You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Zhang Jinkai | -- | 1247 | 2022-07-29 05:31:00 | | | |

| 2 | Camila Xu | Meta information modification | 1247 | 2022-07-29 07:12:09 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Ma, J.; Zhang, J. Multi-Mode Process. Encyclopedia. Available online: https://encyclopedia.pub/entry/25643 (accessed on 24 December 2025).

Ma J, Zhang J. Multi-Mode Process. Encyclopedia. Available at: https://encyclopedia.pub/entry/25643. Accessed December 24, 2025.

Ma, Jie, Jinkai Zhang. "Multi-Mode Process" Encyclopedia, https://encyclopedia.pub/entry/25643 (accessed December 24, 2025).

Ma, J., & Zhang, J. (2022, July 29). Multi-Mode Process. In Encyclopedia. https://encyclopedia.pub/entry/25643

Ma, Jie and Jinkai Zhang. "Multi-Mode Process." Encyclopedia. Web. 29 July, 2022.

Copy Citation

Multi-mode processing is a central feature of modern industry. The application of monitoring technology to multi-mode processing is crucial to ensure process safety and to enhance product quality.

multi-mode process

steady-state

transitional process

1. Introduction

Multi-mode processing is common in modern complex engineering systems and has become a leading production method in industry [1]. In recent years, with the development of automation, it has become possible to collect data continuously from complex non-stationary industrial processes. This data-driven monitoring method can greatly improve the efficiency and applicability of industrial systems through the analysis of data characteristics. Process monitoring refers to monitoring of data that represent the state of the system. Core issues include the prediction of trends in data changes, multi-scale data processing, the elimination of sensor noise, addressing process data uncertainty and the need to establish models that reflect the process of change. The primary goals are to develop systems that can identify important information relating to the state of the production process and to eliminate irrelevant content. Compressing data helps in reducing storage space and in the prediction of changing trends in the data that is processed. According to the operational mode and its scale, modern industrial processes can generally be divided into continuous processes and batch processes [2]. Air conditioning and unmanned helicopters represent examples of continuous processes. An air conditioning system is divided into different mode areas according to the seasons and continuously adjusts to changes in outdoor meteorological parameters [3]. Unmanned helicopters have the capacity for a range of flight modes, including vertical take-off and landing, aerial hovering, coordinated turning, and forward and backward flight and are able to continuously adjust position and posture [4]. Glutamate and penicillin fermentation and injection-molding processes represent examples of batch processes. The glutamate fermentation process is divided into the growth period, formation period and decline period [5]. The fermentation of penicillin includes a rapid bacterial growth stage, a penicillin synthesis stage and a bacterial autolysis stage [6][7]. Injection-molding processes can be divided into three stages: injection, pressure retention and cooling. Traditional monitoring methods used in single-mode processing inevitably lead to inaccurate process performance analysis and false or missed alarms of faults. Effective multi-mode process monitoring, on the other hand, can greatly improve the safety and stability of the equipment production process and reduce production costs. Therefore, research on multi-mode process monitoring is potentially of great theoretical significance and engineering application value [8].

2. Definition, Data Characteristics and Causes of Multi-Mode Processes

2.1. Definition, Data Characteristics of the Multi-Mode Process

-

Multi-mode: multiple operation states and stages in industrial production processes are referred to as multi-mode. Modes and physical phases do not necessarily closely correspond to each other.

-

Multi-mode process: a process with multiple stable mode states in the same production process affected by changes in the external environment and other conditions, or by changes in the production scheme or inherent characteristics of the process itself, is referred to as a multi-mode process. Depending on the different production modes adopted, multi-mode processes can be divided into multi-mode continuous processes and batch processes. A multi-mode system will continuously switch between the following modes: steady-state mode 1—transition mode—steady-state mode 2. The data characteristics corresponding to each mode will be different, such as shifts in the mean value of variables and changes in the covariance structure.

-

Continuous process: a continuous process is a mode that works stably according to the state. Its characteristic variables change slowly.

-

Batch process: batch processes involve a cyclic mode of work. There are multiple steady-state modes in batch processes and their time characteristics change with progress of the process; there are also short-term transition modes in adjacent batch processes.

-

Steady-state mode: a steady-state mode is a mode in which the operating state of the system is relatively stable during production. The variables characterizing the steady-state mode, such as the mean, variance, and correlation, do not change with operation time. In the production process, a system will usually operate in a steady-state mode, which is the crucial mode that determines product quality.

-

Transition mode: when a production process goes from one steady-state mode to another, it cannot do so suddenly. A gradual and dynamic transition mode is required to connect two steady-state modes. In the transition mode, the process variables and operation modes can change greatly over a short period, and the running track is generally different each time. The characteristic variables of the transition mode show strong time-varying, dynamic and non-linear characteristics and have a considerable impact on the production process.

2.2. Causes of the Multi-Mode Process

-

Changes in raw material properties, the occurrence of chemical reactions, changes in the external environment, and changes in the operational task and production scheme, can cause the normal mode area of the process to drift over time, such as in chemical distillation processes and other multi-mode processes.

-

Changes in the process parameters or loads, equipment reorganization, and equipment aging, can lead to changes in the relationships between process variables, thus showing obvious multi-mode characteristics. For example, reciprocating mechanical steam turbines show variable working modes during startup, shutdown and load changes. During the operation of mills, steel balls are constantly worn, resulting in slow changes in modes [9]. With different loads, an engine can respond using several speeds, or different gears to influence power, resulting in multi-mode processes.

-

The inherent characteristics of a production process mean that it will include multiple operation periods. For example, the injection-molding of plastic products is divided into five operational stages for an injection batch: mold closing, injection, pressure maintenance, cooling and mold opening. It represents a typical batch process [10].

-

In the start-up and shutdown stages of a process, operation modes, such as mode adjustment and mode switching, inevitably involve a transition mode. The transition mode usually lasts for a short time with less easy access to process data. Therefore, a transition mode will not only require the intervention of many operators but often also results in the production of unassessed products, which can greatly impact both safety of production and product quality [11].

3. Multi-Mode Process Monitoring Methods

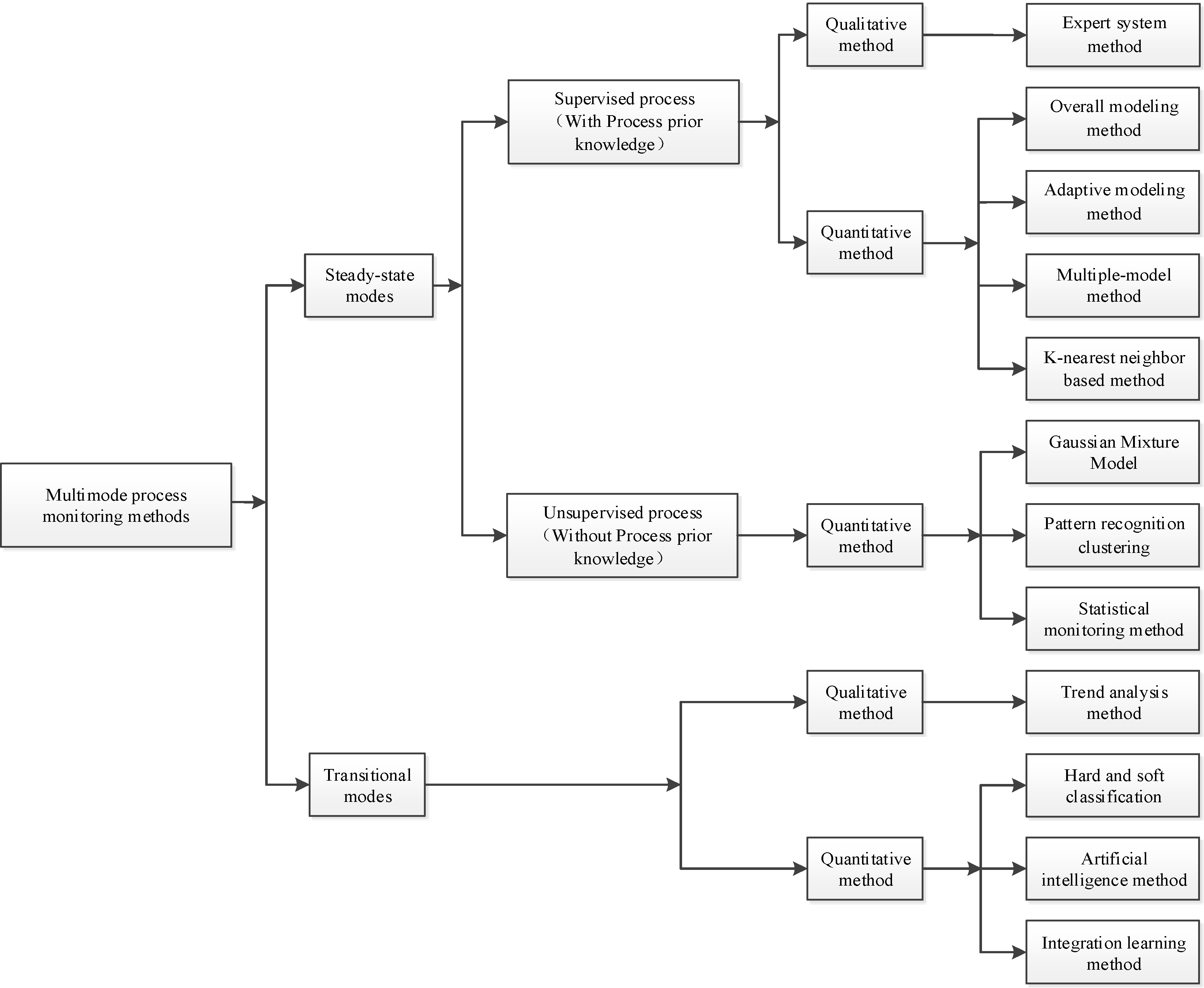

The identification and classification of multi-mode processes are based on information changes occurring in the production process relating to different modes in the process. Classification is a necessary step for multi-mode process monitoring, evaluation, modeling, quality prediction and process optimization [12]. Whether in continuous or batch processes, a multi-mode process will include both steady-state and transition modes [13]. A complete and comprehensive classification framework for multi-mode process monitoring methods requires to include both steady-state mode and transition mode process monitoring methods. A classification framework for multi-mode process monitoring methods is shown in Figure 1.

Figure 1. A classification framework for multi-mode process monitoring methods.

Figure 1. A classification framework for multi-mode process monitoring methods.The main purpose of multi-mode process monitoring methods is to detect and avoid abnormal states during system operation to minimize possible accidents and losses and to ensure the normal and stable operation of systems. The main task of process monitoring is to identify, diagnose and isolate faults. The steps involved in multi-mode process monitoring include fault detection, fault identification, fault diagnosis and process recovery. In the monitoring and identification stage, it is necessary to determine whether the system working state is normal. In the event of abnormalities, the system data needs to be analyzed to identify variables that may lead to failure of the system. The analysis of variable data contributes to locating the fault, assessing the severity of the fault, and then enabling determination of causes. System faults are diagnosed by isolation and troubleshooting. Finally, process recovery is achieved through the action of relevant operators with respect to the fault [14].

References

- Tan, S.; Wang, F.L.; Chang, Y.Q.; Wang, S.; Zhou, H. Fault detection of multi-mode process using segmented PCA based on differential transform. Acta Autom. Sin. 2010, 36, 1626–1636.

- Xie, X. Multimode Industrial Process Modeling and Monitoring Method Based on Statistical Theory. Ph.D. Thesis, East China University of Technology, Shanghai, China, 2012.

- Gao, Y.; Gong, Z.H.; Huang, H. Energy saving through centralized air conditioners control and implementation of expert system. J. Beijing Univ. Technol. 1997, 17, 393–396.

- Zhang, Q.J. Study on Multi-Mode Switching Fuzzy Control Method and Logic Management of Unmanned Helicopter. Master’s Thesis, University of Defense Science and Technology, Beijing, China, 2006.

- Qian, M.Y. Optimal Control of Fermentation Engineering; Jiangsu Science and Technology Press: Nanjing, China, 1998.

- Guo, J.Y.; Yuan, T.M.; Li, Y. Fault detection method for uneven-length multimode batch processes. CIESC J. 2016, 67, 2916–2924.

- Peng, K.X.; Ma, L.; Zhang, K. Review of quality-related detection and diagnosis technology for complex industrial process. Acta Autom. Sin. 2017, 3, 349–365.

- Xu, L. Research on Statistical Monitoring of Multimode Process Based on PCA Mixture Model. Master’s Thesis, Zhejiang University, Hangzhou, China, 2010.

- He, M.; Zhi, E.W.; Cheng, L.; Yan, G.W. Soft sensor of ball mill load parameters based on multi-mode transfer learning. Control Eng. China 2019, 26, 1994–1999.

- Zhao, F. Study on Some Key Issues in Product Quality Control of Injection Molding Process. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2014.

- Tan, S.; Wang, F.L.; Peng, J.; Shi, H.T. Modeling algorithm for new mode process. Control. Decis. 2012, 27, 1241–1246.

- Chang, Y.Q.; Ma, R.X.; Wang, F.L.; Zheng, W.; Wang, S. Multimode process mode identifification with coexistence of quantitative information and qualitative information. Trans. Autom. Sci. Eng. 2020, 3, 1516–1527.

- Xie, L. Research on Statistical Performance Monitoring of Batch Process. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2005.

- Marcos, Q.; Alberto, P.; Cristina, V.; Orestes, L. Data-driven monitoring of multimode continuous processes: A review. Chemom. Intell. Lab. Syst. 2019, 189, 56–71.

More

Information

Subjects:

Automation & Control Systems

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

951

Revisions:

2 times

(View History)

Update Date:

29 Jul 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No