buildings, this choice led to a remarkable increase in the length of needed BHE. However, OpenLCA software calculated the carbon footprint of the BHE during the installation phase, showing an amount 25.61 kgCO

2eq/m of BHE. Regarding the carbon footprint of other fluids: 4.67 and 1.02 kgCO

2eq/kg emitted for the propylene glycol and the calcium chloride, respectively, while the water’s carbon footprint was negligible.

In the spirit of economic and environmental efficiency, Huang and Mauerhofer stated that, apart from the energy saving measures adopted by governments worldwide due to the greenhouse effect, environmental and social impacts should also be considered, ensuring that these measures can also meet sustainable development requirements. An advanced sustainability evaluation method is based on the life cycle theory designed in that study. Case studies were used to evaluate this concept, since GSHP is a renewable technology widely used in China’s building sector. The energy usage of the GSHP cases studied was found to be 40.2% lower than that of a conventional air conditioning system. Global warming, acidification and eutrophication in the manufacturing process and soil temperature change in the operation phase were shown to be the primary environmental consequences of GSHP

[17]. Aiming at the public buildings sector, the environmental impacts of a GHP application in a university building were studied. A process-based hybrid LCI modeling technique was utilized to provide a full system boundary for footprint accounting, offering unique insights into the design and functioning of the researched technology

[18].

However, Heating, Ventilation and Air Conditioning (HVAC) systems were examined in the Winnebago Reservation in northeastern Nebraska as part of an LCC investigation. Rooftop gas heat and direct expansion (DX) cooling units (air-cooled condensers) were one option, as were air-source heat pumps and geothermal heat pumps (GHPs). Building energy modeling software was implemented to evaluate the heating and cooling demands. An estimated 264,000 Btu/h of cooling capacity and 178,000 Btu/h of heating capacity were calculated. Heat demand for the building was 246 kBtu and cooling demand for the building was 479 kBtu, both all year long. The NPV of 30 years of an LCC was calculated for each option in order to compare them. There were no significant differences in LCCs between the GHP and the traditional systems in terms of their NPV, which was determined to be around 18% lower. Installing the GHP system was a little more expensive, but the running and maintenance expenses were far cheaper than with traditional systems. GHG emissions may be reduced by 15 tCO

2eq and 33 tCO

2eq per year by using a GHP system instead of a rooftop gas heat unit or an air-source heat pump, according to their GHG study

[19].

GHPS economic viability was further affected by the Seasonal Coefficient of Performance (SCOP), as described by Junghans. Air-to-air GHPSs were studied on their economic and environmental viability, and the author established the importance of the envelope’s insulation level in determining whether heat pump systems were economically and environmentally viable. A geothermal water-to-air heat pump and an exterior air-to-air heat pump were evaluated for their economic and environmental viability in the context of their local climate and building insulation. Increased insulation levels were shown to have a significant impact on the SCOP, which in turn affects the heat pump system’s economic and environmental viability. SCOP values for heat pump systems were shown to be climatic and building insulation dependent

[20].