| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Hebah AL Ubeed | + 1702 word(s) | 1702 | 2022-03-07 03:27:14 | | | |

| 2 | Peter Tang | Meta information modification | 1702 | 2022-03-08 09:27:20 | | | | |

| 3 | Peter Tang | Meta information modification | 1702 | 2022-03-08 09:28:13 | | |

Video Upload Options

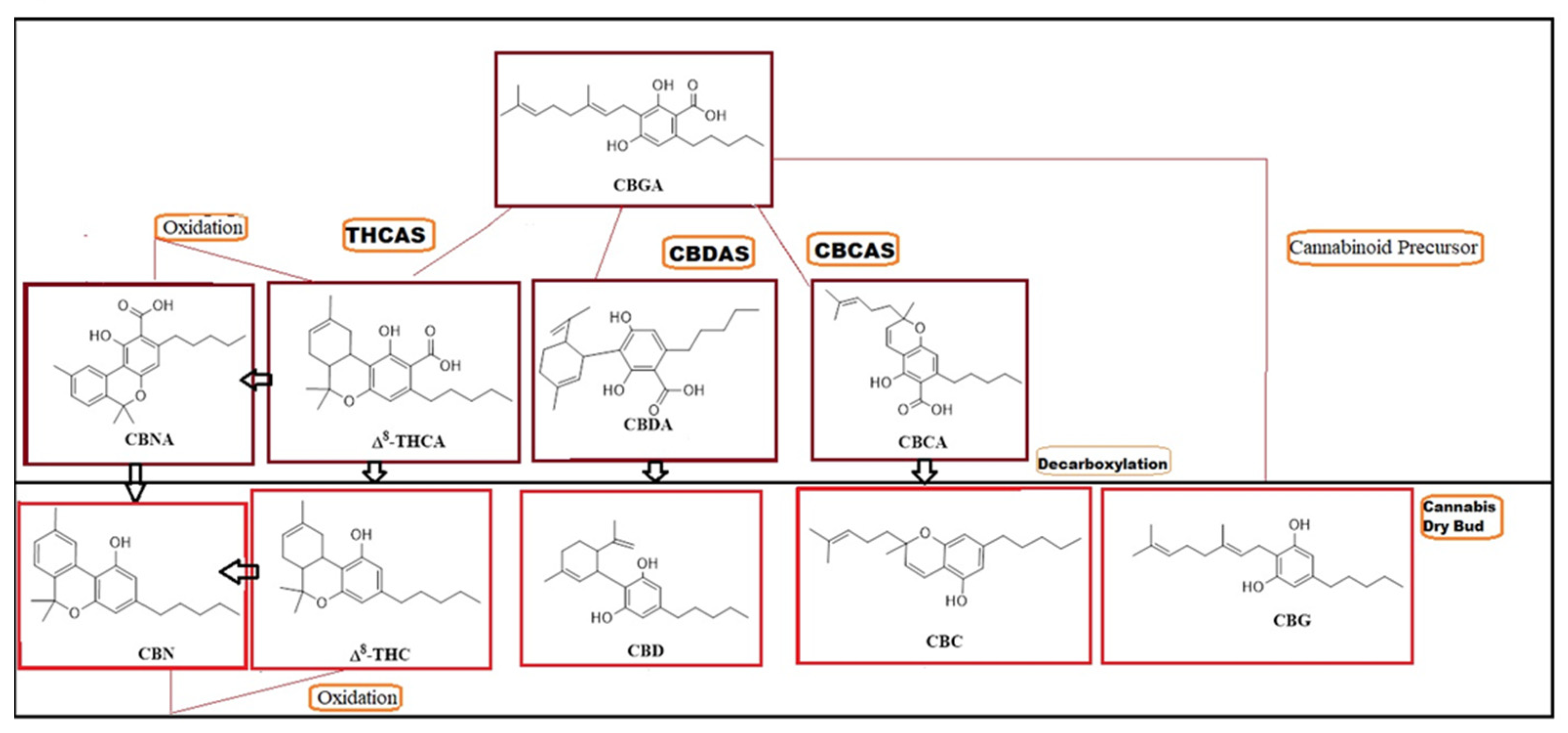

Cannabis has been a traditional medicinal herb in central Asia, with reports of such usage back to 4700 B.P. in China, India, Persia, Egypt, Greece and Rome. It is now also cultivated and used as a drug crop in at least 172 countries and territories worldwide. It is classified as Cannabis Sativa, C. Indica and C. Ruderalis based on genetics, phenotypic properties and chemical structure. The Cannabis industry is rapidly growing; therefore, there is no medicinal cannabis that can be produced without optimising drying methods. Producing high-quality medical products have been a hot topic in recent years.

1. Introduction

2. Harvesting of Cannabis

2.1. Determining the Time to Harvest

2.2. Harvesting Technology

|

Drying Technique |

Drying Conditions/Procedures |

Advantages and Disadvantage |

References |

|---|---|---|---|

|

Hot Air Drying |

The plant materials were hanged on either string lines, wire cages, or static wires upside-down to allow for air circulation and uniform drying by control system has been set between 18–21 °C, relative humidity at 50–55% and air circulation using a small fan under these controlled conditions. Trimmed flowers take only 4–5 days, but the whole plant takes up to 14 days. |

A simple technique, but required regularly maintain optimal conditions. |

|

|

Oven Drying |

Buds were hanging upside down in the oven and oven must be preheated at 37 °C for 24 h to prevent decarboxylation for Phyto cannabinoids |

A simple technique, but under optimal conditions and difficult for commercial production. |

|

|

Microwave-assisted hot air-drying |

Samples were dried by applied volumetric heating and creating a temperature gradient and standard microwaves frequency set at 915 MHz and 240 W to maintain high-quality medicinal cannabis |

An advanced technique, but under optimal conditions. |

|

|

Vacuum Freeze-Drying |

Vacuum freezing the cannabis bud by reducing the temperature to approximately −40 °C before drying the buds to retain a high quality of phytochemicals. |

Quite effective and most suitable advanced technique, but prohibitive operational cost. |

|

|

Microwave-Assisted Freeze Drying |

Circulates cold, dry air over the frozen material at a temperature below −40 °C to −45 °C, pressure at 100 Pa, microwave frequency 2450 MHz. |

An advanced technique, but under optimal conditions. |

3. Drying of Cannabis

References

- Abel, E.L. Cannabis in the ancient world. In Marihuana the First Twelve Thousand Years; Springer Science & Business Media: Boston, MA, USA, 1980; pp. 3–35.

- UNODC. World Drug Report; United Nations Publication: Vienna, Austria, 2008; pp. 95–111.

- Small, E.; Jui, P.Y.; Lefkovitch, L.P. A numerical taxonomic analysis of cannabis with special reference to species delimitation. Syst. Bot. 1976, 1, 67–84.

- Small, E. Evolution and classification of Cannabis sativa (marijuana, hemp) in relation to human utilisation. Bot. Rev. 2015, 81, 189–294.

- Schultes, R.E.; Klein, W.M.; Plowman, T.; Lockwood, T.E. Cannabis: An example of taxonomic neglect. Cannabis Cult. 1975, 23, 21–38.

- Aizpurua-Olaizola, O.; Soydaner, U.; Öztürk, E.; Schibano, D.; Simsir, Y.; Navarro, P.; Etxebarria, N.; Usobiaga, A. Evolution of the cannabinoid and terpene content during the growth of Cannabis sativa plants from different chemotypes. J. Nat. Prod. 2016, 79, 324–331.

- Booth, J.K.; Bohlmann, J. Terpenes in Cannabis sativa–from plant genome to humans. Plant Sci. 2019, 284, 67–72.

- AL Ubeed, H.M.S.; Bhuyan, D.J.; Alsherbiny, M.A.; Basu, A.; Vuong, Q.V. A comprehensive review on the techniques for extraction of bioactive compounds from medicinal cannabis. Molecules 2022, 27, 604.

- Rong, C.; Lee, Y.; Carmona, N.E.; Cha, D.S.; Ragguett, R.-M.; Rosenblat, J.D.; Mansur, R.B.; Ho, R.C.; McIntyre, R.S. Cannabidiol in medical marijuana: Research vistas and potential opportunities. Pharmacol. Res. 2017, 121, 213–218.

- Mohammed, N.; Ceprian, M.; Jimenez, L.; Ruth Pazos, M.; Martínez-Orgado, J. Neuroprotective effects of cannabidiol in hypoxic ischemic insult. The therapeutic window in newborn mice. CNS Neurol. Disord.-Drug Targets 2017, 16, 102–108.

- Kwiatkoski, M.; Guimaraes, F.S.; Del-Bel, E. Cannabidiol-treated rats exhibited higher motor score after cryogenic spinal cord injury. Neurotox. Res. 2012, 21, 271–280.

- Malfait, A.; Gallily, R.; Sumariwalla, P.; Malik, A.; Andreakos, E.; Mechoulam, R.; Feldmann, M. The nonpsychoactive cannabis constituent cannabidiol is an oral anti-arthritic therapeutic in murine collagen-induced arthritis. Proc. Natl. Acad. Sci. USA 2000, 97, 9561–9566.

- Singh, K.; Nassar, N.; Bachari, A.; Schanknecht, E.; Telukutla, S.; Zomer, R.; Piva, T.J.; Mantri, N. The pathophysiology and the therapeutic potential of cannabinoids in prostate cancer. Cancers 2021, 13, 4107.

- Morales, P.; Jagerovic, N. Antitumor cannabinoid chemotypes: Structural insights. Front. Pharmacol. 2019, 10, 621.

- Schley, M.; Legler, A.; Skopp, G.; Schmelz, M.; Konrad, C.; Rukwied, R. Delta-9-thc based monotherapy in fibromyalgia patients on experimentally induced pain, axon reflex flare and pain relief. Curr. Med. Res. Opin. 2006, 22, 1269–1276.

- Eubanks, L.M.; Rogers, C.J.; Beuscher IV, A.E.; Koob, G.F.; Olson, A.J.; Dickerson, T.J.; Janda, K.D. A molecular link between the active component of marijuana and alzheimer’s disease pathology. Mol. Pharm. 2006, 3, 773–777.

- Zeissler, M.-L.; Eastwood, J.; McCorry, K.; Hanemann, C.O.; Zajicek, J.P.; Carroll, C.B. Delta-9-tetrahydrocannabinol protects against mpp+ toxicity in sh-sy5y cells by restoring proteins involved in mitochondrial biogenesis. Oncotarget 2016, 7, 46603.

- Rajavashisth, T.B.; Shaheen, M.; Norris, K.C.; Pan, D.; Sinha, S.K.; Ortega, J.; Friedman, T.C. Decreased prevalence of diabetes in marijuana users: Cross-sectional data from the national health and nutrition examination survey (nhanes) iii. BMJ Open 2012, 2, e000494.

- Eisohly, H.N.; Turner, C.E.; Clark, A.M.; Eisohly, M.A. Synthesis and antimicrobial activities of certain cannabichromene and cannabigerol related compounds. J. Pharm. Sci. 1982, 71, 1319–1323.

- Shinjyo, N.; Di Marzo, V. The effect of cannabichromene on adult neural stem/progenitor cells. Neurochem. Int. 2013, 63, 432–437.

- Usami, N.; Kobana, K.; Yoshida, H.; Kimura, T.; Watanabe, K.; Yoshimura, H.; Yamamoto, I. Synthesis and pharmacological activities in mice of halogenated δ9-tetrahydrocannabinol derivatives. Chem. Pharm. Bull. 1998, 46, 1462–1467.

- Fellermeier, M.; Zenk, M.H. Prenylation of olivetolate by a hemp transferase yields cannabigerolic acid, the precursor of tetrahydrocannabinol. FEBS Lett. 1998, 427, 283–285.

- Sirikantaramas, S.; Morimoto, S.; Shoyama, Y.; Ishikawa, Y.; Wada, Y.; Shoyama, Y.; Taura, F. The gene controlling marijuana psychoactivity: Molecular cloning and heterologous expression of δ1-tetrahydrocannabinolic acid synthase from Cannabis sativa L. J. Biol. Chem. 2004, 279, 39767–39774.

- Taura, F.; Morimoto, S.; Shoyama, Y.; Mechoulam, R. First direct evidence for the mechanism of. Delta. 1-tetrahydrocannabinolic acid biosynthesis. J. Am. Chem. Soc. 1995, 117, 9766–9767.

- Gagne, S.J.; Stout, J.M.; Liu, E.; Boubakir, Z.; Clark, S.M.; Page, J.E. Identification of olivetolic acid cyclase from Cannabis sativa reveals a unique catalytic route to plant polyketides. Proc. Natl. Acad. Sci. USA 2012, 109, 12811–12816.

- Thomas, B.F.; Elsohly, M. The botany of Cannabis sativa L. In The Analytical Chemistry of Cannabis: Quality Assessment, Assurance and Regulation of Medicinal Marijuana and Cannabinoid Preparations; Elsevier: Oxford, UK, 2015; pp. 1–22.

- Radwan, M.M.; Chandra, S.; Gul, S.; ElSohly, M.A. Cannabinoids, phenolics, terpenes and alkaloids of cannabis. Molecules 2021, 26, 2774.

- Petrovska, B. Historical review of medicinal plants’ usage. Pharmacogn. Rev. 2012, 6, 1–5.

- Jin, D.; Dai, K.; Xie, Z.; Chen, J. Secondary metabolites profiled in cannabis inflorescences, leaves, stem barks and roots for medicinal purposes. Sci. Rep. 2020, 10, 3309.

- Lozano, I. The therapeutic use of Cannabis sativa (L.) in arabic medicine. J. Cannabis Ther. 2001, 1, 63–70.

- Stuart, G.; Smith, F. Part 1 vegetable kingdom. In Chinese Materia Medica; American Presbyterian Mission Press: Shanghai, China, 1911.

- Balant, M.; Gras, A.; Ruz, M.; Vallès, J.; Vitales, D.; Garnatje, T. Traditional uses of cannabis: An analysis of the cannuse database. J. Ethnopharmacol. 2021, 279, 114362.

- Lima, K.S.B.; da Cruz Silva, M.E.G.; de Lima Araújo, T.C.; da Fonseca Silva, C.P.; Santos, B.L.; de Araújo Ribeiro, L.A.; Menezes, P.M.N.; Silva, M.G.; Lavor, É.M.; Silva, F.S. Cannabis roots: Pharmacological and toxicological studies in mice. J. Ethnopharmacol. 2021, 271, 113868.

- Minghetti, P.; Marini, V.; Zaccara, V.; Casiraghi, A. Regulation for prescribing and dispensing system of cannabis: The italian case. Curr. Bioact. Compd. 2019, 15, 196–200.

- Sirikantaramas, S.; Taura, F.; Tanaka, Y.; Ishikawa, Y.; Morimoto, S.; Shoyama, Y. Tetrahydrocannabinolic acid synthase, the enzyme controlling marijuana psychoactivity, is secreted into the storage cavity of the glandular trichomes. Plant Cell Physiol. 2005, 46, 1578–1582.

- Morimoto, S.; Tanaka, Y.; Sasaki, K.; Tanaka, H.; Fukamizu, T.; Shoyama, Y.; Shoyama, Y.; Taura, F. Identification and characterisation of cannabinoids that induce cell death through mitochondrial permeability transition in cannabis leaf cells. J. Biol. Chem. 2007, 282, 20739–20751.

- Lam, E.; Kato, N.; Lawton, M. Programmed cell death, mitochondria and the plant hypersensitive response. Nature 2001, 411, 848–853.

- Mechoulam, R. Marihuana chemistry: Recent advances in cannabinoid chemistry open the area to more sophisticated biological research. Science 1970, 168, 1159–1166.

- Balk, J.; Chew, S.K.; Leaver, C.J.; McCabe, P.F. The intermembrane space of plant mitochondria contains a dnase activity that may be involved in programmed cell death. Plant J. 2003, 34, 573–583.

- Matile, P. Chloroplast senescence. In Crop Photosynthesis: Spatial Temporal Determinants; Baker, N.R., Thomas, H.C., Eds.; Elsevier: Amsterdam, The Netherlands, 1992; Volume 12, pp. 413–440.

- Baines, C.P.; Kaiser, R.A.; Purcell, N.H.; Blair, N.S.; Osinska, H.; Hambleton, M.A.; Brunskill, E.W.; Sayen, M.R.; Gottlieb, R.A.; Dorn, G.W. Loss of cyclophilin d reveals a critical role for mitochondrial permeability transition in cell death. Nature 2005, 434, 658–662.

- Gaoni, Y.; Mechoulam, R. Isolation, structure and partial synthesis of an active constituent of hashish. J. Am. Chem. Soc. 1964, 86, 1646–1647.

- Rosenthal, E. Harvest and beyond In Ed Rosenthal’s Marijuana Grower’s Handbook: Your Complete Guide for Medical & Personal Marijuana Cultivation; Angela Bacca, H.L., Johnson-Igra, D., Eds.; Quick American Publishing: Oakland, CA, USA, 2010; pp. 393–411.

- Jin, D.; Jin, S.; Chen, J. Cannabis indoor growing conditions, management practices and post-harvest treatment: A review. Am. J. Plant Sci. 2019, 10, 925.

- Xiao, K.; Mao, X.; Lin, Y.; Xu, H.; Zhu, Y.; Cai, Q.; Xie, H.; Zhang, J. Trichome, a functional diversity phenotype in plant. Mol. Biol. 2017, 6, 183.

- Clarke, R.; Merlin, M. Ethnobotanical origins, early cultivation and evolution through human selection. In Cannabis: Evolution and Ethnobotany; University of California Press: London, UK, 2016; pp. 29–57.

- Upton, R.; ElSohly, M.; Craker, L.; Romm, A.; Russo, E.; Sexton, M. Commercial sources and handling. In Cannabis Inflorescence: CANNABIS spp.: Standards of Identity, Analysis and Quality Control; American Herbal Pharmacopoeia: Soquel, CA, USA, 2013; pp. 18–33.

- Rosenthal, E.; Downs, D. Marijuana Harvest: How to Maximize Quality and Yield in Your Cannabis Garden, illustrated ed.; Quick American: Piedmont: San Francisco, CA, USA, 2017.

- Tettey, J. Description of the cannabis plant and illicit cannabis products. In Recommended Methods for the Identification and Analysis of Cannabis and Cannabis Products; United Nations Office on Drugs and Crime: New York, NY, USA, 2009; p. 60.

- Crispim Massuela, D.; Hartung, J.; Munz, S.; Erpenbach, F.; Graeff-Hönninger, S. Impact of harvest time and pruning technique on total cbd concentration and yield of medicinal cannabis. Plants 2022, 11, 140.

- Jin, D.; Henry, P.; Shan, J.; Chen, J. Identification of chemotypic markers in three chemotype categories of cannabis using secondary metabolites profiled in inflorescences, leaves, stem bark and roots. Front. Plant Sci. 2021, 12, 699530.

- Bergman, R. Harvesting. In The Marijuana Grow Bible; Amazon Digital Services LLC-Kdp Print Us: Seattle, WA, USA, 2019; pp. 52–58.

- Chandra, S.; Lata, H.; ElSohly, M.A.; Walker, L.A.; Potter, D. Cannabis cultivation: Methodological issues for obtaining medical-grade product. Epilepsy Behav. 2017, 70, 302–312.

- Clarke, R.C. Maturation and harvesting of cannabis In Marijuana Botany: An Advanced Study: The Propagation and Breeding of Distinctive Cannabis; Ronin Publishing: Berkeley, CA, USA, 1981; pp. 60–78.

- Vogelmann, A.F.; Turner, J.C.; Mahlberg, P.G. Cannabinoid composition in seedlings compared to adult plants of Cannabis sativa. J. Nat. Prod. 1988, 51, 1075–1079.

- Pacifico, D.; Miselli, F.; Carboni, A.; Moschella, A.; Mandolino, G. Time course of cannabinoid accumulation and chemotype development during the growth of Cannabis sativa L. Euphytica 2008, 160, 231–240.

- De Backer, B.; Maebe, K.; Verstraete, A.G.; Charlier, C. Evolution of the content of thc and other major cannabinoids in drug-type cannabis cuttings and seedlings during growth of plants. J. Forensic Sci. 2012, 57, 918–922.

- Davidson, M.; Reed, S.; Oosthuizen, J.; O’Donnell, G.; Gaur, P.; Cross, M.; Dennis, G. Occupational health and safety in cannabis production: An australian perspective. Int. J. Occup. Environ. Health 2018, 24, 75–85.

- Zhang, J.-Q.; Chen, S.-L.; Wei, G.-F.; Ning, K.; Wang, C.-Q.; Wang, L.; Chen, H.; Dong, L.-L. Cultivars breeding and production of non-psychoactive medicinal cannabis with high cbd content. China J. Chin. Mater. Med. 2019, 44, 4772–4780.

- Russo, E.B.; Jiang, H.-E.; Li, X.; Sutton, A.; Carboni, A.; Del Bianco, F.; Mandolino, G.; Potter, D.J.; Zhao, Y.-X.; Bera, S. Phytochemical and genetic analyses of ancient cannabis from central asia. J. Exp. Bot. 2008, 59, 4171–4182.

- Shen, C.; Zhang, B.; Huang, J.; Tian, K.; Liu, H.; Li, X.; Yin, G. Research status and suggestions of mechanical harvesting technology for high-stalk bast-fiber crops. Int. Agric. Eng. J. 2020, 29, 269–284.

- Fike, J. Industrial hemp: Renewed opportunities for an ancient crop. Crit. Rev. Plant Sci. 2016, 35, 406–424.

- Sausserde, R.; Adamovics, A.; Ivanovs, S.; Bulgakov, V. Investigations into growing and harvesting industrial hemp. J. Res. Appl. Agric. Eng. 2013, 58, 150–154.

- Cheng, S.; Bin, Z.; Xianwang, L.; Guodong, Y.; Qiaomin, C.; Chunhua, X. Bench cutting tests and analysis for harvesting hemp stalk. Int. J. Agric. Biol. Eng. 2017, 10, 56–67.

- Rodriguez, G.; Munir, Z. Good manufacturing practices (gmp) approach to post-harvest activities for cannabis. J GXP Compl 2019, 23, 6.

- Ilikj, M.; Brchina, I.; Ugrinova, L.; Karcev, V.; Grozdanova, A. Gmp/gacp-new standards for quality assurance of cannabis. Maced. Pharm. Bull. 2021, 66, 91–101.

- Farag, S.; Kayser, O. Cultivation and breeding of Cannabis sativa L. For preparation of standardised extracts for medicinal purposes. In Medicinal and Aromatic Plants of the World; Springer: Dordrecht, The Netherlands, 2015; pp. 165–186.

- Green, G.; Kryptonite, S.; Chimera, B.; Ralpheme, R. Harvesting and Curing Your Bud in the Cannabis Grow Bible, 4th ed.; Green Candy Press: San Francisco, CA, USA, 2001; pp. 280–284.

- Hawes, M.D.; Cohen, M.R. Method of Drying Cannabis Materials. U.S. Patent 20150096189A1, 9 April 2015. Available online: https://patents.google.com/patent/US20150096189A1/en (accessed on 2 March 2022).

- Challa, S.K.R.; Misra, N.; Martynenko, A. Drying of cannabis—State of the practices and future needs. Dry. Technol. 2021, 39, 2055–2064.

- Ross, S.A.; ElSohly, M.A. The volatile oil composition of fresh and air-dried buds of Cannabis sativa. J. Nat. Prod. 1996, 59, 49–51.

- Coffman, C.; Gentner, W. Cannabis sativa L.: Effect of drying time and temperature on cannabinoid profile of stored leaf tissue. Bull. Narc. 1974, 26, 68–70.

- Turner, J.C.; Mahlberg, P.G. Effects of sample treatment on chromatographic analysis of cannabinoids in Cannabis sativa L. (cannabaceae). J. Chromatogr. A 1984, 283, 165–171.

- Dev, S.; Geetha, P.; Orsat, V.; Gariépy, Y.; Raghavan, G. Effects of microwave-assisted hot air drying and conventional hot air drying on the drying kinetics, color, rehydration and volatiles of moringa oleifera. Dry. Technol. 2011, 29, 1452–1458.

- Chasiotis, V.; Tsakirakis, A.; Termentzi, A.; Machera, K.; Filios, A. Drying and quality characteristics of Cannabis sativa L. Inflorescences under constant and time-varying convective drying temperature schemes. Therm. Sci. Eng. Prog. 2022, 28, 101076.

- Kwaśnica, A.; Pachura, N.; Masztalerz, K.; Figiel, A.; Zimmer, A.; Kupczyński, R.; Wujcikowska, K.; Carbonell-Barrachina, A.A.; Szumny, A.; Różański, H. Volatile composition and sensory properties as quality attributes of fresh and dried hemp flowers (Cannabis sativa L.). Foods 2020, 9, 1118.

- Tang, X.C.; Pikal, M.J. Design of freeze-drying processes for pharmaceuticals: Practical advice. Pharm. Res. 2004, 21, 191–200.

- Tambunan, A.; Yudistira; Kisdiyani; Hernani. Freeze drying characteristics of medicinal herbs. Dry. Technol. 2001, 19, 325–331.

- Kasper, J.C.; Friess, W. The freezing step in lyophilisation: Physico-chemical fundamentals, freezing methods and consequences on process performance and quality attributes of biopharmaceuticals. Eur. J. Pharm. Biopharm. 2011, 78, 248–263.

- Patel, S.M.; Doen, T.; Pikal, M.J. Determination of end point of primary drying in freeze-drying process control. Aaps Pharmscitech 2010, 11, 73–84.

- Mujumdar, A.S.; Woo, M.W. Effects of electric and magnetic field on freezing. In Drying Technologies for Biotechnology Pharmaceutical Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2020; pp. 283–301.

- Duan, X.; Zhang, M.; Mujumdar, A.; Wang, R. Trends in microwave-assisted freeze drying of foods. Dry. Technol. 2010, 28, 444–453.

- Liapis, A.; Bruttini, R. Exergy analysis of freeze drying of pharmaceuticals in vials on trays. Int. J. Heat Mass Transf. 2008, 51, 3854–3868.

- Zhang, M.; Jiang, H.; Lim, R.-X. Recent developments in microwave-assisted drying of vegetables, fruits and aquatic products—Drying kinetics and quality considerations. Dry. Technol. 2010, 28, 1307–1316.

- Taschwer, M.; Schmid, M.G. Determination of the relative percentage distribution of thca and δ9-thc in herbal cannabis seized in austria–impact of different storage temperatures on stability. Forensic Sci. Int. 2015, 254, 167–171.

- Grafström, K.; Andersson, K.; Pettersson, N.; Dalgaard, J.; Dunne, S.J. Effects of long term storage on secondary metabolite profiles of cannabis resin. Forensic Sci. Int. 2019, 301, 331–340.

- Milay, L.; Berman, P.; Shapira, A.; Guberman, O.; Meiri, D. Metabolic profiling of cannabis secondary metabolites for evaluation of optimal post-harvest storage conditions. Front. Plant Sci. 2020, 11, 583605.

- Chen, C.; Wongso, I.; Putnam, D.; Khir, R.; Pan, Z. Effect of hot air and infrared drying on the retention of cannabidiol and terpenes in industrial hemp (Cannabis sativa L.). Ind. Crops Prod. 2021, 172, 114051.

- ElSohly, M.A.; Radwan, M.M.; Gul, W.; Chandra, S.; Galal, A. Phytochemistry of Cannabis sativa L. In Phytocannabinoids; Springer: Cham, Switzerland, 2017; pp. 1–36.