Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Alifdalino Sulaiman | + 1907 word(s) | 1907 | 2022-02-18 03:12:44 | | | |

| 2 | Lindsay Dong | Meta information modification | 1907 | 2022-03-24 06:35:05 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Sulaiman, A. Innovative Technologies for Polyphenol Oxidase Inactivation. Encyclopedia. Available online: https://encyclopedia.pub/entry/20965 (accessed on 07 February 2026).

Sulaiman A. Innovative Technologies for Polyphenol Oxidase Inactivation. Encyclopedia. Available at: https://encyclopedia.pub/entry/20965. Accessed February 07, 2026.

Sulaiman, Alifdalino. "Innovative Technologies for Polyphenol Oxidase Inactivation" Encyclopedia, https://encyclopedia.pub/entry/20965 (accessed February 07, 2026).

Sulaiman, A. (2022, March 24). Innovative Technologies for Polyphenol Oxidase Inactivation. In Encyclopedia. https://encyclopedia.pub/entry/20965

Sulaiman, Alifdalino. "Innovative Technologies for Polyphenol Oxidase Inactivation." Encyclopedia. Web. 24 March, 2022.

Copy Citation

Polyphenol oxidase (PPO) catalyses the browning reaction during fruit processing and storage. It is considered a threat to clean labels and minimally processed fruit products. Unwanted changes in fruits’ appearance and quality represent a cost to the industry. High pressure and ultrasound, in addition to thermal treatment, are effective in reducing PPO activity and producing high-quality products. PPO from different fruit cultivars behaves differently when submitted to different treatments.

high hydrostatic pressure

sonication

heat

browning

polyphenol oxidase

1. Introduction

Browning is a common occurrence during the preparation and storage of fruits and vegetables such as apples, potatoes, bananas, and avocado. It occurs when food undergoes chemical reactions that turn it brown. There are two types of browning: enzymatic browning and non-enzymatic browning. Enzymatic browning is believed to cause more than 50% loss during pre-harvest and post-harvest processing of fruits and vegetables [1]. The enzyme that is responsible for food browning is polyphenol oxidase (PPO). Browning occurs when PPO oxidises phenolic substances, resulting in food darkening [2]. PPO activity is a major problem in the production and marketing of food items, particularly fruit juices. When browning occurs, the appearance, and the quality of fruit juices are altered. Many researchers have investigated how to inhibit undesirable browning to increase their shelf life [3]. However, in certain foods such as coffee, cocoa beans, and tea, browning is needed to produce the desired colour and flavour [4]. This is also the case for dry fruits such as raisins. It is critical in food processing to use physical (thermal and non-thermal processing) or chemical agents (Such as citric or ascorbic acid) to avoid or slow down enzymatic browning.

Thermal or non-thermal processing can be used to inactivate polyphenol oxidase. The PPO enzyme in fruit (juice) is inactivated during thermal processing by heating the juice to a temperature of 70 °C to 90 °C. Thermal treatment of fruits and vegetables is a classic method for destroying bacteria and inactivating enzymes. For a long time, thermal food preservation methods have dominated the food processing sector [5]. Thermal treatment, on the other hand, can result in negative changes in food attributes such as loss of colour, texture, and flavour, as well as nutrient quality degradation [6][7]. Heat treatment of fruits can cause heat-sensitive components including vitamins to be destroyed [1]. Industry and researchers have developed non-thermal food preservation techniques in response to consumer demand for safe and nutritious juices. Some of the technologies include high pressure processing (HPP), high pressure carbon dioxide (HPCD), ultrasound, and irradiation [8][9][10][11]. The latter can be used alone or in combination with heat to enhance bacterial and enzyme inactivation. The adverse effects of thermal treatment on a variety of fruits have been mitigated using these strategies [6]. Food will be less impacted by the moderate heat/no heat employed in these processes, allowing for the retention of nutritional, physical, taste, and flavour properties identical to those of fresh foods [12][13][14][15]. These non-thermal processing methods have the potential to help with product development in order to address the rising demand for high-value, complex, and diverse food items. The approach for thermal treatment, high pressure processing, and ultrasonic technologies for the inactivation of PPO enzymes are discussed in this study.

2. Enzymatic Browning: Polyphenol Oxidase

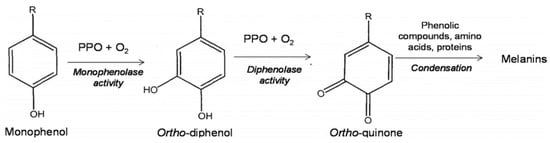

Enzymatic browning is a chemical process that discolours fruits or fruit products (juice, puree, etc.) into a brown colour. The enzymes polyphenol oxidase (PPO), 1,2 benzenediol oxygen oxidoreductase, phenolase, monophenol oxidase, diphenol oxidase (DPO), and tyrosinase catalyse browning [16]. Browning is caused by the presence of oxygen in the air in contact with sliced fruit (oxidation reaction). Figure 1 indicates that quick browning occurs in the presence of oxygen due to the enzymatic oxidation of phenols to orthoquinones, which subsequently polymerise in a sequence of processes, resulting in the development of brown or black pigments (melanins) on the food’s surface [17].

Figure 1. Browning reaction of PPO enzyme taken from [18].

Most fruits and vegetables that are exposed to air after being chopped, sliced, or pulped, will be affected by enzymatic browning due to mechanical damage of plant tissues and cells. Enzymatic browning can occur during frozen or cold food transit and storage. PPO produces quinones that bind to plant proteins, reducing protein digestion and nutritional value for herbivores [19]. The PPO enzyme is structurally composed of two copper ions in its active region, which is surrounded by six histidines and one cysteine residue [1]. Copper ions in the enzyme are important factors in the oxidation–reduction process by cyclically transitioning the active site between met-, oxy-, and deoxy- forms during the catalysis reaction [20]. PPO has two copper atoms in its activity site, and the enzyme catalyses two distinct processes in the presence of molecular oxygen: the hydroxylation of monophenols (monophenolase activity) and the oxidation of o-diphenols to o-quinones (diphenolase activity) [21]. This is followed by non-enzymatic polymerisation of the quinones, which produces the pigment melanins, resulting in dark colours [22][23].

3. Thermal and Innovative Technologies for PPO Inactivation

3.1. Thermal Treatment

Thermal processing is a traditional food preservation method that employs heat to preserve and process food products. The inactivation of polyphenol oxidase (PPO) by heat treatment is the most effective and standard method to control enzymatic browning. Heat is used in this treatment to destroy microorganisms and inactivate enzymes. However, the thermal treatment causes undesirable changes in food qualities, such as loss of colour, flavour, texture, and nutrients [24]. Blanching is a common thermal treatment used to inactivate enzymes in fruits and vegetables. Blanching is a water-intensive technology and is deemed as uneconomical technology [25]. It involves rapid heating of fruits and vegetables to a predetermined temperature and holding it for a set period, usually 1 to less than 10 min [26]. The most common method of blanching is hot water blanching, during which the products are immersed in hot water (70 to 100 °C) for several minutes [27][28].

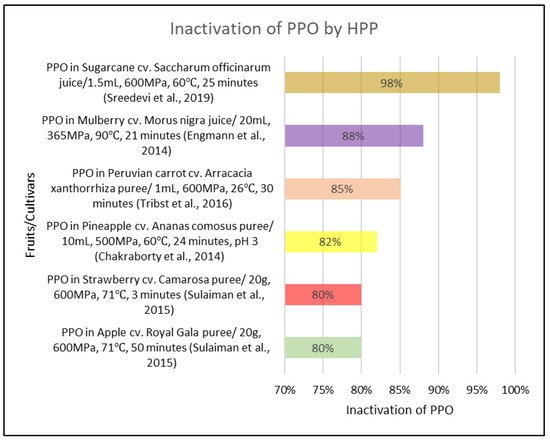

Figure 2 shows studies on the thermal inactivation of PPO enzymes that have been carried out by various scholar [29][30][31][32][33][34]. The effect of temperature on PPO stability is commonly investigated by incubating the enzyme at a higher temperature. Processes from 70 °C to 80 °C for 5–25 min were seen to provide more than 80% of PPO inactivation. However, studies by Sreedevi [30] on sugarcane and Sulaiman [29] on strawberry PPOs show that at a lower temperature of 60 °C, 80% of PPO inactivation can also be achieved. This proves that different fruits can react at different temperatures and times to achieve similar PPO inactivation. Different technologies used to produce juice and puree, different fruit cultivars, and different methods used to determine PPO activity could explain the differences in the inactivation after processing.

3.2. High Pressure Processing

High pressure processing (HPP) has been considered as an alternative technology to preserve food without heat or chemical preservatives [35]. HPP is a non-thermal process that is very effective in assuring the safety and quality of minimally processed food products. In contrast to thermal treatment, this technology can inactivate foodborne microorganisms and enzymes while maintaining food quality [36]. For high pressure processing, raising treatment pressures will generally result in faster microbial inactivation in shorter times. However, the increased pressure can cause protein denaturation and other potentially harmful changes in food quality, which might affect the appearance and texture of the food [35].

For the inactivation of enzymes, the pressure is strongly dependent on the type of endogenous enzymes—some enzymes can deactivate at room temperature by a few hundred MPa [26][30][37][38], while others can withstand 1000 MPa [39][40]. As some food enzymes are highly stable, pressure must be combined with other factors such as temperature to inactivate them. During the process, hydraulic fluid (typically water) is poured into a chamber and pressurised with a pump. This pressure is then transferred to the food isostatically through the packaging, where the pressure at all sides is at the same magnitude (Isostatic principle). This procedure can increase the product’s shelf life without the addition of preservatives while maintaining the product’s quality (e.g., nutrients).

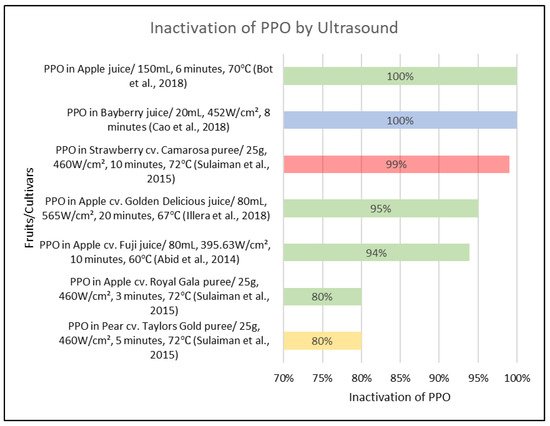

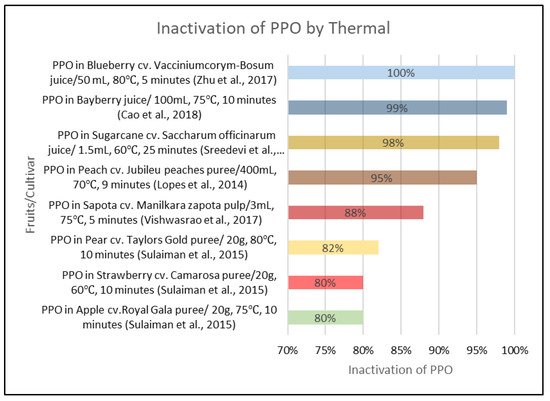

When using a high pressure treatment for food processing, it is crucial to understand the interactions between the processing parameters (pressure, time, and temperature) to figure out the best conditions to achieve desired levels of microbial inactivation while maintaining a high degree of nutritional quality, good flavour, and texture [41]. Increased treatment pressures for high pressure processing will generally result in higher microbial inactivation. However, some food enzymes are extremely stable, so the pressure must be paired with other factors such as temperature to inactivate them. Several studies [26][42] demonstrated that by utilising higher pressure (600 MPa) and a moderate temperature, fruits juice and puree could achieve PPO inactivation of more than 80%. For example, data by Engmann [43] show that Mulberry can achieve 88% of inactivation with pressure 365 MPa and a combination of thermal treatment at 90 °C. Applying pressure without heat treatment in fruits puree and juice is insufficient to totally inactivate the oxidative enzymes. Temperature assistance is required to achieve significant inactivation of these enzymes, which may improve the shelf stability of the products. The efficiency and effectiveness of HPP can be determined by various factors such as the type of food, processing time, initial pH, and the presence of certain additives in the food. The effect of high pressure processing (HPP) on PPO inactivation of various fruits is shown in Figure 3 [9][26][30][38][43].

3.3. Ultrasound Processing

Food products that are free of additives or preservatives have become a consumer demand for high quality and fresh products, especially juice products. This demand has led researchers or producers to employ ultrasonic technology in the production of fruit juice. Ultrasonic or ultrasound is a promising technology that can be used to replace traditional thermal treatment processes. It has the potential to improve the quality and safety of juice by converting electrical energy into mechanical energy through piezoelectric materials [42]. When sound waves pass through the fluid, continuous compression and relaxation will occur, and then the negative pressure overcomes the tensile force, the transmission of sound waves to the relaxed position causes the formation of micron-sized bubbles and spaces [44]. Ultrasound is also transmitted at frequencies higher than the audible frequency of 20 kHz [45]. The frequency of ultrasonic equipment is usually 20 kHz to 10 MHz [46].

The applications of ultrasound in the food industry include low-energy and high-energy ultrasound. Low energy intensities of ultrasound, less than 1 W·cm−2, and frequency greater than 100 kHz [42] can be used to monitor food composition and physicochemical properties of food during processing and storage, for quality control purposes. High-energy ultrasound is also called power ultrasound because the intensity is higher than 1 W·cm−2, and the frequency range is 20 to 100 kHz [42]. Ultrasound can be applied to a product using two methods: submergence in an ultrasonic bath [47] or direct treatment to the product using a probe sonicator [48][49].

Figure 4 summarises PPO inactivation by ultrasound in fruit juice [29][34][50]. Ultrasound occurs at frequencies ranging from 20 kHz to 24 kHz, inactivating PPO by more than 80%. Ultrasound combined with heat, also known as thermosonication (TS), is another emerging preservation method. TS treatment on apple juice of different cultivars shows an inactivation PPO of more than 80% at various temperatures (ranging between 60 °C and 70 °C) and time (6 to 20 min) [51][50][52]. A comparison of apple juice shows that different parameters used such as sound intensity, time, and temperature would affect the inactivation of PPO in the fruits. The higher the intensity (or amplitude) of ultrasound applied is, the more enzyme is inactivated, because high intensity releases high energy. The wide range of data on PPO inactivation in fruits shows that enzyme inactivation is influenced by various parameters, including source, sub-type, environment, and physicochemical conditions such as pH and temperature.

References

- Iqbal, A.; Murtaza, A.; Hu, W.; Ahmad, I.; Ahmed, A.; Xu, X. Activation and inactivation mechanisms of polyphenol oxidase during thermal and non-thermal methods of food processing. Food Bioprod. Process. 2019, 117, 170–182.

- Ferreira-Holderbaum, D.; Kon, T.; Kudo, T.; Pedro Guerra, M. HortScience: A publication of the American Society for Horticultural Science. HortScience 2010, 45, 1150–1154.

- Kaanane, A.; Labuza, T.P. The Maillard reaction in foods. Prog. Clin. Biol. Res. 1989, 304, 301–327.

- He, Q.; Luo, Y.; Chen, P. Elucidation of the mechanism of enzymatic browning inhibition by sodium chlorite. Food Chem. 2008, 110, 847–851.

- Jiménez-Sánchez, C.; Lozano-Sánchez, J.; Segura-Carretero, A.; Fernández-Gutiérrez, A. Alternatives to conventional thermal treatments in fruit-juice processing. Part 1: Techniques and applications. Crit. Rev. Food Sci. Nutr. 2017, 57, 501–523.

- Iqbal, A.; Murtaza, A.; Muhammad, Z.; Elkhedir, A.E.; Tao, M.; Xu, X. Inactivation, aggregation and conformational changes of polyphenol oxidase from quince (Cydonia oblonga Miller) juice subjected to thermal and high pressure carbon dioxide treatment. Molecules 2018, 23, 1743.

- How, M.S.; Jones, J.R.; Morgenstern, M.P.; Gray-Stuart, E.; Bronlund, J.E.; Saint-Eve, A.; Trelea, I.C.; Souchon, I. Modelling the role of oral processing on in vivo aroma release of white rice: Conceptual model and experimental validation. LWT 2021, 141, 110918, Corrigendum to LWT 2021, 144, 111391.

- Sulaiman, A.; Silva, F.V.M. High pressure processing, thermal processing and freezing of ‘Camarosa’ strawberry for the inactivation of polyphenoloxidase and control of browning. Food Control 2013, 33, 424–428.

- Sulaiman, A.; Soo, M.J.; Yoon, M.M.L.; Farid, M.; Silva, F.V.M. Modeling the polyphenoloxidase inactivation kinetics in pear, apple and strawberry purees after High Pressure Processing. J. Food Eng. 2015, 147, 89–94.

- Selvarajan, E.; Veena, R.; Manoj Kumar, N. Polyphenol oxidase, beyond enzyme browning. In Microbial Bioprospecting for Sustainable Development; Springer: Singapore, 2018; pp. 203–222.

- Xu, J.; Zhou, L.; Miao, J.; Yu, W.; Zou, L.; Zhou, W.; Liu, C.; Liu, W. Effect of Cinnamon Essential Oil Nanoemulsion Combined with Ascorbic Acid on Enzymatic Browning of Cloudy Apple Juice. Food Bioprocess Technol. 2020, 13, 860–870.

- Chakraborty, S.; Rao, P.S.; Mishra, H.N. Kinetic modeling of polyphenoloxidase and peroxidase inactivation in pineapple (Ananas comosus L.) puree during high pressure and thermal treatments. Innov. Food Sci. Emerg. Technol. 2015, 27, 57–68.

- Zhou, L.; Liu, W.; Xiong, Z.; Zou, L.; Liu, J.; Zhong, J.; Chen, J. Effect of ultrasound combined with malic acid on the activity and conformation of mushroom (Agaricus bisporus) polyphenoloxidase. Enzym. Microb. Technol. 2016, 90, 61–68.

- Ma, Q.; Hamid, N.; Oey, I.; Kantono, K.; Farouk, M. The impact of high pressure processing on physicochemical properties and sensory characteristics of three different lamb meat cuts. Molecules 2020, 25, 2665.

- Characteristics, C.; Cuts, L. Effect of high hydrostatic pressure processing on the chemical characteristics of different lamb cuts. Foods 2020, 9, 1444.

- Corzo-Martinez, M.; Corzo, N.; Villamiel, M.; del Castillo, M.D. Chapter 4: Browning reactions. In Browning Reactions; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 56–83.

- Laurila, E.; Kervinen, R.; Ahvenainen, R. The inhibition of enzymatic browning in minimally processed vegetables and fruits. Postharvest. News Inf. 1998, 9, 53–65.

- Taranto, F.; Pasqualone, A.; Mangini, G.; Tripodi, P.; Miazzi, M.M.; Pavan, S.; Montemurro, C. Polyphenol oxidases in crops: Biochemical, physiological and genetic aspects. Int. J. Mol. Sci. 2017, 18, 377.

- Ryan, C.A. The systemin signaling pathway: Differential activation of plant defensive genes. Biochim. Biophys. Acta-Protein Struct. Mol. Enzymol. 2000, 1477, 112–121.

- Mishra, B.B.; Gautam, S. Polyphonel oxidases: Biochemical and molecular characterization, distribution, role and its control. Enzym. Eng. 2016, 5, 141–149.

- Queiroz, C.; Mendes Lopes, M.L.; Fialho, E.; Valente-Mesquita, V.L. Polyphenol oxidase: Characteristics and mechanisms of browning control. Food Rev. Int. 2008, 24, 361–375.

- Espín, J.C.; García-Ruiz, P.A.; Tudela, J.; Varón, R.; García-Cánovas, F. Monophenolase and Diphenolase Reaction Mechanisms of Apple and Pear Polyphenol Oxidases. J. Agric. Food Chem. 1998, 46, 2968–2975.

- Peñalver, M.J.; Fenoll, L.G.; Rodríguez-López, J.N.; García-Ruiz, P.A.; García-Molina, F.; Varón, R.; García-Cánovas, F.; Tudela, J. Reaction mechanism to explain the high kinetic autoactivation of tyrosinase. J. Mol. Catal. B Enzym. 2005, 33, 35–42.

- Cheng, X.F.; Zhang, M.; Adhikari, B. The inactivation kinetics of polyphenol oxidase in mushroom (Agaricus bisporus) during thermal and thermosonic treatments. Ultrason. Sonochem. 2013, 20, 674–679.

- Myer, P.R.; Parker, K.R.; Kanach, A.T.; Zhu, T.; Morgan, M.T.; Applegate, B.M. The effect of a novel low temperature-short time (LTST) process to extend the shelf-life of fluid milk. Springerplus 2016, 5, 660.

- Chakraborty, S.; Rao, P.S.; Mishra, H.N. Effect of pH on Enzyme inactivation kinetics in high pressure processed pineapple (Ananas comosus L.) puree using response surface methodology. Food Bioprocess Technol. 2014, 7, 3629–3645.

- Xiao, H.W.; Pan, Z.; Deng, L.Z.; El-Mashad, H.M.; Yang, X.H.; Mujumdar, A.S.; Gao, Z.J.; Zhang, Q. Recent developments and trends in thermal blanching—A comprehensive review. Inf. Process. Agric. 2017, 4, 101–127.

- Mukherjee, S.; Chattopadhyay, P.K. Whirling bed blanching of potato cubes and its effects on product quality. J. Food Eng. 2007, 78, 52–60.

- Sulaiman, A.; Soo, M.J.; Farid, M.; Silva, F.V.M. Thermosonication for polyphenoloxidase inactivation in fruits: Modeling the ultrasound and thermal kinetics in pear, apple and strawberry purees at different temperatures. J. Food Eng. 2015, 165, 133–140.

- Sreedevi, P.; Jayachandran, L.E.; Rao, P.S. Kinetic modeling of high pressure induced inactivation of polyphenol oxidase in sugarcane juice (Saccharum officinarum). J. Sci. Food Agric. 2019, 99, 2365–2374.

- Vishwasrao, C.; Chakraborty, S.; Ananthanarayan, L. Partial purification, characterisation and thermal inactivation kinetics of peroxidase and polyphenol oxidase isolated from Kalipatti sapota (Manilkara zapota). J. Sci. Food Agric. 2017, 97, 3568–3575.

- Lopes, A.M.; Toralles, R.P.; Rombaldi, C.V. Thermal inactivation of polyphenoloxidase and peroxidase in Jubileu clingstone peach and yeast isolated from its spoiled puree. Food Sci. Technol. 2014, 34, 150–156.

- Zhu, J.; Wang, Y.; Li, X.; Li, B.; Liu, S.; Chang, N.; Jie, D.; Ning, C.; Gao, H.; Meng, X. Combined effect of ultrasound, heat, and pressure on Escherichia coli O157:H7, polyphenol oxidase activity, and anthocyanins in blueberry (Vaccinium corymbosum) juice. Ultrason. Sonochem. 2017, 37, 251–259.

- Cao, X.; Cai, C.; Wang, Y.; Zheng, X. The inactivation kinetics of polyphenol oxidase and peroxidase in bayberry juice during thermal and ultrasound treatments. Innov. Food Sci. Emerg. Technol. 2018, 45, 169–178.

- Hogan, E.; Kelly, A.L.; Sun, D.W. High pressure processing of foods: An Overview. In Emerging Technologies for Food Processing; Academic Press: Cambridge, MA, USA, 2005; pp. 3–32.

- Seyderhelm, I.; Boguslawski, S.; Michaelis, G.; Knorr, D. Pressure induced inactivation of selected food enzymes. J. Food Sci. 1996, 61, 308–310.

- Marszałek, K.; Mitek, M.; Skąpska, S. The effect of thermal pasteurization and high pressure processing at cold and mild temperatures on the chemical composition, microbial and enzyme activity in strawberry purée. Innov. Food Sci. Emerg. Technol. 2015, 27, 48–56.

- Tribst, A.A.L.; Leite Júnior, B.R.D.C.; De Oliveira, M.M.; Cristianini, M. High pressure processing of cocoyam, Peruvian carrot and sweet potato: Effect on oxidative enzymes and impact in the tuber color. Innov. Food Sci. Emerg. Technol. 2016, 34, 302–309.

- Cano, M.P.; Hernandez, A.; De Ancos, B. High pressure and temperature effects on enzyme inactivation in strawberry and orange products. J. Food Sci. 1997, 62, 85–88.

- Heinisch, O.; Kowalski, E.; Goossens, K.; Frank, J.; Heremans, K.; Ludwig, H.; Tauscher, B. Pressure effects on the stability of lipoxygenase: Fourier transform-infrared spectroscopy (FT-IR) and enzyme activity studies. Z. Lebensm. Unters. Forsch. 1995, 201, 562–565.

- Kaur, B.P.; Srinivasa Rao, P. Process optimization for high pressure processing of black tiger shrimp (Penaeus monodon) using response surface methodology. Food Sci. Technol. Int. 2017, 23, 197–208.

- Abdullah, N.; Chin, N.L. Application of Thermosonication Treatment in Processing and Production of High Quality and Safe-to-Drink Fruit Juices. Agric. Agric. Sci. Procedia 2014, 2, 320–327.

- Engmann, F.N.; Ma, Y.; Zhang, H.; Yu, L.; Deng, N. The application of response surface methodology in studying the effect of heat and high hydrostatic pressure on anthocyanins, polyphenol oxidase, and peroxidase of mulberry (Morus nigra) juice. J. Sci. Food Agric. 2014, 94, 2345–2356.

- Ba, M.; Yildirim, H.B.; Tekin, Z.H. Handbook of Ultrasonics and Sonochemistry; Springer: New York, NY, USA, 2016.

- Butz, P.; Tauscher, B. Emerging technologies: Chemical aspects. Food Res. Int. 2002, 35, 279–284.

- López-Malo, A.; Palou, E.; Jiménez-Fernández, M.; Alzamora, S.M.; Guerrero, S. Multifactorial fungal inactivation combining thermosonication and antimicrobials. J. Food Eng. 2005, 67, 87–93.

- Wu, J.; Gamage, T.V.; Vilkhu, K.S.; Simons, L.K.; Mawson, R. Effect of thermosonication on quality improvement of tomato juice. Innov. Food Sci. Emerg. Technol. 2008, 9, 186–195.

- Rawson, A.; Tiwari, B.K.; Patras, A.; Brunton, N.; Brennan, C.; Cullen, P.J.; O’Donnell, C. Effect of thermosonication on bioactive compounds in watermelon juice. Food Res. Int. 2011, 44, 1168–1173.

- Šimunek, M.; Jambrak, A.R.; Dobrović, S.; Herceg, Z.; Vukušić, T. Rheological properties of ultrasound treated apple, cranberry and blueberry juice and nectar. J. Food Sci. Technol. 2014, 51, 3577–3593.

- Illera, A.E.; Sanz, M.T.; Benito-Román, O.; Varona, S.; Beltrán, S.; Melgosa, R.; Solaesa, A.G. Effect of thermosonication batch treatment on enzyme inactivation kinetics and other quality parameters of cloudy apple juice. Innov. Food Sci. Emerg. Technol. 2018, 47, 71–80.

- Abid, M.; Jabbar, S.; Hu, B.; Hashim, M.M.; Wu, T.; Lei, S.; Khan, M.A.; Zeng, X. Thermosonication as a potential quality enhancement technique of apple juice. Ultrason. Sonochem. 2014, 21, 984–990.

- Bot, F.; Calligaris, S.; Cortella, G.; Plazzotta, S.; Nocera, F.; Anese, M. Study on high pressure homogenization and high power ultrasound effectiveness in inhibiting polyphenoloxidase activity in apple juice. J. Food Eng. 2018, 221, 70–76.

More

Information

Subjects:

Food Science & Technology

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

6.1K

Revisions:

2 times

(View History)

Update Date:

24 Mar 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No