| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ángel Calín-Sánchez | + 3099 word(s) | 3099 | 2020-09-22 09:52:49 | | | |

| 2 | Conner Chen | -8 word(s) | 3091 | 2020-10-12 04:42:19 | | |

Video Upload Options

Drying is an ancient and unparalleled physical procedure of food conservation used for direct preparation of food products as well as for further processing in the food in Drying is an ancient and unparalleled physical procedure of food conservation used for direct preparation of food products as well as for further processing in the food industry. It has always been a valuable and common practice of conservation, ensuring the availability of food and medicinal products all year long dustry. It has always been a valuable and common practice of conservation, ensuring the availability of food and medicinal products all year long. Drying used to be natural and simple as the process was driven by solar energy. Nowadays, it became more sophisticated and complex as it uses a lot of equipment and the drying parameters are carefully examined and optimized at every stage of the process. Emerging new methods have been extensively studied in terms of chemical and biochemical changes in the product during the dehydration process. Drying not only preserves the product but also can have a positive impact on materials quality e.g., in spices, medicinal plants, herbs, bioactive enzymes, and nuts that can generate value-added compounds during drying [1,2].

The most important objectives of drying are: (i) preservation of fresh products, making them available whole year (ii) conversion of the fresh product into a dry one while maintaining or improving its final quality; (iii) reduction of the volume and weight of the product for an easier transportation and storage; and last but not least (iv) sustainable processing as the most popular drying methods use enormous quantities of energy at low efficiency [8]. Thus, the new drying techniques should provide advantages such as higher energy efficiency, better product quality, cost reduction, and lower environmental impact.

1. Drying Techniques in Fruits, Vegetable, and Herbs Preservation

Numerous drying techniques have been developed and used for dehydration of vegetal products over the years. In this section, the most relevant drying techniques, such as convective drying (CD), spray drying (SD), freeze-drying (FD), and osmotic dehydration (OD) are reviewed and their characteristics provided. However, these broadly applied methods are not without some drawbacks and therefore extensive research has been carried out to limit these negative aspects as well as minimize the energy consumption throughout the process (Figure 1). According to other authors [1] novel drying technologies that might be accepted by the food industry include energy saving solutions such as dryers with the use of heat pumps, combination of existing technologies in order to optimize the cost and quality of dried products, and every method that allows better control over process conditions and food quality. Hence, these new technologies are described and compared with existing, conventional methods in this section.

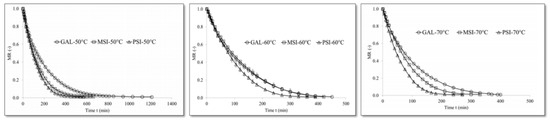

Figure 1. Convective drying of different jujube cultivars at different temperatures [2].

1.1. Heat Pump Drying (HP)

Energy losses during the conventional hot air drying are quite significant. Therefore, many methods have been designed to focus on recovering of the exhausted air in the process [3]. However, those methods could only recover sensible heat from the exhaust losing the rest of the heat in form of the latent heat of steam. To avoid this phenomenon, heat pump dryer was designed. In this type of dryer, a refrigerator is used in order to recover the latent heat by water condensation. In fact, this dryer is an improved convection dryer with refrigeration system, which contributes to energy efficiency and improves the product quality limiting negative environmental impact. In the process, dry heated air is supplied to the product as a result releasing humid air. The air travels to the heat pump evaporator, where it is condensed, allowing the latent heat of vaporization to be reused for reheating of the drying air. The advantage of this drying method is the reduction of time and temperature due to the relative humidity decline when compared to the conventional hot air dryer [4][5].

An alternative to the compression heat pump is a chemical heat pump. This method is considered as one of the most energy efficient and consists of a solar collector, storage tank, and a drying chamber. The chemical heat pump stores misused heat from the dryer exhaust or solar energy in the form of chemical energy and release it at different temperatures during the drying process. This method works by utilizing the reversible chemical reaction needed to change the temperature level of the thermal energy stored by the chemical substances. The chemical substances such as metal hydrides are very important in absorbing and eliminating heat. This method has the advantages of reducing energy consumption and is designed for a continuous operation [5].

1.2. Electromagnetic Radiation Techniques

Many conventional drying methods use hot air obtained through electric heater or flue gas to enforce heat transfer between the hot air and the material principally through convection. However, there are plenty of other methods that use electromagnetic wavelength spectrum as energy. Electromagnetic waves of a certain length reach out to the product generating in this way heat, which increases the drying rate [4]. This method works by indirect electro heating because the electrical energy is first converted to electromagnetic radiation to later be transformed into heat in the food product [6]. Some of the drying techniques using this mechanism are described below:

1.2.1. Microwave Drying (MD)

Microwave drying is based on the volumetric heating occurring when electromagnetic waves pass through the material causing a molecules oscillation. This oscillation generates thermal energy that is then used to remove water from the wet material. Microwave radiation is included in the electromagnetic spectrum, and its wavelengths range from 1 mm to 1 m. The most used frequencies within the food drying are 915 and 2450 MHz. This drying method is able to obtain high quality dried products with reduced costs and high energy efficiency due to the volumetric heating that is spread through the whole sample reducing the time of drying when compared to the conventional methods. However, it is considered to cause product damage due to improper heat control and mass transfer during the process [7]. Hence, researchers recommend combining this technique with other techniques e.g., by combining the use of microwaves with reduced pressure (microwave-vacuum drying described in the next section).

1.2.2. Infrared Drying (ID)

The infrared drying occurs by the exposure of the fresh product to electromagnetic radiation in the wavelength range of 0.8–1000 µm. The infrared radiation energy is transferred from the heating source to the product surface. However, the surrounded air is not heated in the process. This method is one of the most appropriate to be used in combination with conventional drying methods due to the equipment simplicity and energy savings. In addition, it is considered to produce a quick and efficient heat transfer obtaining in this way a better organoleptic and nutritional value of the product with a uniform heating and lower final costs [8].

1.2.3. Radio Frequency Drying (FR)

This technology can be used not only for wireless communication but also in food processing. Radio frequency heating consists of the interaction between electromagnetic field, which is produced by radio frequency generator, and the molecular species in the product. Thus, the food product is situated between two electrodes displayed to an electric field which alternates around 40,000,000 times per second. The electric fields alternate and so do the polar molecules from the food product creating friction, which heats the whole product. As the water is naturally bipolar it gets heated leading to the evaporation in the process. Radiofrequency has been widely studied as an alternative to conventional hot air-drying process (convective drying) in different horticultural products such as apple slices and snack foods [6].

1.2.4. Refractance Window Drying (RW)

This drying technique includes three types of heat transfer mechanisms, (i) convection, (ii) conduction and (iii) radiation. All these heat transfer modes are needed in order to obtain an energy efficient drying method. The product submitted at refractance window must be of liquid or semiliquid texture. The material is applied to a conveyer belt surface, normally an infrared transparent plastic which floats on the area of heated circulating water. This method works by refractive principle of the water surface that creates a window when infrared energy crosses by. The infrared window is formed at the contact between the wet material and the transparent plastic and permits direct infrared energy transfer to the material. Studies on pure pumpkin concluded that the drying time for this method is very short [9]. Refractance window dehydration is conducted under atmospheric pressure and lower temperatures (~30 °C), being a good option for heat-sensitive foods. This method has emerged as a new low-cost possibility for dehydration of vegetal material such as mango, avocado, and herbs [10].

1.3. Explosion Puffing Drying (EPD)

This method is usually applied in an intermediate phase of the drying process and is caused by the product bounded water vaporization and its expansion due to an abrupt pressure decrease or temperature increase. In this moment, the released vapor is used for both development of an internal structure or expansion and/or breaking of an existing one by producing a porous structure, saving time and energy. There are different methods of puffing, such as high-temperature and short-time air puffing and superheated steam puffing. Explosion puffing drying (EPD) system consists of a puffing chamber, vacuum chamber, vacuum pump, decompression valve steam generator, and air compressor. This method is usually combined with CD and FD and is used as a cheaper alternative to FD products [11][12].

1.4. Low-Pressure Superheated Steam Drying (LPSSD)

The benefits of low-pressure superheated steam drying (LPSSD) results from the reduction of operation temperature due to lowered pressure and completely lack of oxygen as the drying agent is a steam instead of hot air, which is commonly used for heat and mass exchange in traditional drying methods. The process of dehydration using superheated steam takes place in insulated drying chamber under reduced pressure maintained by vacuum pump. A steam trap is installed to reduce the excess steam condensation in the reservoir, which receives the drying agent from the boiler. With the use of a heater equipped with the temperature control system the initial steam condensation during the start-up period is reduced considerably. A variable-speed electric fan is used to disperse steam throughout the drying chamber.

1.5. Combined Drying Methods

Combined drying methods represent the next group of novel drying techniques that overcome the shortcomings mentioned before by combining the advantages of selected methods and reducing negative aspects occurring when only one technique is applied. There are several combined drying methods. However, some of them deserve special attention due to their applicability in the food industry.

1.5.1. Microwave-Assisted Convective Drying (CD-MD)

Hot air is an effective drying medium to produce dried fruits, vegetables, and aromatic herbs. However, as presented in the Convective drying has some weaknesses i.e., long time of drying and the crust formation on the product surface due to the high temperatures. These issues can be diminished if microwave-assisted convective drying is applied. Therefore, the hot air reduces the products surface unbound moisture while the microwave energy eliminates the bound moisture from the inside of the product via volumetric heating. Nevertheless, there is still the need for further development regarding the time at which microwaves should be optimally incorporated into the process, whether when the drying rate starts to fall or when the drying rate is already falling or maybe even at very low moisture content [13].

1.5.2. Vacuum-Microwave Drying (VMD)

Vacuum-microwave drying is a modern technique that might overcome the conventional drying weaknesses having an ability to enhance the quality of the dried products. In general, vacuum-microwave drying (VMD) gathers the four most important requirements for food drying: high operational speed, high energetic efficiency, low operational costs, and high quality of the dried product. The process involves the use of vacuum, which assures a quick mass transfer and low temperature and is combined with the microwave heating which guarantees an accelerated energy transfer. Thus, all together result in prompt, low temperature drying process. In addition, the absence of air prevents the product oxidation. This system is not yet very common in the food industry; however, there is a large number of scientific studies that have successfully applied this method to obtain better quality products (including nutritional and sensory properties), such as fruits, vegetables, and aromatic herbs. However, one of its major limitations is the non-uniformity of the microwave radiation, which induces over-heating in borders and corners of the sample [5][14][15][16]. In recent years, several studies have been focused on using VMD, because of the shorter drying time and lower temperature in comparison with microwave drying. Several vegetal materials have been studied under this technique such as apple, blackcurrant, blueberry, pomegranate, garlic, strawberries, cranberries, and tomatoes [15][17][18][19].

1.5.3. Convective Drying Followed by Vacuum Microwave Drying (CD-VMD)

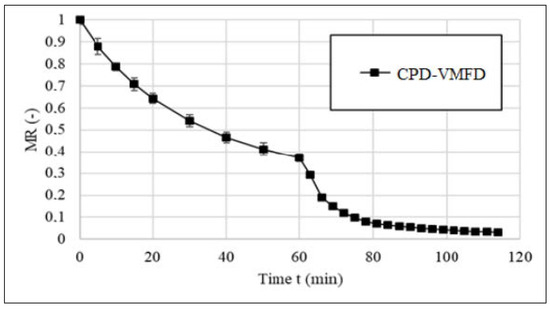

Combining convective drying with vacuum-microwave drying leads to obtaining products with improved quality with lower cost of the process as well as lower energy consumption. The process consists of two stages: in the first stage, the fresh product is subjected to a convective pre-drying followed by the second stage in which a vacuum microwave finishing drying is applied to the product. The convective pre-drying diminishes considerably the unbound moisture of the fresh material without affecting their bioactive compounds. Later the vacuum-microwave finishing drying brings the moisture content to the desired level. These two combined drying processes have been reported to be more effective than either of the methods applied separately. The positive impact on the quality was observed in large number of fruits and herbs: sour cherries, jujube, orange peel, beetroot, blackcurrant, pumpkin, plums, and hemp [20][21][22] (Figure 2).

Figure 2. Combined drying consisting on convective pre-drying (CPD) at 60 °C and vacuum microwave finishing drying (VMFD) at 360 W of hemp [22].

1.5.4. Fluidized Bed Drying (FBD)-Assisted by Microwaves, Far Infrared Rays, and Ultrasounds

Traditional fluidized bed drying can be assisted by microwave energy in a similar way to convective drying. However, this method requires different steps of drying and especially further research on the usefulness for various products. Also, the initial system costs are immense.

Far infrared rays are found at the farthest side of the visible rays and have the purpose to raise the temperature of the food product to the above wavelength, which coincides with the vibration of the molecules. As a difference to the microwave-assisted fluidized bed drier this method can be applied in any stage to control the matter components quality. For instance, it was possible to control the influence of allicin (the organosulfur compound of garlic) in the drying process when far infrared rays assisted fluidized bed was applied in the first stage of drying. In addition, functional components such as amino acids were not affected by both individual fluidized bed, or combined with far infrared rays methods.

It is considered that high power ultrasound application to the heat-sensitive horticultural products can raise drying rate by accelerating the mass transfer process contributing to a high quality of dried product. These important aspects can be achieved due to the lower temperatures and times needed for the drying treatment. It was found that using ultrasound methods for fruits and vegetables could avoid negative effects such as shrinkage, color darkening, cracking, or nutritional changes due to the low temperatures needed within this method. Besides, it is considered not only to have an intuitive mechanism of utilization but also to be low-cost and energy efficient method [23].

1.5.5. Intermittent Drying (IMD) of Food Products Assisted by Temperature, Pressure, Humidity, Convection, Radiation, and Microwave

As previously mentioned, drying is probably the most energy process of the major industrial process. Intermittent drying has been considered as one of the most energy efficient drying processes. Intermittent drying is a drying method where drying conditions are changed with time. It can be achieved by varying drying air temperature, humidity, pressure or even mode of heat input [24]. Intermittent drying can be accomplished by controlling the supply of thermal energy, which can be achieved by varying the airflow rate, air temperature, humidity, or operating pressure. One can also vary the mode of energy input (e.g., convection, conduction, radiation, or microwave) to achieve intermittency [24].

Regarding the food quality, authors reported that the intermittent drying can reduce the browning effects, the hydro-thermo-mechanical stress inside sample and the chemical reactions which help to protect the bioactive compounds of the product [25]. Intermittent drying is a technique specially developed to overcome essential limitations of convective drying which are longer time and energy consumption, case hardening and low-quality products [25]. Thus, is an effective method developed to improve the drying kinetics, enhancing product quality, and reducing energy consumption.

Intermittent microwave convective drying (IMCD) significantly reduces drying time and improves product quality compared to convection drying and overcomes the problem of overheating that persist in continuous microwave convective drying. Moreover, the non-uniformity of temperature distribution is one of the major drawbacks of microwave drying which can be minimized by supplying microwave power intermittently [26].

This method (IMCD), it has been already used in drying of thermolabile plant-based food products due to its soft processing conditions which protect the sample from overheating and product deterioration [25]. For instance, during the drying period the superficial moisture is evaporated, and the inner moisture is carried to the surface; this repeated process of rewetting help to reduce the overheating maintaining stable thermolabile product characteristics such as color, pigments, browning, etc. Moreover, the reduction in oxidation, hydrolytic enzymes, and microorganism can be also reduced due to the short time of heat during IMD which can inactivate them without damaging the heat-sensitive bioactive compounds and enhance the product shelf life [25].

Authors reported that using the optimum level microwave power and intermittency could significantly enhance the preservation of nutrient contents, microstructure, and color of the dried sample. For instance, using IMCD at 1:4 power ratio in kiwifruit, was the optimum condition with the highest ascorbic acid retention, the lowest color change and with a porous structure resembling the fresh sample; however, using higher microwave density a (1:3) the highest polyphenol content was maintained [27].

Finally, a study on the effect of IMCD on a heat-sensitive fruit such as Red Flesh papaya (cv. Red Hill) was also reported [28]. The authors developed an IMCD model describing simultaneous heat and mass transfers, together with microwave volumetric heating (for temperature of 60 °C, 100 W and 1:3, 1:4, and 1:5 power ratios) to predict the distribution of moisture and temperature and its effect product quality. They concluded that power rate had a key role in quality attributes as was also above-mentioned. For instance, around 70% of the ascorbic acid was degraded using 1:3 power rate, but these losses were decreased when the power rate was reduced to 1:4 or 1:5. Additionally, the total phenolic content, was reported to be degraded significantly during the early stages (first 60 min) but was stabilized at later stages.

References

- Wojdyło, A.; Lech, K.; Nowicka, P.; Hernández, F.; Figiel, A.; Carbonell‐Barrachina, Á. Influence of different drying techniques on phenolic compounds, antioxidant capacity and colour of ziziphus jujube Mill. Fruits. Molecules 2019, 24, 2361, doi:10.3390/molecules24132361.

- Calín-Sánchez, Ángel; Figiel, A.; Szarycz, M.; Lech, K.; Nuncio-Jáuregui, N.; Carbonell‐Barrachina, Á. Drying kinetics and energy consumption in the dehydration of pomegranate (Punica granatum L.) arils and rind. Food Bioprocess Technol. 2013, 7, 2071–2083, doi:10.1007/s11947-013-1222-5.

- Moses, J.A.; Norton, T.; Alagusundaram, K.; Tiwari, B. Novel drying techniques for the food industry. Food Eng. Rev. 2014, 6, 43–55, doi:10.1007/s12393-014-9078-7.

- Kudra, T.; Mujumdar, A.S. Advanced Drying Technologies; Informa UK Limited: Colchester, UK, 2009.

- Marra, F.; Zhang, L.; Lyng, J. Radio frequency treatment of foods: Review of recent advances. J. Food Eng. 2009, 91, 497–508, doi:10.1016/j.jfoodeng.2008.10.015.

- Joardder, M.U.H.; Karim, A.; Kumar, C. Effect of temperature distribution on predicting quality of microwave dehydrated food. J. Mech. Eng. Sci. 2013, 5, 562–568, doi:10.15282/jmes.5.2013.2.0053.

- Boudhrioua, N.; Bahloul, N.; Ben Slimen, I.; Kechaou, N. Comparison on the total phenol contents and the color of fresh and infrared dried olive leaves. Ind. Crop. Prod. 2009, 29, 412–419, doi:10.1016/j.indcrop.2008.08.001.

- Rahman, M.S. Handbook of Food Preservation; Informa UK Limited: Colchester, UK, 2020.

- Sabarez, H. Drying of food materials. In Reference Module in Food Science; Elsevier BV: Amsterdam, The Netherlands, 2016.

- Nindo, C.I.; Tang, J. Refractance window dehydration technology: A novel contact drying method. Dry. Technol. 2007, 25, 37–48, doi:10.1080/07373930601152673.

- Zou, K.; Teng, J.; Huang, L.; Dai, X.; Wei, B. Effect of osmotic pretreatment on quality of mango chips by explosion puffing drying. LWT 2013, 51, 253–259, doi:10.1016/j.lwt.2012.11.005.

- Chen, Q.; Li, Z.; Bi, J.; Zhou, L.; Yi, J.; Wu, X. Effect of hybrid drying methods on physicochemical, nutritional and antioxidant properties of dried black mulberry. LWT 2017, 80, 178–184, doi:10.1016/j.lwt.2017.02.017.

- Kumar, C.; Karim, M.A. Microwave-convective drying of food materials: A critical review. Crit. Rev. Food Sci. Nutr. 2017, 59, 379–394, doi:10.1080/10408398.2017.1373269.

- Nawirska-Olszańska, A.; Stępień, B.; Biesiada, A.; Kolniak-Ostek, J.; Oziembłowski, M. Rheological, Chemical and physical characteristics of golden berry (Physalis peruviana L.) after convective and microwave drying. Foods 2017, 6, 60, doi:10.3390/foods6080060.

- Figiel, A. Drying kinetics and quality of vacuum-microwave dehydrated garlic cloves and slices. J. Food Eng. 2009, 94, 98–104, doi:10.1016/j.jfoodeng.2009.03.007.

- Sutar, P.; Prasad, S. Microwave Drying Technology-Recent Developments and R&D Needs in India; Publisher: 42nd ISAE Annual Convention, Bhopal, India, 2008; pp. 1–3.

- Calín-Sánchez, Ángel; Figiel, A.; Hernández, F.; Melgarejo, P.; Lech, K.; Carbonell‐Barrachina, Á. Chemical composition, antioxidant capacity, and sensory quality of pomegranate (Punica granatum L.) arils and rind as affected by drying method. Food Bioprocess Technol. 2012, 6, 1644–1654, doi:10.1007/s11947-012-0790-0.

- Figiel, A.; Michalska-Ciechanowska, A. Overall quality of fruits and vegetables products affected by the drying processes with the assistance of vacuum-microwaves. Int. J. Mol. Sci. 2016, 18, 71, doi:10.3390/ijms18010071.

- Zielinska, D.; Michalska-Ciechanowska, A. Microwave-assisted drying of blueberry (Vaccinium corymbosum L.) fruits: Drying kinetics, polyphenols, anthocyanins, antioxidant capacity, colour and texture. Food Chem. 2016, 212, 671–680, doi:10.1016/j.foodchem.2016.06.003.

- Figiel, A. Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum-microwave methods. J. Food Eng. 2010, 98, 461–470, doi:10.1016/j.jfoodeng.2010.01.029.

- Nowicka, P.; Wojdyło, A.; Lech, K.; Figiel, A. Chemical composition, antioxidant capacity, and sensory quality of dried sour cherry fruits pre-dehydrated in fruit concentrates. Food Bioprocess Technol. 2015, 8, 2076–2095, doi:10.1007/s11947-015-1561-5.

- Kwaśnica, A.; Pachura, N.; Masztalerz, K.; Figiel, A.; Zimmer, A.; Kupczyński, R.; Wujcikowska, K.; Carbonell‐Barrachina, Ángel; Szumny, A.; Różański, H. Volatile composition and sensory properties as quality attributes of fresh and dried hemp flowers (Cannabis sativa L.). Foods 2020, 9, 1118, doi:10.3390/foods9081118.

- Singh, D.B.; Kingsly, A.R.P. Effect of convective drying on qualilty of Anardana. Indian J. Hortic. 2008, 65, 413–416.

- Kumar, C.; Karim, M.A.; Joardder, M.U.H. Intermittent drying of food products: A critical review. J. Food Eng. 2014, 121, 48–57, doi:10.1016/j.jfoodeng.2013.08.014.

- Pham, N.D.; Khan, I.H.; Joardder, M.U.H.; Rahman, M.M.; Mahiuddin; Abesinghe, A.N.; Karim, M.A. Quality of plant-based food materials and its prediction during intermittent drying. Crit. Rev. Food Sci. Nutr. 2017, 59, 1197–1211, doi:10.1080/10408398.2017.1399103.

- Vadivambal, R.; Jayas, D.S. Non-uniform temperature distribution during microwave heating of food materials—A review. Food Bioprocess Technol. 2008, 3, 161–171, doi:10.1007/s11947-008-0136-0.

- Pham, N.D.; Martens, W.; Karim, M.A.; Joardder, M.U.H. Nutritional quality of heat-sensitive food materials in intermittent microwave convective drying. Food Nutr. Res. 2018, 62, 62, doi:10.29219/fnr.v62.1292.

- Pham, N.D.; Khan, M.; Karim, M. A mathematical model for predicting the transport process and quality changes during intermittent microwave convective drying. Food Chem. 2020, 325, 126932, doi:10.1016/j.foodchem.2020.126932.