Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Lingyu Meng | -- | 2700 | 2022-06-06 09:48:33 | | | |

| 2 | Dean Liu | Meta information modification | 2700 | 2022-06-07 03:05:04 | | | | |

| 3 | Dean Liu | -1 word(s) | 2699 | 2022-06-07 03:05:37 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Meng, L.; , .; See, K.; Zhou, R. Large-Scale Li-Ion Battery in Mining Industry. Encyclopedia. Available online: https://encyclopedia.pub/entry/23738 (accessed on 15 January 2026).

Meng L, , See K, Zhou R. Large-Scale Li-Ion Battery in Mining Industry. Encyclopedia. Available at: https://encyclopedia.pub/entry/23738. Accessed January 15, 2026.

Meng, Lingyu, , K.w. See, Rulin Zhou. "Large-Scale Li-Ion Battery in Mining Industry" Encyclopedia, https://encyclopedia.pub/entry/23738 (accessed January 15, 2026).

Meng, L., , ., See, K., & Zhou, R. (2022, June 06). Large-Scale Li-Ion Battery in Mining Industry. In Encyclopedia. https://encyclopedia.pub/entry/23738

Meng, Lingyu, et al. "Large-Scale Li-Ion Battery in Mining Industry." Encyclopedia. Web. 06 June, 2022.

Copy Citation

The lithium-ion battery (LIB) has the advantages of high energy density, low self-discharge rate, long cycle life, fast charging rate and low maintenance costs. It is one of the most widely used chemical energy storage devices at present. The safety of LIB is the main factor that restricts its commercial scalable application, specifically in hazardous environments such as underground coal mines.

lithium-ion battery

thermal runaway

battery safety

1. Research of Large-Scale LIB in Mining Industry

Table 1 lists the recent progress for large-scale LIB applications in mining industry.

Table 1. Recent progress of large-scale LIB applications in mining industry [1][2][3][4][5][6][7][8].

| Time | Research Group | Contribution |

|---|---|---|

| 1986 | Kuchta, J.M. | Observed the lowest spontaneous combustion temperature of CH4 |

| 2005 | MSHA | The ignition temperature of coal dust cloud is 440 °C to 640 °C |

| 2017 | MPSACC | Studied LIB safety performance requirements, chassis design, body structure, automatic protection and monitoring system, etc. |

| 2018 | MPSACC | Conducted short circuit and overcharge experiments on 60 Ah LFP battery |

| 2020 | CCTEG | Analysis on explosion—proof techniques and standards for lithium—ion battery power supply used in underground coal mine |

| 2020 | NIOSH | Measured TR pressures of LFP cells as a function of free space within sealed enclosures and observed an inverse power relationship. |

| 2021 | Binbin Mao | Conducted 300 Ah large-scale LFP batteries under external heating. TR can be divided to 4 stages. |

| 2022 | CCTEG | Conducted nail penetration test for 202 Ah large-scale battery under encapsulation protection. |

Thomas H. dubaniewicz et al. [5] studied 18,650 and 26,650 cylindrical LIBs, analyzed the morphology and composition of battery anode, cathode and separator with a scanning electron microscope and then sealed LFP units in different free spaces in the ARC device for steady-state heating until battery thermal runaway occurred. Because the safety performance of the LFP battery is better than 18,650 battery and 26,650 batteries, the relationship between the free space and maximum pressure during LFP thermal runaway is studied and fitted by measuring the maximum pressure that the LFP battery can reach. It takes about 34 times the volume of free space of the LFP unit to meet the thresholds of 18,650 and 26,650.

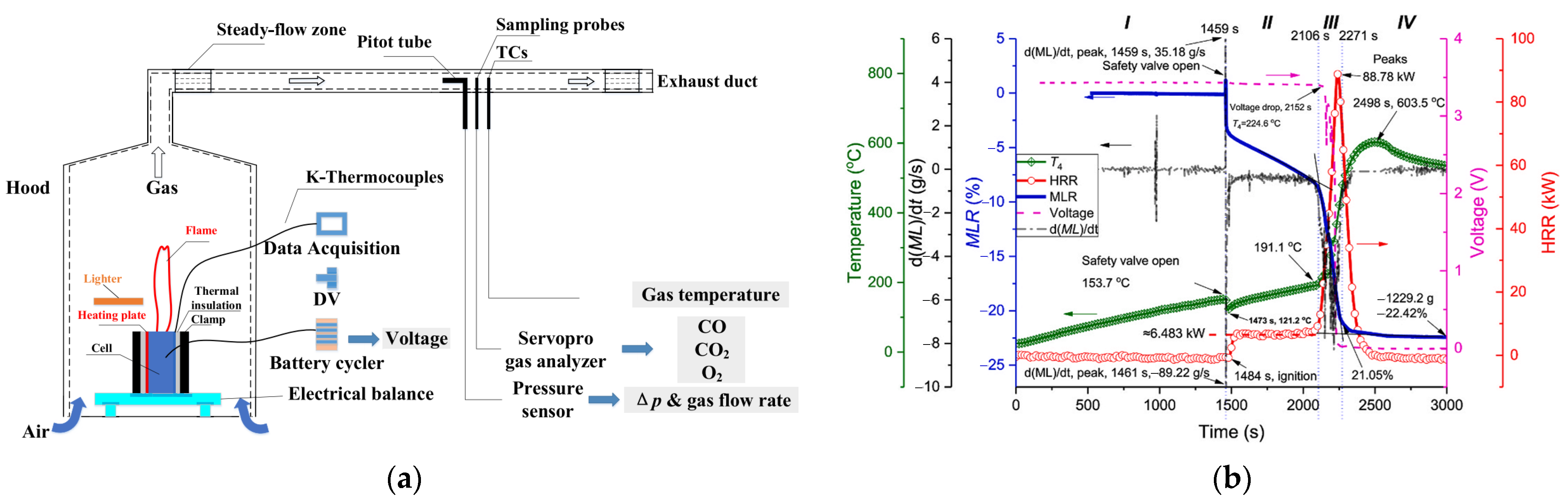

Binbin Mao et al. [7] conducted a series of thermal runaway tests on a 300 Ah large-scale LFP battery under external heating. The experimental rig of LIB combustion tests is shown in Figure 1. Figure 1a presents a combustion chamber (1.8 m × 1.8 m × 2 m) as well as some monitoring apparatuses. Figure 1b shows the gas analysis and exhaust system. After externally heating the battery to thermal runaway, the safety valve opens, and an aggressive cylindrical flame is observed. Four stages were divided during battery external heating processes: (i) Constant heating until the safety valve deformed and swelled; (ii) the safety valve cracked and heat is released; (iii) combustion and aggressive thermal runaway; (iv) abatement and extinguishment. However, the flaming combustion accelerates the occurrence of TR but has little influence on the peak surface temperature.

Figure 1. Active safety protection technology of LIB: (a) Thermal runaway experimental test setup for large-scale LFP battery; (b) stage division of thermal runaway process [7].

Kuchta [2] indicated the lowest spontaneous combustion temperature of CH4 is 600 °C in their experiment, and the ignition temperature of methane in air is 1040 °C. Even if the external heating LFP battery is under thermal runaway, the maximum temperature reached by the battery is 450 °C, which cannot reach the temperature of CH4 detonation. The ignition temperature of coal dust measured by Kuchta ranges from 160 °C to 220 °C. During coal mining or processing, coal dust accumulates into the explosion-proof shell of the battery. MSHA [3] requires that the outer surface temperature of the explosion-proof shell shall not exceed 150 °C. The ignition temperature of the coal dust cloud is 440 °C to 640 °C. If the temperature of gas released by LFP is higher than 440 °C, it is possible to detonate external CH4, resulting in an explosion.

Lei Wo et al. [4] conducted short-circuit and overcharge experiments on a 60 Ah LFP battery and studied the influence of the LFP battery after thermal runaway on a CH4 explosion. The experimental results show that under the condition of an external short circuit, the appearance of the battery is intact, there is no combustion, explosion, leakage and pressure relief and the battery voltage is reduced to 0 V. The battery was seriously damaged after overcharge, and the battery underwent a combustion explosion and pressure relief, but it did not cause a secondary CH4 explosion; however, the internal pressure of the explosion-proof shell reached 4 MPa, exceeding its design pressure. It is verified that the LFP battery will not cause a secondary explosion even under the condition of a high concentration of CH4 after thermal runaway; however, the release of gas could potentially lead to excessive pressure in the explosion-proof shell and further cause catastrophic events. Hence, it is necessary to design a pressure relief technique for the battery enclosure.

Yong Zhang [1] interpreted the LIB vehicle in terms of vehicle operating conditions, LIB safety performance requirements, chassis design, body structure, automatic protection, monitoring system, etc. In terms of battery safety performance, all on-board electrical appliances are required to meet the requirements of the GB 3836 explosive environment [9] series standards: (i) The temperature of the battery surface shall not exceed 150 °C; (ii) the capacity of the LFP battery for mining shall not exceed 100 Ah; (iii) the connection mode of the single battery shall adopt a low-resistance design to avoid heat accumulation; (iv) the LIB shall be placed separately in an explosion-proof chamber with a pressure of 1.5 MPa, and a pressure relief valve shall be installed; (v) the protection grade of the LIB shell shall not be lower than IP55; (vi) when the LIB is fully charged, the braking regenerative energy shall be completely consumed and absorbed by the special device without overcharging the battery pack [10][11].

The authors presented a thorough analysis and experimental results on the effect of encapsulation on the lithium cell that undergoes nail penetration thermal runaway. Regarding the nail penetrating the cell, the rising temperature and voltage profile of the cell’s thermal runaway behavior are shown in Figure 2 [8]. Each battery was installed with 3 sensors, located in the cell’s left wide face, safety valve, and negative terminal respectively, total 30 sensors. Sensor 31, 32 and 33, as shown in Figure 2c, were installed in the upper space enclosure to measure the ambient environment above the encapsulated cells. Note that the instantaneous drop of the cell’s voltage at the onset of thermal runaway shows that the cell short-circuited internally through the nail penetration. Temperature sensors T25, T26 and T27 are recorded for the triggered battery. In Figure 2b, the voltage dropped to 0 within 3 min. The temperature of the safety valve (T26) increased faster than T25 and T27 due to the reaction gasses and electrolyte breaking through the safety valve. The highest temperature of the cell’s wide surface (T25) occurred after 5 min of the triggering, and reaches up to around 490 K. The heat released from the thermal runaway battery dissipated quickly through the heat conduction of the encapsulation and blocked transmission by resin separator. The investigations illustrated that the encapsulated cells have exceptional advantages in providing the required protection to a large number of series-connected battery cells, particularly for a high-capacity cell.

Figure 2. Large-scale LIB pack thermal runaway experiment: (a) Model of encapsulated cell pack in enclosure; (b) experimental measurement of temperature, voltage vs. time; (c) front view of battery pack sensor installation position; (d) top view of battery pack sensor installation position.

The LFP battery has a large thermal stability range and is safer than other types of LIBs in faulty conditions such as short circuits and fire [6]. However, the thermal runaway heat generation of the LFP battery will also cause a sharp increase in temperature and may be accompanied by the release of high-temperature gas. The explosion-proof design must be adopted, and the internal pressure of the explosion-proof container must meet the static pressure of 1 MPa. There are three explosion-proof protection technologies for LIB vehicles: Explosion-proof (Ex’d’), intrinsically safe (‘ia’/’ib’) and encapsulation (Ex ‘ma’/’mb’). At the same time, the increased safety type (Ex ‘e’) or the combination of several protection technologies may also be considered to achieve the required protection level. Table 2 shows the relationship between the protection type and equipment protection level (EPL).

Table 2. Relationship between protection type and equipment protection level.

| EPL | Protection Type | Sign | Group | Standards |

|---|---|---|---|---|

| ‘Ma’ | Intrinsically safe | ‘ia’ | I | GB 3836.4 & IEC 60079.11 |

| Encapsulation | ‘ma’ | I | GB 3836.9 & IEC 60079.18 | |

| Special | ‘s’ | I | GB 3836.24 & IEC 60079.33 | |

| 2 independent EPL Mb | I | GB 3836.23 & IEC 60079.14 | ||

| ‘Mb’ | Intrinsically safe | ‘ib’ | I | GB 3836.4 & IEC 60079.11 |

| Explosion-proof | ‘d’ | I | GB 3836.2 & IEC 60079.1 | |

| Increased safe | ‘e’ | I | GB 3836.3 & IEC 60079.7 | |

| Positive-pressure | ‘p’,‘px’ | I | GB 3836.5 & IEC 60079.2 | |

| Encapsulation | ‘m’,‘mb’ | I | GB 3836.9 & IEC 60079.18 | |

| Sand filling | ‘q’ | I | GB 3836.7 & IEC 60079.5 | |

| Special | ‘s’ | I | GB 3836.24 & IEC 60079.33 |

2. Application of Large-Scale LIB in Mining Industry

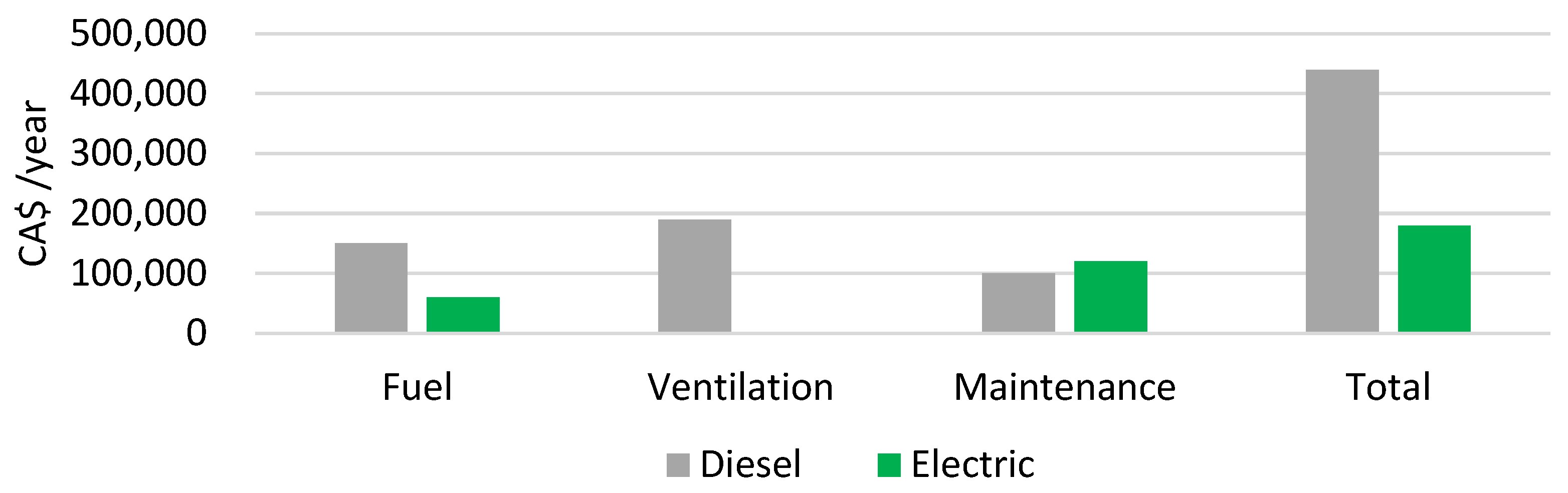

The South African mining health and safety bureau defines engineering mobile machinery for mining operations as “any self-propelled machine used for mining, transportation or related operations underground or on the mine surface, including any mobile device that is driven by wheels, slides, rails, machinery or installed on the machine”. With the progress of battery technology, the trend of replacing diesel-driven trackless vehicles with EVs is becoming more and more prominent. Although EVs are more expensive than gasoline or diesel vehicles and require fixed charging equipment, the working efficiency of the motor is much higher than that of the traditional internal combustion engine, and the braking energy can be recovered. When EVs are implemented in mining projects, their operating costs are much lower than diesel vehicles. Figure 3 compares the operating costs of diesel vehicles and EVs in detail [12].

Figure 3. Cost comparison between diesel vehicle and EV.

In 2019, the carbon emissions of commercial vehicles in Australia accounted for 38% of the total emissions. Commercial vehicles mainly include light commercial trucks, light and medium trucks, waste-disposal vehicles, mining and multipurpose vehicles and customized and special vehicles. Furthermore, 84% of freight vehicles in Australia are light commercial vehicles. The transformation of light and medium fuel vehicles can significantly reduce carbon emissions.

Australia’s mining industry is also prone to using EVs. Replacing heavy mining vehicles and light multipurpose vehicles with EVs brings great benefits to workers and operators in open-pit mines and underground mines. As with all electric vehicles, electric mining vehicles provide quiet and stable driving, can output higher torque and generate less heat. They have irreplaceable advantages under the mining conditions of sharp turns and limited space operation. They are not affected by ventilation and have no quantity restrictions on underground operation. In addition, electric vehicles can carry out regenerative braking in complex terrain, greatly reducing energy waste [13].

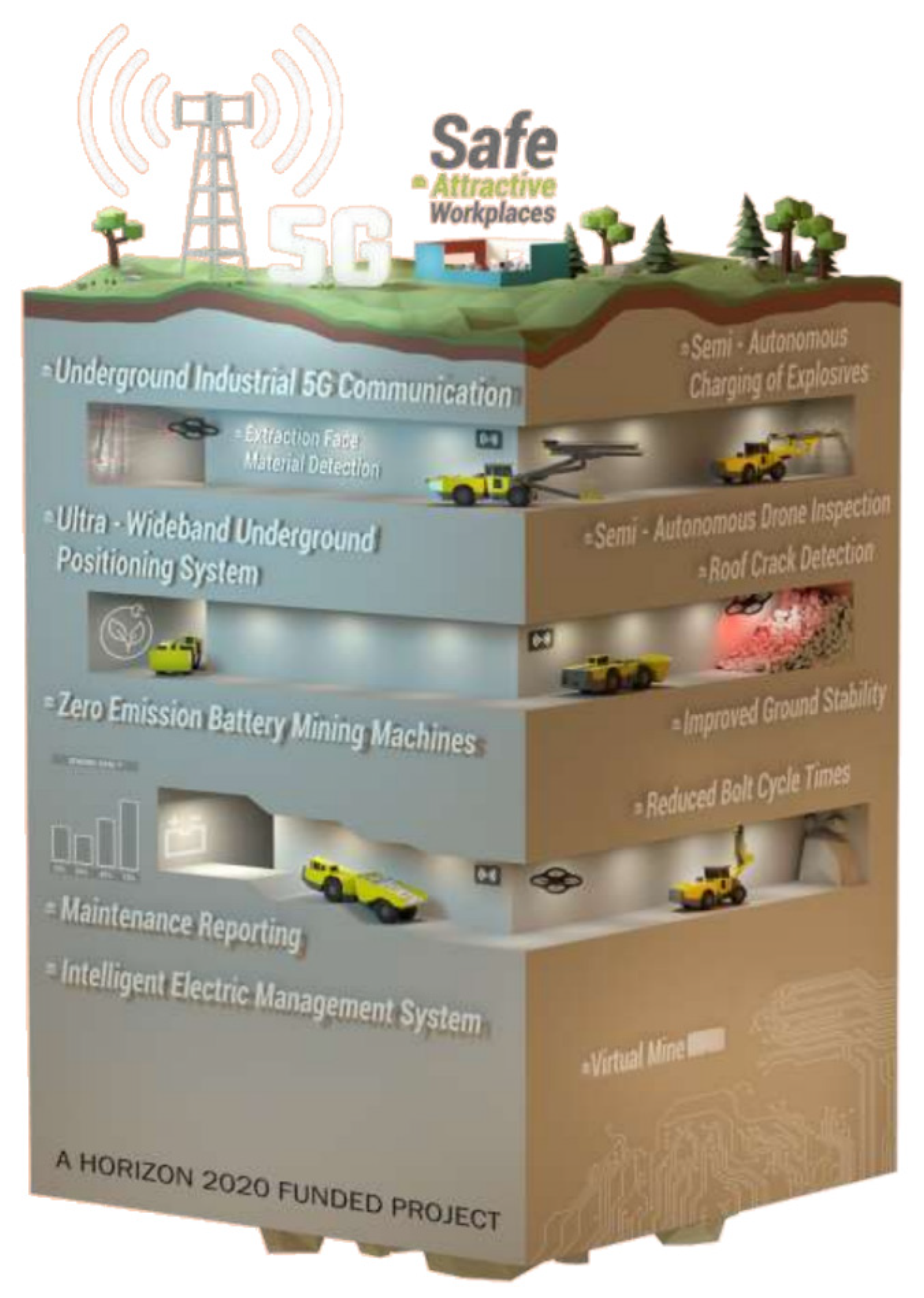

European Sustainable Intelligent Mining Systems for the global mining industry proposes the creation of a digital mine in a three-year plan [12]. With a total investment of nearly US $20 million, the project aims to establish a connected, efficient, safe and attractive workplace, which has been successfully demonstrated in Germany, Poland, Sweden and Finland. The project includes the use of an LIB drilling rig and an auxiliary transportation system to improve the underground air pollution caused by diesel engines, as shown in Figure 4.

Figure 4. European sustainable intelligent mining system.

The global mining guidelines Association (GMG) and the mining Innovation Council of Canada issued proposed methods for EVs in underground mining environments in 2018 [14]. The guide focuses on seven parts, explaining the basic knowledge and application of EVs, mine design, EV design, energy storage system, charging system, operation precautions and performance standards, which provided application guidelines for global mining companies and equipment manufacturers.

The rechargeable LIB in the energy storage system is at the core of the operation of electric vehicles. The battery capacity and energy density determine the operation range of a single charge of EVs. Energy-storage materials with small volume, light weight, high efficiency, low price and high energy density promote the development of the battery industry. These excellent characteristics are more critical in mining, because mining vehicles have a larger volume and weight and higher energy consumption. However, with the increase in the energy density of a single battery, the safety of the battery decreases. GMG proposed three main approaches to battery safety: First, limit the number of active materials to achieve a balance between energy density and safety. Second, add safety mechanisms inside the battery, such as CID, a safety valve, etc. Third, add an electronic guaranteed circuit to the battery pack. The test standards of the energy-storage system have multiple criteria. Table 3 summarizes international standards related to the energy-storage system [14].

Table 3. Test standards for energy-storage systems.

| Recommended Industry Standard | Topic | Citation |

|---|---|---|

| E/ECE/324/Rev.2/Add.99/Rev.2 | Safety requirements of vehicle electric power train | United Nations, 2013 |

| ST/SG/AC.10/11/Rev.5 | Criteria, test methods and procedures for classifying dangerous goods | United Nations, 2019 |

| J2288_200806 | Standardized test method to determine the expected life cycles of BEV battery modules | SAE International, 2008 |

| UL 1642 | Requirements to reduce the risk of and injury from fire or explosion when lithium batteries are used or removed from a product and discarded | UL, 2012b |

| UL 2580 | Evaluates the ability of the electrical energy storage assembly to safely withstand simulated abuse conditions and prevents exposure of persons to hazards as a result of the abuse | UL, 2013 |

| CAN/CSA-E62660-1:15 | Performance and life testing of rechargeable lithium-ion cells for propulsion of BEVs and hybrid electric vehicles | CSA Group, 2015a |

| CAN/CSA-E62660-2:15 | Test procedures to observe the reliability and abuse behavior of rechargeable lithium-ion cells for propulsion of BEVs and hybrid electric vehicles | CSA Group, 2105b |

| IEC 62133–2:2017 | Requirements and tests for safe operation of portable sealed rechargeable lithium cells and LIBs containing non-acid electrolyte | International Electrotechnical Commission, 2017 |

| IEC 61508:2010 | Aspects to be considered when electrical/electronic/programmable electronic systems are used to carry out safety functions | International Electrotechnical Commission, 2010 |

| IEC 62061:2005 (plus amendments) | Requirements and recommendations for the design, integration, and validation of safety-related electronical, electronic and programmable electronic control systems for machines | International Electrotechnical Commission, 2015 |

| US CFR Parts 100–177 | United States Code of Federal Regulations on Transportation | United States Office of the Federal Register, 2012 |

| Canada TDG | Transportation of dangerous goods regulations | Transport Canada, 2016 |

| IMDG 2014,2016 | International Maritime Dangerous Goods Code. IMDG 2014 in force as of January 2016; IMDG 2016 in force as of January 2018 | International Maritime Organization, 2017 |

| IATA Dangerous Goods Regulations | International Air Transport Association Dangerous Goods Regulations | International Air Transport Association, 2018 |

| ISO 14990–1:2016 | General safety requirements for electrical equipment and components incorporated into earth-moving machines as defined in 1506165:2012 | International Organization for Standardization, 2016a |

| ISO 6165:2012 | Terms and definitions and an identification structure for classifying earth-moving machinery | International Organization for Standardization, 2012a |

China’s EV industry has developed rapidly in recent years, with nearly 6 million in use, accounting for more than 50% of the world. The intelligent electrification of vehicles has penetrated the whole auto industry, and the development of EVs can be divided into three stages: (i) From 1995–2000, EVs were mainly used for passenger cars; (ii) from 2001–2020, the number of EV passenger cars, buses and logistics vehicles increased sharply; (iii) after 2020, special EVs will become a new growth engine of the market. Through structural innovation, BYD, an EV company, invented blade batteries, which are designed by skipping the module when they are grouped. Compared with the modular battery pack design, the weight-specific energy density of blade batteries can reach up to 180 Wh/kg. Depending on the particularity of the shape of the blade battery and the stability of the material, the densely arranged blade battery can act as a simple structural part, and the space utilization rate is increased from 40% to 60%. Moreover, the blade battery also improves the disadvantage of the low-temperature resistance of lithium iron phosphate. Even in a severe cold environment of minus 20 degrees, the discharge capacity of the blade battery is at least 90% of that at room temperature. It can still maintain the stability of the battery performance in the low-temperature environment, thus better improving the problem of low-temperature endurance attenuation of the lithium iron phosphate battery [15]. The new battery technology accelerates the development of the EV industry.

In the coming period of time, auxiliary transport vehicles for coal mines will change from diesel engines to electric engines to a large extent. There are 2403 auxiliary transportation vehicles in use in the Shendong Coal Group, including 456 LIB vehicles. Zhongtian Hechuang Energy Co., Ltd. has 218 explosion-proof auxiliary transportation vehicles, including 36 LIB vehicles. It can be seen that LIB vehicles have been preliminarily applied in some companies, and there is a great space for their development in the future.

References

- Zhang, Y. Technical analysis of safety performance for mining flam—Proof trackless vehicles powered by lithium battery. Coal Sci. Technol. 2017, 45, 4.

- Kuchta, J.M. Investigation of Fire and Explosion Accidents in the Chemical, Mining, and Fuel-Related Industries–A Manual; U.S. Department of the Interior, Bureau of Mines: Washington, DC, USA, 1986.

- MSHA. Requirements for explosion testing per 30 CFR, 18.62. In ASTP 2137; U.S. Department of Labor, Mine Safety and Health Administration: Arlington, VA, USA. Available online: https://arlweb.msha.gov/TECHSUPP/ACC/StandardTestProcs/ASTP2137.pdf (accessed on 1 August 2019).

- Wo, L.; Zhang, Y.; He, J. Study on safety of large volume lithium ion battery applied in flameproof enclosure. Coal Sci. Technol. 2018, 46, 145–148.

- Dubaniewicz, T.H.; Zlochower, I.; Barone, T.; Thomas, R.; Yuan, L. Thermal runaway pressures of iron phosphate lithium-ion cells as a function of free space within sealed enclosures. Min. Metall. Explor. 2020, 38, 539–547.

- Liu, J.; Wang, Y.; Xie, B.; Zhao, X.; Zhu, K. Analysis on explosion-proof techniques and standards for lithium-ion battery power supply used in underground coal mine. Coal Sci. Technol. 2020, 48, 203–208.

- Mao, B.; Liu, C.; Yang, K.; Li, S.; Liu, P.; Zhang, M.; Meng, X.; Gao, F.; Duan, Q.; Wang, Q.; et al. Thermal runaway and fire behaviors of a 300 Ah lithium ion battery with LiFePO4 as cathode. Renew. Sustain. Energy Rev. 2021, 139, 110717.

- Meng, L.; See, K.W.; Wang, G.; Wang, Y.; Zhang, Y.; Zang, C.; Xie, B. Explosion-proof lithium-ion battery pack–In-depth investigation and experimental study on the design criteria. Energy 2022, 249, 23715.

- GB 3836; Explosive Atmospheres. Standards Press of China: Beijing, China, 2017.

- Safety Requirements for Mining Lithium ion Battery (Trial); China Mining Products Safety Approval and Certification Center: Beijing, China, 2020.

- Safety Requirements for Mine Flameproof (Intrinsically Safe) Lithium ion Battery Power Supply (Trial); China Mining Products Safety Approval and Certification Center: Beijing, China, 2020.

- Mitchell, P. Will Electrification Spark the Next Wave of Mining Innovation; EY: London, UK, 2019.

- Electric Vehicle Council. State of Electric Vehicles. Available online: https://electricvehiclecouncil.com.au (accessed on 18 April 2022).

- GMG Recomended Practices for Battery Electric Vehicles in Underground Mining—2nd ed. 2020. Available online: https://gmggroup.org/wp-content/uploads/2018/11/20180621_UG_Mining_BEV_GMG-WG-v02-r01.pdf (accessed on 18 April 2022).

- Shang, X.-F.; Cheol, C.M. A study on corporate culture of BYD. Int. J. Adv. Cult. Technol. 2020, 8, 135–140.

More

Information

Subjects:

Mining & Mineral Processing

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.7K

Revisions:

3 times

(View History)

Update Date:

07 Jun 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No