Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Alexandra Kaas | -- | 1919 | 2022-04-25 09:32:08 | | | |

| 2 | Conner Chen | -6 word(s) | 1913 | 2022-04-27 08:49:56 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kaas, A.; Mütze, T.; Peuker, U. Design and Operation Mode of Zigzag Air Classifier. Encyclopedia. Available online: https://encyclopedia.pub/entry/22225 (accessed on 07 February 2026).

Kaas A, Mütze T, Peuker U. Design and Operation Mode of Zigzag Air Classifier. Encyclopedia. Available at: https://encyclopedia.pub/entry/22225. Accessed February 07, 2026.

Kaas, Alexandra, Thomas Mütze, Urs Peuker. "Design and Operation Mode of Zigzag Air Classifier" Encyclopedia, https://encyclopedia.pub/entry/22225 (accessed February 07, 2026).

Kaas, A., Mütze, T., & Peuker, U. (2022, April 25). Design and Operation Mode of Zigzag Air Classifier. In Encyclopedia. https://encyclopedia.pub/entry/22225

Kaas, Alexandra, et al. "Design and Operation Mode of Zigzag Air Classifier." Encyclopedia. Web. 25 April, 2022.

Copy Citation

The zigzag (ZZ) classifier is a sorting and classification device with a wide range of applications (e.g. recycling, food industry). Due to the possible variation of geometry and process settings, the apparatus is used for various windows of operation due to the specifications of the separation (e.g. cut sizes from 100 µm to several decimetres, compact and fluffy materials as well as foils).

zigzag

classifier

separation

recycling

1. General Design

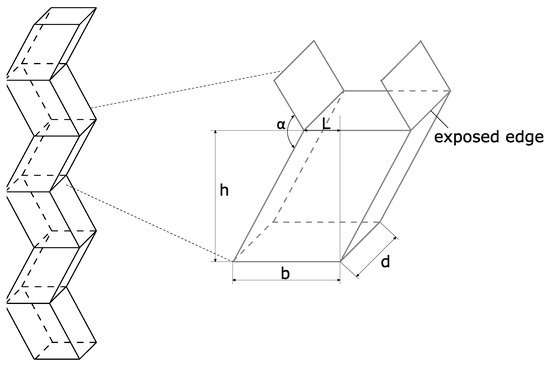

The main component of a ZZ-classifier is a characteristic, segmented channel. The ZZ classifier was first mentioned by Stebbins in 1932 in a patent (A.H: Stebbins: US Patent 1861248) [1]. Figure 1 illustrates a typical zigzag channel with its characteristic geometric parameters height (h), width (b), depth (d), horizontal distance (L) of the exposed edges, and step angle (α). Different geometries are documented for industry and research. In industry, a stage has an angle of 120°. Companies like JÖST [2], Trennso [3], Hosakawa Alpine [4], Hamatec [5], and RecyclingWorld [6] offer ZZ with this geometry. However, the other geometric parameters vary depending on the manufacturer. Although the distance between the exposed edges of the channel (see Fig 1) usually differs, most of the ZZ classifiers offered tend to have a distance greater than L > 0. Alternatively, the edges lie directly on top of each other (L ≈ 0). Overlapping classifier edges (L < 0) are rare and can be found only in special applications [7]. Decisive for the throughput are the dimensions of the cross-section (b/d) which is usually scaled to the channel depth d. In industry, a ratio b/d of less than or equal to 1 is usually used. For higher mass throughputs, smaller ratios are also used [8].

Figure 1. Structure and geometric parameters of a zigzag channel.

2. Mode of Operation

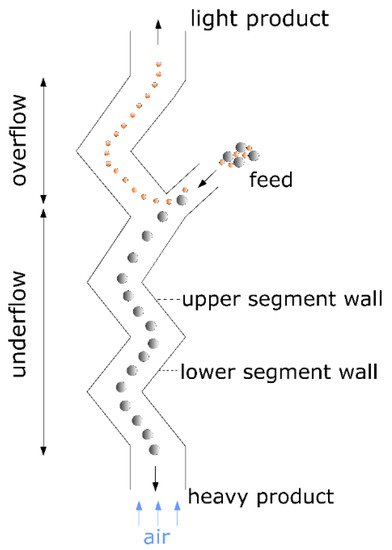

As shown in Figure 2, a mixed feed material is fed into the ZZ channel [9]. On the one hand, heavy, dense and/or compact particles will fall down the channel in the direction of the heavy product outlet. On the other one, fine, light and/or non-compact particles are carried upwards by the air flow in the direction of the light product outlet. Therefore regarding the product outlets, the classifier is considered a counter-flow classifier [10].

Figure 2. Characteristic terms for ZZ classifiers.

Due to the characteristic form of the ZZ channel, the particles oriented to heavy product outlet will hit the lower segment wall and either rebound and continue falling or start sliding down the wall. At the edge of each segment, those particle trajectories cross the fluid flow. Therefore, the ZZ classifiers are also referred to as cross-flow separators in the other literature At each edge of the ZZ classifier, the particles are fluidised on their way to one of the product outlets, where, the particles are fluidized again and separated according to their size, shape and density. This offers the distinct advantage over upstream classifiers with straight channel geometries since the ZZ channels aligns several separating units in series increasing the total separation efficiency of the apparatus [11].

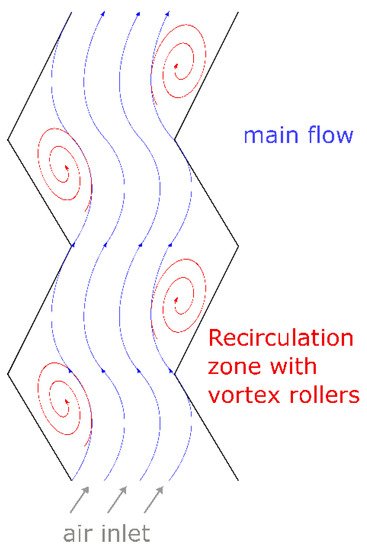

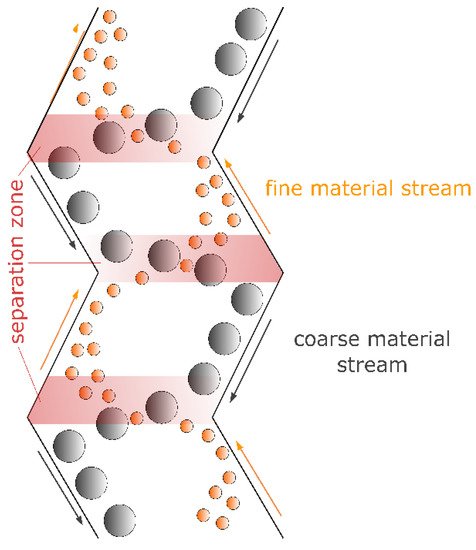

Another feature of the ZZ geometry are the "vortex rolls" [12], which occur in the convex parts of the segments [9][13]. These vortex rolls (Figure 3) generate the so-called recirculation zones where the air flow detaches from the lower channel wall behind an edge [14]. As a result, the “main flow” (Figure 3) has the highest air velocities [15][16][17] and vortices form between the wall and main flow [10]. As described above, particulate material is not lifted in this recirculation zone by a directed air flow butcontinues to move downwards, e.g. by sliding down the lower wall due to gravity (Figure 4). Material close to the separation criteria (e.g. cut size) will be recirculated repeatedly in vortex roll the until it is randomly discharged in one of the products [10].

Figure 3. Flow regime in the ZZ.

Figure 4. Solids flows and separation zones in the ZZ.

In addition to separation, the vortices can cause deagglomeration from being supported by wall friction and impact forces through the interaction of particles with the wall [21]. All those deagglomerating effects contribute to the comparatively high separation efficiency of ZZ classifiers [10]. In addition, the separation efficiency increases by increasing the number of stages, i.e., the number of fluidisation events in the apparatus.

An air cyclone has to be installed next to the ZZ channel in order to remove the light product from the air flow [7]. The cut sizes of ZZclassifiers amount to 0.1–10 mm [9][12] depending on the particle density and shape. The specific throughput is typically between 5 and 15 t/(m2 h) [15][16]. The throughput can be easily increased by operating several classifiers in parallel [22][23].

Moreover, there are other factors that influence the separation mechanism (cut size, selectivity) and thus the quality of the separation. Flow fields and therefore process performance in air classifiers are usually significantly influenced by secondary flows. These are caused by walls bounding the separation zone [10]. The secondary effects include particle rotation as well as oscillating of particles, especially for flat particles tumbling [18]. Besides, interactions of particles with each other or between particles and the wall influence the process, of which collisions, friction, sticking and vicinity effects are examples. But particle-airflow interactions also influence the process result [9]. For example, excessive loading of the gas flow can lead to swarm effects [24].

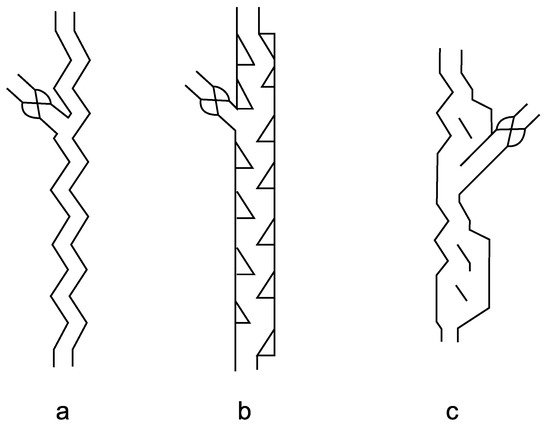

Over the years, different variations of the geometry were developed, which were supposed to circumvent the influences mentioned by the geometry in the best possible way. However, the variations shown below could only be used for special cases and are not state of the art today. The Duke and Utah channels (Figure 5) were developed and are mainly used in the USA [8]. The Utah throat attempts to increase the intensity of the eddies through its geometry and thus supports deagglomeration. The Duke throat attempts to solve the problem of reagglomeration that occurs with the conventional and Utah designs. This is achieved by providing a clear path for the rising material and a separate chute for the descending material. Furthermore, additional air supply stages as well as variants for the production of more than two products have been developed [9]. In addition, chutes with a circular cross-section are also possible, as are variations of the chute using flattened corners and baffles. Moreover, the design of the air inlet influences the flow regime at the bottom of the ZZ channel promoting back-mixing effects and thus reducing the separation efficiency [18]. The design of the air outlet at the upper part of the ZZ channel influences the particle removal rate due to exit effects of the air flow. When the channel narrows, the flow accelerates, resulting in a faster discharge of particles [18].

Figure 5. Variation of ZZ classifier geometry: (a) zigzag (b) Utah (c) Duke.

3. Advantages and Disadvantages of the Classifier Concept

The ZZ classifier is mainly used as a sorting but sometimes also as classifying device, mainly because of its simple design, low CAPEX and OPEX as well as good separation characteristics [7]. As already mentioned, the channel geometry offers a sufficient variability (e.g. channel depth or stage angle) to adapt the device to specific conditions or material properties [9]. Furthermore, the classifier offers a multi-stage separation in a single channel with one single air stream [18]. Due to the repetitive sorting of rising and descending particles, the particles undergo repetitive individual sorting stages [18]. This cascade of sorting zones results in the high separation efficiency of the classifier, which is κ = 0.59–0.8 [10][11][12][25][26]. In addition, it is possible to cover a wide range of cut sizes going from ten to microns and a broad range of particle density and shape for sorting [15].

However, disadvantages of the ZZ classifier are problems with inhomogeneous feed materials. Variations of size, shape, and density can cause segregation and funnel flow in the feed hopper [16][17] decreasing the separation efficiency due to fluctuating feed compositions. Unknown dynamics during the process can lead to insufficient reliability of ZZ operation [15][27]. In addition, particle interactions contribute to reduce the efficiency in separation [27]. Increasing the number of stages has a positive effect on the separation efficiency. However, it also increases the height of the apparatus as well as the pressure drop [24] and energy consumption [15][17][28]. High settling velocities of individual particles cause additional complications, as high air velocities are required for separation. These lie in the highly turbulent flow regime, whereby turbulent remixing negatively influences the sorting result [27].

According to Senden [18], a negative influence also arises from the geometry of the duct in general. The resulting turbulence leads to back-mixing in several parts of the apparatus and additionally to stochastic disturbances such as particle wall and particle particle interactions. Since there is no defined directional movement of the particles, it is difficult to predict the individual particle behaviour and thus the separation result only on the basis of the particle properties. In addition, the repeated crossing of air flow and uplifted particles with the trajectories of larger and/or heavier particles causes mixing and thus decreases the separation efficiency [24].

4. Fields of Application

The ZZ classifier is mainly used in the field of recycling of solid waste materials. This can be explained by the already mentioned high selectivity in a wide range of sizes and densities as well as the advantageous dispersion of material in the process chamber. A ZZ classifier is usually operated at feed rates of 5–15 t/m2h [26]. In addition, a solid to air ratio of up to 2 kg/m3 can still lead to stable separation at a separation efficiency of 0.8 [7]. Air velocity of 2 m/s is industrially considered the lower limit, industrially, whereas 1 m/s is the lower limit of laboratory applications [7].

The ZZ classifier can be used for classification (e.g. classification of choppy, fibrous and flat material) and sorting of primary and secondary raw materials [9], especially in the tobacco and tea industry, where the device is used to separate stalks and leaves [26]. In addition, vegetables are separated from grains, husks and shells or stones [26][29]. Furthermore the ZZ classifier is applied during the processing of spices and herbs as well as in the textile industry for the separation of fibres and finished textiles [22].

Another major field of application is the processing of municipal and industrial solid waste [1][18][30][31][32][33][34]. Here, ZZ classifiers have been established for composting plants and separating foils [35] and harder materials such as glass, stones, and metal pieces from compostable material [36][37]. In the recycling of building materials, impurities such as paper, plastics, foils and wood chips [38][39][40] are separated from mineral constituents. Also, the recycling and purification of thermal insulation systems (mainly polystyrene) [41] and thermoset composites is a common application [42].

Another field of application is the processing of electronic scrap [36][43]. For example, copper wires are separated from the insulation in cable recycling [14][22][26][43]. Plastics, wood, fibres, glass, and rubber [14][43] are separated from metal scrap (e.g. in recycling of fridges). And in the recycling of printed circuit boards, fine metallic and non-metallic particles are separated [44][45][46][47]. The ZZ classifier is also used in car recycling producing the so-called shredder light fraction [43][48][49], which is a mixture of chopped light polymeric materials.

In general, in plastics recycling, metal is sorted from plastics and different types of plastics can be separated. The ZZ is also used for the recycling of PET bottles [50], or bottle capsules [51], as well as for dedusting plastic granulate [26]. Although more than 100 years old, latest studies show that the ZZ classifier is still up to date and will be a solid pillar for future recycling topics, e.g. the recycling of electric vehicles components. One example in this field is the recycling of lithium-ion batteries [52][53]. Here, the ZZ was already used in several pilot studies for the separation of current collector foils from cell housing and separator foils [54][55][56].

References

- Technik der Gas/Feststoff-Strömung: Sichten, Abscheiden, Fördern, Wirbelschichten. In Proceedings of the Technik der Gas/Feststoffströmung—Sichten, Abscheiden, Fördern, Wirbelschichten, Köln, Germany, 2–3 December 1986; Available online: http://www.gbv.de/dms/tib-ub-hannover/016765354.pdf (accessed on 28 January 2022).

- JÖST. Available online: https://www.joest.com/ (accessed on 28 January 2022).

- Trennso. Available online: https://www.tst.de/ (accessed on 28 January 2022).

- Hosakawa Alpine. Available online: https://www.hosokawa-alpine.de/mechanische-verfahrenstechnik/ (accessed on 28 January 2022).

- Hamatec. Available online: https://www.hamatec.de/ (accessed on 28 January 2022).

- Recycling World GmbH. Available online: https://www.recyclingworld.ch/ (accessed on 28 January 2022).

- Schwechten, D.; Straetmans, K. A New Type of Zig-Zag Classifier for Dedusting, Separation and Sorting in the Fines Range. Aufbereitungstechnik 2003, 44, 43–44.

- Bartscher, S. Numerische und Experimentelle Untersuchung des Sortiervorgangs im Zick-Zack-Sichter; Schriftenreihe zur Aufbereitung und Veredlung; Shaker Verlag: Düren, Germany, 2019.

- Kaiser, F. Der Zickzack-Sichter-ein Windsichter nach neuem Prinzip. Chem. Ing. Tech. 1963, 35, 273–282.

- Leschonski, K. Probleme der Strömungstrennverfahren, dargestellt am Beispiel der Windsichtung. Aufbereitungstechnik 1972, 12, 751–759.

- Rumpf, H.; Leschonski, K. Prinzipien und neuere Verfahren der Windsichtung. Chem. Ing. Tech. 1967, 39, 1231–1241.

- Schubert, H. Aufbereitung Mineralischer Rohstoffe, 4th ed.; VEB Deutscher Verlag für Grundstoffindustrie: Leipzig, Germany, 1989.

- Fastov, B.; Valuiskii, P.F.; Lebedev, V.N.; Oskalenko, G.N. Testing of the zigzag classifier for granulated materials. Chem. Pet. Eng. 1975, 11, 477–479.

- Böhme, S. Zur Stromtrennung Zerkleinerter Metallischer Sekundärrohstoffe, in Freiberger Forschungsheft; Deutscher Verlag für Grundstoffindustrie: Leipzig, Germany, 1989.

- Lukas, E.; Roloff, C.; Mann, H.; Kerst, K.; Hagemeier, T.; van Wachem, B.; Thévenin, D.; Tomas, J. Experimental Study and Modelling of Particle Behaviour in a Multi-Stage Zigzag Air Classifier, in Dynamic Flowsheet Simulation of Solids Processes; Springer: Berlin/Heidelberg, Germany, 2020; pp. 391–410.

- Hagemeier, T.; Glöckner, H.; Roloff, C.; Thévenin, D.; Tomas, J. Simulation of Multi-Stage Particle Classification in a Zigzag Apparatus. Chem. Eng. Technol. 2014, 37, 879–887.

- Gloeckner, H.; Hagemeier, T.; Roloff, C.; Thévenin, D.; Tomas, J. Experimental investigation on the multistage particle classification in a zigzag air classifier. In Proceedings of the World Congress on Engineering, London, UK, 2–4 July 2014.

- Senden, M.M.G. Stochastic models for individual particle behavior in straight and zig zag air classifiers. PhD Thesis, Technical University Eindhoven, Eindhoven, The Netherlands, 30 March 1979.

- Friedrichs, J.; Tomas, J. Aerosortierung von Bauschutt. Arb. -Und Ergeb. Des Sonderforschungsbereiches 1996, 385, 197–250.

- Mann, H. Experimentelle Untersuchung, Modellierung und Dynamische Simulation der Mehrstufigen Turbulenten Partikel-Querstromklassierung. Ph.D. Thesis, Otto-von-Guericke-Universität Magdeburg, Magdeburg, Germany, 2016.

- Sweeney, P. An Investigation of the Effects of Density, Size and Shape upon the Air Classification of Municipal Type Solid Waste; Final report; Civil and Environmental Engineering Development Office: Tyndall, FL, USA, 1977.

- Stieß, M. Mechanische Verfahrenstechnik-Partikeltechnologie 1; Springer-Verlag: Berlin/Heidelberg, Germany, 2008.

- Mann, H.; Roloff, C.; Hagemeier, T.; Thévenin, D.; Tomas, J. Model-based experimental data evaluation of separation efficiency of multistage coarse particle classification in a zigzag apparatus. Powder Technol. 2017, 313, 145–160.

- Shapiro, M.; Galperin, V. Air classification of solid particles: A review. Chem. Eng. Processing Process Intensif. 2005, 44, 279–285.

- Bernotat, S. Stand der Sichtertechnik―Sichter fur Massenguter. ZKG Int. 1990, 43, 81–90.

- Furchner, B.; Zampini, S. Air Classifiying. Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2012; p. 215.

- Biddulph, M.W. Design of vertical air classifiers for municipal solid waste. Can. J. Chem. Eng. 1987, 65, 571–580.

- Schubert, H. Handbuch der Mechanischen Verfahrenstechnik; John Wiley & Sons: Hoboken, NJ, USA, 2012.

- Lewis, M. Solids separation processes. Sep. Processes Food Biotechnol. Ind. Princ. Appl. 1996, 27, 243.

- Alter, H.; Natof, S.L.; Woodruff, K.L.; Freyberger, W.L.; Michaels, E.L. Classification and concentration of municipal solid waste. In Proceedings of the Fourth Mineral WasteUtilization Symposium, Chicago, IL, USA, 13–14 April 1974.

- Howell, S.G. A ten year review of plastics recycling. J. Hazard. Mater. 1992, 29, 143–164.

- Colon, F. Recycling of paper. Conserv. Recycl. 1976, 1, 129–136.

- Everett, J.W.; Peirce, J.J. The development of pulsed flow air classification theory and design for municipal solid waste processing. Resour. Conserv. Recycl. 1990, 4, 185–202.

- Vesilind, P.A.; Henrikson, R.A. Effect of feed rate on air classifier performance. Resour. Conserv. 1981, 6, 211–221.

- Peirce, J.J.; Wittenberg, N. Zigzag configurations and air classifier performance. J. Energy Eng. 1984, 110, 36–48.

- Bilitewski, B.; Bilitewski, B.; Gewiese, A.; Härdtle, G.; Marek, K. Vermeidung und Verwertung von Reststoffen in der Bauwirtschaft. Beih. Zu Müll Und Abfall 1995, 30, 40–63.

- Görner, K. Abfallwirtschaft und Bodenschutz: Mit 171 Tabellen; VDI-Buch, Görner, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2002.

- Tomas, J. Gravity separation of particulate solids in turbulent fluid flow. Part. Sci. Technol. 2004, 22, 169–187.

- Tomas, J.; Gröger, T.; Küchler, C.; Friedrichs, J. Abtrennen von Wertstoffen aus Bauschutt. Chem. Ing. Tech. 1999, 71, 637–642.

- Tomas, J.; Gröger, T. Mehrstufige turbulente Aerosortierung von Bauschutt. Aufbereit.-Tech. 1999, 40, 379–386.

- Heller, N.; Flamme, S. Entwicklung und Modellierung von Entsorgungswegen für WDVS-Abfälle. In Mineralische Nebenprodukte und Abfälle 4: Flaschen, Schlacken, Stäube und Baurestmassen; TK-Verlag: Neuruppin, Germany, 2017.

- Palmer, J.; Ghita, O.; Savage, L.; Evans, K. Successful closed-loop recycling of thermoset composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 490–498.

- Martens, H.; Goldmann, D. Recyclingtechnik; Springer: Berlin/Heidelberg, Germany, 2011.

- Kumar, V.; Lee, J.-C.; Jeong, J.; Jha, M.K.; Kim, B.-S.; Singh, R. Recycling of printed circuit boards (PCBs) to generate enriched rare metal concentrate. J. Ind. Eng. Chem. 2015, 21, 805–813.

- Kumar, V.; Lee, J.-C.; Jeong, J.; Jha, M.K.; Kim, B.-S.; Singh, R. Novel physical separation process for eco-friendly recycling of rare and valuable metals from end-of-life DVD-PCBs. Sep. Purif. Technol. 2013, 111, 145–154.

- Yoo, J.-M.; Jeong, J.; Yoo, K.; Lee, J.C.; Kim, W. Enrichment of the metallic components from waste printed circuit boards by a mechanical separation process using a stamp mill. Waste Manag. 2009, 29, 1132–1137.

- Havlik, T.; Orac, D.; Berwanger, M.; Maul, A. The effect of mechanical–physical pretreatment on hydrometallurgical extraction of copper and tin in residue from printed circuit boards from used consumer equipment. Miner. Eng. 2014, 65, 163–171.

- Schubert, G.; Jäckel, H.-G.; Grunert, V. Verfahren und Anlage zur Aufbereitung der Schredderleichtfraktion aus Aufbereitung metallhaltiger Abfälle. Patent DE10334646. Patent DE10334646, 27 April 2006.

- Kox, W.M.A.; Senden, M.M.G. Theory and Practical Application of Multicomponent Separation in Solid Waste Technology. Resour. Conserv. 1982, 1, 75–94.

- Friedlander, T.; Kuyumcu, H.Z.; Rolf, L. Untersuchungen zur Sortierung von PET-Flakes nach der Teilchenform. Aufbereit. Tech. -Miner. Processing 2006, 47, 24–43.

- Straetmans, K.; Brückmann, R. Trockensortierung mit einem Zick-Zack-Sichter und einem Kegelsichter; Freiberger Forschungsheft: Freiberg, Germany, 1999.

- Kwade, A.; Diekmann, J. Recycling of Lithium-Ion Batteries; The LithoRec Way; Springler International Publishing AG: Cham, Switzerland, 2018.

- Georgi-Maschler, T.; Friedrich, B.; Weyhe, R.; Heegn, H.; Rutz, M. Development of a Recycling Process for Li-ion Batteries. J. Power Sources 2012, 207, 173–182.

- Wuschke, L.; Jäckel, H.-G.; Borsdorff, D.; Werner, D.; Peuker, U.A.; Gellner, M. Zur mechanischen Aufbereitung von Li-Ionen-Batterien. BHM Berg-Und Hüttenmännische Mon. 2016, 161, 267–276.

- Wuschke, L. Mechanische Aufbereitung von Lithium-Ionen-Batteriezellen, 1st ed.; Freiberger Forschungshefte/A.; Technische Universität Bergakademie Freiberg: Freiberg, Germany, 2018.

- Wuschke, L.; Jäckel, H.G.; Peuker, U.A.; Gellner, M. Recycling of Li-ion batteries—A challenge. Recovery 2015, 4, 48–59.

More

Information

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

3.7K

Revisions:

2 times

(View History)

Update Date:

27 Apr 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No