Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Chatchawal Wongchoosuk | -- | 1242 | 2022-06-28 14:48:50 | | | |

| 2 | Conner Chen | Meta information modification | 1242 | 2022-06-29 03:13:44 | | | | |

| 3 | Chatchawal Wongchoosuk | + 12 word(s) | 1254 | 2022-06-29 03:40:52 | | | | |

| 4 | Chatchawal Wongchoosuk | Meta information modification | 1254 | 2022-06-29 03:45:09 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Seesaard, T.; Wongchoosuk, C. History and Basic Principle of E-Nose. Encyclopedia. Available online: https://encyclopedia.pub/entry/24581 (accessed on 07 February 2026).

Seesaard T, Wongchoosuk C. History and Basic Principle of E-Nose. Encyclopedia. Available at: https://encyclopedia.pub/entry/24581. Accessed February 07, 2026.

Seesaard, Thara, Chatchawal Wongchoosuk. "History and Basic Principle of E-Nose" Encyclopedia, https://encyclopedia.pub/entry/24581 (accessed February 07, 2026).

Seesaard, T., & Wongchoosuk, C. (2022, June 28). History and Basic Principle of E-Nose. In Encyclopedia. https://encyclopedia.pub/entry/24581

Seesaard, Thara and Chatchawal Wongchoosuk. "History and Basic Principle of E-Nose." Encyclopedia. Web. 28 June, 2022.

Copy Citation

Fermented foods and beverages have become a part of daily diets in several societies around the world. Emitted volatile organic compounds play an important role in the determination of the chemical composition and other information of fermented foods and beverages. Electronic nose (E-nose) technologies enable non-destructive measurement and fast analysis, have low operating costs and simplicity, and have been employed for this purpose.

E-nose

gas sensor

Electronic nose

electronic sensing

odor assessment

chemosensor

Machine olfaction

sense of smell

Artificial Intelligence

1. Introduction

Due to uncertainties and unpredictable crisis situations (e.g., war conflicts) and global pandemics, the demand for fermented food and beverages has been significantly increasing because they are easy to cook and have a long shelf life [1]. In the production of fermented foods and beverages, different types of microorganisms, such as bacteria, yeast and mold, have been used to modify the chemical composition, resulting in changes in taste, smell, color and nutrients. For example, fermentation with probiotic microorganisms such as a lactic acid bacterium in products such as yogurt, kefir and kimchi can increase the nutritional value, for example, by reducing cholesterol and promoting healthy digestive function [2]. In countries, the fermentation technique has been developed specifically from local wisdom to large-scale manufacturing industries by selecting pure microbial strains, resulting in unique fermented foods and beverage products, such as pla ra (fermented fish) in Thailand, Chinese kombucha, Indonesian tempeh, natto and miso in Japan, Korean kimchi, etc. In the fermentation process, microorganisms can produce a variety of enzymes to modify food precursors. For example, the fermentation of natto employs bacteria of the genus Bacillus to create a fibrous texture that is sticky and stretchy [3]. The fermentation of coconut water (nata de coco) is produced via the bacterium Acetobacter xylinum [4]. Fermented tofu employs Monascus purpureus [5]. Different microorganisms make products with distinctive flavor compounds, nutrients and shelf lives.

To assess the quality of fermented food and beverages, such as the physical quality, nutrition value, microbiological quality, safety and sensory quality, there have been several types of equipment and techniques developed, ranging from spectroscopies to sensory evaluation techniques [6][7][8][9][10]. Equipment and methods enabling non-destructive measurement, rapid analysis and on-site testing with low operating costs and simplicity have received great interest in recent years. One of the effective tools for qualitative food and beverage identification meeting these criteria is an electronic nose (E-nose). There is a global trend in the development of E-nose systems instead of standard equipment such as GC, GC/MS, SPME/GC-TOFMS, GC-IMS, etc., in the qualitative analysis of food and beverages [11][12][13][14][15][16][17][18][19][20]. Although there are a set of review articles on the E-nose in food and beverage applications, comprehensive reviews focusing on fermented food and beverages based on E-nose technology are still limited.

2. History and Basic Principle of E-Nose

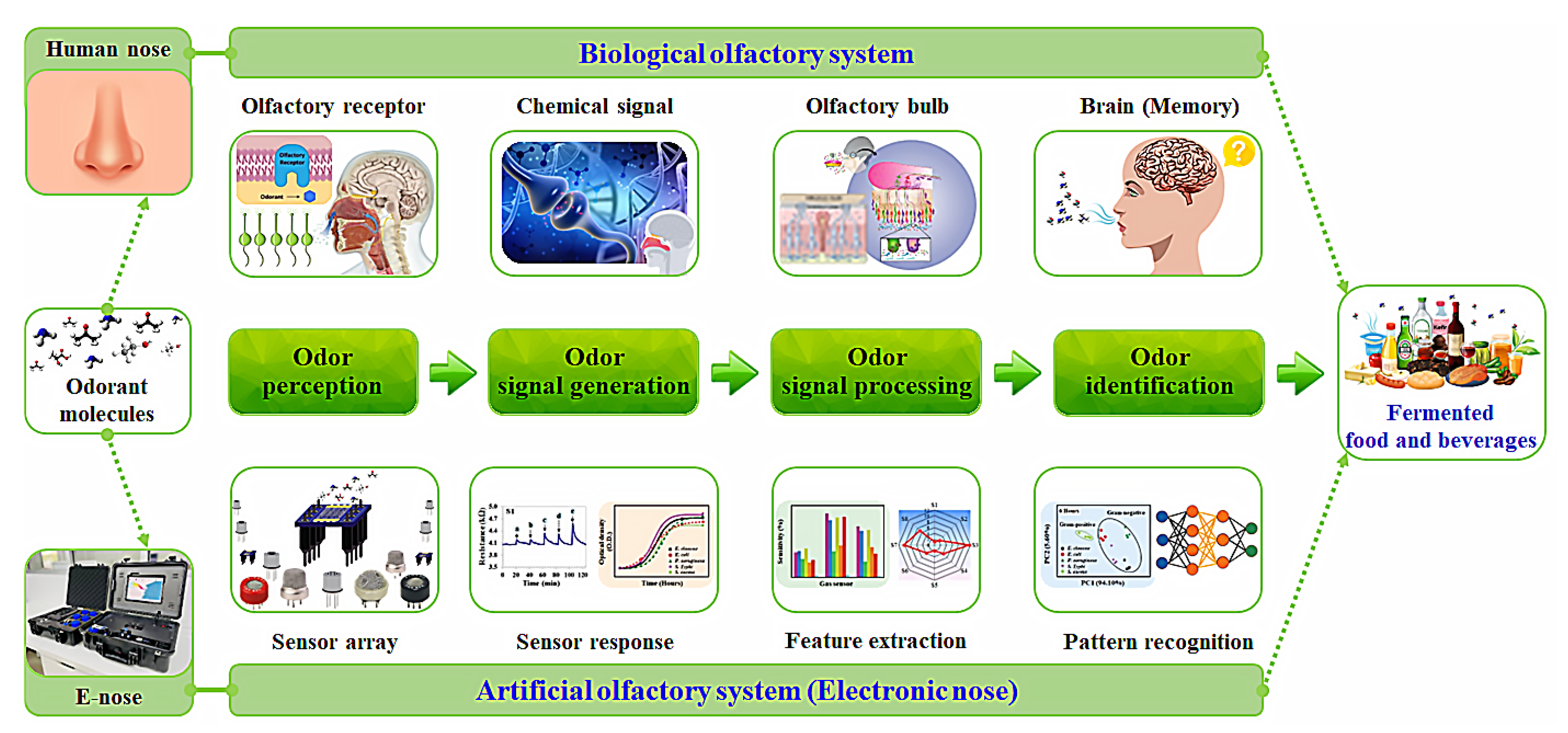

One of the first reports on the E-nose was in 1982, originated by Dodd, G. H. and Persaud, K. from the University of Warwick, England [21]. They employed three Figaro semiconducting gas sensors as transducers. The results showed fine discriminations between odors according to the mammalian olfactory system. This pioneering work has inspired several research groups to develop E-nose systems for various applications [22][23]. The concept of the E-nose is based on mimicking the human olfactory system, as shown in Figure 1. The mechanisms, odor recognition and limitations of human olfactory perception at a molecular level were first investigated by Buck and Axel from Columbia University, USA, in 1991 [24]. Their discovery helped to establish new ways/ideas to develop an E-nose system instead of using complex human olfactory perception for multifunctional purposes. The human olfactory system can be considered to consist of three main parts: (I) the odor-receiving part, consisting of olfactory receptor glands and scent delivery systems [25], (II) the nervous system for the transmission of signals between the brain and the rest of the body and (III) a decision system that is able to recognize, identify and act on the sense of smell experienced via the brain. The mechanism of smell perception is very complex. On the basis of psychophysical testing, humans are able to discriminate > 1 trillion olfactory stimuli [26]. However, the emotions and age of humans have a significant effect on odor recognition and classification [27][28][29]. Moreover, toxic agents in the sample and testing time are crucial obstacles in the ability to identify smells via the human olfactory system. The E-nose has thus become one of the powerful tools as an alternative to human evaluation of scent in samples.

Figure 1. Schematic diagram of E-nose device versus biological olfactory system.

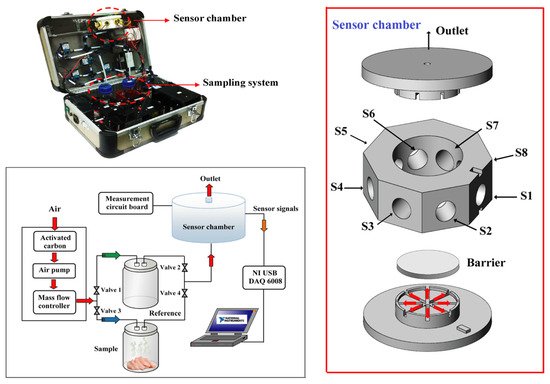

A comparison between an E-nose system and the biological olfactory system is displayed in Figure 1. In the E-nose system, the olfactory receptor section consists of the odor delivery unit (including the pipes, pumps and valves), which creates a path for aroma delivery into the sensor chamber. Numerous gas sensors, a so-called sensor array, are the heart and most important component of the olfactory receptor. Various sensing materials, such as conducting polymers [30][31], carbon-based nanomaterials [32][33][34], metal oxides [35][36][37][38] and nanocomposites [39][40], have been used to adsorb odor molecules based on both physisorption and chemisorption. When the odor molecules adsorb on the sensing material surface, they lead to charge transfers, volume expansion, ion exchange or interaction with ion species that can cause changes in the electrical conductivity/resistivity of the sensing materials. The electrical signals generated by various sensors are converted from analog to digital via an A/D converter and modified via signal processing, such as noise reduction or signal amplification. The data are stored on a local computer/online platform for further analysis. Due to the multivariate data obtained from the gas sensor array of the E-nose system, data analysis is usually performed via supervised/unsupervised machine learning algorithms with statistical methods such as principal component analysis (PCA) [41][42][43], hierarchical cluster analysis (CA) [44][45], analysis of variance (ANOVA) [46], linear discriminant analysis (LDA) [47], partial least squares discriminant analysis (PLS-DA) [48], simple visualization techniques [49], multivariate data analysis [50], artificial neural networks (ANNs) [51][52][53], artificial intelligence (AI) [54] and F-test [55]. A photograph and schematic diagram of a prototype portable E-nose system are displayed in Figure 2.

Figure 2. Photograph and schematic diagram of a prototype portable E-nose system [16].

Nowadays, E-nose systems based on a diversity of gas sensor arrays are applied in all major sectors, such as agriculture and forestry [56][57][58], industrial processes [59], environmental toxin/pollutant analysis [60][61][62], space stations [63][64], medical/healthcare [65][66][67][68], authentication of a person [69], medicine/pharmaceuticals [70], forensic science [71], military [72], toxicology/security [73][74] and the food and beverage industry [75][76][77]. Another emerging direction in the field could be to develop mobile and affordably priced devices for people who suffer from anosmia (loss of smell) [78][79]. With a focus on applications in the food and beverage industry, E-nose systems have been used for both direct/indirect identification via odor analysis for multiple purposes, such as product quality inspection [80], batch-to-batch uniformity studies [81], contamination detection [82], spoilage detection [83][84][85], adulteration detection [13][86], the detection of pathogenic bacteria [87][88], the study of storage conditions/shelf life [89][90][91][92] and the creation of specific sensory profiles [93][94]. In terms of food business competition, they have been used to analyze aromas and compare them with competitor products [95][96], evaluate the impact of changes in the production process and components that affect organoleptic characteristics [97][98] and compare different food formulations [76][99]. Moreover, E-nose systems have showed high performance in identifying the quality of many products, including wine [100], beer [101], coffee [102], carbonated drinks [103], dairy products [104][105], pork [106], beef [107][108], chicken [109], fish [110][111][112] and shrimp [113][114]. However, the sensors in E-nose systems may have a drift effect. Due to the aging of the sensors, measurements performed at different time intervals have a slight bias [115][116][117]. From the past to the present, research is still ongoing for the development of E-noses with high precision and accuracy, on online platforms, and for quantitative identification.

References

- Moretti, A.F.; Moure, M.C.; Quiñoy, F.; Esposito, F.; Simonelli, N.; Medrano, M.; León-Peláez, A. Water kefir, a fermented beverage containing probiotic microorganisms: From ancient and artisanal manufacture to industrialized and regulated commercialization. Future Foods 2022, 5, 100123.

- Kesika, P.; Thangaleela, S.; Sivamaruthi, B.S.; Bharathi, M.; Chaiyasut, C. Fermented foods and their role in respiratory health: A mini-review. Fermentation 2022, 8, 162.

- Song, Y.; Yu, J.; Song, J.; Wang, S.; Cao, T.; Liu, Z.; Gao, X.; Wei, Y. The antihypertensive effect and mechanisms of bioactive peptides from Ruditapes philippinarum fermented with Bacillus natto in spontaneously hypertensive rats. J. Funct. Foods 2021, 79, 104411.

- Zhang, J.; Yang, Y.; Deng, J.; Wang, Y.; Hu, Q.; Li, C.; Liu, S. Dynamic profile of the microbiota during coconut water pre-fermentation for nata de coco production. LWT-Food Sci. Technol. 2017, 81, 87–93.

- Tachibana, S.; Yasuda, M. Purification and characterization of heterogeneous glucoamylases from Monascus purpureus. Biosci. Biotechnol. Biochem. 2007, 71, 2573–2576.

- Sarkar, T.; Salauddin, M.; Kirtonia, K.; Pati, S.; Rebezov, M.; Khayrullin, M.; Panasenko, S.; Tretyak, L.; Temerbayeva, M.; Kapustina, N.; et al. A review on the commonly used methods for analysis of physical properties of food materials. Appl. Sci. 2022, 12, 2004.

- Md Noh, M.F.; Gunasegavan, R.D.N.; Khalid, N.M.; Balasubramaniam, V.; Mustar, S.; Rashed, A.A. Recent techniques in nutrient analysis for food composition database. Molecules 2020, 25, 4567.

- Bukhari, M.A.; Banasser, T.M.; El-Bali, M.; Bulkhi, R.A.; Qamash, R.A.; Trenganno, A.; Khayyat, M.; Kurdi, M.A.; Majrashi, A.A.; Bahewareth, F. Assessment of microbiological quality of food preparation process in some restaurants of Makkah city. Saudi J. Biol. Sci. 2021, 28, 5993–5997.

- Mihafu, F.D.; Issa, J.Y.; Kamiyango, M.W. Implication of sensory evaluation and quality assessment in food product development: A review. Curr. Res. Nutr. Food Sci. 2020, 8, 690–702.

- Drake, M.A. Encyclopedia of Dairy Sciences, 3rd ed.; Elsevier Science: Cambridge, MA, USA, 2022; pp. 572–576.

- Putri, S.; Malikul Ikram, M.M.; Sato, A.; Dahlan, H.D.; Rahmawati, D.; Ohto, Y.; Fukusaki, E. Application of gas chromatography-mass spectrometry-based metabolomics in food science and technology. J. Biosci. Bioeng. 2022, 133, 425–435.

- Adebo, O.A.; Oyeyinka, S.A.; Adebiyi, J.A.; Feng, X.; Wilkin, J.D.; Kewuyemi, Y.O.; Abrahams, A.M.; Tugizimana, F. Application of gas chromatography–mass spectrometry (GC-MS)-based metabolomics for the study of fermented cereal and legume foods: A review. Food Sci. Technol. 2021, 56, 1514–1534.

- Roy, M.; Yadav, B.K. Electronic nose for detection of food adulteration: A review. J. Food Sci. Technol. 2022, 59, 84–858.

- Timsorn, K.; Wongchoosuk, C. Inkjet printing of room-temperature gas sensors for identification of formalin contamination in squids. J. Mater. Sci. Mater. Electron. 2019, 30, 4782–4791.

- Timsorn, K.; Lorjaroenphon, Y.; Wongchoosuk, C. Identification of adulteration in uncooked Jasmine rice by a portable low-cost artificial olfactory system. Measurement 2017, 108, 67–76.

- Timsorn, K.; Thoopboochagorn, T.; Lertwattanasakul, N.; Wongchoosuk, C. Evaluation of bacterial population on chicken meats using a briefcase electronic nose. Biosyst. Eng. 2016, 151, 116–125.

- Wongchoosuk, C.; Wisitsoraat, A.; Tuantranont, A.; Kerdcharoen, T. Portable electronic nose based on carbon nanotube-SnO2 gas sensors and its application for detection of methanol contamination in whiskeys. Sens. Actuators B Chem. 2010, 147, 392–399.

- Hernández-Mesa, M.; Ropartz, D.; García-Campaña, A.M.; Rogniaux, H.; Dervilly-Pinel, G.; Bizec, B.L. Ion mobility spectrometry in food analysis: Principles, current applications and future trends. Molecules 2019, 24, 2706.

- Wang, S.; Chen, H.; Sun, B. Recent progress in food flavor analysis using gas chromatography–ion mobility spectrometry (GC–IMS). Food Chem. 2020, 315, 126158.

- Yang, X.; Zhang, T.; Yang, D.; Xie, J. Application of gas chromatography-ion mobility spectrometry in the analysis of food volatile components. Acta Chromatogr. 2022, 46, e13840.

- Persaud, K.; Dodd, G. Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature 1982, 299, 352–355.

- Gardner, J.W.; Bartlett, P.N. A brief history of electronic noses. Sens. Actuators B Chem. 1994, 18, 211–220.

- Wilson, A.D.; Baietto, M. Applications and advances in electronic-nose technologies. Sensors 2009, 9, 5099–5148.

- Buck, L.; Axel, R. A novel multigene family may encode odorant receptors: A molecular basis for odor recognition. Cell 1991, 65, 175–187.

- Dunkel, A.; Steinhaus, M.; Kotthoff, M.; Nowak, B.; Krautwurst, D.; Schieberle, P.; Hofmann, T. Nature’s chemical signatures in human olfaction: A foodborne perspective for future biotechnology. Angew. Chem. Int. Ed. 2014, 53, 7124–7143.

- Bushdid, C.; Magnasco, M.O.; Vosshall, L.B.; Keller, A. Humans can discriminate more than 1 trillion olfactory stimuli. Science 2014, 343, 1370–1372.

- Calvi, E.; Quassolo, U.; Massaia, M.; Scandurra, A.; D’Aniello, B.; D’Amelio, P. The scent of emotions: A systematic review of human intra- and interspecific chemical communication of emotions. Brain Behav. 2020, 10, e01585.

- Vieillard, S.; Ronat, L.; Baccarani, A.; Schaal, B.; Baudouin, J.Y.; Brochard, R. Age differences in olfactory affective responses: Evidence for a positivity effect and an emotional dedifferentiation. Aging Neuropsychol. Cogn. 2021, 28, 570–583.

- Freemantle, A.W.J.; Stafford, L.D.; Wagstaff, C.R.D.; Akehurst, L. The relationship between olfactory function and emotional contagion. Chem. Percept. 2021, 1–11.

- Seesaard, T.; Lorwongtragool, P.; Kerdcharoen, T. Development of fabric-based chemical gas sensors for use as wearable electronic noses. Sensors 2015, 15, 1885–1902.

- Seekaew, Y.; Lokavee, S.; Phokharatkul, D.; Wisitsoraat, A.; Kerdcharoen, T.; Wongchoosuk, C. Low-cost and flexible printed graphene–PEDOT:PSS gas sensor for ammonia detection. Org. Electron. 2014, 15, 2971–2981.

- Kondee, S.; Arayawut, O.; Pon-On, W.; Wongchoosuk, C. Nitrogen-doped carbon oxide quantum dots for flexible humidity sensor: Experimental and SCC-DFTB study. Vacuum 2022, 195, 110648.

- Seekaew, Y.; Arayawut, O.; Timsorn, K.; Wongchoosuk, C. Chapter nine—Synthesis, characterization, and applications of graphene and derivatives. In Carbon-Based Nanofillers and Their Rubber Nanocomposites, 1st ed.; Yaragalla, S., Mishra, R., Thomas, S., Kalarikkal, N., Maria, H.J., Eds.; Elsevier: Cambridge, MA, USA, 2019; pp. 259–283.

- Kerdcharoen, T.; Wongchoosuk, C. 11-Carbon nanotube and metal oxide hybrid materials for gas sensing. In Semiconductor Gas Sensors, 1st ed.; Jaaniso, R., Tan, O.K., Eds.; Woodhead Publishing: Shaston, UK, 2013; pp. 386–407.

- Traiwatcharanon, P.; Timsorn, K.; Wongchoosuk, C. Flexible room-temperature resistive humidity sensor based on silver nanoparticles. Mater. Res. Express 2017, 4, 085038.

- Arayawut, O.; Kerdcharoen, T.; Wongchoosuk, C. Structures, electronic properties, and gas permeability of 3D pillared silicon carbide nanostructures. Nanomaterials 2022, 12, 1869.

- Traiwatcharanona, P.; Siriwatcharapiboonb, W.; Jongprateep, O.; Wongchoosuk, C. Electrochemical paraquat sensor based on lead oxide nanoparticles. RSC Adv. 2022, 12, 16079–16092.

- Chaloeipote, G.; Prathumwan, R.; Subannajui, K.; Wisitsoraat, A.; Wongchoosuk, C. 3D printed CuO semiconducting gas sensor for ammonia detection at room temperature. Mater. Sci. Semicond. Processing 2021, 123, 105546.

- Chaloeipote, G.; Samarnwong, J.; Traiwatcharanon, P.; Kerdcharoen, T.; Wongchoosuk, C. High-performance resistive humidity sensor based on Ag nanoparticles decorated with graphene quantum dots. R. Soc. Open Sci. 2021, 8, 210407.

- Seekaew, Y.; Pon-On, W.; Wongchoosuk, C. Ultrahigh selective room-temperature ammonia gas sensor based on tin–titanium dioxide/reduced graphene/carbon nanotube nanocomposites by the solvothermal method. ACS Omega 2019, 4, 16916–16924.

- Seesaard, T.; Thippakorn, C.; Kerdcharoen, T.; Kladsomboon, S. A hybrid electronic nose system for discrimination of pathogenic bacterial volatile compounds. Anal. Methods 2020, 12, 5671–5683.

- Kladsomboon, S.; Thippakorn, C.; Seesaard, T. Development of organic-inorganic hybrid optical gas sensors for the non-invasive monitoring of pathogenic bacteria. Sensors 2018, 18, 3189.

- Grane, A.; Jach, A. Applications of principal component analysis (PCA) in food science and technology. In Mathematical and Statistical Methods in Food Science and Technology, 1st ed.; Granato, D., Ares, G., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014; pp. 55–85.

- Ferraz da Silva Torres, E.A.; Garbelotti, M.L.; Moita Neto, J.M. The application of hierarchical clusters analysis to the study of the composition of foods. Food Chem. 2006, 99, 622–629.

- Thanh-Blicharz, J.L.; Lewandowicz, J. Functionality of native starches in food systems: Cluster analysis grouping of rheological properties in different product matrices. Foods 2020, 9, 1073.

- Kuti, T.; Hegyi, A.; Kemény, S. Analysis of sensory data of different food products by ANOVA. Chemom. Intell. Lab. Syst. 2004, 72, 253–257.

- Kiselev, I.; Sysoev, V.; Kaikov, I.; Koronczi, I.; Adil Akai Tegin, R.; Smanalieva, J.; Sommer, M.; Ilicali, C.; Hauptmannl, M. On the temporal stability of analyte recognition with an e-nose based on a metal oxide sensor array in practical applications. Sensors 2018, 18, 550.

- Huang, M.; Li, Y.; Zhan, P.; Liu, P.; Tian, H.; Fan, J. Correlation of volatile compounds and sensory attributes of Chinese traditional sweet fermented flour pastes using hierarchical cluster analysis and partial least squares-discriminant analysis. J. Chem. 2017, 2017, 3213492.

- Mazalan, N.M.; Idrus, Z.; Abdullah, N.A.S.; Ibrahim, Z. An overview of visualization techniques: A survey of food-related research. In Soft Computing in Data Science, 1st ed.; Berry, M., Yap, B., Mohamed, A., Köppen, M., Eds.; Springer: Singapore, 2019; Volume 1100, pp. 91–104.

- Buvé, C.; Saeys, W.; Rasmussen, M.A.; Neckebroeck, B.; Hendrickx, M.; Grauwet, T.; Loey, A.V. Application of multivariate data analysis for food quality investigations: An example-based review. Food Res. Int. 2022, 151, 110878.

- Gonzalez Viejo, C.; Fuentes, S. Digital detection of olive oil rancidity levels and aroma profiles using near-infrared spectroscopy, a low-cost electronic nose and machine learning modelling. Chemosensors 2022, 10, 159.

- Gonzalez Viejo, C.; Fuentes, S.; Hernandez-Brenes, C. Smart detection of faults in beers using near-infrared spectroscopy, a low-cost electronic nose and artificial intelligence. Fermentation 2021, 7, 117.

- Summerson, V.; Gonzalez Viejo, C.; Torrico, D.D.; Pang, A.; Fuentes, S. Digital smoke taint detection in pinot grigio wines using an e-nose and machine learning algorithms following treatment with activated carbon and a cleaving enzyme. Fermentation 2021, 7, 119.

- Gonzalez Viejo, C.; Fuentes, S. Low-cost methods to assess beer quality using artificial intelligence involving robotics, an electronic nose, and machine learning. Fermentation 2020, 6, 104.

- Al-Marshadi, A.H.; Aslam, M. Statistical analysis for food quality in the presence of vague information. J. Food Qual. 2021, 2021, 7373620.

- Wilson, A.D. Diverse applications of electronic-nose technologies in agriculture and forestry. Sensors 2013, 13, 2295–2348.

- Seesaard, T.; Goel, N.; Kumar, M.; Wongchoosuk, C. Advances in gas sensors and electronic nose technologies for agricultural cycle applications. Comput. Electron. Agric. 2022, 193, 106673.

- Jia, W.; Liang, G.; Jiang, Z.; Wang, J. Advances in electronic nose development for application to agricultural products. Food Anal. Methods 2019, 12, 2226–2240.

- Deshmukh, S.; Bandyopadhyay, R.; Bhattacharyya, N.; Pandey, R.A.; Jana, A. Application of electronic nose for industrial odors and gaseous emissions measurement and monitoring—An overview. Talanta 2015, 144, 329–340.

- Wongchoosuk, C.; Subannajui, K.; Wang, C.; Yang, Y.; Güder, F.; Kerdcharoen, T.; Cimalla, V.; Zacharias, M. Electronic nose for toxic gas detection based on photostimulated core–shell nanowires. RSC Adv. 2014, 4, 35084–35088.

- Wilson, A.D. Review of electronic-nose technologies and algorithms to detect hazardous chemicals in the environment. Procedia Technol. 2012, 1, 453–463.

- Capelli, L.; Sironi, S.; Rosso, R.D. Electronic noses for environmental monitoring applications. Sensors 2014, 14, 19979–20007.

- Young, R.C.; Buttner, W.J.; Linnell, B.R.; Ramesham, R. Electronic nose for space program applications. Sens. Actuators B 2003, 93, 7–16.

- Ryan, M.A.; Manatt, K.S.; Gluck, S.; Shevade, A.V.; Kisor, A.K.; Zhou, H.; Lara, L.M.; Homer, M.L. The JPL electronic nose: Monitoring air in the U.S. Lab on the international space station. In Proceedings of the IEEE Sensors 2010, Waikoloa, HI, USA, 1–4 November 2010; pp. 1242–1247.

- Farraia, M.V.; Rufo, J.C.; Paciência, I.; Mendes, F.; Delgado, L.; Moreira, A. The electronic nose technology in clinical diagnosis: A systematic review. Porto Biomed. J. 2019, 4, e42.

- Wojnowski, W.; Dymerski, T.; Gębicki, J.; Namieśnik, J. Electronic noses in medical diagnostics. Curr. Med. Chem. 2019, 26, 197–215.

- Siyang, S.; Wongchoosuk, C.; Kerdcharoen, T. Diabetes diagnosis by direct measurement from urine odor using electronic nose. In Proceedings of the 5th 2012 Biomedical Engineering International Conference, Muang, Thailand, 5–7 December 2012; pp. 1–4.

- Wu, W.; Liu, T.; Haick, H. Electronic nose sensors in healthcare. In Reference Module in Biomedical Sciences, 1st ed.; Elsevier: Cambridge, MA, USA, 2021.

- Wongchoosuk, C.; Lutz, M.; Kerdcharoen, T. Detection and classification of human body odor using an electronic nose. Sensors 2009, 9, 7234–7249.

- Wasilewski, T.; Migon, D.; Gebicki, J.; Kamysz, W. Critical review of electronic nose and tongue instruments prospects in pharmaceutical analysis. Anal. Chim. Acta 2019, 1077, 14–29.

- Wilson, A.D. Electronic-nose applications in forensic science and for analysis of volatile biomarkers in the human breath. J. Forensic Sci. Criminol. 2014, 1, 1–21.

- Nagappan, P.G.; Subramaniam, S.; Wang, D.Y. Olfaction as a soldier– a review of the physiology and its present and future use in the military. Mil. Med. Res. 2017, 4, 9.

- Lim, S.H.; Feng, L.; Kemling, J.W.; Musto, C.J.; Suslick, K.S. An optoelectronic nose for the detection of toxic gases. Nat. Chem. 2009, 1, 562–567.

- Jońca, J.; Pawnuk, M.; Arsen, A.; Sówka, I. Electronic noses and their applications for sensory and analytical measurements in the waste management plants—A review. Sensors 2022, 22, 1510.

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Balaguru Rayappan, J.B. Electronic noses for food quality: A review. J. Food Eng. 2015, 144, 103–111.

- Mamat, M.; Samad, S.A.; Hannan, M.A. An electronic nose for reliable measurement and correct classification of beverages. Sensors 2011, 11, 6435–6453.

- Ghasemi-Varnamkhasti, M.; Mohtasebi, S.S.; Rodriguez-Mendez, M.L.; Lozano, J.; Razavi, S.H.; Ahmadi, H. Potential application of electronic nose technology in brewery. Trends Food Sci. Technol. 2011, 22, 165–174.

- Pinger, M.; Draf, J.; Lakner, T.; Ferdenzi, C.; Rouby, C.; Hummel, T.; Bensafi, M. Perceived utility of electronic noses in patients with loss of smell. Eur. Arch. Oto-Rhino-Laryngol. 2021, 278, 2155–2156.

- Ramírez, H.L.; Soriano, A.; Gómez, S.; Iranzo, J.U.; Briones, A.I. Evaluation of the food sniffer electronic nose for assessing the shelf life of fresh pork meat compared to physicochemical measurements of meat quality. Eur. Food Res. Technol. 2018, 244, 1047–1055.

- Ali, M.M.; Hashim, N.; Aziz, S.A.; Lasekan, O. Principles and recent advances in electronic nose for quality inspection of agricultural and food products. Trends Food Sci. Technol. 2020, 99, 1–10.

- Sharmilan, T.; Premarathne, I.; Wanniarachchi, I.; Kumari, S.; Wanniarachchi, D. Application of electronic nose to predict the optimum fermentation time for low-country Sri Lankan tea. J. Food Qual. 2022, 2022, 7703352.

- Sanaeifar, A.; ZakiDizaji, H.; Jafari, A.; Guardia, M.D.L. Early detection of contamination and defect in foodstuffs by electronic nose: A review. Trends Anal. Chem. 2017, 97, 257–271.

- Andre, R.S.; Facure, M.H.M.; Mercante, L.A.; Correa, D.S. Electronic nose based on hybrid free-standing nanofibrous mats for meat spoilage monitoring. Sens. Actuators B Chem. 2022, 353, 131114.

- Feng, H.; Zhang, M.; Liu, P.; Liu, Y.; Zhang, X. Evaluation of IoT-enabled monitoring and electronic nose spoilage detection for salmon freshness during cold storage. Foods 2020, 9, 1579.

- Vajdi, M.; Varidi, M.J.; Varidi, M.; Mohebbi, M. Using electronic nose to recognize fish spoilage with an optimum classifier. J. Food Meas. Charact. 2019, 13, 1205–1217.

- Peris, M.; Escuder-Gilabert, L. Electronic noses and tongues to assess food authenticity and adulteration. Trends Food Sci. Technol. 2016, 58, 40–54.

- Falasconi, M.; Concina, I.; Gobbi, E.; Sberveglieri, V.; Pulvirenti, A.; Sberveglieri, G. Electronic nose for microbiological quality control of food products. Int. J. Electrochem. 2012, 2012, 715763.

- Abdallah, S.A.; Al-Shatti, L.A.; Alhajraf, A.F.; Al-Hammad, N.; Al-Awadi, B. The detection of foodborne bacteria on beef: The application of the electronic nose. SpringerPlus 2013, 2, 687.

- Xing, M.; Sun, K.; Liu, Q.; Pan, L.; Tu, K. Development of novel electronic nose applied for strawberry freshness detection during storage. Int. J. Food Eng. 2018, 14, 20180111.

- Cozzolino, R.; Cefola, M.; Laurino, C.; Pellicano, M.P.; Palumbo, M.; Stocchero, M.; Pace, B. Electronic-nose as non-destructive tool to discriminate “Ferrovia” sweet cherries cold stored in air or packed in high CO2 modified atmospheres. Front. Nutr. 2021, 8, 720092.

- Modesti, M.; Taglieri, I.; Bianchi, A.; Tonacci, A.; Sansone, F.; Bellincontro, A.; Venturi, F.; Sanmartin, C. E-nose and olfactory assessment: Teamwork or a challenge to the last data? The case of virgin olive oil stability and shelf life. Appl. Sci. 2021, 11, 8453.

- Liu, L.; Li, X.; Li, Z.; Shi, Y. Application of electronic nose in detection of fresh vegetables freezing time considering odor identification technology. Chem. Eng. Trans. 2018, 68, 265–270.

- Sipos, L.; Kovacs, Z.; Szollosi, D.; Kókai, Z.; Dalmadi, I.; Fekete, A. Comparison of novel sensory panel performance evaluation techniques with e-nose analysis integration. J. Chemom. 2011, 25, 275–286.

- Rizzolo, A.; Bianchi, G.; Vanoli, M.; Lurie, S.; Spinelli, L.; Torricelli, A. Electronic nose to detect volatile compound profile and quality changes in ‘Spring Belle’ peach (Prunus persica L.) during cold storage in relation to fruit optical properties measured by time-resolved reflectance spectroscopy. J. Agric. Food Chem. 2013, 61, 1671–1685.

- Aleixandre, M.; Lozano, J.; Gutierrez, J.; Sayago, I.; Fernandez, M.J.; Horrillo, M.C. Portable e-nose to classify different kinds of wine. Sens. Actuators B 2008, 131, 71–76.

- Men, H.; Shi, Y.; Fu, S.; Jiao, Y.; Qiao, Y.; Liu, J. Discrimination of beer based on e-tongue and e-nose combined with SVM: Comparison of different variable selection methods by PCA, GA-PLS and VIP. Preprints 2017, 2017050054.

- Quarto, A.; Soldo, D.; Di Lecce, F.; Giove, A.; Di Lecce, V.; Castronovo, A. Electronic nose for evaluating water use in beer production. In Proceedings of the 2017 ISOCS/IEEE International Symposium on Olfaction and Electronic Nose (ISOEN), Montreal, QC, Canada, 28–31 May 2017; pp. 1–3.

- Fujioka, K. Comparison of cheese aroma intensity measured using an electronic nose (e-nose) non-destructively with the aroma intensity scores of a sensory evaluation: A pilot study. Sensors 2021, 21, 8368.

- Romano, A.; Cuenca, M.; Makhoul, S.; Biasioli, F.; Martinello, L.; Fugatti, A.; Scampicchio, M. Comparison of e-noses: The case study of honey. Ital. J. Food Sci. 2019, 28, 326–337.

- Rodríguez-Méndez, M.L.; De Saja, J.A.; González-Antón, R.; García-Hernández, C.; Medina-Plaza, C.; García-Cabezón, C.; Martín-Pedrosa, F. Electronic noses and tongues in wine industry. Front. Bioeng. Biotechnol. 2016, 4, 81.

- Nimsuk, N. Improvement of accuracy in beer classification using transient features for electronic nose technology. J. Food Meas. Charact. 2018, 13, 656–662.

- Rodríguez, J.; Durán, C.; Reyes, A. Electronic nose for quality control of Colombian coffee through the detection of defects in “Cup Tests”. Sensors 2010, 10, 36–46.

- Yang, Y.; Xu, W.; Wu, M.; Mao, J.; Sha, R. Application of e-nose combined with ANN modelling for qualitative and quantitative analysis of benzoic acid in cola-type beverages. J. Food Meas. Charact. 2021, 15, 5131–5138.

- Gomes, M.T.S.R. Chapter 3—Electronic nose in dairy products. In Electronic Noses and Tongues in Food Science, 1st ed.; Rodríguez Méndez, M.L., Ed.; Academic Press: San Diego, CA, USA, 2016; pp. 21–30.

- Yakubu, H.G.; Kovacs, Z.; Toth, T.; Bazar, G. Trends in artificial aroma sensing by means of electronic nose technologies to advance dairy production—A review. Crit. Rev. Food Sci. Nutr. 2021, 1–15.

- Li, H.; Chen, Q.; Zhao, J.; Ouyang, Q. Non-destructive evaluation of pork freshness using a portable electronic nose (E-nose) based on a colorimetric sensor array. Anal. Methods 2014, 6, 6271–6277.

- Górska-Horczyczak, E.; Guzek, D.; Molęda, Z.; Wojtasik-Kalinowska, I.; Brodowska, M.; Wierzbicka, A. Applications of electronic noses in meat analysis. Food Sci. Technol. 2016, 36, 389–395.

- Wojnowski, W.; Majchrzak, T.; Dymerski, T.; Gębicki, J.; Namieśnik, J. Electronic noses: Powerful tools in meat quality assessment. Meat Sci. 2017, 131, 119–131.

- Raudiene, E.; Gailius, D.; Vinauskiene, R.; Eisinaite, V.; Balčiunas, G.; Dobiliene, J.; Tamkute, L. Rapid evaluation of fresh chicken meat quality by electronic nose. Czech J. Food Sci. 2018, 36, 420–426.

- Grassi, S.; Benedetti, S.; Opizzio, M.; Nardo, E.D.; Buratti, S. Meat and fish freshness assessment by a portable and simplified electronic nose system (Mastersense). Sensors 2019, 19, 3225.

- Güney, S.; Atasoy, A. Freshness classification of horse mackerels with e-nose system using hybrid binary decision tree structure. Int. J. Pattern Recognit. Artif. Intell. 2020, 34, 2050003.

- Radi, R.; Wahyudi, E.; Adhityamurti, M.D.; Yuroto Putro, J.P.L.; Barokah, B.; Rohmah, D.N. Freshness assessment of Tilapia fish in traditional market based on an electronic nose. Bull. Electr. Eng. Inform. 2021, 10, 2466–2476.

- Jiang, J.; Li, J.; Zheng, F.; Lin, H.; Hui, G. Rapid freshness analysis of mantis shrimps (Oratosquilla oratoria) by using electronic nose. Food Meas. 2016, 10, 48–55.

- Srinivasan, P.; Robinson, J.; Geevaretnam, J.; Rayappan, J.B.B. Development of electronic nose (Shrimp-Nose) for the determination of perishable quality and shelf-life of cultured Pacific white shrimp (Litopenaeus Vannamei). Sens. Actuators B. Chem. 2020, 317, 128192.

- Zhang, L.; Tian, F.; Liu, S.; Dang, L.; Peng, X.; Yin, X. Chaotic time series prediction of E-nose sensor drift in embedded phase space. Sens. Actuators B Chem. 2013, 182, 71–79.

- Zhang, L.; Liu, Y.; He, Z.; Liu, J.; Deng, P.; Zhou, X. Anti-drift in E-nose: A subspace projection approach with drift reduction. Sens. Actuators B Chem. 2017, 253, 407–417.

- Romain, A.C.; Nicolas, J. Long term stability of metal oxide-based gas sensors for e-nose environmental applications: An overview. Sens. Actuators B Chem. 2010, 146, 502–506.

More

Information

Subjects:

Instruments & Instrumentation

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

7.9K

Revisions:

4 times

(View History)

Update Date:

29 Jun 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No