| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mariam Shakeel | + 2610 word(s) | 2610 | 2020-09-09 04:35:36 | | | |

| 2 | Dean Liu | -1281 word(s) | 1329 | 2020-09-25 04:52:58 | | | | |

| 3 | Dean Liu | -1281 word(s) | 1329 | 2020-09-25 04:53:25 | | | | |

| 4 | Dean Liu | + 1 word(s) | 1330 | 2020-10-26 05:00:30 | | |

Video Upload Options

Hybrid EWPF has been experimentally investigated for both sandstone and carbonate reservoirs by various researchers. The idea behind hybrid EWPF is to enhance oil recovery by the combined effect of optimized injection water composition and polymer flooding. Most of the studies have shown the synergistic benefits of the hybrid method in terms of two- to four-fold decreases in the polymer adsorption, leading to 30–50% reductions in polymer consumption, making the project economically viable for carbonates. EWPF has resulted in 20–30% extra oil recovery in various carbonate coreflood experiments compared to high-salinity water flooding.

xz1. Introduction

60% of oil reserves globally are concentrated in carbonate reservoirs[1]. However, due to the presence of organic and polar acidic compounds in crude oil, the majority of carbonate reservoirs tend to be oil-wet[2][3][4]. This results in higher residual oil saturations in carbonates, even after water flooding. During the primary recovery phase, only 10–15% of oil originally in place (OOIP) is recovered. Secondary recovery using water or gas injection can further extract 10–30% of the remaining oil. However, almost 40–60% of oil remains trapped and inaccessible, even after secondary recovery. Various enhanced oil recovery (EOR) practices are in use to recover the trapped oil volume, such as polymer flooding (PF), surfactant EOR, miscible gas injection, and steam injection. Each EOR method modifies the rock–fluid interaction (oil–water–rock, OWR) properties in a certain manner, resulting in improved recovery. For example, polymer flooding increases the displacing fluid viscosity, resulting in a favorable mobility ratio, whereas surfactant EOR causes reductions in the oil–water interfacial tension (IFT) and residual oil saturation (Sor)[5].

Engineered water flooding (EWF) is a relatively new EOR technique, which involves the injection of properly designed low-salinity water (LSW), disturbing the original equilibrium state of the OWR system, resulting in incremental oil recovery, which is mainly caused by the wettability modification. Additional oil recovery resulting from EWF in sandstone was first documented in 1967[6]. In 2004, the first ever field application of EWF in sandstone as an EOR technique was published. The idea of EWF as a potential EOR process in carbonates was triggered first in the 1980s, when exceptionally high oil recovery rates were observed from the injection of seawater into fractured chalk formations under the North Sea[7][8][9]. Engineered water for use in carbonates is designed by tuning the injected water salinity, ionic strength, and the concentrations of potential determining ions (PDIs) Ca2+, Mg2+, and SO42−. EWF also has some inherent limitations, such as viscous fingering due to unfavorable mobility ratios, oil trapping, and fines migration[10]. Hence, this method may not qualify as an optimum EOR option under certain conditions, even though it is a low-cost technique.

The development and implementation of novel, cost-effective EOR methods is critical for the sustainable growth of the oil industry. Research is underway on various levels to develop economically viable hybrid EOR methods and overcome the limitations of individual methods, such as hybrid engineered water–polymer flooding (EWPF) or surfactant flooding. The idea behind hybrid EWPF is to enhance oil recovery via the combined effects of optimization of the injection water composition and PF, mainly through two mechanisms. (1) Engineered water modifies the wetting characteristics of the rock surface due to the salinity and composition differences, which affects the bonding of the crude oil polar components (carboxylic material, -COOH group) with the carbonate surface and helps in oil detachment[11][12][13]. (2) Polymer flooding improves the macroscopic sweep efficiency by decreasing the mobility ratio[14]. In addition, EW promotes polymer stability and a reduction in the polymer concentration requirement, making PF applicable to high-salinity, high-temperature carbonate formations[15]. Hence, the hybrid method results in greater incremental oil recovery than that obtained by standalone methods.

2.Hybrid Engineered Water–Polymer Flooding (EWPF)

Literature and field case studies have proven that the synergistic combination of two or more EOR techniques provides better results in terms of oil recovery and economics. For instance, the combined use of an alkali, surfactant, and polymer in the alkaline–surfactant–polymer (ASP) flooding technique results in enhanced macroscopic and microscopic sweep efficiencies, owing to the favorable mobility ratio of the polymer, the microscopic sweep efficiency due to pH change caused by alkali, and the reduction in IFT caused by surfactants [16][17]. Any EOR method involving two or more EOR techniques is known as a hybrid EOR method. Much research is being carried out in the field of hybrid EOR, particularly aiming to increase the applicability of chemical methods. As discussed in previous sections, both PF and EWF have associated challenges that limit their field-scale applications. In order to overcome these limitations and take advantage of the synergetic effects of the two methods, the hybrid EWPF technology comes into play. The hybrid process can be simply represented as:

Engineered Water (EW)+Polymer Flooding (PF)=Incremental Oil Recovery

(Wettabilityttability Modification) (Reduction in Mobility Ratio)

This hybrid EWPF method provides the following obvious benefits:

-

The addition of a polymer to low-salinity water flooding enhances the volumetric sweep and can also mobilize the oil released due to wettability modification after LSWF, which otherwise would be trapped[18];

-

Various studies have shown the added benefit of the reduced polymer concentration needed to attain the desired in situ viscosity by using low-salinity brine compared to high-salinity water[19]. This can result in a significant cost reduction;

-

Other advantages include the improved polymer stability (particularly at high temperatures), reduced sensitivity to shear-rate-induced degradation, less polymer adsorption, improved viscoelasticity of the polymer, and decreased scaling and souring tendency[20][21];

-

Most of the studies have been conducted on sandstones[22][23][24][25], however the experiments performed on carbonates have also proved the synergetic effects of EWPF;

-

Recently, osmosis was proposed as the mechanism for the LSW EOR effect instead of wettability alteration in a sandstone sample[26][27][28][29].

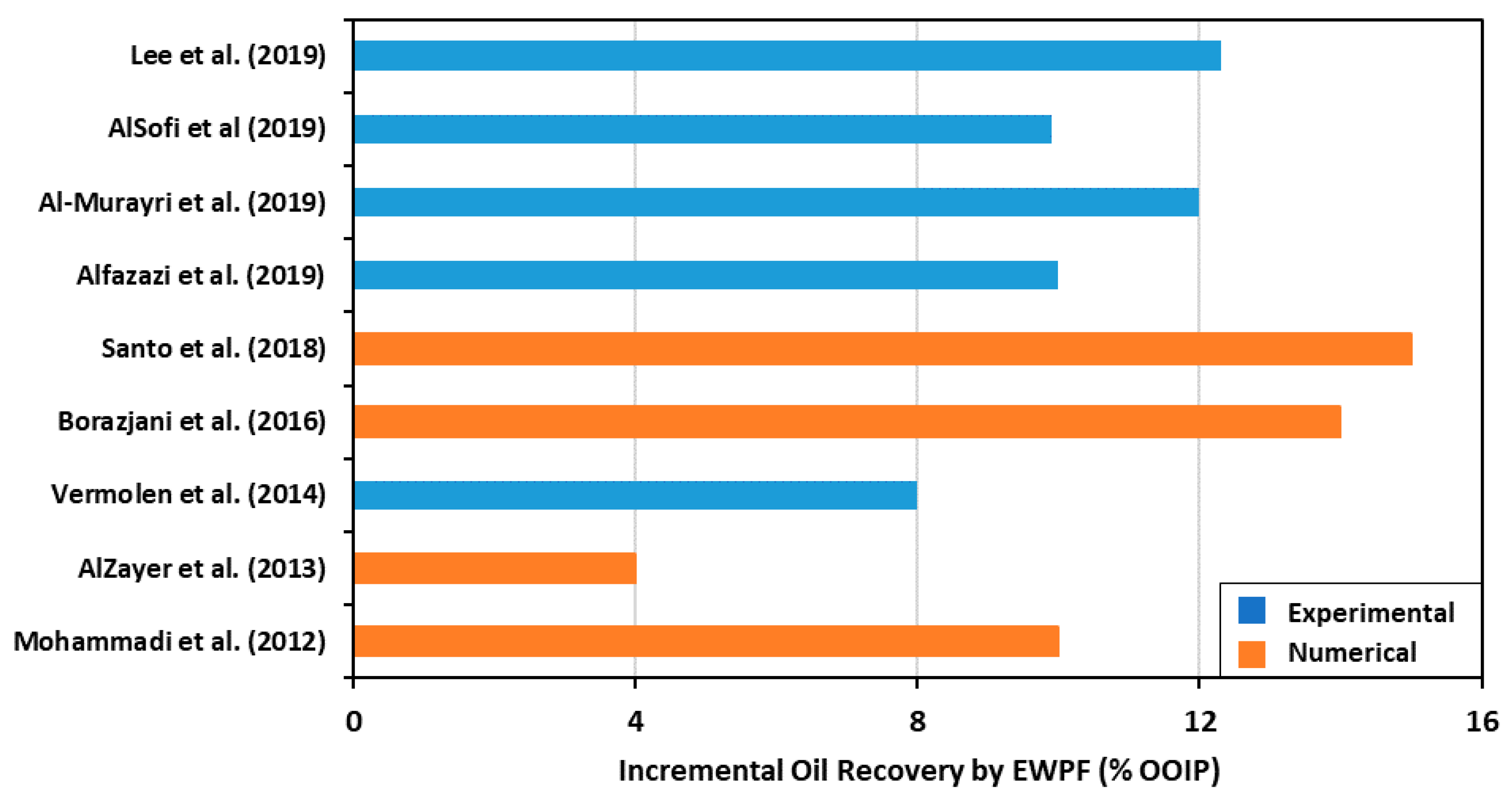

Various experiment-based and modeling studies have been carried out in recent years to prove the effectiveness of hybrid EWPF as an EOR method[31][32][33][34][35][36][37]. These studies have shown an average of 11% incremental oil recovery using the hybrid method in different carbonate formations (Figure 1).

Figure 1. Summary of experimental and simulation studies involving incremental oil recovery using engineered water–polymer flooding (EWPF) in carbonates.4.1. Enhanced Oil Recovery using Hybrid EWPF in Carbonates.

Figure 1. Summary of experimental and simulation studies involving incremental oil recovery using engineered water–polymer flooding (EWPF) in carbonates.4.1. Enhanced Oil Recovery using Hybrid EWPF in Carbonates.

The limited literature on the application of EWPF EOR in carbonates shows that it can increase oil recovery by equal to or more than the sum of the recovery from each process. Rivet[38] and Seright et al. [39]studied the combined effects of EWPF in terms of the better polymer stability and yield, improved microscopic and macroscopic sweep efficiency, and reduction in chemical costs. A seawater desalination process was developed for combined EWPF applications in an offshore field[40]. EW hybrid methods can achieve up to 30% of OOIP incremental recovery[41].

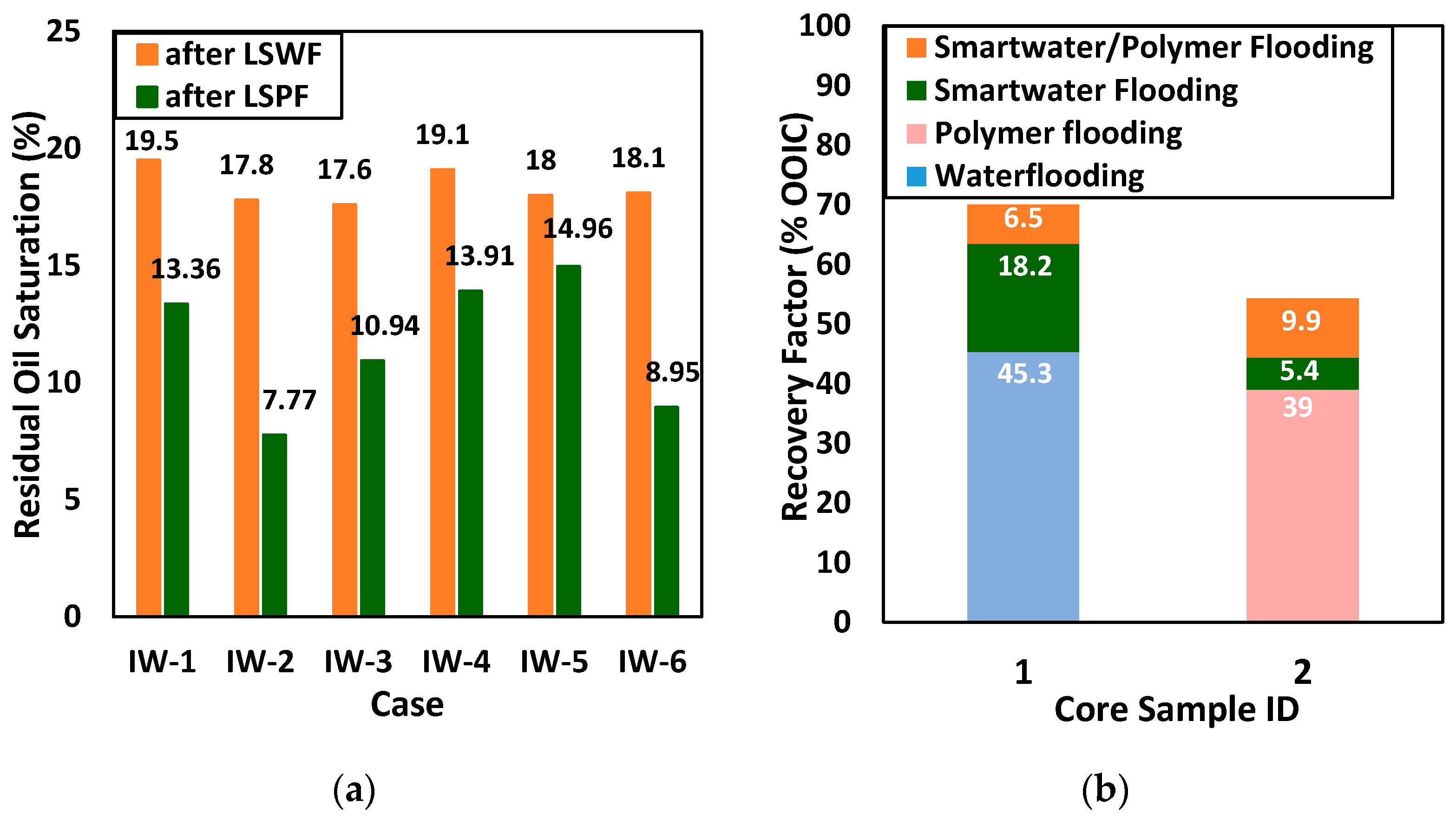

Lee et al.[37] performed experiments on carbonate samples using LSW with ion adjustments followed by PF. The Sor value was considerably decreased by using low-salinity polymer flooding (LSPF) compared to conventional high-salinity water flooding and EWF. All designed injection water (IW) solutions (IW-1: pH 7, 1000 ppm SO42−, IW-2: pH 7, 4000 ppm SO42−, IW-3: pH 4, 4000 ppm SO42−, IW-4: pH 7, 100 ppm Ca2+, IW-5: pH 7, 1000 ppm Ca2+, and IW-6: pH 4, 1000 ppm Ca2+) reduced the Sor value, however the neutral low-salinity water containing only SO42– ions gave the lowest Sor value (Figure 2a).

Figure 2. (a) Reduction in Sor after LSPF[37] (b) additional recovery using EWPF in carbonate reservoir cores[42].

Incremental oil recovery resulting from the synergy between smart water (SW) and polymer in carbonates was also confirmed by AlSofi et al.[42]. Hybrid EWPF resulted in 6–10% OOIP recovery after PF, showing that LSW modifies fluid–rock interactions, creating a moveable oil volume that is displaced easily by the polymer in EWPF (Figure 2b). Similarly, Vermolen et al.[20] conducted oil displacement experiments on reservoir cores, resulting in ~45% incremental oil recovery using LSPF. An incremental OOIP recovery value of 8% was achieved by further reducing the salinity of the water, confirming the synergistic effect of the hybrid process.

[1][2][3][4][5][6][7][8][9][10][11][12][13][14][15][16][17][18][19][20][21][22][23][24][25][26][27][28][29][15][30][31][32][33][34][35][36][37][38][39][40][41]Engineered Water (EW)+Polymer Flooding (PF)=Incremental Oil Recovery(Wettabilityttability Modification) (Reduction in Mobility Ratio)

Engineered Water (EW)+Polymer Flooding (PF)=Incremental Oil Recovery(Wettabilityttability Modification) (Reduction in Mobility Ratio)

References

- Ahmadi, A.; Moosavi, M. Investigation of the effects of low-salinity waterflooding for improved oil recovery in carbonate reservoir cores. Energy Source Part A Recovery Util. Environ. Eff. 2018, 40, 1035–1043.

- Mwangi, P.; Brady, P.V.; Radonjic, M.; Thyne, G. The effect of organic acids on wettability of sandstone and carbonate rocks. J. Pet. Sci. Eng. 2018, 165, 428–435.

- Chilingar, G.V.; Yen, T. Some notes on wettability and relative permeabilities of carbonate reservoir rocks, II. Energy Sources 1983, 7, 67–75.

- Treiber, L.; Owens, W. A laboratory evaluation of the wettability of fifty oil-producing reservoirs. Soc. Pet. Eng. J. 1972, 12, 531–540.

- Lee, K.S.; Lee, J.H. Hybrid Enhanced Oil Recovery Using Smart Waterflooding; Gulf Professional Publishing: Cambridge, MA, USA, 2019.

- Bernard, G.G. Effect of floodwater salinity on recovery of oil from cores containing clays. In Proceedings of the SPE California Regional Meeting, Los Angeles, CA, USA, 26–27 October 1967.

- Hallenbeck, L.D.; Sylte, J.E.; Ebbs, D.J.; Thomas, L.K. Implementation of the Ekofisk field waterflood. SPE Form. Eval. 1991, 6, 284–290.

- Sylte, J.; Hallenbeck, L.; Thomas, L. Ekofisk formation pilot waterflood. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 2–5 October 1988.

- Austad, T.; Shariatpanahi, S.F.; Strand, S.; Black, C.J.J.; Webb, K.J. Conditions for a low-salinity enhanced oil recovery (EOR) effect in carbonate oil reservoirs. Energy Fuels 2012, 26, 569–575.

- Rivet, S.M. Coreflooding Oil Displacements with Low Salinity Brine. Ph.D. Thesis, University of Texas at Austin, Austin, TX, USA, 2009.

- Khaledialidusti, R.; Kleppe, J. Significance of geochemistry in single-well chemical-tracer tests by coupling a multiphase-flow simulator to the geochemical package. SPE J. 2018, 23, 1126–1144.

- Mahani, H.; Keya, A.L.; Berg, S.; Nasralla, R. Electrokinetics of carbonate/brine interface in low-salinity waterflooding: Effect of brine salinity, composition, rock type, and pH on ζ-potential and a surface-complexation model. SPE J. 2017, 22, 53–68.

- Khaledialidusti, R.; Kleppe, J. Surface-charge alteration at the carbonate/brine interface during single-well chemical-tracer tests: Surface-complexation model. SPE J. 2018, 23, 2302–2315.

- Chang, H.L. Polymer flooding technology yesterday, today, and tomorrow. J. Pet. Technol. 1978, 30, 1113–1128.

- Al-Murayri, M.T.; Kamal, D.S.; Al-Sabah, H.M.; AbdulSalam, T.; Al-Shamali, A.; Quttainah, R.; Glushko, D.; Britton, C.; Delshad, M.; Liyanage, J.; et al. Low-Salinity Polymer Flooding in a High-Temperature Low-Permeability Carbonate Reservoir in West Kuwait. In Proceedings of the SPE Kuwait Oil & Gas Show and Conference, Mishref, Kuwait, 13–16 October 2019.

- Pye, D.J. Improved secondary recovery by control of water mobility. J. Pet. Technol. 1964, 16, 911–916.

- Sandiford, B. Laboratory and field studies of water floods using polymer solutions to increase oil recoveries. J. Pet. Technol. 1964, 16, 917–922.

- Mungan, N. Rheology and adsorption of aqueous polymer solutions. J. Can. Pet. Technol. 1969, 8, 45–50.

- Gogarty, W. Mobility control with polymer solutions. Soc. Pet. Eng. J. 1967, 7, 161–173.

- Manrique, E.; Ahmadi, M.; Samani, S. Historical and recent observations in polymer floods: An update review. CtF-Cienc. Tecnol. Y Futuro 2017, 6, 17–48.

- Gao, C.H. Scientific research and field applications of polymer flooding in heavy oil recovery. J. Pet. Explor. Prod. Technol. 2011, 1, 65–70.

- Needham, R.B.; Doe, P.H. Polymer flooding review. J. Pet. Technol. 1987, 39, 1503–1507.

- Zhang, Y. Survey and Data Analysis of Polymer Flooding Pilot and Field Applications in China. Master′s Thesis, Missouri University of Science and Techology, Rolla, MI, USA, 2015.

- Al-Saadi, F.S.; Al-amri, B.A.; Al Nofli, S.M.; Van Wunnik, J.N.M.; Jaspers, H.F.; Al Harthi, S.; Shuaili, K.; Cherukupalli, P.K.; Chakravarthi, R. Polymer Flooding in a large field in South Oman-initial results and future plans. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012.

- Saleh, L.D.; Wei, M.; Bai, B. Data analysis and updated screening criteria for polymer flooding based on oilfield data. Spe Reserv. Eval. Eng. 2014, 17, 15–25.

- Sheng, J.J.; Leonhardt, B.; Azri, N. Status of polymer-flooding technology. J. Can. Pet. Technol. 2015, 54, 116–126.

- Standnes, D.C.; Skjevrak, I. Literature review of implemented polymer field projects. J. Pet. Sci. Eng. 2014, 122, 761–775.

- Campbell, T.; Bachman, R. Polymer-Augmented Waterflood in the Rapdan Upper Shaunavon Unit. J. Can. Pet. Technol. 1987, 26.

- DeHekker, T.; Bowzer, J.L.; Coleman, R.V.; Bartos, W.B. A Progress Report on Polymer-Augmented Waterflooding in Wyoming′s North Oregon Basin and Byron Fields. In Proceedings of the SPE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 20–23 April 1986.

- Weiss, W.; Baldwin, R. Planning and implementing a large-scale polymer flood. J. Pet. Technol. 1985, 37, 720–730.

- Moore, J.K. Reservoir Barrier and Polymer Waterflood, Northeast Hallsville Crane Unit. J. Pet. Technol. 1969, 21, 1130–1136.

- Olajire, A.A. Review of ASP EOR (alkaline surfactant polymer enhanced oil recovery) technology in the petroleum industry: Prospects and challenges. Energy 2014, 77, 963–982.

- Sorbie, K. Polymer-Improved Oil Recovery; Blackie & Son: Glasgow, Scotland, 1991; pp. 126–163. [Google Scholar]

- Borthakur, A.; Rahman, M.; Sarmah, A.; Subrahmanyam, B. Partially Hydrolyzed Polyacrylamide for Enhanced Oil-Recovery. Res. Ind. 1995, 40, 90–94.

- Morgan, S.E.; McCormick, C.L. Water-soluble polymers in enhanced oil recovery. Prog. Polym. Sci. 1990, 15, 103–145.

- Sun, Y.; Saleh, L.; Bai, B. Measurement and impact factors of polymer rheology in porous media. Rheol. Intech 2012, 187–188.

- Wever, D.; Picchioni, F.; Broekhuis, A. Polymers for enhanced oil recovery: A paradigm for structure–property relationship in aqueous solution. Prog. Polym. Sci. 2011, 36, 1558–1628.

- Liu, J.-F.; Feng, J.-Y.; Yang, S.-Z.; Gang, H.-Z.; Mu, B.-Z. The recovery of viscosity of HPAM solution in presence of high concentration sulfide ions. J. Pet. Sci. Eng. 2020, 107605.

- Thomas, A. Polymer Flooding, Chemical Enhanced Oil Recovery (cEOR)-a Practical Overview, Dr. Laura Romero-Zerón. InTech 2016, 10, 64623.

- Saboorian-Jooybari, H.; Dejam, M.; Chen, Z. Heavy oil polymer flooding from laboratory core floods to pilot tests and field applications: Half-century studies. J. Pet. Sci. Eng. 2016, 142, 85–100.

- Kaminsky, R.D.; Wattenbarger, R.C.; Szafranski, R.C.; Coutee, A. Guidelines for polymer flooding evaluation and development. In Proceedings of the International Petroleum Technology Conference, Dubai, UAE, 4–6 December 2007. [Google Scholar]

- Zhao, F.-L.; Wang, Y.-F.; Dai, C.-L.; Ren, S.; Jiao, C. Techniques of enhanced oil recovery after polymer flooding. Zhongguo Shi You Daxue Xuebao. J. China Univ. Pet. 2006, 30, 86–89.