| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Corina Covaci | -- | 1391 | 2022-06-02 11:33:03 | | | |

| 2 | Corina Covaci | + 431 word(s) | 1822 | 2022-06-06 07:43:14 | | | | |

| 3 | Vivi Li | -652 word(s) | 1170 | 2022-06-06 09:41:10 | | |

Video Upload Options

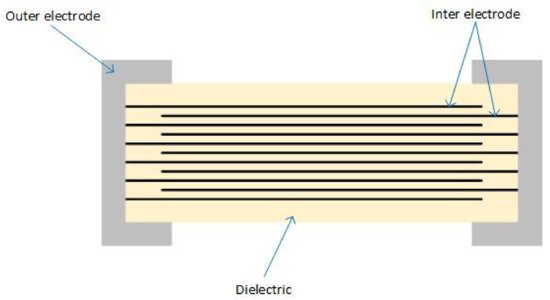

Multilayer Ceramic Capacitors (MLCC) have a major role in modern electronic devices due to their small price and size, large range of capacitance, small ESL and ESR, and good frequency response. Unfortunately, the main dielectric material used for MLCCs, Barium Titanate, makes the capacitors vibrate due to the piezoelectric and electrostrictive effects. This vibration is transferred to the PCB, making it resonate in the audible range of 20 Hz–20 kHz, and in this way the singing capacitors phenomenon occurs. This phenomenon is usually measured with a microphone, to measure the sound pressure level, or with a Laser Doppler Vibrometer (LDV), to measure the vibration. Besides this, other methods are mentioned in the literature, for example, the optical fiber and the active excitation method. There are several solutions to attenuate or even eliminate the acoustic noise caused by MLCC. Specially designed capacitors for low acoustic levels and different layout geometries are only two options found in the literature. To prevent the singing capacitor phenomenon, different simulations can be performed, the harmonic analysis being the most popular technique.

1. Introduction

-

the MLCC itself—the capacitor acts as an excitation source;

-

the mounting situation—the solder joint is the vibration transfer path;

-

the PCB—the board is the acoustic noise resonator.

2. The Acoustic Noise Caused by MLCCs

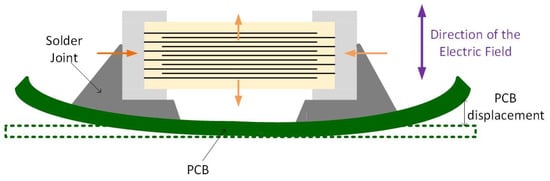

Due to the piezoelectric and electrostrictive effects of BaTiO3, the MLCCs’ inter electrodes vibrate, causing a chain reaction. The vibration is transferred from the inter electrodes to the capacitor terminals, from the terminals to the solder joint, and finally from the solder joint to the PCB, causing the singing capacitor phenomenon. Therefore, to eliminate the audible noise caused by MLCC, researchers must interrupt the vibration transfer.

The first solution would be to use capacitors with a low dielectric constant. These capacitors would solve the singing capacitor phenomenon from the root cause.

For the vibration transfer from MLCC to the solder joint, many alternatives are available. The component suppliers offer low acoustic noise capacitors, such as metal terminals or metal plate capacitors, interposer or alumina substrate MLCCs, thicker dielectric layer capacitors, and dipped radial leads capacitors. The most effective commercial solution is the metal terminal capacitor, which attenuates the noise by 25 dB. Some authors suggest increasing the cover layer thickness to reduce the transmitted vibration.

For the vibration transfer to the PCB, some authors suggested decreasing the solder joint. Unfortunately, to date, this has not been demonstrated to be efficient. Other authors suggested placing the MLCC in a vertical orientation on PCB to increase the resonating frequency. Of course, the layout geometry has a big impact on the PCB acoustic noise. The mirror or back-to-back configuration is considered the best solution in the literature.

As mentioned before, it is better to prevent than to correct. By simulating the design, researchers can avoid the apparition of the singing capacitor phenomenon. To simulate the acoustic behavior, researchers need a harmonic analysis. The simulation is more precise if researchers also implement a statistical simulation and a parameter sensitivity analysis. Some authors recommend a three-dimensional FEM simulation and a vibration analysis [17].

The two most popular methods found in the literature to measure the acoustic noise caused by MLCCs are SPL measurement and LDV measurement. These two can be correlated with a linear equation. Other methods to investigate the singing capacitor phenomenon are the optical sensor fiber, piezoelectric accelerometer, active excitation method, and vibration and rail voltage coherence method.

In conclusion, the acoustic noise caused by MLCCs is a current problem in modern electronic systems. Therefore, the interest in this issue is high among the experts who study electronics in specialized literature. Unfortunately, the solution for this phenomenon is not straightforward due to the design-oriented behavior of the MLCCs.

References

- Kim, D.; Kim, W.; Kim, W.-C. Dynamic Analysis of Multilayer Ceramic Capacitor for Vibration Reduction of Printed Circuit Board. J. Mech. Sci. Technol. 2019, 33, 1595–1601.

- Ko, B.-H.; Park, H.-G.; Kim, D.; Park, N.-C.; Park, Y.-P. Reduction of Multilayer Ceramic Capacitor Vibration by Changing the Cover Thickness. Microsyst. Technol. 2016, 22, 1375–1380.

- Johnson, W.L.; Kim, S.A.; Quinn, T.P.; White, G.S. Nonlinear Acoustic Effects in Multilayer Ceramic Capacitors. AIP Conf. Proc. 2013, 1511, 1462–1469.

- Lu, T.; Ding, M.; Wu, K. Simulation and Characterization of Singing Capacitors in Consumer Electronics. In Proceedings of the 2019 IEEE International Symposium on Electromagnetic Compatibility, Signal & Power Integrity (EMC+SIPI), New Orleans, LA, USA, 22–26 July 2019; pp. 522–526.

- Yu, D.; Dai, K.; Zhang, J.; Yang, B.; Zhang, H.; Ma, S. Failure Mechanism of Multilayer Ceramic Capacitors under Transient High Impact. Appl. Sci. 2020, 10, 8435.

- Wang, Y.-Q.; Ko, B.-H.; Jeong, S.-G.; Park, K.-S.; Park, N.-C.; Park, Y.-P. Analysis of the Influence of Soldering Parameters on Multi-Layer Ceramic Capacitor Vibration. Microsyst. Technol. 2015, 21, 2565–2571.

- Ko, B.-H.; Jeong, S.-G.; Ahn, Y.-G.; Park, K.-S.; Park, N.-C.; Park, Y.-P. Analysis of the Correlation between Acoustic Noise and Vibration Generated by a Multi-Layer Ceramic Capacitor. Microsyst. Technol. 2014, 20, 1671–1677.

- Ko, B.; Jeong, S.; Kim, D.; Park, N. Identification of the Electromechanical Material Properties of a Multilayer Ceramic Capacitor. Int. J. Appl. Ceram. Technol. 2017, 14, 424–432.

- Sun, Y.; Zhang, J.; Yang, Z.; Hwang, C.; Wu, S. Measurement Investigation on Acoustic Noise Caused by “Singing” Capacitors on Mobile Devices. In Proceedings of the 2019 IEEE International Symposium on Electromagnetic Compatibility, Signal & Power Integrity (EMC+SIPI), New Orleans, LA, USA, 22–26 July 2019; pp. 505–510.

- Sun, Y.; Wu, S.; Zhang, J.; Hwang, C.; Yang, Z. Measurement Methodologies for Acoustic Noise Induced by Multilayer Ceramic Capacitors of Power Distribution Network in Mobile Systems. IEEE Trans. Electromagn. Compat. 2020, 62, 1515–1523.

- Kim, H.; Kim, D.; Park, N.-C.; Park, Y.-P. Acoustic Noise and Vibration Analysis of Solid State Drive Induced by Multi-Layer Ceramic Capacitors. Microelectron. Reliab. 2018, 83, 136–145.

- Margielewicz, J.; Gąska, D.; Litak, G.; Wolszczak, P.; Trigona, C. Nonlinear Dynamics of a Star-Shaped Structure and Variable Configuration of Elastic Elements for Energy Harvesting Applications. Sensors 2022, 22, 2518.

- Ko, B.-H.; Kim, D.; Park, N.-C.; Park, Y.-P. Study on Effective Piezoelectric Coefficient for Finite Element Analysis of Multi-Layer Ceramic Capacitor. In Proceedings of the 2015 Joint IEEE International Symposium on the Applications of Ferroelectric (ISAF), International Symposium on Integrated Functionalities (ISIF), and Piezoelectric Force Microscopy Workshop (PFM), Singapore, 24–27 May 2015; pp. 64–66.

- Jia, Y.; Luo, H.; Zhao, X.; Wang, F. Giant Magnetoelectric Response from a Piezoelectric/Magnetostrictive Laminated Composite Combined with a Piezoelectric Transformer. Adv. Mater. 2008, 20, 4776–4779.

- Wu, Z.; Xiang, Z.; Jia, Y.; Zhang, Y.; Luo, H. Electrical Impedance Dependence on the Direct and Converse Magnetoelectric Resonances in Magnetostrictive/Piezoelectric Laminated Composites. J. Appl. Phys. 2012, 112, 106102.

- Kim, D.; Park, N.-C.; Park, Y.-P. Analysis of High-Pitched Noise from Solid-State Drives Generated by Multilayer Ceramic Capacitors. Microsyst. Technol. 2016, 22, 1367–1374.

- Yang, H.; Wang, B.; Grigg, S.; Zhu, L.; Liu, D.; Marks, R. Acoustic Emission Source Location Using Finite Element Generated Delta-T Mapping. Sensors 2022, 22, 2493.