Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Leila Bazli | + 1292 word(s) | 1292 | 2022-02-09 04:42:31 | | | |

| 2 | Rita Xu | Meta information modification | 1292 | 2022-03-07 03:54:24 | | | | |

| 3 | Lindsay Dong | Meta information modification | 1292 | 2022-03-28 06:05:47 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Bazli, L. Fibre-Reinforced Polymer at Elevated Temperatures. Encyclopedia. Available online: https://encyclopedia.pub/entry/20239 (accessed on 08 February 2026).

Bazli L. Fibre-Reinforced Polymer at Elevated Temperatures. Encyclopedia. Available at: https://encyclopedia.pub/entry/20239. Accessed February 08, 2026.

Bazli, Leila. "Fibre-Reinforced Polymer at Elevated Temperatures" Encyclopedia, https://encyclopedia.pub/entry/20239 (accessed February 08, 2026).

Bazli, L. (2022, March 05). Fibre-Reinforced Polymer at Elevated Temperatures. In Encyclopedia. https://encyclopedia.pub/entry/20239

Bazli, Leila. "Fibre-Reinforced Polymer at Elevated Temperatures." Encyclopedia. Web. 05 March, 2022.

Copy Citation

Fibre-reinforced polymer is a composite material that consists of a polymer matrix and fibre reinforcement. Numerous FRPs have been produced, including basalt fibre-reinforced polymers (BFRP), glass fibre-reinforced polymers (GFRP), aramid fibre-reinforced polymers (AFRP), and carbon fibre-reinforced polymers (CFRP).

Fibre-reinforced polymer

FRP strengthening

FRP-reinforced concrete

Elevated temperature

1. Introduction

FRPs have exceptional properties, including light weight, high strength, electrical insulation, low thermal conductivity, impact resistance, dimensional stability, corrosion resistance, and they are non-magnetic [1][2][3][4]. Due to the significant advantages of FRPs over conventional construction materials, including steel and concrete, for retrofitting and strengthening concrete structures, they have gained attention as viable alternatives for reinforcing and retrofitting concrete structures [4][5][6]. These composites are typically employed as “externally bonded” systems to increase the axial sectional, flexural, torsion, and shear capacities of the structural elements of the reinforced concrete, increase the structural members’ stability and serviceability, and provide additional confinement [7][8][9]. Two distinct types of strengthening methods for FRP-reinforced concrete (FRP-RC) are presented: the first makes use of FRP sheets and/or plates and the second uses near-surface mounted (NSM) bars [10]. To prepare the external surface of the concrete for FRP plates and sheets, either high-pressure jet washing or sandblasting is used. Following that, FRP products are used on the concrete surface [11][12][13][14]. This form of external reinforcement is simple and quick to implement. Three types of FRP reinforcements are available for new structures: (1) internal reinforcement with FRP bars; (2) FRP formwork for RC members that stays in place; and (3) FRP tendons for prestressed concrete (PC) components [15][16][17].

Due to concerns about the performance of FRPs at high temperatures, the widespread application of FRP-RC in structures has been limited [18][19][20]. In general, prolonged contact with temperatures around and above the glass transition temperature (Tg) of the resin degrades the mechanical properties of FRP materials [21]. Tg is normally represented by a single Tg (often between 50 and 120 °C for resins cured at ambient temperatures), which can be evaluated experimentally using differential scanning calorimetry (DSC) or determined by dynamic mechanical analyses (DMA) [13][22]. In design decision-making, Tg is frequently used as a “critical temperature”, although mechanical performance degrades prior to reaching Tg [23]. When subjected to elevated temperatures (usually greater than 300–400 °C), the thermal decomposition of the FRP organic matrix occurs, potentially emitting smoke, soot, toxic/combustible volatiles, and heat [3][24][25][26]. Organic fibres (e.g., biofibres, PBO, and aramid) employed to strengthen some polymer composites may also degrade and form smoke, fumes, and heat [27][28]. These decomposition processes often result in the further deterioration of the physical and mechanical properties of FRPs due to the degradation of the matrix and, in certain circumstances, the fibres [2][29][30]. Deuring [31] is one of the leading researchers conducting fire tests on externally reinforced concrete beams. According to Deuring’s report, unprotected beams that were strengthened with FRP could withstand a fire for 81 min. In comparison, a similar beam with protected FRP systems could withstand a fire for 146 min. Williams et al. [32] conducted a more recent investigation, in which they tested the performance of CFRP-strengthened RC T-beams under normal fire conditions. The beams were insulated with vermiculite gypsum (VG) insulation. The findings of this experiment revealed that FRP and reinforcing steel components can be kept at a temperature below the critical value necessary to retain their structural integrity by using a suitably insulated system.

2. Mechanical Properties of Individual Components at Elevated Temperature

2.1. FRP

FRPs exhibit significantly different behaviours from steel or concrete at high temperatures. When exposed to a substantial amount of heat, all polymer matrix composites will burn. Additionally, matrix elements, such as epoxy, vinylester, and polyester, not only facilitate burning but also produce huge amounts of dense black smoke [33]. Furthermore, FRPs degrade in terms of stiffness, strength, and bond characteristics when exposed to even mildly elevated temperatures [34][35]. Numerous research investigations focusing on the mechanical characteristics of FRPs and their constituents at elevated temperatures have been published in the literature [36][37][38][39][40].

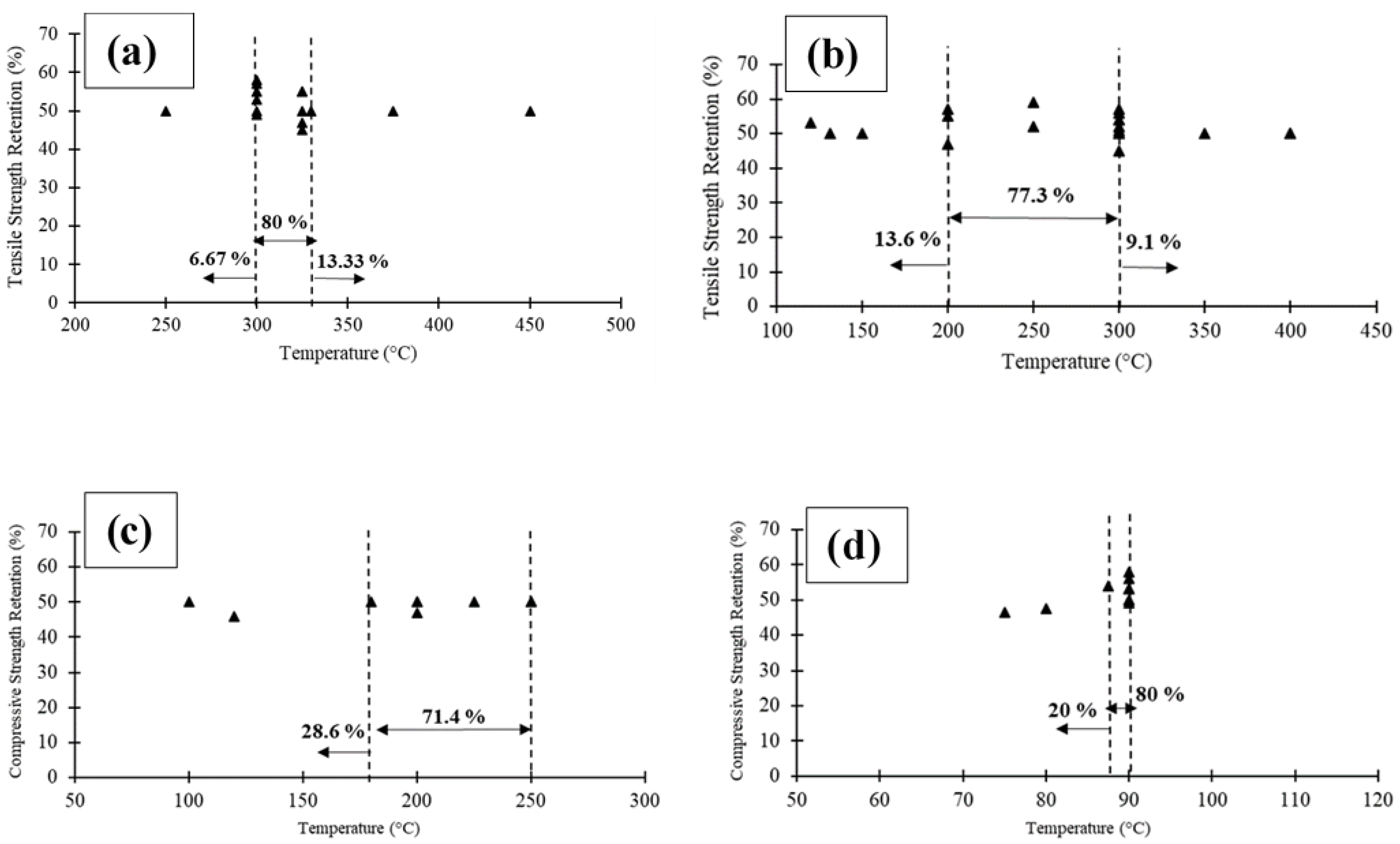

When elevated temperatures below Tg are applied to the resin matrix, the resin matrix remains relatively unaffected (i.e., some microcracks may form) and the surface of the resin matrix remains rough and similar to that of the unconditioned sample [41]. In this situation, no significant changes occur in the strength or stiffness of the FRP composites. When FRP composites reach their Tg, the resin undergoes a phase transition from glassy to rubbery. In this instance, the FRP materials soften and creep, resulting in a significant loss of stiffness and strength [42]. It has been observed that when FRP materials are subjected to temperatures that are near the resin’s decomposition temperature, their organic matrix decomposes, which emits heat, soot, smoke, and hazardous volatiles. Exposure to such high temperatures (e.g., 300–500 °C) causes the breakage of the modular chains of the resin, chemical bonds, and bonds between the fibres [43][44]. At higher temperatures, the composites ignite and burn. The critical temperature (i.e., the temperature at which 50% of the strength is lost) was reported to be typically between 87–90 °C for pultruded GFRP profiles in compression, 300–330 °C for FRP reinforcing bars in tension, 180–250 °C for laminates in bending, and 200–300 °C for laminates in tension [45]. Figure 1 shows the reported critical temperatures in the literature (i.e., the temperatures that are equivalent to an approximately 50% reduction in mechanical properties) for different FRP composites under different loading conditions.

Figure 1. The FRP strength retention versus critical temperature as reported in the literature [46]: (a) FRP bars; (b) FRP laminates; (c) FRP laminates; and (d) pultruded FRP profiles.

The compression and interlaminar shear failure of FRP composites occurs at substantially lower loads and temperatures than flexure and tension [46]. Elevated temperatures have a lesser effect on the elastic modulus of FRP composites than on the corresponding strength values. This is mostly due to the fact that the elastic modulus of FRP composites is more closely related to the elastic modulus of the fibres than to the elastic modulus of the resin [45].

A few of the parameters that influence the properties of FRPs are the configuration of fibres and resin, the production technique, and the quality control of the final products. The stiffness and strength properties of FRPs decrease with increasing temperature, although there are considerable variations in the results due to the wide variety of fibre volume fractions, formulations of the matrix, and fibre orientations represented in the data [29][47].

2.2. Concrete

While concrete generally has a high resistance to fire, its mechanical characteristics, such as elastic modulus and strength, degrade when exposed to high temperatures. At elevated temperatures, the failure is mostly due to the creation of cracks that are parallel to the heated surface, changes in the chemistry, and an increase in pore pressure owing to water evaporation. At elevated temperatures, concrete undergoes a variety of physical (vapor diffusion, evaporation, phase expansion, and condensation), chemical (dehydration and thermo-chemical damage), and mechanical (cracking, spalling, and thermo-mechanical damage) phenomena that degrade its qualities [48][49]. The water on the surface of the concrete and capillary water evaporates as the temperature rises and this process is hastened by the reduced cohesive interactions between the water molecules, which is caused by water expansion. At 105 °C, the free water begins to evaporate rapidly. The dehydration of ettringite occurs between 80 and 150 °C, followed by gypsum decomposition between 150 and 170 °C. When the temperature approaches 300 °C, the evaporation of the chemically bound water begins, which reduces the compressive strength of concrete [27][32][50][51][52][53]. Portlandite decomposes between 400 and 540 °C as the temperature increases further. When the temperature of the concrete exceeds 400 °C, the strength of the concrete deteriorates more rapidly due to the breakdown of calcium–silica–hydrate (C–S–H). Between 600 and 800 °C, the second phase of the C–S–H decomposes to create β-dicalcium silicate (β-C2S). At 900 °C, the C–S–H fully degrades. As a result, the critical temperature range for concrete is around 400–900 °C and concrete loses the majority of its strength within this range [54].

References

- Cao, S.; Wu, Z.; Wang, X. Tensile Properties of CFRP and Hybrid FRP Composites at Elevated Temperatures. J. Compos. Mater. 2009, 43, 315–330.

- Mouritz, A.P.; Gibson, A.G. Fire Properties of Polymer Composite Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007.

- Wang, K.; Young, B.; Smith, S. Mechanical properties of pultruded carbon fibre-reinforced polymer (CFRP) plates at elevated temperatures. Eng. Struct. 2011, 33, 2154–2161.

- Najafabadi, E.P.; Bazli, M.; Ashrafi, H.; Oskouei, A.V. Effect of applied stress and bar characteristics on the short-term creep be-havior of FRP bars. Constr. Build. Mater. 2018, 171, 960–968.

- Jafari, A.; Oskouei, A.V.; Bazli, M.; Ghahri, R. Effect of the FRP sheet’s arrays and NSM FRP bars on in-plane behavior of URM walls. J. Build. Eng. 2018, 20, 679–695.

- Oskouei, A.V.; Kivi, M.P.; Araghi, H.; Bazli, M. Experimental study of the punching behavior of GFRP reinforced lightweight concrete footing. Mater. Struct. 2017, 50, 256.

- Chowdhury, E.; Eedson, R.; Bisby, L.; Green, M.; Benichou, N. Mechanical characterization of fibre reinforced polymers materials at high temperature. Fire Technol. 2011, 47, 1063–1080.

- Yu, B.; Kodur, V. Effect of temperature on strength and stiffness properties of near-surface mounted FRP reinforcement. Compos. Part B Eng. 2014, 58, 510–517.

- Miller, J.; Weaver, P. Temperature profiles in composite plates subject to time-dependent complex boundary conditions. Compos. Struct. 2003, 59, 267–278.

- Bazli, M.; Heitzmann, M.; Hernandez, B.V. Hybrid fibre reinforced polymer and seawater sea sand concrete structures: A sys-tematic review on short-term and long-term structural performance. Constr. Build. Mater. 2021, 301, 124335.

- Sweeting, R.; Liu, X. Measurement of thermal conductivity for fibre-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 933–938.

- Bascom, W.D.; Cottington, R.L. Effect of Temperature on the Adhesive Fracture Behavior of an Elastomer-Epoxy Resin. J. Adhes. 1976, 7, 333–346.

- Phan, L.T.; Carino, N.J. Review of Mechanical Properties of HSC at Elevated Temperature. J. Mater. Civ. Eng. 1998, 10, 58–65.

- Ashrafi, H.; Bazli, M.; Oskouei, A.V. Enhancement of bond characteristics of ribbed-surface GFRP bars with concrete by using carbon fiber mat anchorage. Constr. Build. Mater. 2017, 134, 507–519.

- Naser, M.; Hawileh, R.; Abdalla, J. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A criti-cal review. Eng. Struct. 2019, 198, 109542.

- Chalioris, C.E.; Kosmidou, P.-M.K.; Papadopoulos, N.A. Investigation of a New Strengthening Technique for RC Deep Beams Using Carbon FRP Ropes as Transverse Reinforcements. Fibers 2018, 6, 52.

- Belarbi, A.; Bae, S.-W.; Brancaccio, A. Behavior of full-scale RC T-beams strengthened in shear with externally bonded FRP sheets. Constr. Build. Mater. 2012, 32, 27–40.

- A.C.I. 440, Guide for the Design and Construction of Concrete Reinforced with FRP Bars: ACI 440.1 R-03; American Concrete Institute: Farmington Hills, MI, USA, 2003; Available online: https://www.concrete.org/publications/internationalconcreteabstractsportal/m/details/id/12639 (accessed on 25 December 2021).

- Blontrock, H.; Taerwe, L.; Matthys, S. Properties of fiber reinforced plastics at elevated temperatures with regard to fire re-sistance of reinforced concrete members. Spec. Publ. 1999, 188, 43–54.

- Zhu, H.; Wu, G.; Zhang, L.; Zhang, J.; Hui, D. Experimental study on the fire resistance of RC beams strengthened with near-surface-mounted high-Tg BFRP bars. Compos. Part B Eng. 2014, 60, 680–687.

- Khaneghahi, M.H.; Najafabadi, E.P.; Bazli, M.; Oskouei, A.V.; Zhao, X.-L. The effect of elevated temperatures on the compres-sive section capacity of pultruded GFRP profiles. Constr. Build. Mater. 2020, 249, 118725.

- Jiangtao, Y.; Yichao, W.; Kexu, H.; Kequan, Y.; Jianzhuang, X. The performance of near-surface mounted CFRP strengthened RC beam in fire. Fire Saf. J. 2017, 90, 86–94.

- Bazli, M.; Jafari, A.; Ashrafi, H.; Zhao, X.-L.; Bai, Y.; Raman, R.S. Effects of UV radiation, moisture and elevated temperature on mechanical properties of GFRP pultruded profiles. Constr. Build. Mater. 2020, 231, 117137.

- Nigro, E.; Cefarelli, G.; Bilotta, A.; Manfredi, G.; Cosenza, E. Fire resistance of concrete slabs reinforced with FRP bars. Part I: Experimental investigations on the mechanical behavior. Compos. Part B Eng. 2011, 42, 1739–1750.

- Bai, Y.; Keller, T. Time Dependence of Material Properties of FRP Composites in Fire. J. Compos. Mater. 2009, 43, 2469–2484.

- Kodur, V.K.R.; Bisby, L.A.; Green, M. Preliminary Guidance for the Design of FRP-strengthened Concrete Members Exposed to Fire. J. Fire Prot. Eng. 2007, 17, 5–26.

- Bisby, L.A.; Green, M.; Kodur, V.K.R. Modeling the Behavior of Fiber Reinforced Polymer-Confined Concrete Columns Exposed to Fire. J. Compos. Constr. 2005, 9, 15–24.

- Vinson, J.R.; Sierakowski, R.L.; Bert, C.W. The Behavior of Structures Composed of Composite Materials. J. Appl. Mech. 1987, 54, 249.

- Hamad, R.J.; Johari, M.M.; Haddad, R.H. Mechanical properties and bond characteristics of different fiber reinforced polymer rebars at elevated temperatures. Constr. Build. Mater. 2017, 142, 521–535.

- Wang, Y.C.; Wong, P.M.H.; Kodur, V. An experimental study of the mechanical properties of fibre reinforced polymer (FRP) and steel reinforcing bars at elevated temperatures. Compos. Struct. 2007, 80, 131–140.

- Deuring, M. Fire tests on strengthened reinforced concrete beams. Res. Rep. 1994, 795.

- Williams, B.; Kodur, V.; Green, M.; Bisby, L. Fire Endurance of Fiber-Reinforced Polymer Strengthened Concrete T-Beams. ACI Struct. J. 2008, 105, 60–67.

- Masuelli, M.A. Introduction of fibre-reinforced polymers−polymers and composites: Concepts, properties and processes. In Fiber Reinforced Polymers—The Technology Applied for Concrete Repair; IntechOpen: London, UK, 2013; Available online: https://www.intechopen.com/books/fiber-reinforced-polymers-the-technology-applied-for-concrete-repair/introduction-of-fibre-reinforced-polymers-polymers-and-composites-concepts-properties-and-processes (accessed on 25 December 2021).

- Bazli, M. Mechanical and Microstructural Properties of Different FRP Composites under Various Environmental Conditions. Ph.D. Thesis, Monash University, Melbourne, VI, Australia, 2020.

- Bazli, M.; Zhao, X.-L.; Jafari, A.; Ashrafi, H.; Raman, R.S.; Bai, Y.; Khezrzadeh, H. Durability of glass-fibre-reinforced polymer composites under seawater and sea-sand concrete coupled with harsh outdoor environments. Adv. Struct. Eng. 2020, 24, 1090–1109.

- Sumida, A.; Fujisaki, T.; Watanabe, K.; Kato, T. Heat resistance of continuous fiber reinforced plastic rods, FRPRCS-5: Fibre-reinforced plastics for reinforced concrete structures Volume 1. In Proceedings of the Fifth International Conference on Fibre-Reinforced Plastics for Reinforced Concrete Structures, Cambridge, UK, 16–18 July 2001; Thomas Telford Publishing: London, UK, 2001; pp. 557–565. Available online: https://www.icevirtuallibrary.com/doi/abs/10.1680/frprcsv1.30299.0057 (accessed on 25 December 2021).

- Hensher, D.A. Fiber-Reinforced-Plastic (FRP) Reinforcement for Concrete Structures: Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2016.

- Wang, Y.; Wong, P.; Kodur, V. Mechanical Properties of Fibre Reinforced Polymer Reinforcing Bars at Elevated Temperatures. In ASCE–SFPE Specialty Conference on Designing Structures for Fire; Citeseer: 2003; pp. 183–192. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.10.7147&rep=rep1&type=pdf (accessed on 25 December 2021).

- Reid, E.R.; Bilotta, A.; Bisby, L.; Nigro, E. Mechanical Properties of Fibre Reinforced Polymer Reinforcement for Concrete at High Temperature. In Proceedings of the 8th International Conference on Structures in Fire; Tongji University Press: Shanghai, China, 2014; pp. 1227–1234. Available online: https://www.research.ed.ac.uk/en/publications/mechanical-properties-of-fibre-reinforced-polymer-reinforcement-f (accessed on 25 December 2021).

- Ashrafi, H.; Bazli, M.; Oskouei, A.V.; Bazli, L. Effect of Sequential Exposure to UV Radiation and Water Vapor Condensation and Extreme Temperatures on the Mechanical Properties of GFRP Bars. J. Compos. Constr. 2018, 22, 04017047.

- Ashrafi, H.; Bazli, M.; Najafabadi, E.P.; Oskouei, A.V. The effect of mechanical and thermal properties of FRP bars on their ten-sile performance under elevated temperatures. Constr. Build. Mater. 2017, 157, 1001–1010.

- Bazli, M.; Ashrafi, H.; Jafari, A.; Zhao, X.-L.; Gholipour, H.; Oskouei, A.V. Effect of thickness and reinforcement configuration on flexural and impact behaviour of GFRP laminates after exposure to elevated temperatures. Compos. Part B Eng. 2018, 157, 76–99.

- Saafi, M. Effect of fire on FRP reinforced concrete members. Compos. Struct. 2002, 58, 11–20.

- Adam, M.A.; Said, M.; Mahmoud, A.A.; Shanour, A.S. Analytical and experimental flexural behavior of concrete beams rein-forced with glass fiber reinforced polymers bars. Constr. Build. Mater. 2015, 84, 354–366.

- Bazli, M.; Abolfazli, M. Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: An Overview. Polymers 2020, 12, 2600.

- Bazli, M.; Zhao, X.-L.; Jafari, A.; Ashrafi, H.; Bai, Y.; Raman, R.S.; Khezrzadeh, H. Mechanical properties of pultruded GFRP pro-files under seawater sea sand concrete environment coupled with UV radiation and moisture. Constr. Build. Mater. 2020, 258, 120369.

- Bilotta, A.; Compagnone, A.; Esposito, L.; Nigro, E. Structural behaviour of FRP reinforced concrete slabs in fire. Eng. Struct. 2020, 221, 111058.

- Hajiloo, H.; Green, M.F.; Noël, M.; Bénichou, N.; Sultan, M. Fire tests on full-scale FRP reinforced concrete slabs. Compos. Struct. 2017, 179, 705–719.

- Daghash, S.M.; Ozbulut, O.E. Flexural performance evaluation of NSM basalt FRP-strengthened concrete beams using digital image correlation system. Compos. Struct. 2017, 176, 748–756.

- Bisby, L.; Chen, J.-F.; Li, S.; Stratford, T.; Cueva, N.; Crossling, K. Strengthening fire-damaged concrete by confinement with fi-bre-reinforced polymer wraps. Eng. Struct. 2011, 33, 3381–3391.

- Ahmed, A.; Kodur, V. Effect of bond degradation on fire resistance of FRP-strengthened reinforced concrete beams. Compos. Part B Eng. 2011, 42, 226–237.

- Leone, M.; Matthys, S.; Aiello, M.A. Effect of elevated service temperature on bond between FRP EBR systems and concrete. Compos. Part B Eng. 2009, 40, 85–93.

- Firmo, J.; Correia, J.; Pitta, D.; Tiago, C.; Arruda, M. Experimental characterization of the bond between externally bonded rein-forcement (EBR) CFRP strips and concrete at elevated temperatures. Cem. Concr. Compos. 2015, 60, 44–54.

- Tufail, M.; Shahzada, K.; Gencturk, B.; Wei, J. Effect of elevated temperature on mechanical properties of limestone, quartzite and granite concrete. Int. J. Concr. Struct. Mater. 2017, 11, 17–28.

More

Information

Subjects:

Engineering, Civil

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.8K

Revisions:

3 times

(View History)

Update Date:

28 Mar 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No