Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Peter Dekker | -- | 2897 | 2022-08-10 12:29:00 | | | |

| 2 | Peter Tang | -75 word(s) | 2822 | 2022-08-12 03:18:01 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Dekker, P.J.T.; Koenders, D.; Bruins, M.J. Market, Production and Nutritional Benefits of Lactose-Free Dairy. Encyclopedia. Available online: https://encyclopedia.pub/entry/26087 (accessed on 08 February 2026).

Dekker PJT, Koenders D, Bruins MJ. Market, Production and Nutritional Benefits of Lactose-Free Dairy. Encyclopedia. Available at: https://encyclopedia.pub/entry/26087. Accessed February 08, 2026.

Dekker, Peter J. T., Damiet Koenders, Maaike J. Bruins. "Market, Production and Nutritional Benefits of Lactose-Free Dairy" Encyclopedia, https://encyclopedia.pub/entry/26087 (accessed February 08, 2026).

Dekker, P.J.T., Koenders, D., & Bruins, M.J. (2022, August 11). Market, Production and Nutritional Benefits of Lactose-Free Dairy. In Encyclopedia. https://encyclopedia.pub/entry/26087

Dekker, Peter J. T., et al. "Market, Production and Nutritional Benefits of Lactose-Free Dairy." Encyclopedia. Web. 11 August, 2022.

Copy Citation

The lactose-free dairy market is the fastest growing segment in the dairy industry. Many different LF-dairy products made with the aid of lactase enzymes are currently available and provide textural, sensorial, nutritional and health benefits to those that are unable to digest lactose.

lactose-free

lactose intolerance

lactase

dairy products

1. Introduction

The percentage of people with an impaired ability to digest lactose varies widely per country and per continent, from 98–100% of adults in Southeast Asia to just 1% in the Netherlands [1]. However, lactose-free dairy has currently a wide and growing health appeal to all consumers, also in countries where most people are lactose tolerant. Lactose-free dairy products can provide essential nutrients present in milk to people that are lactose intolerant. There are a number of dairy products that contain very little or no lactose, and these are generally well-tolerated by people that are intolerant to lactose; e.g. in ripened cheeses and butter lactose content is <0.1%. However, many fresh dairy products do contain an appreciable amount of lactose [2]. Besides milk and milk drinks, these include fermented milk products like yoghurt, sour cream, crème fraiche, kefir etc.; fresh and 5young cheeses; ice cream; and other dairy desserts like dulce de leche, (whipped) dairy cream and sweetened condensed milk. Also, products made from whey (e.g., whey protein concentrates (WPC), whey protein isolates (WPI) and whey permeate) or milk powders will contain lactose. Outside the direct dairy space, many food products are, therefore, also not lactose free, like chocolate, coffee drinks and many baked products.

For lactose intolerant people, it is nowadays not necessary to completely avoid the indulgence and nutritional value of dairy products [3]. There are very good solutions that rely on the hydrolysis of lactose into glucose and galactose with the enzyme lactase. These monosaccharides are readily adsorbed in the small intestine and prevent the occurrence of lactose intolerance symptoms. Two different type of lactases are currently commercially available: neutral lactases and acid lactases [4]. Neutral lactases are mainly used in the production of lactose-free dairy products on an industrial scale, although in some countries, this enzyme is also offered to consumers for treating milk at home. Acid lactase is available to consumers as a nutritional supplement to be taken together with regular dairy products and works by splitting lactose in the stomach.

2. Market Developments of Lactose-Free Dairy

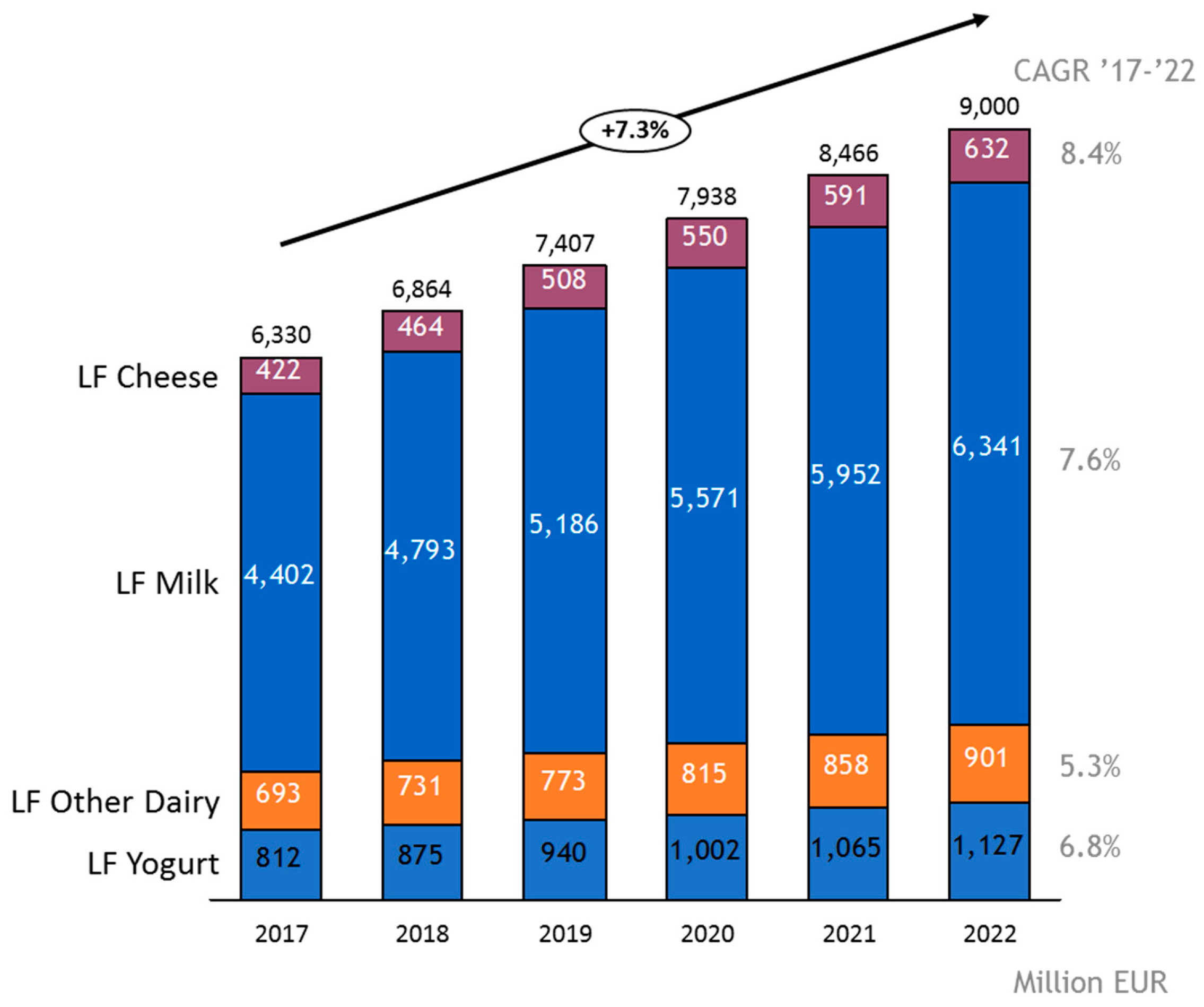

The lactose-free dairy market is the fastest growing segment in the dairy industry. Lactose-free dairy is expected to reach a €9 billion turnover by 2022 and continues to outgrow overall dairy (7.3% vs. 2.3%) (data extracted from a Euromonitor analysis [5]). Potable milk is the largest category of lactose-free dairy, represents two-thirds of the market and drives the absolute growth of the category (Figure 1). The second category is lactose-free yogurt, which will reach a €1 billion turnover by 2020. Lactose-free cheese is expected to grow fastest (8.4%) over the forecast period. Western Europe is the biggest and fastest growing lactose-free market, followed by Latin America.

Figure 1. A compounded annual growth rate (CAGR) estimate of the lactose-free dairy market segment over the period 2017–2022. The total yearly turnover in M€ is indicated. LF: lactose-free. The figure was created from data of the Euromonitor analysis [5].

3. Production of Lactose-Free Dairy

3.1. Milk

Potable cow’s milk for dairy intolerant people is available in many countries in different forms. Although most people with lactose intolerance have few symptoms with a lactose dosage of <12 gram per meal [3], the general trend in this industry is to reduce the lactose content as low as possible. There is no global consensus on the regulatory requirements for lactose-free claims. While in the past most dairy producers regarded lactose reduction to 0.5% or 0.1% as sufficient, the current requirement in some countries is even a reduction to <0.01% before the milk can be called lactose-free. A half-liter of lactose-free milk will, therefore, have less than 50 mg of lactose, much less than would be symptomatic for most people with lactose intolerance. Obtaining such low amounts of lactose in milk production requires special attention not only to the processing of the milk and to the dosage and effectiveness of the enzyme used in this process but also to sensitive analytical methods to determine such low amounts of lactose [6].

In general, the majority of potable milk in Northern European countries, North America and Australia is pasteurized and stored under cooled conditions for a couple of weeks. In Southern European countries, South America and Asia most milk is UHT sterilized and stored at ambient temperatures up to 9 months. Curiously, besides the consumer preference for the flavor of either pasteurized or UHT sterilized milk, the preference for sweetness in milk roughly divides between these lines: the extra sweetness generated in milk by lactose hydrolysis is especially appreciated in Latin and Asian countries but disliked in traditional milk-drinking areas like Northern Europe and North America.

Currently, two processes (batch and aseptic) are in use to produce lactose-free milk [7][8], and both these processes use soluble neutral lactase enzyme. In the batch process, a neutral lactase sample is added to a cooled tank of raw or thermized milk and, commonly, incubated for approx. 24 h under slow stirring to prevent creaming. After this incubation, the milk is pasteurized, homogenized and packaged. In the aseptic process, the milk is first sterilized using the UHT procedure, after which a sterile lactase preparation is injected into the milk just before packaging [9]. The lactose conversion will take place in the milk package.

Processes relying on an immobilized enzyme have been suggested in the scientific literature a long time ago and even trialed on a pilot scale [10]. However, the immobilization of lactase has not been used in industrial practice for lactose-free milk production until today due to problems with the microbial stability of the final product. The recycling of the immobilized enzyme in an industrial setting is therefore limited, making the procedure less cost-effective and more prone to quality defects than hydrolysis with a soluble enzyme.

3.2. Fermented Milk Products

The presence of a substantial amount of lactose in most fermented milk products, like 30–40 gram/kg in yoghurt [2], would suggest that lactose-intolerant people will have a problem with these dairy products. However, this seems to be much less the case than expected from the amount of lactose that is consumed. There have been two different theories put forward to explain this phenomenon [11][12].

-

It has been suggested that the lactic acid bacteria present in yoghurt will survive the stomach, and the lactase enzyme present in these bacteria aids the digestion of (or part of) the lactose in the small intestine. This hypothesis will only hold if the yoghurt bacteria and their intracellular lactase enzyme will survive the stomach. Indeed, the pasteurization of yoghurt seems to worsen lactose intolerance symptoms.

-

A second explanation that was put forward suggests that the lactose in yoghurt is better digested due to the decreased transit time of a viscous yoghurt meal compared to liquid milk. Due to this, any residual lactase in the small intestine will have more time to digest lactose and, thereby, reduces intolerance symptoms. It has indeed been found that having a meal together with a glass of milk will reduce symptoms, suggesting that transit time may play a role in lactose digestion.

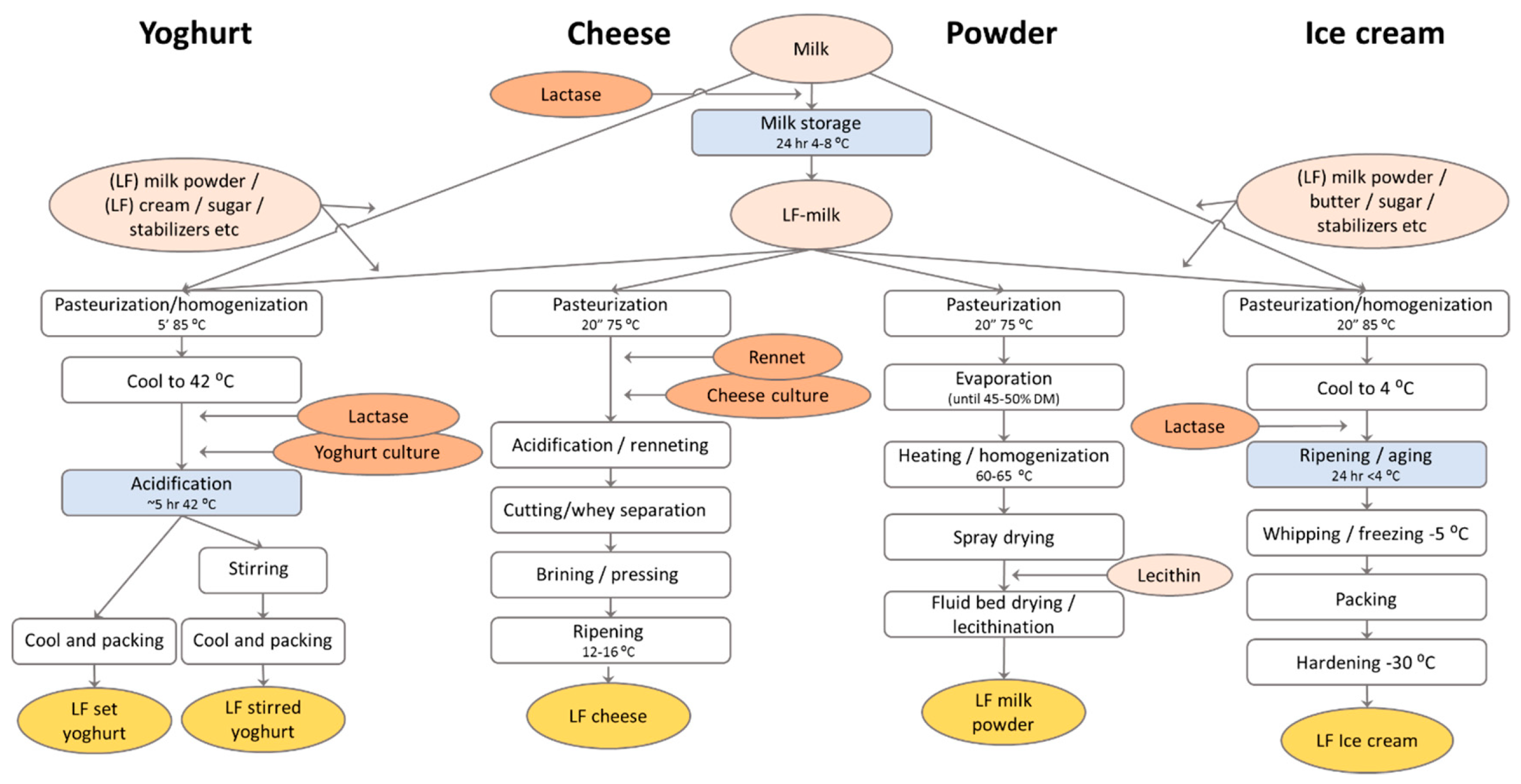

Regardless of which of these effects play the major role in tolerating fermented milk products by lactose intolerant people, the most reliable remedy seems to be the complete enzymatic digestion of lactose in yoghurt. This can be done by incubating the milk with lactase before pasteurization (familiar to the batch process for milk) or adding the lactase together with the culture after the pasteurization of the milk (Figure 2). Most yoghurt producers opt for the latter, co-hydrolysis, approach since predigestion seems to inhibit the activity of some yoghurt cultures [13], probably due to the switch from lactose to glucose as a main carbon source or to the increased osmotic pressure in lactose-hydrolyzed milk.

A major advantage of using lactases in the production of yoghurt is the increase in sweetness due to the splitting of lactose [14]. Hence, the total added sugar can be reduced by 1.5–2 g/100 g without changing the flavor profile. The enzyme addition can be reduced for this application since the final product does not have to be lactose-free, but a slightly higher residual lactose is allowed without noticeable difference in sweetness. Another advantage of the digestion of lactose in yoghurt is that the post-acidification during shelflife can be reduced when specific yoghurt cultures are used. Apparently, some yoghurt bacteria are less active in the absence of lactose or have difficulties in switching from one carbon source (lactose) to another (glucose), leading to a better sensory stability of the product.

Figure 2. A flow scheme for the production of different lactose-free (LF) dairy products: The process conditions may vary from one factory to another, and additional process steps and additions are commonly included. All products can be made from LF-dairy ingredients, but yoghurt and ice cream may also be treated with lactase in the process. The process steps where lactose hydrolysis can take place are indicated in blue.

3.3. Other Dairy Products

Many other dairy products are made lactose-free using an enzymatic treatment. Every application has its own pitfalls when lactose is converted into monosaccharides, so it is important to realize that, often, the process or the recipe has to be adapted to obtain the optimal result.

- Flavored milk is made with a process that is familiar to the batch LF-milk process (Figure 2). However, the generation of the extra sweetness by the lactase treatment is an advantage since it will allow a reduction of sugar addition, similar to the situation in most yoghurts [14]. Flavored lactose-free milk also has much less problems with Maillard-related off-flavors and browning than regular lactose-free UHT milk, since the product often has a strong flavor and color by itself.

- Dairy powders can be produced from milk or whey that is made lactose-free via the batch process (Figure 2). A major problem is the presence of a high concentration of monosaccharides in the treated milk, leading to a drop in the glass-transition temperature. Hence, this product will lead to the fouling of the spray dryer when the drying conditions are not adapted [15]. The much milder spray drying conditions lead to dramatic decreases in the productivity of the drying process and to increased costs. Additionally, the lactose-free milk (or whey) powder is highly hygroscopic, leading to caking during storage when not packaged with extra caution. Due to these challenging technical problems, lactose-free dairy powders is still a small market in contrast to regular milk powders.

- Cheese can be made lactose-free by incubating the cheese milk with lactase before renneting (Figure 2). This is mostly useful for young, fresh cheeses that are known to contain a significant amount of lactose, and lactases are currently used for this purpose. In ripened cheeses, all lactose will have been consumed by the lactic acid bacteria, so no lactase incubation is required. In contrast to the situation in yoghurt, the treatment of cheese milk with lactase is in the older literature often mentioned to stimulate the acidification during cheese making. Also, the lactase addition is mentioned to increase cheese flavor formation during ripening. However, it is not entirely clear if these effects are due to the stimulation of the cheese microbial flora due to the hydrolysis of the lactose or to residual proteolytic activity present in the lactase preparations that were commercially available in the past. The release of amino acids from milk proteins may have stimulated the cheese culture activity in these experiments. The latter explanation seems to be the most likely (see, for example, the discussion on this subject in Reference [16]).

- Ice cream can also be made lactose-free by either using lactose-free milk and powders in the ice cream mix [17] or by adding the lactase enzyme after pasteurization and incubation during the aging period before freezing (Figure 2). Because of the increase in monosaccharide content after lactose hydrolysis, the freezing point of the ice cream mix will decrease. This will lead to a softer ice cream at the same temperature. Although for some frozen desserts this may be an advantage because of the “soft scoop”, it will also lead to faster melting. Since the sweetness increases due to lactose hydrolysis, the ice cream maker can, however, decide to decrease sugar addition and, thereby, increase the melting temperature again. Since such changes in the recipe will decrease total solids in the mix, additional measures may be required to comply to the local regulation for ice cream. Lactase treatment is also used in ice cream to prevent lactose crystallization. Especially when whey powder or WPC is used in the ice cream mix, the amount of lactose may be high enough to form crystals during freezing. This leads to a sensory defect that is called “sandiness”. Lactase treatment can prevent the formation of sandiness in ice cream by splitting lactose into glucose and galactose, which are more soluble at low temperature. It was found that lactose hydrolysis increases the apparent viscosity of the ice cream mix, decreases the freezing point, increases the sweetness to allow a 25% reduction in sugar addition, decreases sandiness, and improves the overall acceptability of ice cream [17].

- Dulce de Leche is produced by heating sugared concentrated milk until caramelization occurs due to Maillard reactions. Lactase treatment of the milk will not only make the final product lactose-free but also stimulates the Maillard reaction due to the release of galactose. Hence, treatment with lactase may enhance the flavor and color formation in the production process for Dulce de Leche. Additionally, like in ice cream, lactose hydrolysis prevents the occurrence of sandiness when the final product is stored refrigerated.

- For many dairies, the cheese whey is a valuable by-product that is fractionated into proteins, lactose and milk salts and sold as WPC, WPI and different grades of lactose. However, not all dairies have the capabilities or facilities to produce these products. The sweet dairy flavor of liquid whey or whey permeate may also be upgraded by digesting the lactose with a neutral lactase, either in free form, immobilized or as cell suspension, before concentrating it into a syrup or powder [18]. Such lactose-free products may be used as sweetener in, for example, ice cream, confectionary or bakery applications. An additional advantage of hydrolyzing the lactose in whey or whey permeates is that a microbially stable syrup may be formed without crystallization problems, thereby saving on drying costs. Depending on the pH of the substrate, either neutral or acid lactase may be used for the conversion [18].

Besides these examples of lactose-free dairy products where lactase-treatment may have additional advantages, many other lactose-free dairy products like desserts, creams, etc. are nowadays being produced and aid to expand the lactose-free product portfolio.

4. Health Aspects of Lactose-Free Dairy

4.1. Nutritional Difference between Lactose-Free Dairy and Normal Dairy

Lactose-free dairy may confer benefits to lactose intolerant people, allowing them to enjoy the taste of dairy without the uncomfortable intestinal symptoms from the ingestion of lactose. In addition, lactose-free dairy also has a growing health appeal to lactose tolerant people. In lactose-free dairy, the lactose is predigested into glucose and galactose. Consequently, the lactose content may be very low (<0.1 g/L), but the glucose and galactose content of lactose-free milk will be approx. 25 g/L. As mentioned above, the glucose and galactose in lactose-free dairy are sweeter than lactose, enabling a reduction of the added sugar in dairy products by up to 10–15 g/kg, thereby reducing calorie addition [14]. Besides the advantages of reduced lactose intake for lactose intolerant people, lactose-free dairy is not likely to have different nutritional effects on the human body as compared to normal dairy. When predigested lactose is consumed, the glucose and galactose will also be absorbed in the small intestine like will be the case for the digestion products glucose and galactose when intact lactose is consumed by lactose tolerant dairy consumers. No difference in gastric emptying was found in rats when comparing lactose versus glucose and galactose consumption [19]. A study in calves found no difference in the glycemic responses between milk and lactose-free milk [20]. The absence of differences in glycemic response between milk and lactose-free milk was confirmed by a study on healthy subjects (internal unpublished data). Also, no difference was observed in the glycemic response of diabetes patients when consuming lactose compared to the lactose digestion products glucose and galactose [21].

4.2. Potential Health and Economic Impact of Lactose-Free Dairy vs. Dairy Avoidance

The National Institute of Health (NIH) concluded that the vast majority of lactose mal-absorbers will tolerate up to 12 g of lactose per serving and that smaller amounts of lactose will generally not cause major problems [3]. Still, most subjects with self-diagnosed or physician-diagnosed lactose intolerance will try to avoid all lactose-containing products. However, in its Updated Consensus Statement, the National Medical Association reports that lactose free dairy products are the most ideal substitute for regular dairy products among individuals with lactose intolerance. In addition, evidence indicates that children prefer lactose-free cow’s milk over soy beverages [22].

References

- Silanikove, N.; Leitner, G.; Merin, U. The Interrelationships between Lactose Intolerance and the Modern Dairy Industry: Global Perspectives in Evolutional and Historical Backgrounds. Nutrients 2015, 7, 7312–7331.

- The Really BIG List of Lactose Percentages. Available online: http://www.stevecarper.com/li/list_of_lactose_percentages.htm (accessed on 3 January 2019).

- Suchy, F.J.; Brannon, P.M.; Carpenter, T.O.; Fernandez, J.R.; Gilsanz, V.; Gould, J.B.; Hall, K.; Hui, S.L.; Lupton, J.; Mennella, J.; et al. National Institutes of Health Consensus Development Conference: Lactose intolerance and health. Ann. Intern. Med. 2010, 152, 792–796.

- Dekker, P.J.T. Enzymes Exogenous to Milk in Dairy Technology: β-D-Galactosidase. In Reference Module in Food Sciences, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–8.

- Euromonitor Database. Available online: https://www.euromonitor.com/ (accessed on 1 March 2018).

- Van Scheppingen, W.B.; van Hilten, P.H.; Vijverberg, M.P.; Duchateau, A.L.L. Selective and sensitive determination of lactose in low-lactose dairy products with HPAEC-PAD. J. Chromatogr. B. 2017, 1060, 395–399.

- Harju, M. Chromatographic and enzymatic removal of lactose from milk. Bull. Int. Dairy Fed. 2004, 389, 4–8.

- Troise, A.D.; Bandini, E.; De Donno, R.; Meijer, G.; Trezzi, M.; Fogliano, V. The quality of low lactose milk is affected by the side proteolytic activity of the lactase used in the production process. Food Res. Int. 2016, 89, 514–525.

- Dahlqvist, A.; Asp, N.-G.; Burvall, A.; Rausing, H.; Hydrolysis of lactose in milk and whey with minute amounts of lactase. J. Dairy Res. 1977, 44, 541-548.

- Finocchiaro, T.; Olson, N.F.; Richardson, T. Use of immobilized lactase in milk systems. Adv. Biochem. Eng. 1980, 15, 71–88.

- Kies, A.K. Authorised EU health claims related to the management of lactose intolerance: Reduced lactose content, dietary lactase supplements and live yoghurt cultures. In Foods, Nutrients and Food Ingredients with Authorised EU Health Claims; Sadler, M.J., Ed.; Woodhead Publishing: Cambridge, UK, 2014; Chapter 9; pp. 177–211.

- Savaiano, D.A. Lactose digestion from yogurt: Mechanism and relevance. Am. J. Clin. Nutr. 2014, 99, 1251S–1255S.

- Kárnyáczki, Z.; Csanádi, J. Texture profile properties, sensory evaluation, and susceptibility to syneresis of yoghurt prepared from lactose-free milk. Acta Aliment. 2017, 46, 403–410.

- McCain, H.R.; Kaliappan, S.; Drake, M.A. Sugar reduction in dairy products. J. Dairy Sci. 2018, 101, 8619–8640.

- Ferreira Torres, J.K.; Stephani, R.; Miranda-Tavares, G.; de Carvalho, A.F.; Golin Bueno Costa, R.; Rocha de Almeida, C.E.; Ramos Almeida, M.; Cappa de Oliveira, L.F.; Schuck, P.; Tuler Perrone, I. Technological aspects of lactose-hydrolyzed milk powder. Food Res. Int. 2017, 101, 45–53.

- Marschke, R.J.; Nickerson, D.E.J.; Jarrett, W.D.; Dulley, J.R. A cause of increased proteolysis in cheddar cheese manufactured from milk containing added Maxilact. Aust. J. Dairy Technol. 1980, 35, 84–88.

- Abbasi, S.; Saeedabadian, A. Influences of lactose hydrolysis of milk and sugar reduction on some physical properties of ice cream. J. Food Sci. 2015, 52, 367–374.

- Panesar, P.S.; Kennedy, J.F. Biotechnological approaches for the value addition of whey. Crit. Rev. Biotechnol. 2012, 32, 327–348.

- da-Costa-Pinto, E.A.; Collares, E.F. Chronic lactose intake modifies the gastric emptying of monosaccharides but not of disaccharides in weanling rats. Braz. J. Med. Biol. Res. 1997, 30, 723–726.

- Gutzwiller, A. Glucose and galactose absorption after ingestion of milk containing hydrolysed lactose in calves with diarrhoea. J. Vet. Med. A Physiol. Pathol. Clin. Med. 2000, 47, 495–500.

- Ercan, N.; Nuttall, F.Q.; Gannon, M.C.; Redmon, J.B.; Sheridan, K.J. Effects of glucose, galactose, and lactose ingestion on the plasma glucose and insulin response in persons with non-insulin-dependent diabetes mellitus. Metabolism 1993, 42, 1560–1567.

- Bailey, R.K.; Fileti, C.P.; Keith, J.; Tropez-Sims, S.; Price, W.; Allison-Ottey, S.D. Lactose intolerance and health disparities among African Americans and Hispanic Americans: An updated consensus statement. J. Natl. Med. Assoc. 2013, 105, 112–127.

More

Information

Subjects:

Food Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.5K

Revisions:

2 times

(View History)

Update Date:

12 Aug 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No