| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Arya Assadi-Langroudi | -- | 1058 | 2022-06-28 22:36:17 | | | |

| 2 | Amina Yu | -7 word(s) | 1051 | 2022-06-29 03:41:10 | | | | |

| 3 | Amina Yu | -2 word(s) | 1049 | 2022-06-29 03:50:54 | | |

Video Upload Options

The fractal framework could help to better understand the inherent variability of granular materials’ behaviour, how these relate to structures at micro-scale, and how understanding, rationalizing, and reducing the randomness at micro-scale can facilitate the design at macro-scale.

1. Introduction

Granular materials contain particles that vary in size, shape, and crystalline integrity. Varied qualities in particles lead to varied structures within which particles lay next to one another. The main typologies of structures that can appear in granular materials were established. It then shows ways to relax this randomness by sorting structural typologies into certain groups or ‘universal fractal’. Through experimental evidence, it then shows how each material — with structures in a certain universal fractal — responds to stress in unique ways and exhibits stress-strain behaviours of nondifferentiable, self-similar trajectories. An awareness of ‘universal fractals’ allow designers to imitate these in engineered systems and decrease the risks associated with behavioural variability and uncertainty.

This is a novel approach in design that involves in understanding how certain sized particulate matters self-form certain fractions of particle assemblages that cause certain repeatable hydromechanical behaviours. The significance of ‘fractals’ was portrayed in [1], where the concept was unconsciously used in a geological context. Fagg and Smalley [1] correlated the random shape of loessic closed depression landscapes with the random shape of soil particles constructing the landscape. They deployed the Zingg particle-shape system to determine a mean random shape for soil particles and fed that into Monte Carlo analysis to simulate the formation and collapse of metastable loess random structures. The collapse was argued to form land depressions at larger scale. The concept of ‘fractals’ have application beyond geological materials. Some of the problems recently looked at from ‘fractals’ perspective are flow of grains at silos’ outlets [2], mass transport in polymer electrolyte membrane fuel cells [3], characteristics of fat in food [4], breakage of dairy powders and implications on product flowability and solubility [5], and variable dissolution rate of pharmaceutical ingredients [6].

2. Materials and Methods

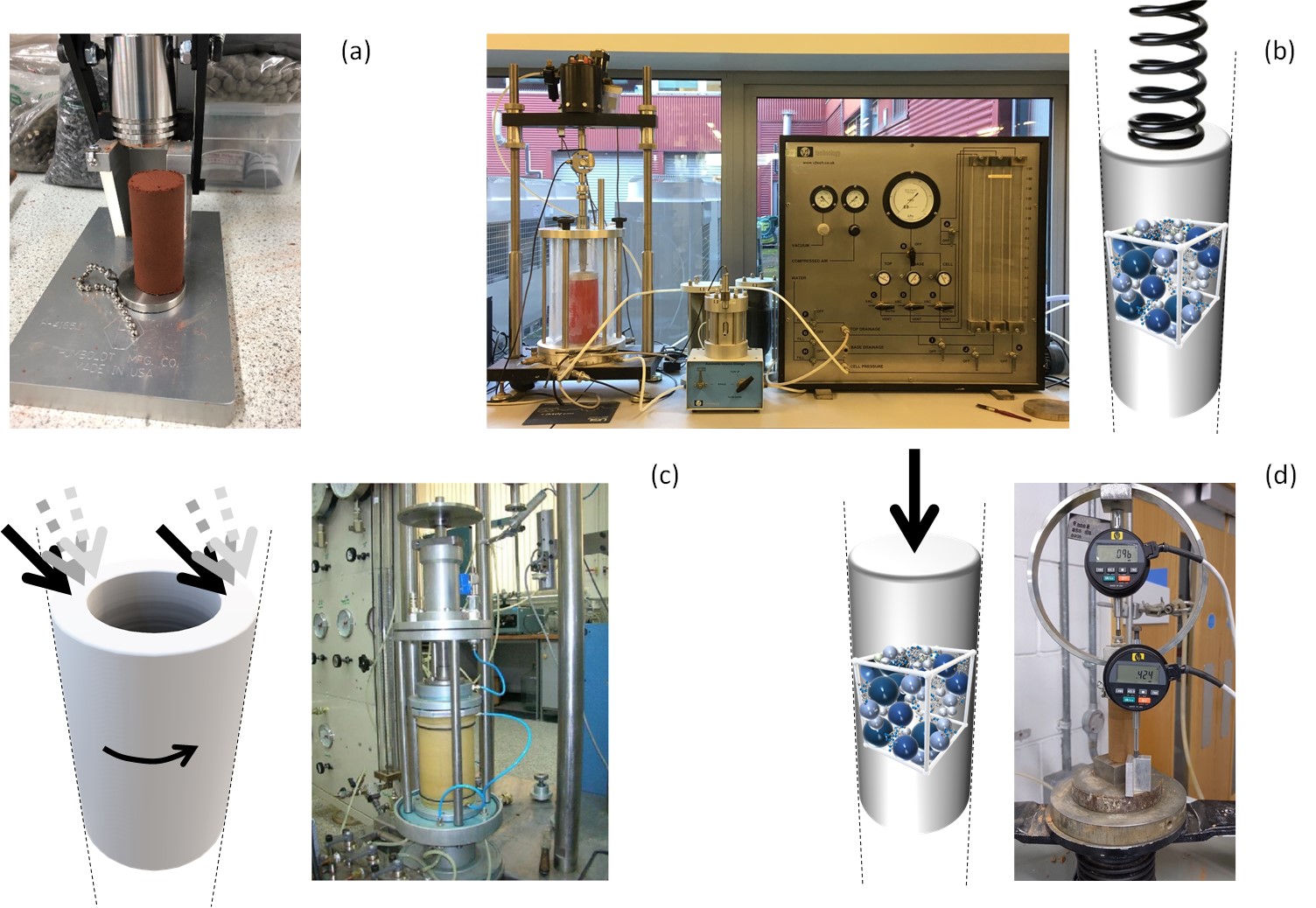

Ten quartz sands, collected from a range of locations on earth, were progressively crushed in finer grades using a range of mills. Mode and particle size distribution of finer grades were then analysed, alongside with particle shape data, to determine particle size ranges that almost always survive the erosive environment, almost always break in the erosive environment, or continuously break and re-aggregate to same size in the erosive environment. These are the ‘universal fractals’. Six select material grades (from pure sands to silty sands) were then subjected to three programmes of laboratory testing: undrained triaxial static compression, undrained triaxial cyclic compression, and undrained triaxial static anisotropic compression, torsion, and combinations of the two. Testing was done on cylindrical 36 mm in diameter 80 mm in height saturated specimens at a void ratio ranging from 0.77 to 0.80. Figure 1 illustrates the pictures of the three experimental programmes.

4. Fractals for Particles

Granular materials, in natural and engineered forms, constitute particles. By appropriating the fractality concept, each particle size can be associated with a ‘universal fractal’. Granular materials with a pronounced particle size in any of the ‘universal fractals’ can be expected to exhibit repeatable, reproducible and predictable stress-strain behaviour, flow and steady-states.

Three universal fractals are proposed: (i) inherently breakable — granular matters with a pronounced particle size of and around 30-34 μm, and 104-193 μm; (ii) inherently unbreakable — granular matters with a pronounced particle size of and around 10 to 17 μm, 45 to 47 μm and 56 to 58 μm; (iii) self-healing — where particles break and reaggregate, that is, granular matters with a pronounced particle size of and around 5, 7, 12, 20, 68, 75, 316, 440, 610 and 720 μm.

5. Fractals for Structures

6. Repeatable Traits

Fractal particles perspective

Granular materials with a pronounced mode size that is within the ‘inherently breakable’ fractal range develop the least strength at phase transformation. This is valid for both clean granular materials and composites (where the granular material is mixed with finer fractions of crystalline or amorphous nature), under any confinement conditions and either of compressive or torsional environments. The strength at phase transformation is higher in clean granular materials that are sized in the ‘self-healing’ range. The behaviour is that of non-flow; the material exhibits brittle failure, followed by strain-hardening. The strength at phase transformation is greatest in clean granular materials that are not sized in the ranges of any of the universal fractals. These materials show strain hardening under undrained static compression, which changes to strain-softening under undrained cyclic compression. All loose clean granular materials, irrespective of their size, develop non-flow strain hardening under undrained static compression; over time, and upon the progressive particle crushing and formation of a second, pronounced finer mode size, these materials develop post-failure softening that can lead to partial or total flow.

Fractal particles perspective

Particles that belong to one of the three universal fractals form packings that belong to one of the three main universal fractal structures. For example, granular materials with particles in the ‘self-healing’ fractal size range are likely to self-form structures in the Random Loose Packing RLP range. On the other hand, particles in the ‘inherently breakable’ range appear to tend to self-form structures in universal random close packing (RCP). Experiments show that stress paths for granular materials in each fractal structure converge, lending further evidence to significance of structure in design of granular materials.

References

- Fagg, R.; Smalley, I. ‘Hardcastle Hollows’ in loess landforms: Closed depressions in aeolian landscapes—In a geoheritage context. Open Geosci. 2018, 10, 58–63.

- Zuriguel, I.; Garcimartín, A.; Maza, D.; Pugnaloni, L.A.; Pastor, J.M. Jamming during the discharge of granular matter from a silo. Phys. Rev. E 2005, 71, 051303

- Trogadas, P.; Cho, J.I.S.; Neville, T.P.; Marquis, J.; Wu, B.; Brett, D.J.L.; Coppens, M.-O. A lung-inspired approach to scalable and robust fuel cell design. Energy Environ. Sci. 2018, 11, 136–143.

- Otto, T.; Baik, B.-K.; Czuchajowska, Z. Microstructure of Seeds, Flours, and Starches of Legumes. Cereal Chem. 1997, 74, 445–451.

- Thomas, M.E.; Scher, J.; Desobry-Banon, S.; Desobry, S. Milk powders ageing: Effect on physical and functional proper-ties. Crit. Rev. Food Sci. Nutr. 2004, 44, 297–322.

- Variankaval, N.; Cote, A.S.; Doherty, M.F. From form to function: Crystallization of active pharmaceutical ingredi-ents. AIChE J. 2008, 54, 1682–1688.

- Variankaval, N.; Cote, A.S.; Doherty, M.F. From form to function: Crystallization of active pharmaceutical ingredi-ents. AIChE J. 2008, 54, 1682–1688.