| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Reggie Davidrajuh | -- | 1254 | 2022-04-21 17:05:40 | | | |

| 2 | Peter Tang | Meta information modification | 1254 | 2022-04-22 04:31:57 | | |

Video Upload Options

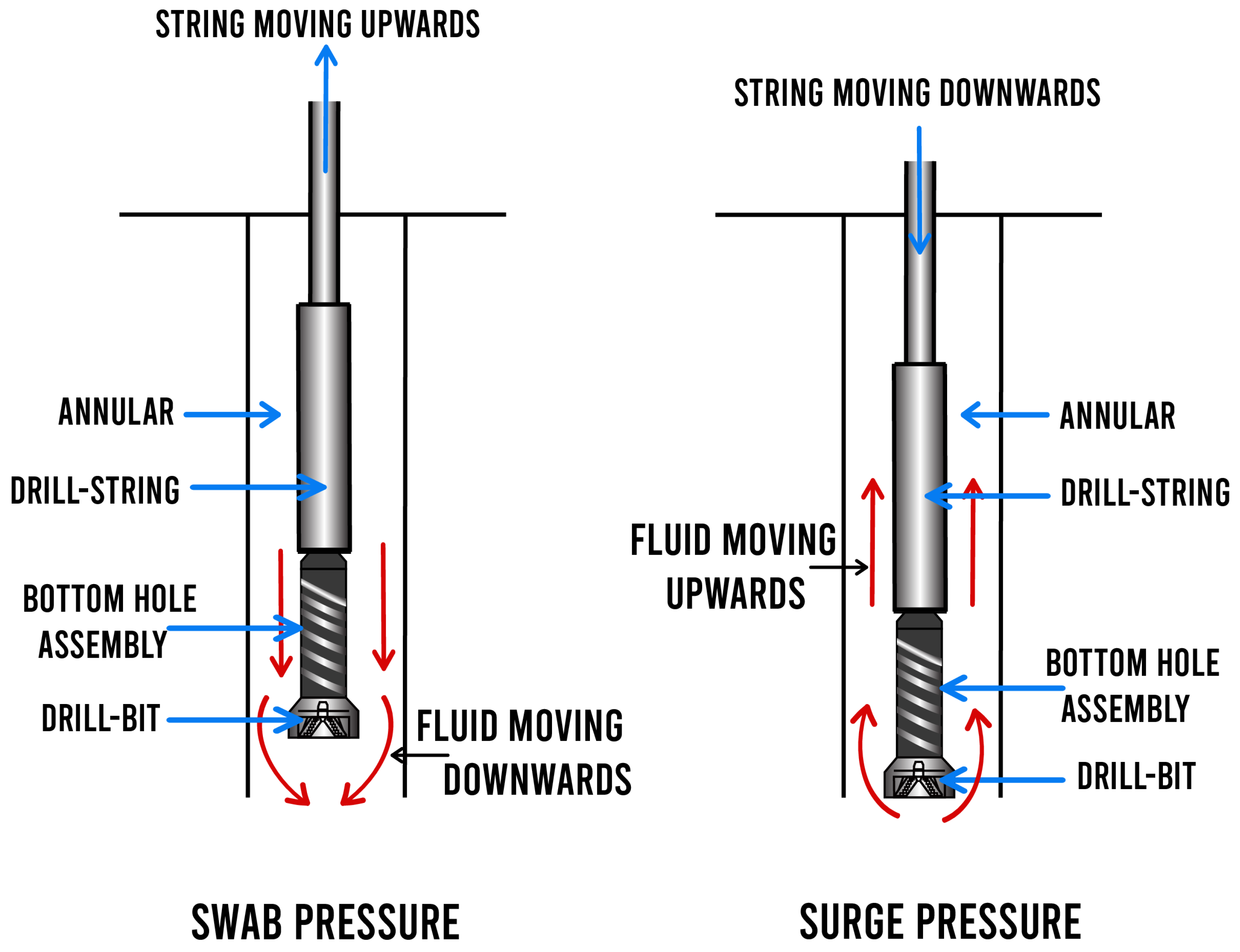

Swab and surge pressure fluctuations are decisive during drilling for oil. The axial movement of the pipe in the wellbore causes pressure fluctuations in wellbore fluid; these pressure fluctuations can be either positive or negative, corresponding to the direction of the movement of the pipe. For example, if the drill string is lowering down in the borehole, the drop is positive (surge pressure), and if the drill string is pulling out of the hole, the drop is negative (swab pressure). The intensity of these pressure fluctuations depends on the speed of the lowering down (tripping in) or withdrawing the pipe out (tripping out). High tripping speed corresponds to higher pressure fluctuations and can lead to fracturing the well formation. Low tripping speed leads to a slow operation, causing non-productive time, thus increasing the overall well budget.

1. Introduction

2. Data-Driven Modeling in Drilling in Well Operations

2.1. Applications of Data-Driven Techniques in Oil and Gas

2.2. Subsurface Characterization and Petrophysics

2.3. Drilling

References

- Balaji, K.; Rabiei, M.; Suicmez, V.; Canbaz, C.H.; Agharzeyva, Z.; Tek, S.; Bulut, U.; Temizel, C. Status of data-driven methods and their applications in oil and gas industry. In Proceedings of the SPE Europec featured at 80th EAGE Conference and Exhibition, Copenhagen, Denmark, 11–14 June 2018.

- Taner, M.T.; Koehler, F.; Sheriff, R. Complex seismic trace analysis. Geophysics 1979, 44, 1041–1063.

- Holdaway, K.R. Harness Oil and Gas Big Data with Analytics: Optimize Exploration and Production with Data-Driven Models; John Wiley & Sons: Hoboken, NJ, USA, 2014.

- Ouenes, A. Practical application of fuzzy logic and neural networks to fractured reservoir characterization. Comput. Geosci. 2000, 26, 953–962.

- Zhang, L.; Wu, S.; Zheng, W.; Fan, J. A dynamic and quantitative risk assessment method with uncertainties for offshore managed pressure drilling phases. Saf. Sci. 2018, 104, 39–54.

- Al-Anazi, A.F.; Gates, I.D. Support vector regression to predict porosity and permeability: Effect of sample size. Comput. Geosci. 2012, 39, 64–76.

- Behnoudfar, P.; Hosseini, P.; Azizi, A. Permeability determination of cores based on their apparent attributes in the Persian Gulf region using Navie Bayesian and Random forest algorithms. J. Nat. Gas Sci. Eng. 2017, 37, 52–68.

- Ozkaya, S.I. Using probabilistic decision trees to detect fracture corridors from dynamic data in mature oil fields. SPE Reserv. Eval. Eng. 2008, 11, 1061–1070.

- Chamkalani, A.; Zendehboudi, S.; Chamkalani, R.; Lohi, A.; Elkamel, A.; Chatzis, I. Utilization of support vector machine to calculate gas compressibility factor. Fluid Phase Equilibria 2013, 358, 189–202.

- El-Sebakhy, E.A. Forecasting PVT properties of crude oil systems based on support vector machines modeling scheme. J. Pet. Sci. Eng. 2009, 64, 25–34.

- Tohidi-Hosseini, S.M.; Hajirezaie, S.; Hashemi-Doulatabadi, M.; Hemmati-Sarapardeh, A.; Mohammadi, A.H. Toward prediction of petroleum reservoir fluids properties: A rigorous model for estimation of solution gas-oil ratio. J. Nat. Gas Sci. Eng. 2016, 29, 506–516.

- Ahmadi, M.A.; Mahmoudi, B. Development of robust model to estimate gas-oil interfacial tension using least square support vector machine: Experimental and modeling study. J. Supercrit. Fluids 2016, 107, 122–128.

- Cranganu, C.; Breaban, M. Using support vector regression to estimate sonic log distributions: A case study from the Anadarko Basin, Oklahoma. J. Pet. Sci. Eng. 2013, 103, 1–13.

- Akande, K.O.; Owolabi, T.O.; Olatunji, S.O.; AbdulRaheem, A. A hybrid particle swarm optimization and support vector regression model for modelling permeability prediction of hydrocarbon reservoir. J. Pet. Sci. Eng. 2017, 150, 43–53.

- Tan, M.; Song, X.; Yang, X.; Wu, Q. Support-vector-regression machine technology for total organic carbon content prediction from wireline logs in organic shale: A comparative study. J. Nat. Gas Sci. Eng. 2015, 26, 792–802.

- Masoudi, P.; Tokhmechi, B.; Jafari, M.A.; Zamanzadeh, S.M.; Sherkati, S. Application of Bayesian in determining productive zones by well log data in oil wells. J. Pet. Sci. Eng. 2012, 94, 47–54.

- Anifowose, F.; Labadin, J.; Abdulraheem, A. Improving the prediction of petroleum reservoir characterization with a stacked generalization ensemble model of support vector machines. Appl. Soft Comput. 2015, 26, 483–496.

- Fatehi, M.; Asadi, H.H. Data integration modeling applied to drill hole planning through semi-supervised learning: A case study from the Dalli Cu-Au porphyry deposit in the central Iran. J. Afr. Earth Sci. 2017, 128, 147–160.

- Al-Yami, A.S.; Al-Shaarawi, A.; Al-Bahrani, H.; Wagle, V.B.; Al-Gharbi, S.; Al-Khudiri, M.B. Using Bayesian network to develop drilling expert systems. In Proceedings of the SPE Heavy Oil Conference and Exhibition, Kuwait City, Kuwait, 6–8 December 2016.

- Bhandari, J.; Abbassi, R.; Garaniya, V.; Khan, F. Risk analysis of deepwater drilling operations using Bayesian network. J. Loss Prev. Process Ind. 2015, 38, 11–23.

- Sule, I.; Khan, F.; Butt, S.; Yang, M. Kick control reliability analysis of managed pressure drilling operation. J. Loss Prev. Process Ind. 2018, 52, 7–20.

- Chang, Y.; Chen, G.; Wu, X.; Ye, J.; Chen, B.; Xu, L. Failure probability analysis for emergency disconnect of deepwater drilling riser using Bayesian network. J. Loss Prev. Process Ind. 2018, 51, 42–53.

- Cai, B.; Liu, Y.; Liu, Z.; Tian, X.; Dong, X.; Yu, S. Using Bayesian networks in reliability evaluation for subsea blowout preventer control system. Reliab. Eng. Syst. Saf. 2012, 108, 32–41.

- Kormaksson, M.; Vieira, M.R.; Zadrozny, B. A data driven method for sweet spot identification in shale plays using well log data. In Proceedings of the SPE Digital Energy Conference and Exhibition, The Woodlands, TX, USA, 3–5 March 2015.

- Bakshi, A.; Uniacke, E.; Korjani, M.; Ershaghi, I. A novel adaptive non-linear regression method to predict shale oil well performance based on well completions and fracturing data. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 23–27 April 2017.

- Temizel, C.; Aktas, S.; Kirmaci, H.; Susuz, O.; Zhu, Y.; Balaji, K.; Ranjith, R.; Tahir, S.; Aminzadeh, F.; Yegin, C. Turning Data into Knowledge: Data-Driven Surveillance and Optimization in Mature Fields. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016.