Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Carlos Cacciuttolo | -- | 2049 | 2022-06-15 19:54:44 | | | |

| 2 | Rita Xu | -3 word(s) | 2046 | 2022-06-16 03:26:22 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Cacciuttolo, C.; , . Efficient Use of Water in Tailings Management. Encyclopedia. Available online: https://encyclopedia.pub/entry/24080 (accessed on 07 February 2026).

Cacciuttolo C, . Efficient Use of Water in Tailings Management. Encyclopedia. Available at: https://encyclopedia.pub/entry/24080. Accessed February 07, 2026.

Cacciuttolo, Carlos, . "Efficient Use of Water in Tailings Management" Encyclopedia, https://encyclopedia.pub/entry/24080 (accessed February 07, 2026).

Cacciuttolo, C., & , . (2022, June 15). Efficient Use of Water in Tailings Management. In Encyclopedia. https://encyclopedia.pub/entry/24080

Cacciuttolo, Carlos and . "Efficient Use of Water in Tailings Management." Encyclopedia. Web. 15 June, 2022.

Copy Citation

Nowadays, many major copper mining projects in desert areas with extremely dry climates, as in northern Chile and the southern coast of Peru, process sulfide ores at high production rates; in some cases over 100,000 metric tonnes per day (mtpd), generating large amounts of tailings, that are commonly managed and transported to tailings storage facilities (TSF) hydraulically using fresh water. Considering the extremely dry climate, water scarcity, community demands, and environmental constraints in these desert areas, the efficient use of water in mining is being strongly enforced.

fresh water

sea water use

dewatered tailings

1. Introduction

Tailings are usually a very fine mud or powder, left over after ore is crushed and valuable minerals are extracted. Tailings production is immense, since only ounces or pounds of metal are extracted for every tonne of processed ore. Tailings may also contain chemicals used in metallurgical processes as well as other metals and sulphides contained in ore, which need to be considered for safe tailings management. For this reason, most tailings are not inert from a geochemical point of view and must be disposed of with control to care for the environment.

The transport and storage of tailings require relevant environmental management. This residue is generally managed and transported hydraulically using fresh water to tailings storage facilities (TSF), this alternative being cheaper than bulk transportation by conveyor belts, trains or trucks. It is relevant to mention that most of the water used for tailings transportation needs to be recovered for reuse in the metallurgical process [1].

Metal production of copper, silver, gold, lead, zinc, among others, is growing quickly, and part of the increasing water demand can be explained by the expansion of existing mines and new projects being developed. In addition, there is an important increase in copper extraction/production caused by declining copper grades at existing mines. As copper grades decline, more ore needs to be processed in order to produce the same amount of copper metal. The use of water is proportional to the amount of ore that is processed, so it follows that more water is needed to produce the same amount of copper when grades decline. The exploitation of large ore deposits with decreasing grades has led to the use of efficient large equipment for the milling and processing of ore, which enables higher production rates, that, in turn, implies an increase in water demand for the metallurgical process [2].

2. Efficient Water Management in Latin American Mining

In general, ore deposits located in Latin America, where countries with dry climates such as Chile, Peru, Mexico, Argentina, Bolivia have the following characteristics: (i) very low precipitation rates (annual precipitation of 10 mm/year or less), and (ii) high evaporation rates (monthly evaporation rates up to 10 mm/day); resulting in annual average evaporation rates over 2000 mm/year, as in the Atacama desert, where water supply becomes a major challenge [3]. These issues have raised the necessity of an efficient water management plan to transport and manage tailings during the mine lifetime. Other sites in Latin America with mining operations that lie in dry and water scarcity, where the themes can be applied, are the following areas:

-

Northern Chile—Atacama Desert (Region of Arica, Region of Tarapaca, Region of Antofagasta, and Region of Atacama).

-

Southern Peru—Atacama Desert (Tacna Department, Moquegua Department, Ica Department, and Arequipa Department).

-

Northern Peru—Sechura Desert (Piura Department, and Lambayeque Department).

-

Southern Bolivia—Atacama Desert (Potosí Department, and Oruro Department).

-

Central and Northern Argentine—Sierra y Pampa (Province of Catamarca, Province of La Rioja, Province of San Juan, and Province of Mendoza).

-

Central and Northern México (Chihuahua State, Sonora State, Zacatecas State, Durango State, and Baja California State).

Due to water scarcity in desert areas, the supply of fresh water (make-up) is not available from groundwater and surface courses, then it is necessary to use sea water. In addition, increasing water demand of communities, agriculture and other productive sectors has led to a vulnerability of freshwater resources, resulting in a conflict of needs for water between different water users. Water resources are increasingly affected by a combination of factors such as climate change, which results in the progressive decline of water supply, recharge and infiltration flows in these basins. Also, the productivity of watersheds has been affected dramatically as a result of dry hydrological conditions.

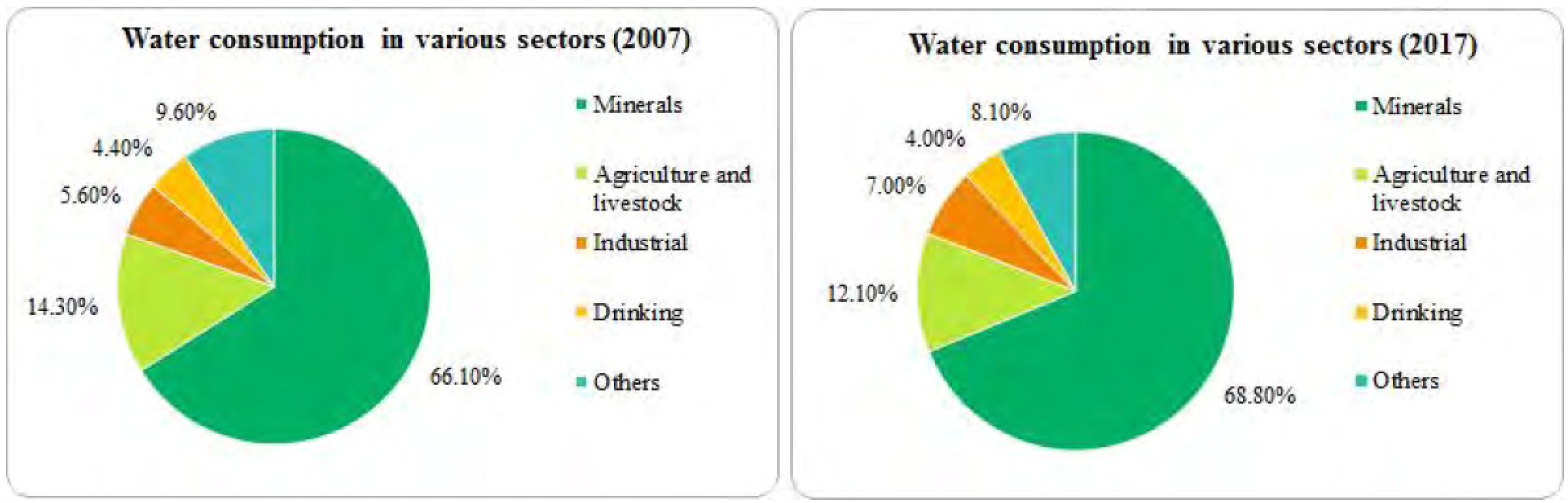

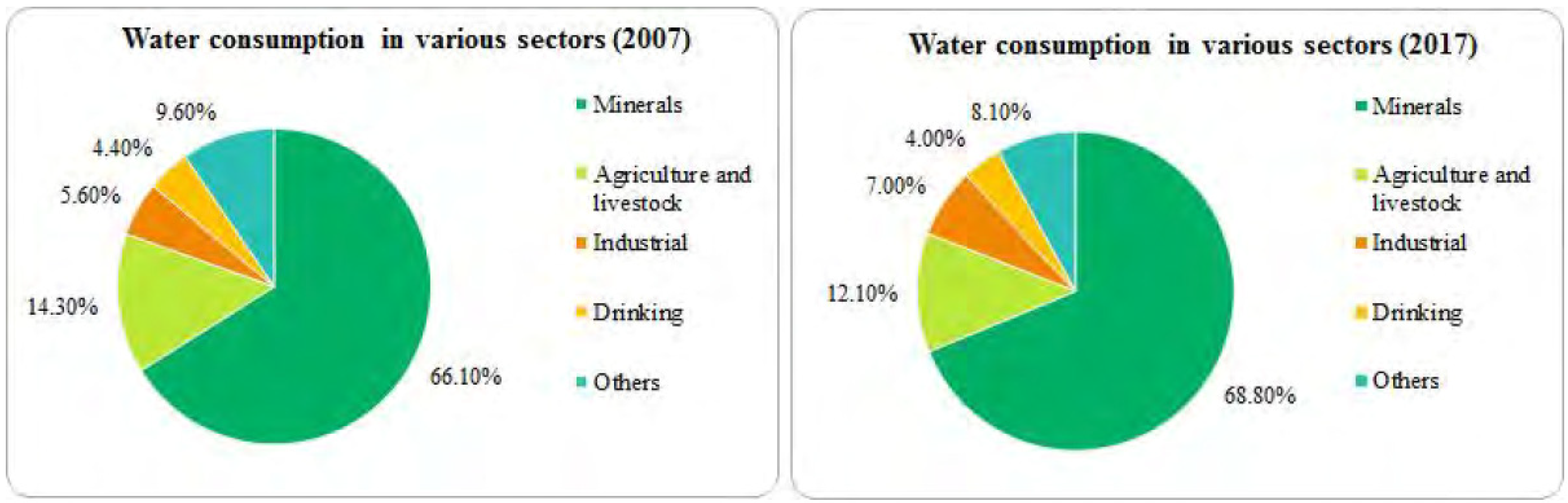

As a consequence, stakeholders have been affected and, in some cases, drinking water resources have been dramatically compromised, resulting in increasing social pressure. Figure 1 and Figure 2 show, as an example, the amount of water consumption in two northern Chile regions registered in 2007 and the consumption projected for the year 2017.

Figure 1. Water consumption in Antofagasta Region (Region II) of Chile [4].

Figure 2. Water consumption in the Atacama Region (Region III) of Chile [4].

As shown in both figures, the proportion of water consumption in mining and industrial activities tends to increase, whereas in agriculture, livestock and drinking water, consumption rate tends to decrease in both regions.

These studies demonstrate a competition for water use; therefore, it is necessary to implement solutions and implement water management tools to meet the water demands of all stakeholders.

3. Tailings Management Methodologies Description

Engineers, scientists, mine operators, and authorities are working to improve the design and operation of tailings storage facilities (TSFs), focusing on the development of optimal solutions, which considers the following aspects: (i) reliable performance of technologies; (ii) a dynamic and robust TSF water balance (considering site-specific conditions); and (iii) efficient water management with the control of water losses (evaporation and infiltration). If these key issues are successfully implemented, a reduction of water make-up requirements, decrease of negative environmental impacts and an increase of natural water supply for the community will promote sustainable development [5]

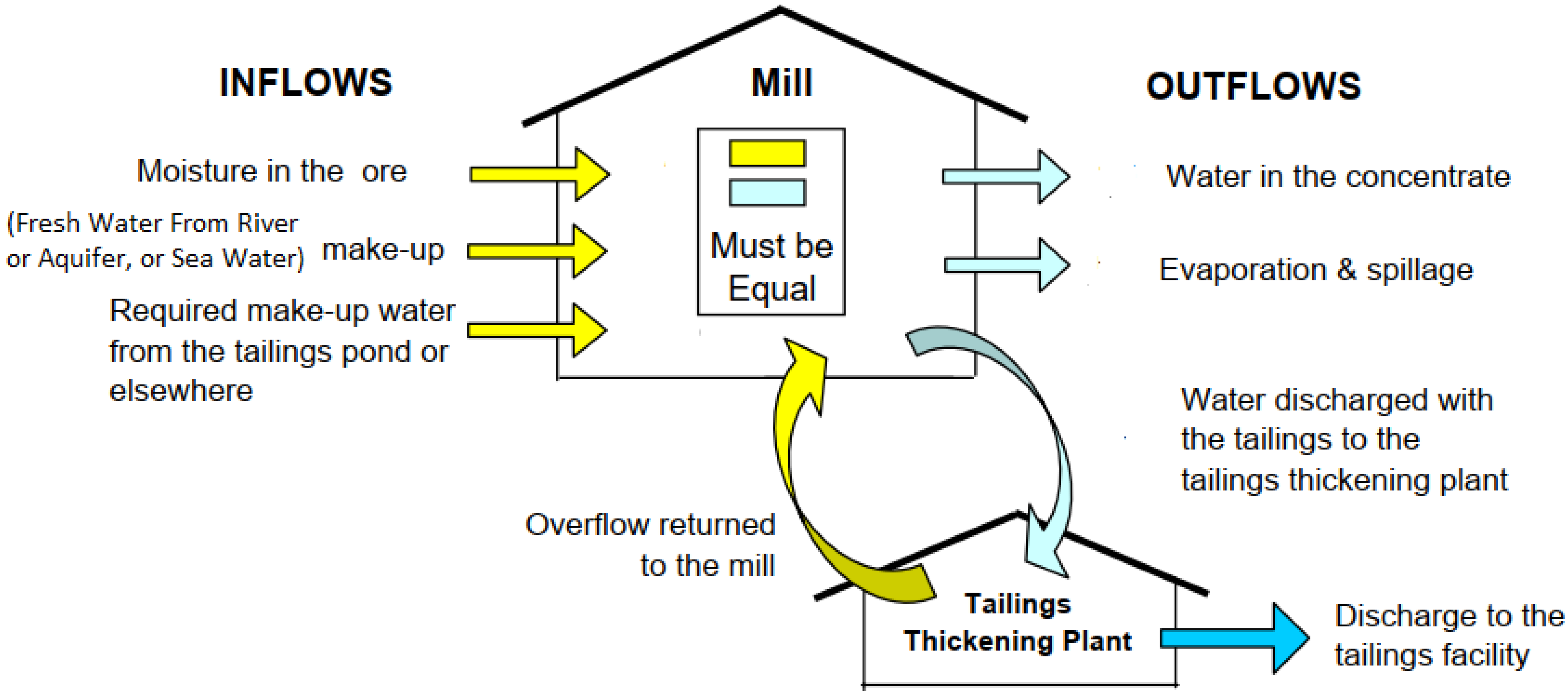

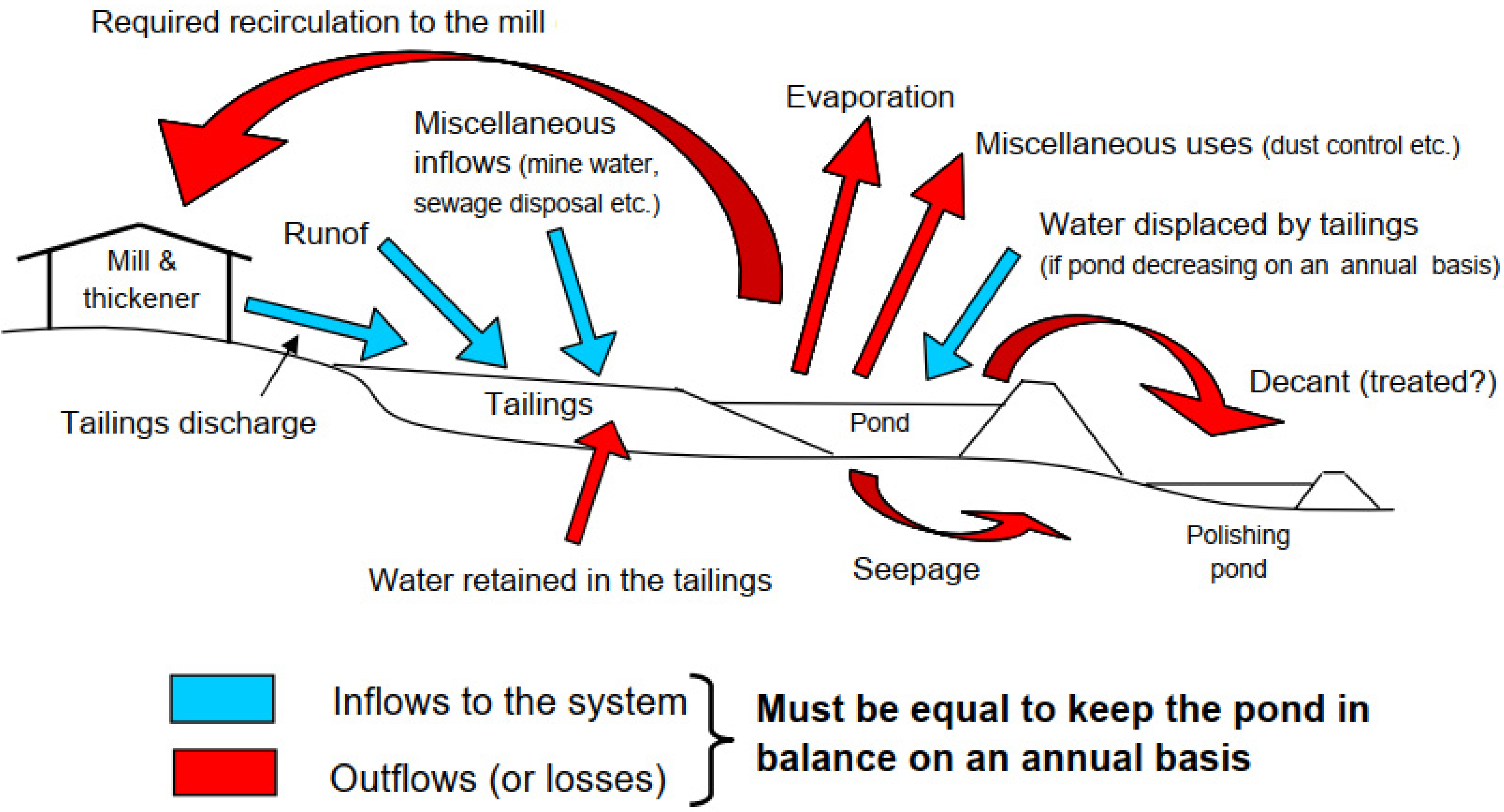

Freshwater sources for mining activities must be carefully studied given the environmental impacts and costs for their implementation. Water supply during the operation must have the capacity to grow to provide the necessary supply of fresh water during the entire useful life of the project. Figure 3 and Figure 4 show typical water flows in a mill and thickening plant and tailings disposal facility in a mining project.

Figure 3. Typical flows into and out of a mill and thickening mining plant.

Figure 4. Typical Flows into and out of a mine tailings disposal facility.

In the case of sea water, the different possible locations for the water intake plant at the coast, the requirement or not for desalination, the required pumping station, and the transport pipelines must be analyzed [6]. In the design phase of the desalination and pumping plant, it is important to consider the variability of the required water flow from the ocean. In general, water losses in tailings deposits increase over time due to: (i) increased evaporation area of the pond of clear water, and (ii) increased consolidation of the deposited tailings, which implies higher seepages also involving seasonal variations.

The application of tailings dewatering technologies for increasing tailings water recovery is a relevant step to reduce water losses (resource from freshwater or seawater supplies) caused by evaporation, infiltration and retention at interstitial voids on tailings storage facilities; for this reason, it is necessary to implement new designs in order to make an environmentally friendly tailings management focus on efficiency water use.

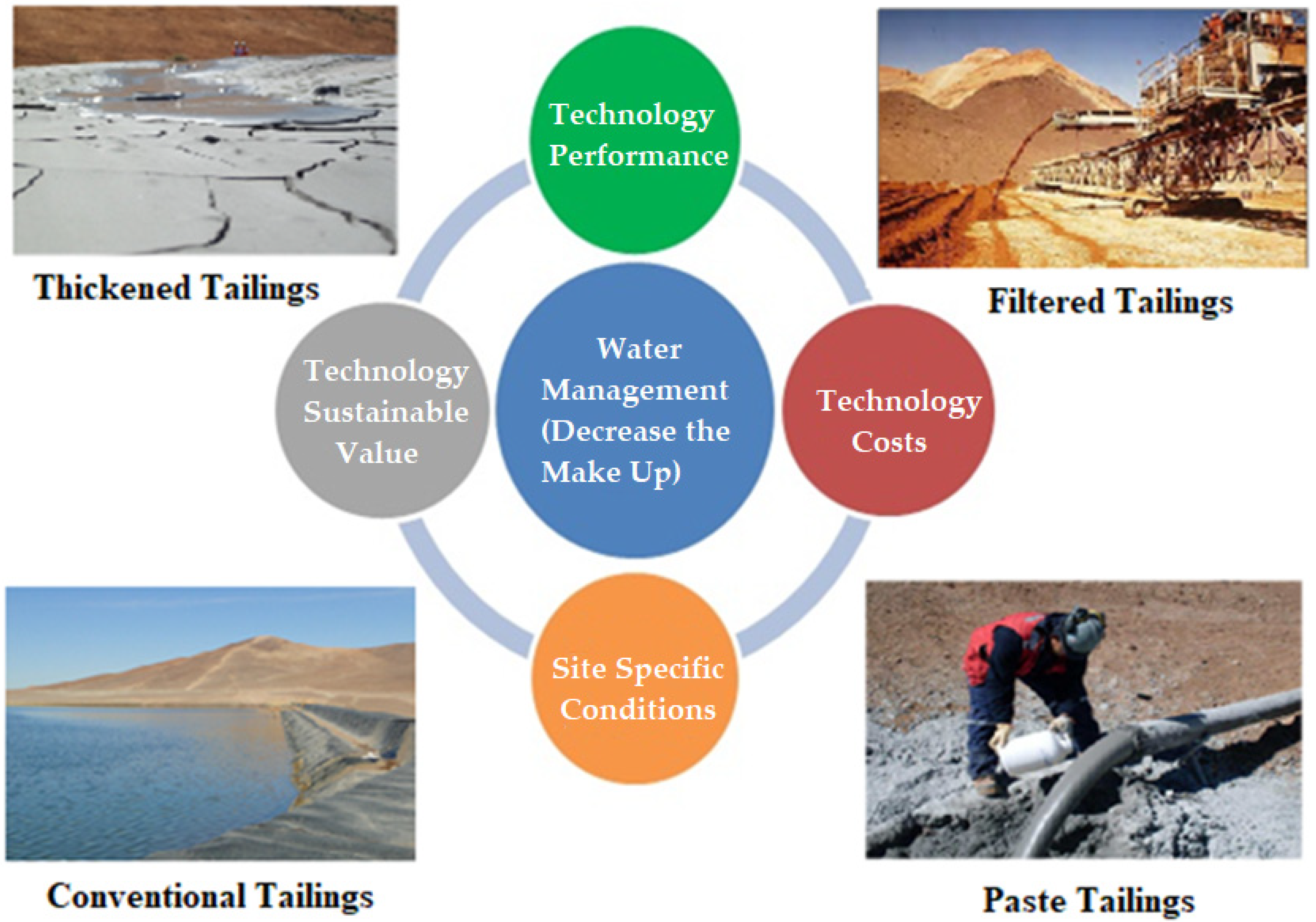

Figure 5 shows different dewatering tailings technologies that focus on water recovery and efficient water management:

Figure 5. Dewatering Tailings Technologies—Efficient Water Management.

3.1. Water Recovery from Tailings with Conventional Technologies (WRCT)

In current Chilean and Peruvian large-scale mining in dry climate areas, most typical tailings disposal schemes consist of conventional or slightly thickened at modest levels of tailings solids weight concentration (Cw 48–52%). Conventional TSFs have dams built of coarse fraction of tailings obtained by hydrocyclones, or have slightly thickened tailings deposits with dams built of borrow material. Conventional tailing dams (Figure 6) may have water recoveries as high as 65–75% in very well operated TSFs, which means they have appropriate tailings distribution, good control of the pond (volume and location) and adequate seepage recovery. In conventional dams, water at the settling pond is decanted and by floating pumps, or decant towers, and dam seepages is collected by a drainage system and cutoff trench systems. However, a high seasonal evaporation rate can substantially reduce water recovery from the pond area, and infiltration from the pond in contact with natural soil can produce water losses [7].

Figure 6. Conventional Tailings Technology—Quebrada Enlozada TSF Cerro Verde Mine Peru [8].

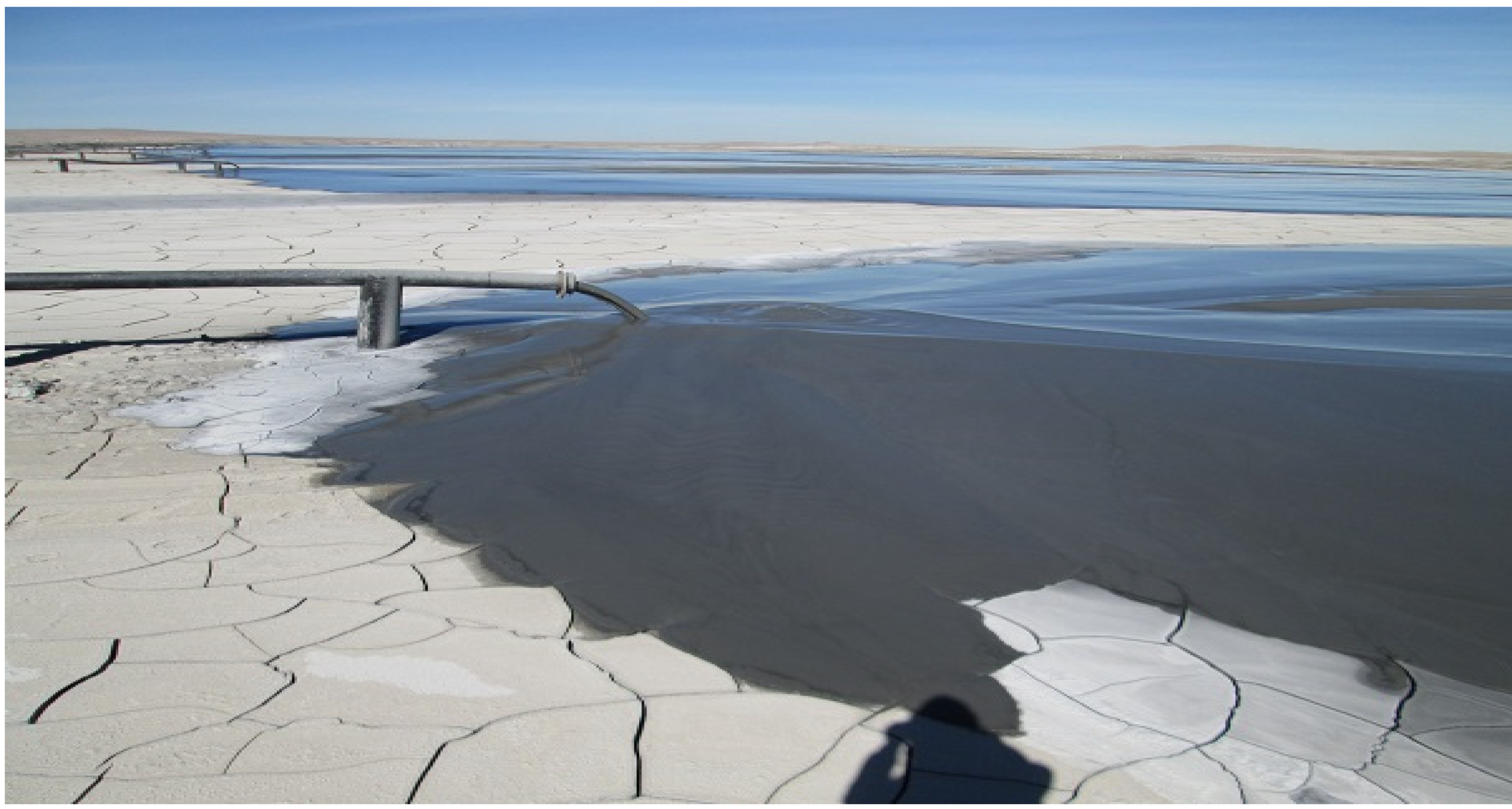

3.2. Water Recovery from Tailings with Thickening Technologies (WRTT)

Thickened Tailings Disposal (TTD) technology (Figure 7) requires more background data than conventional tailings disposal. In the conventional approach, the properties of tailings are fixed by the concentrator plant, whereas in a TTD impoundment, the properties of the tailings and their placement are “engineered” to suit the topography of the disposal area [9]. The behavior of tailings in the two approaches is entirely different. In conventional disposal, tailings segregate as they flow and settle out to an essentially flat deposit, whereas in TTD technology, a sloping surface is obtained. The principal difference is that, in TTD technology, tailings are thickened before discharge to a homogeneous heavy consistency that results in laminar non-segregating flow. In this way, TTD produces high water recovery (80 percent of tailings water recovery) and a self-supporting deposit with sloping sides, requiring small dams [10].

Figure 7. Thickened Tailings Technology—Esperanza TSF Centinela Mine Chile [11].

3.3. Water Recovery from Tailings with Paste Tailings Technologies (WRPTT)

Paste Tailings Technology has been applied at a small production scale because a limitation of equipment manufacturing ability exists. This method permits obtaining medium make-up water requirement. However, in some cases, there are difficulties in tailings transportation requiring the use of positive displacement pumping, resulting in the highest capital/operating costs [9]. The main advantage of this method is that large dams are not required, only small dams are needed (Figure 8).

Figure 8. Paste Tailings Technology—Paste Tailings Demo Plant at Collahuasi Mine Chile [12].

3.4. Water Recovery from Tailings with Filtering Technologies (WRFT)

In the last 20 years, many mining projects around the world have applied a tailings disposal technology called filtered dry stacked tailings (Figure 9). This technique produces an unsaturated cake that allows storage of this material without the need to manage large slurry tailings ponds. The application of this technology has accomplished: (i) an increase of water recovery from tailings (90 percent), (ii) reduction of TSF footprint (impacted areas), (iii) decrease in the risk of physical instability, because TSFs are self-supporting structures under compaction (such as dry stacks), and (iv) a better community perception.

Figure 9. Filtered Tailings Technology—Tailings Filters at Mantos Blancos Mine Chile [11].

The improvements of filtering technologies (pressure and vacuum filtering) in recent years have allowed operational reliability to increase and the development of large capacity filters, reaching in some projects 50,000 metric tonnes per day (mtpd) of filtered tailings [13].

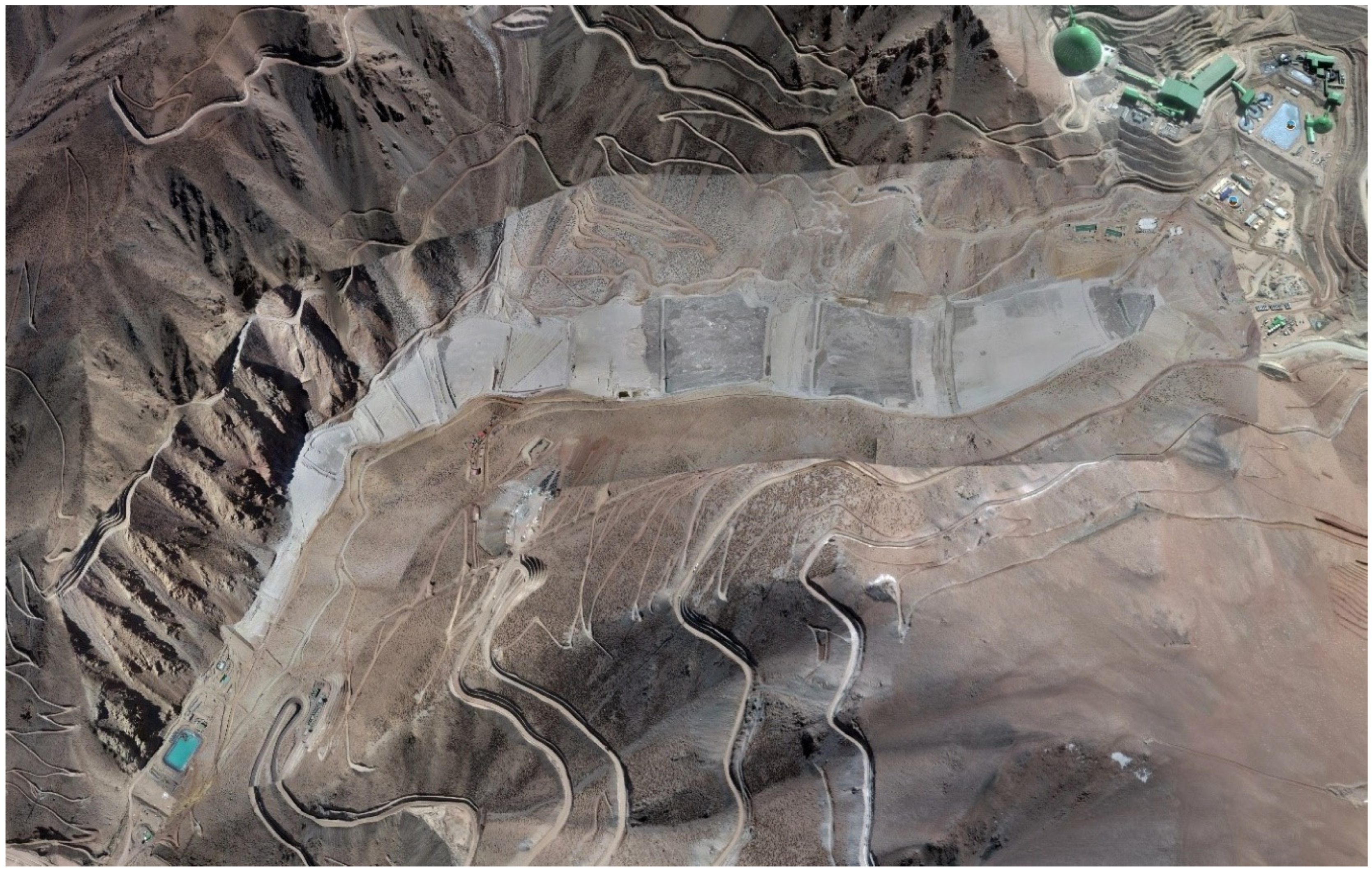

3.5. Water Recovery from Tailings with Hybrid Technologies (WRHT)

The future trend in mining will be the complementary supply of sea water and fresh water, the greater supply being sea water. Along with this, the implementation of dewatering tailings technologies depending on the characteristics of the mineral (grain size, hardness, specific gravity, chemical composition of tailings, etc.), promote a high water recovery. An alternative process to obtain filtered tailings consists of the recovery of the coarse fraction of tailings (cycloned tailings sand) through two cycloning stages, followed by a drainage stage in dewatering vibratory screens to reduce tailings moisture and turn tailings into a paste that can easily be transported to an adjoining dumping facility (Cacciuttolo et al., 2014). On the other hand, the Sand Slimes Split (SSSTT) method is a known tailings technology. SSSTT is a combination of the conventional cyclone tailings classification and thickening, a variant of the construction of a TSF dam using tailings sand. The primary aspect of SSSTT is that the total tailings are separated to produce two streams: (1) “underflow” corresponding to the tailings coarse fraction (sand); and (2) “overflow” corresponding to the fine tailings fraction (slimes). These streams are conveyed to two independent sites: (i) a Sand Stack Facility (SASF) for the coarse fraction of tailings (Figure 10); and (ii) a Slimes Storage Facility (SLSF) for the fine fraction of tailings, which is thickened before depositing (Figure 11). The main benefit of this technology is the increase of the total water recovery by managing different particle size distribution of tailings [14][15][16][17].

Figure 10. Sand Stack TSF (Cycloned Sand Tailings) SSSTT—Caserones Mine, Chile [18].

Figure 11. Slimes Storage Facility (Cycloned Fine Tailings) SSSTT—Caserones Mine, Chile [18].

References

- Barrera, S.; Arredondo, M.; Madariaga, P.; Scognamillo, C. Tailings management a simple way to increase water reclaim. In Proceedings of the 11th International Conference on Tailings and Mine Waste, Vail, CO, USA, 10–13 October 2004; A.A. Balkema: Rotterdam, The Netherlands, 2004; pp. 39–44.

- Cacciuttolo, C.; Scognamillo, C. Improving Water Recovery with Different Tailings Management Technologies. In Proceedings of the 4th International Congress on Water Management in Mining WIM 2014, Viña del Mar, Chile, 10–13 May 2014.

- Wels, C.; MacG, A.R. Water recovery for Pampa Pabellon tailings impoundment, Collahuasi, Chile. In Proceedings of the 11th International Conference on Tailings and Mine Waste, Vail, CO, USA, 10–13 October 2004; A.A. Balkema: Rotterdam, The Netherlands, 2004; pp. 77–88.

- Samad, M.A.; Singh, S. Mine Water Management Strategies in Dry Areas of Chile. In Proceedings of the 1st International Conference on Mine Water Solutions in Extreme Environments, Lima, Peru, 15–17 April 2013.

- Tabra, K.; Lange, S. Active Treatment of Tailings Seepage with Focus on Sulphate and Manganese Removal. In Proceedings of the 2nd International Seminar on Tailings Management TAILINGS 2014, Antofagasta, Chile, 6–8 August 2014.

- Tabra, K.; Gaete, O. Ways to Deal with Mine/Plant Effluent Residues: A roadmap process. In Proceedings of the 142th SME Annual Meeting, Denver, CO, USA, 24–27 February 2013.

- Valenzuela, L. Design, construction, operation and the effect of fines content and permeability on the seismic performance of tailings sand dams in Chile. Obras Y Proy. 2016, 19, 6–22.

- FCX (Freeport McMoran). 2018 Working toward Sustainable Development Report. Available online: https://www.fcx.com/sites/fcx/files/documents/sustainability/wtsd_2018.pdf (accessed on 10 April 2022).

- Schoenbrunn, F. Dewatering to higher densities. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 April 2011; Jewell, R.J., Fourie, A.B., Eds.; ACG: Perth, Australia, 2011; pp. 19–24.

- Robinsky, E.I. Thickened Tailings Disposal in the Mining Industry; E.I. Robinsky Associates Ltd.: Lydia Court, TO, Canada, 1999.

- Ministerio de Minería. Plan Nacional de Depósitos de Relaves para una Minería Sostenible. 2019. Available online: https://www.minmineria.cl/media/2021/05/Plan_Nacional_de_Despositos_de_Relaves_para_una_Mineria_Sostenible_2021.pdf (accessed on 1 April 2022).

- Cacciuttolo, C.; Holgado, A. Management of Paste Tailings in Chile: A Review of Practical Experience and Environmental Acceptance. In Proceedings of the 19th International Seminar on Paste and Thickened Tailings Paste, Santiago, Chile, 3–6 July 2016.

- Cacciuttolo, C.; Barrera, S.; Caldwell, J.; Vargas, W. Filtered Dry Stacked Tailings: Developments and New Trends. In Proceedings of the 2nd International Seminar on Tailings Management, Antofagasta, Chile, 15–17 August 2014.

- Caldwell. Presentation Tailings Facility Failures in 2014 and an Update on Failure Statistics. Available online: https://www.riskope.com/wp-content/uploads/2015/10/Tailings-Facility-Failures-in-2014-and-an-Update-on-Failure-Statistics.pdf (accessed on 5 December 2012).

- Barrera, S.; Riveros, C. Caserones: Option of tailings classifying to improve water reclaim. In Proceedings of the 12th International Seminar on Paste and Thickened Tailings, Viña Del Mar, Chile, 21–24 April 2009.

- Lyell, K.A.; Copeland, A.M.; Blight, G.E. Alternatives to paste disposal with lower water consumption. In Proceedings of the 11th International Seminar on Paste and Thickened Tailings, Kasane, Botswana, 5–8 May 2008; Fourie, A.B., Jewell, R.J., Slatter, P., Paterson, A., Eds.; Australian Center of Geomechanics: Perth, Australia, 2008; pp. 171–178.

- Wels, C.; Caldwell, J. Challenges in tailings water balance analysis—Make-up water, seepage and consolidation. In Proceedings of the 1st Mine Water Solutions in Extreme Environments Conference, Lima, Peru, 15–17 April 2013.

- Consejo Minero. Plataforma Online de Relaves Mineros. Available online: https://consejominero.cl/comunicaciones/plataforma-de-relaves/ (accessed on 2 April 2022).

More

Information

Subjects:

Engineering, Civil

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.9K

Revisions:

2 times

(View History)

Update Date:

16 Jun 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No