| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Dmitry Pashchenko | -- | 1992 | 2022-03-31 19:52:27 | | | |

| 2 | Amina Yu | -38 word(s) | 1954 | 2022-04-01 03:34:58 | | | | |

| 3 | Amina Yu | -3 word(s) | 1951 | 2022-04-01 03:39:35 | | | | |

| 4 | Amina Yu | + 1 word(s) | 1952 | 2022-04-06 10:51:21 | | |

Video Upload Options

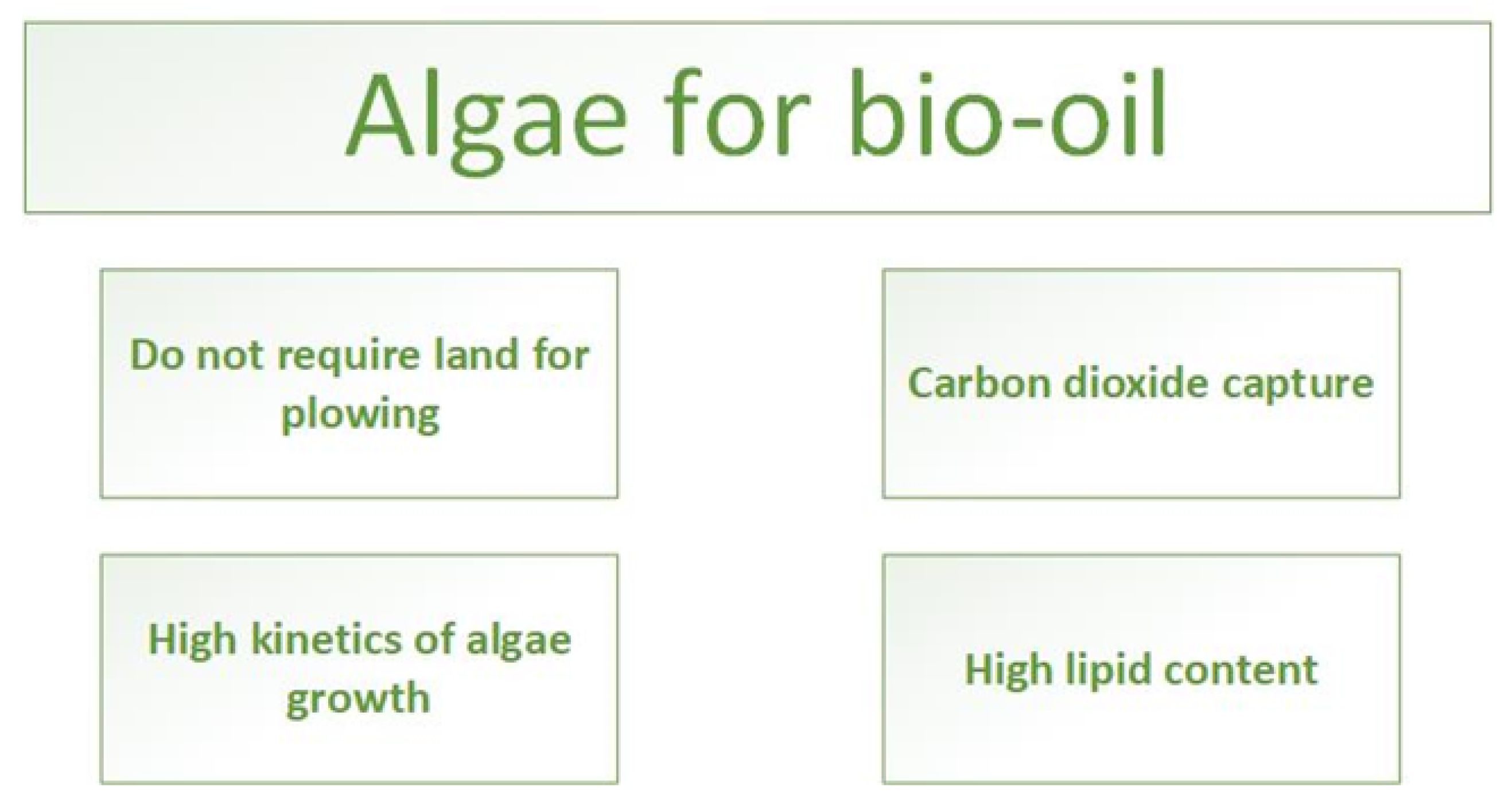

The importance of the cultivation of algae in various fields, including in the field of energy, is very high. Algae as a reserve type of renewable fuel are considered thanks to the rapid growth of algae and the ability of algae to store lipids.

1. Introduction

2. Capture and Sequestration of Carbon Dioxide by Microalgae

It was much devoted to the capture of carbon dioxide. Now, scientists from all over the world are actively offering a completely different approach—not only to capture CO2 but also to immediately use it for energy reproduction. This approach to solving the greenhouse problem is very relevant because of the high cost and complexity of technologies for capturing CO2 emissions, the same CO2 storage facilities also need to be maintained, and they uselessly occupy a considerable area. Thus, the reproduction of biofuels together with the capture of carbon dioxide is an elegant and high-potential solution to the problem of global warming. CO2 accounts for 77% of all greenhouse gases. Thus, despite the content of nitrogen oxides, hydrocarbons, and sulfur dioxide in greenhouse gases, it is necessary to capture CO2. Therefore, if you defeat uncontrolled mass emissions of CO2, you can also defeat a whole host of environmental problems, such as the drying up of natural freshwater, disruption of food chains, and the extinction of entire animal species, and so on.

3. Micro and Macro Algae—Rationale for the Use of Algae to Capture Carbon Dioxide

4. Using Micro and Macroalgae as an Energy Resource

References

- Miyamoto, M.; Takeuchi, K. Climate agreement and technology diffusion: Impact of the Kyoto Protocol on international patent applications for renewable energy technologies. Energy Policy 2019, 129, 1331–1338.

- Kuriyama, A.; Abe, N. Ex-post assessment of the Kyoto Protocol–quantification of CO2 mitigation impact in both Annex B and non-Annex B countries. Appl. Energy 2018, 220, 286–295.

- Aichele, R.; Felbermayr, G. Kyoto and the carbon footprint of nations. J. Environ. Econ. Manag. 2012, 63, 336–354.

- Maamoun, N. The Kyoto protocol: Empirical evidence of a hidden success. J. Environ. Econ. Manag. 2019, 95, 227–256.

- Bauer, A.; Menrad, K. Standing up for the Paris Agreement: Do global climate targets influence individuals’ greenhouse gas emissions? Environ. Sci. Policy 2019, 99, 72–79.

- Morais, R.R.; Pascoal, A.M.; Pereira-Júnior, M.A.; Batista, K.A.; Rodriguez, A.G.; Fernandes, K.F. Bioethanol production from Solanum lycocarpum starch: A sustainable non-food energy source for biofuels. Renew. Energy 2019, 140, 361–366.

- Xu, C.; Wang, H.; Li, X.; Zhou, W.; Wang, C.; Wang, S. Explosion characteristics of a pyrolysis biofuel derived from rice husk. J. Hazard. Mater. 2019, 369, 324–333.

- Chowdhury, H.; Loganathan, B. Third-generation biofuels from microalgae: A review. Curr. Opin. Green Sustain. Chem. 2019, 20, 39–44.

- Pan, S.Y.; Chiang, P.C.; Pan, W.; Kim, H. Advances in state-of-art valorization technologies for captured CO2 toward sustainable carbon cycle. Crit. Rev. Environ. Sci. Technol. 2018, 48, 471–534.

- Rahman, F.A.; Aziz, M.M.A.; Saidur, R.; Bakar, W.A.W.A.; Hainin, M.; Putrajaya, R.; Hassan, N.A. Pollution to solution: Capture and sequestration of carbon dioxide (CO2) and its utilization as a renewable energy source for a sustainable future. Renew. Sustain. Energy Rev. 2017, 71, 112–126.

- Thiyagarajan, S.; Varuvel, E.G.; Martin, L.J.; Beddhannan, N. Mitigation of carbon footprints through a blend of biofuels and oxygenates, combined with post-combustion capture system in a single cylinder CI engine. Renew. Energy 2019, 130, 1067–1081.

- Aziz, M.B.A.; Kassim, K.A.; Bakar, W.A.W.A.; Marto, A. Fossil Free Fuels: Trends in Renewable Energy; CRC Press: Boca Raton, FL, USA, 2019.

- Alami, A.H.; Alasad, S.; Ali, M.; Alshamsi, M. Investigating algae for CO2 capture and accumulation and simultaneous production of biomass for biodiesel production. Sci. Total Environ. 2021, 759, 143529.

- Bhola, V.; Swalaha, F.; Kumar, R.R.; Singh, M.; Bux, F. Overview of the potential of microalgae for CO2 sequestration. Int. J. Environ. Sci. Technol. 2014, 11, 2103–2118.

- Tarhan, S.Z.; Koçer, A.T.; Özçimen, D.; Gökalp, İ. Cultivation of green microalgae by recovering aqueous nutrients in hydrothermal carbonization process water of biomass wastes. J. Water Process. Eng. 2020, 40, 101783.

- Aliyu, A.; Lee, J.; Harvey, A. Microalgae for biofuels via thermochemical conversion processes: A review of cultivation, harvesting and drying processes, and the associated opportunities for integrated production. Bioresour. Technol. Rep. 2021, 14, 100676.

- You, X.; Zhang, Z.; Guo, L.; Liao, Q.; Wang, Y.; Zhao, Y.; Jin, C.; Gao, M.; She, Z.; Wang, G. Integrating acidogenic fermentation and microalgae cultivation of bacterial-algal coupling system for mariculture wastewater treatment. Bioresour. Technol. 2021, 320, 124335.

- Lim, Y.A.; Chong, M.N.; Foo, S.C.; Ilankoon, I. Analysis of direct and indirect quantification methods of CO2 fixation via microalgae cultivation in photobioreactors: A critical review. Renew. Sustain. Energy Rev. 2021, 137, 110579.

- Aron, N.S.M.; Khoo, K.S.; Chew, K.W.; Veeramuthu, A.; Chang, J.S.; Show, P.L. Microalgae cultivation in wastewater and potential processing strategies using solvent and membrane separation technologies. J. Water Process Eng. 2021, 39, 101701.

- Yew, G.Y.; Khoo, K.S.; Chia, W.Y.; Ho, Y.C.; Law, C.L.; Leong, H.Y.; Show, P.L. A novel lipids recovery strategy for biofuels generation on microalgae Chlorella cultivation with waste molasses. J. Water Process Eng. 2020, 38, 101665.

- Mathimani, T.; Uma, L.; Prabaharan, D. Formulation of low-cost seawater medium for high cell density and high lipid content of Chlorella vulgaris BDUG 91771 using central composite design in biodiesel perspective. J. Clean. Prod. 2018, 198, 575–586.

- Kumar, B.R.; Mathimani, T.; Sudhakar, M.; Rajendran, K.; Nizami, A.S.; Brindhadevi, K.; Pugazhendhi, A. A state of the art review on the cultivation of algae for energy and other valuable products: Application, challenges, and opportunities. Renew. Sustain. Energy Rev. 2021, 138, 110649.

- Gallego-Cartagena, E.; Castillo-Ramírez, M.; Martínez-Burgos, W. Effect of stressful conditions on the carotenogenic activity of a Colombian strain of Dunaliella salina. Saudi J. Biol. Sci. 2019, 26, 1325–1330.

- Radmann, E.M.; Reinehr, C.O.; Costa, J.A.V. Optimization of the repeated batch cultivation of microalga Spirulina platensis in open raceway ponds. Aquaculture 2007, 265, 118–126.

- Sirikulrat, K.; Pekkoh, J.; Pumas, C. Illumination System for growth and Net Energy Ratio Enhancement of Arthrospira (Spirulina) platensis Outdoor Cultivation in Deep Raceway Pond. Bioresour. Technol. Rep. 2021, 14, 100661.

- Savage, E.; Nagle, N.; Laurens, L.M.; Knoshaug, E.P. Nitrogen derived from Combined Algal Processing supports algae cultivation for biofuels. Algal Res. 2020, 50, 101987.

- Banerjee, S.; Banerjee, S.; Ghosh, A.K.; Das, D. Maneuvering the genetic and metabolic pathway for improving biofuel production in algae: Present status and future prospective. Renew. Sustain. Energy Rev. 2020, 133, 110155.

- Khan, S.; Fu, P. Biotechnological perspectives on algae: A viable option for next generation biofuels. Curr. Opin. Biotechnol. 2020, 62, 146–152.

- Adeniyi, O.M.; Azimov, U.; Burluka, A. Algae biofuel: Current status and future applications. Renew. Sustain. Energy Rev. 2018, 90, 316–335.

- Karthikeyan, S.; Periyasamy, M.; Prathima, A. Combustion analysis of a CI engine with Caulerpa racemosa algae biofuel with nano additives. Mater. Today Proc. 2020, 33, 3324–3329.

- Karthikeyan, S.; Periyasamy, M.; Prathima, A.; Sabariswaran, K. Performance analysis of diesel engine fueled with S. marginatum Macro algae biofuel-diesel blends. Mater. Today Proc. 2020, 33, 3464–3469.

- Plouviez, M.; Shilton, A.; Packer, M.A.; Guieysse, B. Nitrous oxide emissions from microalgae: Potential pathways and significance. J. Appl. Phycol. 2019, 31, 1–8.

- Mathimani, T.; Baldinelli, A.; Rajendran, K.; Prabakar, D.; Matheswaran, M.; van Leeuwen, R.P.; Pugazhendhi, A. Review on cultivation and thermochemical conversion of microalgae to fuels and chemicals: Process evaluation and knowledge gaps. J. Clean. Prod. 2019, 208, 1053–1064.

- Saengsawang, B.; Bhuyar, P.; Manmai, N.; Ponnusamy, V.K.; Ramaraj, R.; Unpaprom, Y. The optimization of oil extraction from macroalgae, Rhizoclonium sp. by chemical methods for efficient conversion into biodiesel. Fuel 2020, 274, 117841.

- Khammee, P.; Ramaraj, R.; Whangchai, N.; Bhuyar, P.; Unpaprom, Y. The immobilization of yeast for fermentation of macroalgae Rhizoclonium sp. for efficient conversion into bioethanol. Biomass Convers. Biorefin. 2021, 11, 827–835.