Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Theodoros Varzakas | + 4997 word(s) | 4997 | 2022-02-28 07:19:31 | | | |

| 2 | Amina Yu | -6 word(s) | 4991 | 2022-03-04 03:26:23 | | | | |

| 3 | Kärt Saarniit | Meta information modification | 4991 | 2022-03-04 08:21:21 | | | | |

| 4 | Victoria Krauter | Meta information modification | 4991 | 2022-03-04 10:25:42 | | | | |

| 5 | Maria Milousi | Meta information modification | 4991 | 2022-03-05 13:51:08 | | | | |

| 6 | Amina Yu | Meta information modification | 4991 | 2022-03-07 04:49:50 | | | | |

| 7 | Amina Yu | Meta information modification | 4991 | 2022-03-07 04:51:39 | | | | |

| 8 | Anna-Sophia Bauer | Meta information modification | 4991 | 2022-03-08 22:44:35 | | | | |

| 10 | Rubing Xu | Meta information modification | 4991 | 2022-03-29 03:24:58 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Varzakas, T.; Bauer, A.; Saarniit, K.; Galić, K.; Agriopoulou, S.; Uysal-Unalan, I.; Krauter, V.; Milousi, M. Cereal and Confectionary Packaging. Encyclopedia. Available online: https://encyclopedia.pub/entry/20162 (accessed on 07 February 2026).

Varzakas T, Bauer A, Saarniit K, Galić K, Agriopoulou S, Uysal-Unalan I, et al. Cereal and Confectionary Packaging. Encyclopedia. Available at: https://encyclopedia.pub/entry/20162. Accessed February 07, 2026.

Varzakas, Theodoros, Anna-Sophia Bauer, Kärt Saarniit, Kata Galić, Sofia Agriopoulou, Ilke Uysal-Unalan, Victoria Krauter, Maria Milousi. "Cereal and Confectionary Packaging" Encyclopedia, https://encyclopedia.pub/entry/20162 (accessed February 07, 2026).

Varzakas, T., Bauer, A., Saarniit, K., Galić, K., Agriopoulou, S., Uysal-Unalan, I., Krauter, V., & Milousi, M. (2022, March 03). Cereal and Confectionary Packaging. In Encyclopedia. https://encyclopedia.pub/entry/20162

Varzakas, Theodoros, et al. "Cereal and Confectionary Packaging." Encyclopedia. Web. 03 March, 2022.

Copy Citation

Packaging is strongly associated with food, allowing, amongst other functions, containment, protection, and transportation of contents, and thus can be seen as an integral part of food systems. Nevertheless, nowadays it is the subject of intense debates and even stricter legal requirements, mainly due to massive circularity gaps including, for example, unsatisfactory end-of-life scenarios such as limited recyclability or (marine) litter.

food packaging

cereals

confectionary

bakery

food quality

shelf-life

sustainable packaging

active and intelligent packaging

modified atmosphere packaging

vacuum packaging

1. Packaging

1.1. Packaging Functions

No matter how diverse individual products and packaging solutions may be on the market, it is well-agreed in relevant literature that the main functions of packaging can be broken down into a few. Next to the concept of primary and secondary functions, where the former describes in particular the technical functions like storage and transport, and the latter describes functions related to examples, communication, a more holistic concept is frequently mentioned in the packaging literature. This concept describes the four basic functions of food packaging as (i) containment, (ii) protection, (iii) convenience, and (iv) communication [1][2][3][4][5].

Although the containment function is often overlooked, it can be considered one of the most essential, since it prevents product loss and contamination and facilitates storage, transportation, and distribution. There are only a few exceptions, where containment and thus packaging is not needed. Such examples are relatively large, chunky products that are often regionally produced and consumed within a short period of time or that show long shelf-life [1][2][3].

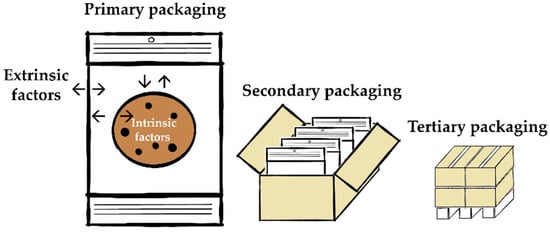

The protection function is often recognised as well as highlighted and can be indeed considered as the most important aspect of packaging. It limits or excludes intrinsic as well as extrinsic physical, chemical, and biological factors that may have negative influences on the quality of the respective food product. In the best case, the packaging is even capable of extending the shelf-life of the product. Therefore, it is of upmost importance to match the food product’s properties and requirements along the supply chain with packaging to achieve optimal results. Both under- and over-packaging should be avoided since this may result, on one hand, in food losses or waste and, on the other hand, in excessive packaging [1][2][3].

Further, the convenience function refers to the practical aspects or user-friendliness of packaging. As an example, easy-to-open or -empty, microwave- or heat-able, resealable, or portion packaging can be named. These features are more and more implemented in package designs, since they allow to specifically address target groups (for example, children, elderly, single-households, on-the-go lifestyle) and therefore frequently influence the market success of a product [1][2][3].

Last but not least, the communication function allows for information transfer and marketing. While the former allows to display legally required (for example, product name, ingredients, shelf-life), necessary (for example, barcodes), or voluntary for example, certificates, cooking recipe) information, the latter enables to transfer an often unique brand image (for example, form, colour, shape), which may be of great recognition value [1][2][3].

It is worth mentioning that a successful package on the market does not only need a strong product in terms of quality but also an effective packaging, which in a clever way combines the above described four functions of containment, protection, convenience and communication. Otherwise, it may result in a short-term success (weak product and effective packaging), a situation where the potential is not achieved (strong product and ineffective packaging), or even failure (weak product and ineffective packaging) [3].

1.2. Packaging Properties

From a technical point of view, the functions containment and protection are closely linked to the right selection of packaging materials which consequently poses a key decision in the development process. The available material classes cover mainly glass, metal, paper/board, (bio)plastic, as well as composite materials (laminated, coextruded, blended). Composites can consist of two or more components combined to form, for example, multilayer materials (for example, plastic-coated cardboard) which frequently show superior functional properties (for example, barrier) and reduced weight [3], but on the downside also reduced recyclability [6][7]. Touching upon the topic of recyclability, many packaging solutions face obstacles, if it is at the stage of collection, sorting, or in general limited technical recyclability. Not even the use of mono-materials guarantees actual recycling, as it is the case for PET trays versus PET bottles (bottles are highly likely to be recycled). On the other hand, specific combinations of compatible materials, even high barrier films, for example, metallized polyolefins, might be considered recyclable in the appropriate infrastructure [8][9]. Summing up, it can be stated that each of the named materials show advantages and disadvantages (see Table 1) and the decision for a specific material must be based on the prevailing requirements (for example, product, supply chain, use, end-of-life). Support is often provided by material specifications and declaration of compliance documents. However, it is recommended to test the materials in question under respective conditions by means of a field or laboratory test. This ensures that deviations from the target value can be recognized at an early stage in the development process [1][2][3][10][11].

Table 1. Overview of the properties and applications of most widely used materials for packaging.

| Packaging Material | Barrier | Heat Seal-Ability | Mechanical, Physical and Chemical Properties | Application | Reference | |||

|---|---|---|---|---|---|---|---|---|

| Oxygen | Moisture | Light | ||||||

| Plastic | Low-density polyethylene (LDPE) | Very low | High | Low | Yes | Toughness, flexibility, resistance to grease and chemicals, temperature range −50 – +80 °C | Bags, flexible lids and bottles | [1] |

| Linear low-density polyethylene (LLDPE) | High | Toughness, extensibility, resistant to grease, temperature range −30 – +100 °C | (Strech) wrap | |||||

| High-density polyethylene (HDPE) | Extremely high | Toughness, stiffness, resistance to grease and chemicals, easy processing and forming, temperature range −40 – +120 °C | Bottles, cardboard liners, tubs, bags | |||||

| Polypropylene (PP) | Low | High | Low | Yes | Moderate stiffness, strong, resistant to grease and chemicals, temperature range −40 – +120 °C | Bottles, cardboard liners, tubs, microwavable packaging, bags | ||

| Polyethylene terephthalate (PET) | Good | Good | Low | Yes | Stiffness, strong, resistance to grease and oil, temperature range −60 – +200 °C | Bottles, jars, tubs, trays, blisters, films (bags and wrappers) | [1][12] | |

| Glass | Transparent | Absolute | Low | No | High temperature and pressure stability, brittle, chemical resistance, microwave-able | Bottles, jars | [1][12][13][14] | |

| Green | Good | |||||||

| Brown | High | |||||||

| Metal (aluminium, tinplate, tin-free steel) | Absolute | No | High temperature stability | Bottles, cans, tubs, caps | [1][12] | |||

| Paper and board | Extremely low | High – extremely high | No | Mechanical stability | Boxes, liners | [1][12][13] | ||

The key properties of packaging materials of interest are physical and mechanical strength, barrier, migration, as well as hygiene. Regarding the physical and mechanical strength, it can be noted that static as well as dynamic stress challenges the packages along the supply chain from packing, storage, and transport to consumer use. Examples for static stress are stacking and increased pressure (vacuum or modified atmosphere packaging—MAP), as well as pointed or angular products. Dynamic stress on the other hand may be caused by the production process (for example, printing, forming, filling) or transport (for example, vibration). The right selection of the material, but also the shape of the packaging, therefore plays a vital role in the success of a primary, secondary or tertiary package (see also Figure 1) [1][2][10][15].

Another key characteristic of materials to be considered is the barrier property. Especially, the barriers against oxygen (O2) and water vapour (H2O) transmission are determinant since these can exhibit significant influences on product quality and safety. The former for example can promote oxidation reactions, loss of quality-determining ingredients (for example, vitamins), and growth of spoilage and pathogenic microorganisms. The latter can influence structural changes such as hardening, agglomeration, or softening of products and promote microbial growth. Additionally, barriers against carbon dioxide (CO2) and nitrogen (N2), which are the often-used gases in MAP, as well as aroma components, are decisive. Depending on the use case and product requirement, material with an appropriate barrier, i.e., permeation characteristics, should be chosen. Complementary to the above described, the barrier against other substances like fat may be considered [1][2][10][16]. Furthermore, electromagnetic radiation (light) has to be taken into consideration, since oxidative or other chemical reactions as well as structural changes may be induced or accelerated, thus impairing product quality [1][13][17][18][19].

What is important regarding chemical safety is the migration of compounds from packaging materials into the food. Migration describes the mass transfer of substances from a packaging material into the food product or vice versa. As for the permeation, the driving force behind this phenomenon is the concentration gradient. Additionally, factors such as material, storage temperature, relative humidity, and time play an influencing role [10][11][20].

Against common perception, possible migration of, for example, additives, are not only present in plastic packaging materials. Migration can also be found in other (primary or secondary (recycled)) materials such as glass (for example, silicates), metal (for example, corrosion of the metal, additive migration from organic coatings), paper and board (for example, fillers, contaminations like mineral oils) and may, next to the packaging material itself, find its origin in packaging aids (e.g., labels, closures, coatings) or even set-off processes (for example, printed and role-to-role processed or stapled materials) [1][2][10]. To ensure safety of food contact materials (including packaging), several legal requirements are in place in the European Union and beyond [11][20][21][22][23][24][25]. It should be noted that in addition to the migration from the packaging material to the food, migration processes from the food to the packaging can also be observed. This process is also called sorption or scalping and may cause alteration of the product (for example, flavour loss) as well as reduced reusability of packaging containers due to the re-release of previously migrated substances [1][2].

In addition to chemical safety, packaging materials also play a role in the hygiene and biological safety of food products. Depending on the material used, a barrier against contamination, microorganisms and animals (for example, food pests) can be given. To achieve a high standard of hygiene, it is crucial to utilize materials that pose a sufficient barrier and that are free from contamination. Further, it is important to use materials that do not support microbial growth. Lastly, it is important to recognise, that most packaging materials carry a low microbial count when freshly produced due to often high process temperatures (e.g., melting of glass). So, the microbial burden is often a result of recontamination during finishing processes, storage, and application, which can sometimes make it necessary to implement decontamination measures prior to the filling process [10][26].

2. Cereal and Confectionary Products

Against the above-summarized background, food packaging can be seen as a mediator between product and the environment, capable of significantly influencing food quality, safety, and shelf-life [1]. Regarding cereal and confectionary products, the following text aims at summarizing and categorizing the product group, presenting an overview of category specific decay mechanisms, as well as respective packaging solutions.

2.1. Categorization of Cereal and Confectionary Products

As shown by Belitz et al. [27], cereal and confectionary products cover a wide and diverse range of food products. They summarized different products in two groups, namely cereals and cereal products. The first group is mainly made from important staple foods such as wheat, rye, rice, barley, millet, oats and corn. These are used to produce different kinds of products. For example, Smith et al. [28] made the following division: “…unsweetened goods (bread, rolls, buns, crumpets, muffins and bagels), sweet goods (pancakes, doughnuts, waffles and cookies) and filled goods (fruit and meat pies, sausage rolls, pastries, sandwiches, cream cakes, pizza and quiche)”.

The group of confectionery products are mainly sugar-based products that, in contrast to cereal products, are predominantly consumed as a “treat” rather than a full meal. These include products such as chocolate, hard candy, and pralines [29][30]. In addition to sweet confectionery, savory snacks can also be found on the market. According to Robertson [2], these include “… a very wide range of products, including potato and corn chips, alkali-cooked corn tortilla chips, pretzels, popcorn, extruded puffed and baked/fried products, half-products, meat snacks and rice-based snacks” [2][31]. In addition to that, there are combinations of sweet and savory snacks like chocolate covered pretzels or sweet popcorn [32].

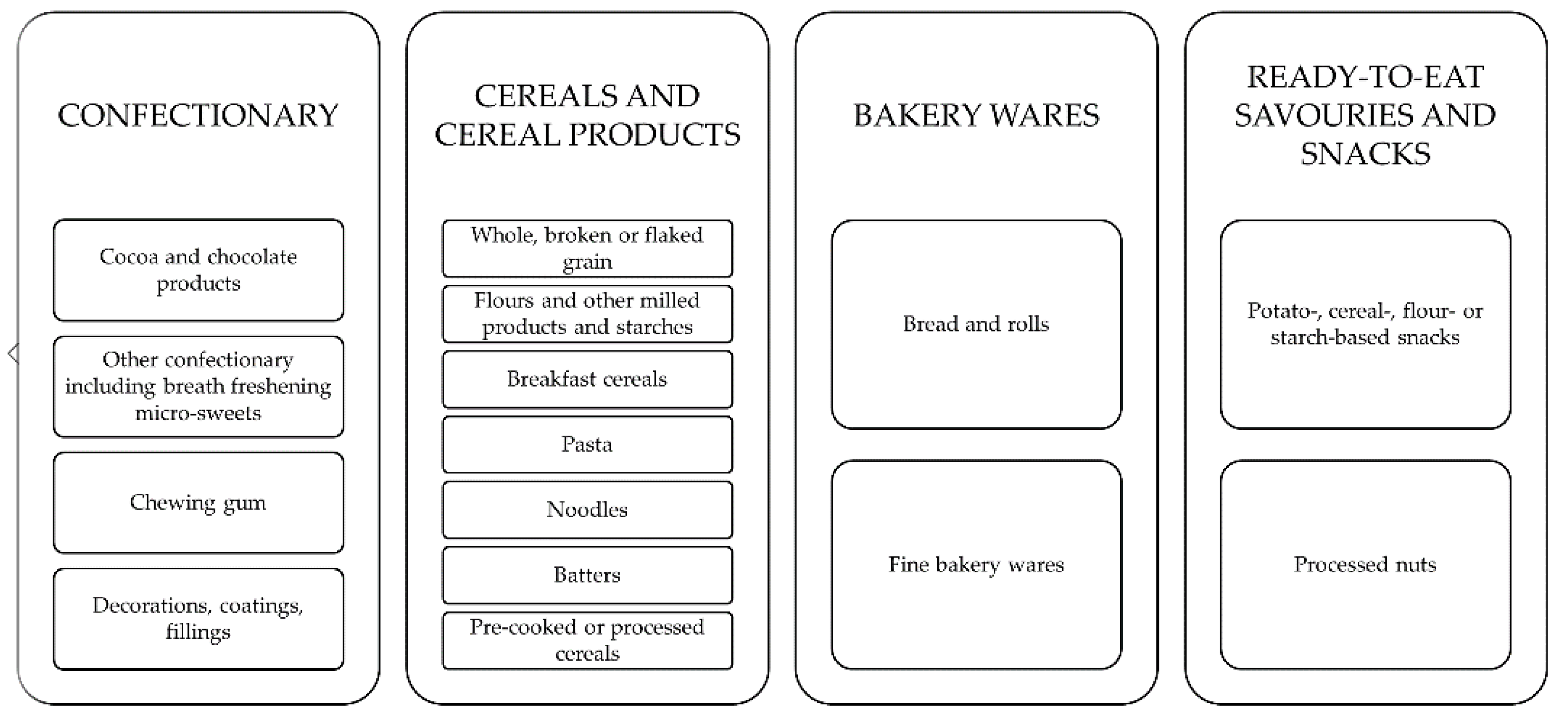

In the available literature and other sources including statistics, codices and regulations, different approaches to properly (sub)categorize cereal and confectionary products can be found [32][33][34]. Taking a food and shelf-life perspective, it is reasonable to cluster products that exhibit similar characteristics or spoilage mechanisms. In the European Union, where there is a strong food law [35] in place, a comprehensive list can be, for example, found in the guidance document to Annex II of regulation (EC) No 1333/2008 on food additives [32][36]. For the field of cereals and confectionary, the four groups of confectionary, cereals and cereal products, bakery wares, and ready-to-eat savories and snacks are of special interest. While confectionary is further subdivided into cocoa and chocolate products, other confectionery products including breath freshening micro-sweets, chewing gum as well as decorations, coatings and fillings, cereals and cereal products are divided into whole, broken or flaked grain, flours, milled products and starches, breakfast cereals as well as pasta, noodles, batters and pre-cooked or processed cereals. For bakery wares, a classification into bread and rolls and fine bakery wares is given. Last but not least, savories and snacks are broken down into potato-, cereal-, flour- or starch-based snacks as well as processed nuts. For each of the above-mentioned subgroups, a comprehensive list of product examples is given in the mentioned document [32]. It adopts this categorization approach and structures relevant information on cereal and confectionary shelf-life, packaging, and shelf-life extension strategies accordingly (Figure 2).

Figure 2. Representation of the followed product categorization. Adapted from [32].

2.2. Decay Mechanisms and Shelf-Life

It is well-established that intrinsic as well as extrinsic factors influence the quality of food and thus its shelf-life [2], which can be defined as the period of time a food maintains its safety and/or quality under reasonably foreseeable conditions of distribution, storage, and use [1][37][38][39]. Intrinsic factors include, amongst others, pH, water activity (aw), initial microbial population, redox potential value (Eh), and nutrient content and therefore determine the nature of decay mechanisms of a food product. On the other hand, extrinsic factors determine how fast decay mechanisms proceed. Typical examples are atmosphere, climatic conditions, and illumination. Packaging itself acts as mediator or separator between intrinsic and extrinsic systems [2][40]. The following paragraphs highlight the main challenges of quality maintenance of cereal and confectionary products but do not go into detail about the physical, chemical, or biological bases of these mechanisms (e.g., oxidation). This information can be found in the relevant scientific literature [2][40][41].

Focusing on cereal and confectionary products (see Table 2), moisture content (MC) and water activity (aw) are some of the most important quality-affecting parameters. Kong and Singh [42] define, that the aw value is “…the vapour pressure of water above a sample (p) divided by that of pure water at the same temperature (p0); i.e,

It describes the degree to which water is free or bound to other components”. They state that this is related to “…the composition, temperature, and physical state of the compounds” [42][43]. This is of importance regarding the potential growth of microorganisms as they depend on free water presence [44].

Table 2. Water activity and moisture content of confectionery products, breakfast cereals, snacks, and bakery products.

| Product category | Subcategory | Product | Water Activity [aw] | Moisture Content [%] | Reference |

|---|---|---|---|---|---|

| Confectionery | Cocoa and chocolate products | Chocolate | 0.42–0.60 | 1.2 | [45] |

| Other confectionery including breath freshening micro-sweets | Hard candy | 0.25–0.40 | 2.0–5.0 | [46][47] | |

| Fudge, toffee | 0.45–0.60 | 6.0–18.0 | |||

| Nougat (white, dark) | 0.55 | 8.00–10.0 | [2][48] | ||

| Jelly, liquorice | 0.50–0.75 | 8.0–22.0 | [46][47] | ||

| Marshmallow | 0.60–0.75 | 12.0–22.0 | |||

| Marzipan | 0.75–0.80 | – | [2] | ||

| Chewing gum | Chewing gum | 0.40–0.65 | 3.0–6.0 | [46][47] | |

| Cereals and cereal products | Whole, broken, or flaked grain | Oats, grains, cereals | 0.34–0.70 | 8.8–9.2 | [2][45] |

| Breakfast cereals | Cornflakes | 0.25–0.38 | 1.7–3.5 | ||

| Puffs | 0.17–0.20 | 0.48–1.70 | |||

| Fresh pasta | Fresh pasta | 0.91–0.98 | ≥24 | ||

| Dry pasta | Dry pasta | 0.33–0.57 | 5.4–8.3 | ||

| Bakery wares | Fine bakery wares | Sponge cake, muffins | 0.84–0.95 | 21.0–40.0 | [49][50] |

| Croissant crust | 0.59–0.61 | 8.0–10–0 | |||

| Croissant crumb | 0.92–0.94 | 30.0–33.0 | |||

| Biscuits | 0.60–0.63 | 1.5–3.0 | [45][51] | ||

| Wafers | 0.13–0.15 | 2.1 | [45] | ||

| Cookies | 0.18–0.64 | 1.4–11.7 | |||

| Bread and rolls | Flat bread (no yeast) | - | 33.0–35.0 | [52] | |

| Sourdough bread, yeast bread crumb | 0.91–0.95 | 29.0–40.0 | [45] | ||

| Sourdough bread, yeast bread crust | 0.88–0.94 | 26.0–32.0 | |||

| Bagel crust | 0.96 | 38.5 | |||

| Bagel crumb | 0.92 | 31.0 | |||

| Ready-to-eat savouries and snacks | Potato-, cereal-, flour- or starch-based snacks | Popcorn | 0.07 | 0.28 | |

| Chips | 0.09–0.27 | 0.3–1.3 | |||

| Crackers, grissini, sticks, pretzels | 0.05–0.54 | 1.1–5.4 | |||

| Processed nuts | Nuts, seeds, nibs | 0.15–0.75 | 0.5–3.1 |

With an aw lower than 0.75, a large proportion of the products listed in Table 2 falls into the group of low-moisture or dried foods that additionally exhibit low (e.g., cornflakes) or high (e.g., crisps) fat content. In this group, water uptake and thus loss of, e.g., crispness, which occurs, e.g., in potato chips and breakfast cereals after gaining moisture at a range of 0.35 to 0.5 aw, is the main decay mechanism [1][2][42][53]. Other mechanisms include loss of aroma (for example, flavoured products) or aroma uptake from the products’ surrounding due to the often porous structure of the food products. Further, structural changes such as loss of integrity due to e.g., mechanical damage (for example, breakage), softening, or caking may occur. While microbial growth is the basis for both, low and high fat types, oxidative mechanisms, which may lead to off-odours and -tastes and subsequently to quality loss in terms of overall acceptance, are often linked to the fat content and thus tend to increase with the same [1]. Examples that can be named are nuts, chips, biscuits, and cookies. All in all, this product group can, however, be described as rather stable and therefore storage under dry and ambient conditions is recommended and possible. For example, breakfast cereals and dry pasta stay stable under temperate conditions for 6–18 months and 48 months, respectively [45][54]. Confectionary products like pulled sugar are stable for 6–9 months under temperate conditions (for example, ~20 °C) [41].

Other products, including chocolate for example, can be allocated to compact foods with high fat content, a group mainly susceptible to the uptake of unwanted flavours and some (often minor) water exchange (uptake or loss) processes [1]. The latter can induce so-called blooming effects [2]. Sugar bloom on the one hand is often provoked by humid storage or rapid temperature changes and leads to the loss of surface gloss. Fat bloom on the other side is also known to cause quality related issues visible as a fine whitish layer [55]. Growth of microorganisms is, however, of minor importance in this product group. Storage under temperate or chilled conditions is therefore possible for up to 12–24 months [30].

Microbial growth is of major concern in the group of ready-to-eat and ready-to-cook convenience food products (for example, fresh pasta). At this point, in addition to spoilage microorganisms, pathogenic microorganisms play an essential role [38][56]. Further, water loss and structural changes can be named. Additionally, oxidation can significantly gain importance regarding shelf-life. Accordingly, chilled storage is often preferred [2][40].

The area of bakery products can be divided into fresh bakery wares and ready-to-bake products. The first group (for example, bread) shows high aw values (>0.8) and thus short shelf-life, which is heavily influenced by water exchange processes that are often interlinked with structural changes (softening of the crust and drying of the crumb). Connected to this, starch retrogradation, which is the main mechanism of staling, can be highlighted [42]. Further, loss of moisture and hardening with aw values below 0.5–0.7 [2][42][53] quickly result in low sensory acceptance of the products. While oxidation and rancidity play a minor role in this food category, uptake of flavours as well as microbial spoilage play a more elaborated role in this product group. The latter point is mainly driven by the often visible growth of moulds and yeasts on the food surface. Characteristic microorganisms are Penicillium roqueforti, Hansenula anomala, Pichia anomala, Candida guilliermondii, C. parapsilosis, Saccharomyces cerevisiae, S. exiguus, S. unisporus, S. bayanus, S. pastorianus. Additionally, Clostridium and Bacillus genera are known bacteria potentially affecting bakery wares (spore-forming), with example Bacillus spp. causing “rope” or “ropy spoilage” (Bacillus amyloliquefaciens, Bacillus subtilis, Bacillus pumilus, Bacillus cereus) [44][57][58]. Oxidation and rancidity play a minor role in this product category. Accordingly, the average shelf-life of fresh bread and cake under ambient conditions is often less than one week [59]. In some cases, chilled or frozen storage is advisable. The group of ready-to-bake rolls show very similar decay mechanisms. However, due to the higher water content, drying and spoilage is even more pronounced. In the case of frozen products, these mechanisms are delayed. A special focus has to be laid on water exchange (freezer burn) and structural damage [60].

2.3. Product Group Specific Packaging

Responding to the above-mentioned predominant decay mechanisms of cereal and confectionary products, the following section aims at highlighting common packaging concepts and material choices.

Chocolate packaging has to provide a good barrier against aroma, gas (especially O2 and H2O) as well as light. This is conventionally achieved by using aluminium foil of different thickness to wrap the product. Since aluminium alone cannot be heat sealed, the per se excellent barrier of the material is, however, interrupted at, for example, overlapping areas or gaps. Hence, diffusion (mass transfer) of aroma, gas and other molecules (for example, mineral oil components) to the product cannot be excluded. Additionally, the originality of the product, an important factor of food safety, may not be ensured [2][40]. For this and other reasons (for example, communication), many described packaging concepts (still) include an additional packaging layer, namely paper or paperboard [2][61][62][63][64][65][66].

Today, more and more multilayer materials can be found on the market. For example, laminates of LDPE (low density polyethylene) and aluminium allow for heat sealing of the aluminium by at the same time keeping the superior barrier and dead-fold properties of aluminium. Further, multilayer materials including paper or other aluminium replacing barrier materials (for example, polyvinylidene dichloride (PVdC)) are available. Possible build-ups may include LDPE/aluminium/paper or LDPE/PVdC, respectively [2]. Nowadays, a shift towards packaging made (solely) from (oriented) PP, which exhibits, due to a stretching process, inter alia, improved mechanical and barrier properties, is notable [67][66]. Additionally, cold sealing, is more and more adopted, since it avoids exposing sensitive products, such as chocolate, to elevated temperatures during heat sealing. This alternative is made possible by applying cold-seal adhesives on the intended sealing areas of the packaging film and pressing of two of the sealing areas together [3].

Individually packed chocolate products, such as chocolate coated bars or pralines, are often bought for hedonistic reasons (for example, treats, gift function) and thus the communication function (design) of these packages is frequently at the forefront [2][29]. While the functions of containment and protection are already met, these packages often use excess packaging materials and/or layers and for example consist of a (for example, polyethylene terephthalate (PET)) tray with individual cavities, (for example, aluminium) wrapping of the individual pieces, a (for example, paperboard) box, (for example, polyethylene (PE) or polypropylene (PP)) overwrapping and packaging aids (for example, labels, stickers). Glass or metal is also used in some cases [2].

Many confections, such as hard candies, gums, toffees and caramels are likewise (twist) wrapped individually. This is either for technical reasons such as provision of an adequate (H2O) barrier and thus avoidance of moisture loss or uptake, resulting in for example, drying or agglutination of the product pieces, hygienic reasons or distinction from other products. As for chocolate, tightness of the package should be in the ideal case assured [46]. Due to their in general good barrier properties and sealability, the market dominating polyolefins (PE and PP) as well as PET [68] are also frequently used in this product category (for example, multipacks) [67][69]. If elevated barriers are needed, different multilayer materials are also adopted. Further, glass and metal packaging can be found on the market and traditional materials include waxed paper, waxed glassine and waterproof, plasticized cellulose fibre [30]. Plain paper and board are, however, hardly used as a primary packaging material, since products tend to stick to the material. The packaging types in this product category are manifold and include, for example, trays, flow packs, boxes (for example cardboard and metal) and jars [2].

Other products such as biscuits, (processed) nuts and fruits are traditionally packaged in regenerated cellulose (trade name Cellophane) fibres (RCF). Therefore, RCF is usually coated with either LDPE or PVdC copolymer and often with a layer of glassine in direct contact with the product if it contains fat. Currently, this combination of materials is replaced by PP, either as plain or pearlized OPP film, coextruded OPP (OPPcoex) film, or acrylic-coated (Ac) on both sides. Plain OPP films require a heat seal coating to improve sealability while coextruded OPP provides superior seal strength. If a high O2 barrier is required, then acrylic-coated OPP (AcOPP) is used. One side is sometimes coated with PVdC copolymer rather than Ac. In addition, Ac and PVdC copolymer-coated OPP films provide a superior flavour and aroma barrier compared with that of uncoated OPP. Biscuits are often packed in PP and additionally a cardboard box, acting as secondary packaging [2][70].

In comparison to other products, the dry and low in fat group of cereals and cereal products, (such as whole, broken, flaked or milled) grains (for example, wheat and rice) show rather low packaging demands. Mostly used are paper bags, flexible plastic bags (for example, PE [71]), as well as cardboard boxes [72][73]. There are also variations of these packages, for example inner flexible plastic bag and a secondary cardboard box. If paper is used and high barriers are needed, LDPE liners for example can be applied [2], also to avoid mineral oil migration [74]. Rigid laminates with paper content and plastic lids usually known in snack product packaging, are also available. Flours for example are commercially packaged in bags or bulk bins [2]. In addition to that, woven PP bags are commonly used in developing countries. However, Forsido et al. [75] discussed that the low moisture barrier led to chemical, physical, sensorial, and microbial changes of flour. Another successful approach for flour packaging that was used for decades, was bags made from cotton twill [2].

The barrier requirements for breakfast cereals packaging are set higher than in the above-mentioned group since crispness, formation of off-flavours, loss of aroma and vitamins or breakage are more critical for consumer acceptance [2]. Consequently, the inner packaging/primary packaging level of these products is a plastic bag, mostly HDPE (high density polyethylene), giving a sufficient water vapour barrier since moisture vapour transmission rates less than or equal to 15 g/m2-day-atm are often required. Sealant polymers such as EVA (ethylene vinyl acetate), ionomer, mPE (metallocene polyethylene), or blends are used for low temperature seals, form-fill-seal packaging, and easy opening seals [71]. In order to increase barrier characteristics, HDPE is also coextruded with a thin layer of EVA or PA (polyamide) and EVOH (ethylene vinyl alcohol) polymers [71][76]. Other O2 barrier materials for breakfast cereals are PVdC and coated polypropylene-low density polyethylene [77]. In addition, PP-bags are common liners. The secondary packaging/outer packaging is most frequently a fibreboard box [2][78]. Alternative packaging concepts include coated paperboard, plastic cups, as well as metal boxes and glass jars [2][79].

Dried pasta is often packaged in paperboard carton, containing a plastic window. At the moment, most pasta products are packaged in plastic films, such as PE or oriented polypropylene [2][80][81][82][83][84]. For fresh pasta/noodle products, packaging solutions might be different, as appropriate barriers (gas and/or water vapour) and/or MAP (for example CO2:N2 20:80% MAP for pasta) is needed [84][85]. The selection of packaging materials for fresh pasta products can also depend on whether or not the product is pasteurized (thus, the package must be able to withstand the pasteurization conditions) and whether or not the product is to be heated in its package (the package must be able to withstand either heating in boiling water or microwave conditions) by the consumer. For products which are not pasteurized nor intended to be heated in their package, a rigid tray of PVC-LDPE sealed with PA-LDPE film is common. When microwave heating is used, the rigid tray is usually made from crystalline polyethylene terephthalate (PET-C), or polystyrene-ethylene vinyl alcohol copolymer-LDPE (PS-EVOH-LDPE) laminate, and the film may be based on PVdC copolymer-coated PET, OPET-EVOH-LDPE, or PP [86].

Packaging of fresh bakery products such as bread is a moisture balancing act. On one hand, moisture needs to be contained to prevent drying of the product and on the other hand, moisture has to be released from the product to avoid softening of the crust and microbial spoilage. Since there is a wide range of products and product characteristics, also a wide range of packaging solutions can be found. Frequently, paper-based materials, LDPE, LLDPE, HDPE bags as well as OPP, either as plain, pearlized, OPPcoex, or Ac/OPP/Ac films are used [2][71][87][88][89][90][91]. The bags are usually closed either with a strip of adhesive tape or a (plastic) clip in order to reduce moisture loss [88][90][92]. EVA polymers are also used for sealability and optics [71]. Perforated LDPE bags are used (for crusty products) in order to prevent the formation of a leathery consistency of the crust due to moisture migration from the crumb [92]. If aroma and taste barriers are needed, PA is used [71]. Vacuum packaging including the use of respective barrier packaging materials is only used in some exceptions (for example, flat breads) in this product category due to mechanical impairment of the often soft products. MAP rich in CO2 is whereas more frequently used (for example, sliced bread, convenience applications). For example, CO2:N2 60:40% MAP for bread, cakes, crumpets, crepes, fruit pies and pita bread. This is also the case for ready-to-bake products, which are intended to have a longer shelf-life [2].

Packaging for fried snack foods such as potato or tortilla chips, which exhibit, due to their production process, low moisture and high fat contents, preliminarily aims at providing a barrier against gases (H2O and O2) and light to avoid loss of crispness and increased oxidation/rancidity levels of the product [71]. Hence, these products are mainly packaged in high barrier multilayer films containing aluminium foil or metallisation (for example, PET/Alu/LDPE; PETmet/LDPE; BOPP/BOPPmet) [3][69][93]. In addition, barrier polymers such EVOH or PVDC can be found in these materials. Further, rigid multilayer paper solutions with aluminium (for example spiral wound paper-board cans) or metal cans are also used. Since extruded and puffed snack foods exhibit lower fat levels and thus primarily rely on a package that provides a barrier against water vapour; these products are less often packaged in metallized materials. An example is OPP/LDPE/OPP [71]. In both scenarios, and whether flexible or rigid packaging is adopted, modified atmosphere packaging is frequently used. For example, the package is usually flushed with an inert gas (N2) before closing [93]. Additional mechanical protection of the often fragile products and dry storage is recommended. This might lead to the use of secondary packaging, such as cardboard boxes [3].

References

- Singh, P.; Wani, A.A.; Langowski, H.-C. (Eds.) Food Packaging Materials: Testing & Quality Assurance; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2017; ISBN 9781466559943.

- Robertson, G.L. Food Packaging: Principles and Practice, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2013; ISBN 9781439862414.

- Soroka, W. Fundamentals of Packaging Technology, 5th ed.; Institute of Packaging Professional: Herndon, WV, USA, 2014; ISBN 0615709346.

- Kaßmann, M. Grundlagen der Verpackung: Leitfaden für die Fächerübergreifende Verpackungsausbildung; DIN Deutsches Institut für Normung: Berlin, Germany, 2014; ISBN 3410241922.

- Wani, A.A.; Singh, P.; Langowski, H.-C. Food Technologies: Packaging. In Encyclopedia of Food Safety; Motarjemi, Y., Ed.; Elsevier Science: Burlington, UK, 2014; ISBN 978-0-12-378613-5.

- Bauer, A.-S.; Tacker, M.; Uysal-Unalan, I.; Cruz, R.M.S.; Varzakas, T.; Krauter, V. Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review. Foods 2021, 10, 2702.

- Dahlbo, H.; Poliakova, V.; Mylläri, V.; Sahimaa, O.; Anderson, R. Recycling potential of post-consumer plastic packaging waste in Finland. Waste Manag. 2018, 71, 52–61.

- Ceflex. Designing for a Circular Economy: Recyclability of Polylefin-Based Flexible Packaging. 2020. Available online: https://guidelines.ceflex.eu (accessed on 16 February 2021).

- FH Campus Wien; Circular Analytics TK GmbH. Circular Packaging Design Guideline: Empfehlungen für Die Gestaltung Recyclinggerechter Verpackungen, Vienna. 2021. Available online: https://www.fh-campuswien.ac.at/fileadmin/redakteure/Forschung/FH-Campus-Wien_Circular-Packaging-Design-Guideline_V04_DE.pdf (accessed on 9 February 2022).

- Bergmair, J.; Washüttl, M.; Wepner, B. Prüfpraxis für Kunststoffverpackungen: Lebensmittel-, Pharma- und Kosmetikverpackungen; Behr: Hamburg, Germany, 2012; ISBN 9783899479072.

- Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on Materials and Articles Intended to Come into Contact with Food and Repealing Directives 80/590/EEC and 89/109/EEC; European Parliament, Council of the European Union: Brussels, Belgium, 2004.

- Han, J.H. (Ed.) Innovations in Food Packaging; Elsevier Ltd.: Amsterdam, The Netherlands, 2005; ISBN 978-0-12-311632-1.

- Campbell-Platt, G. (Ed.) Food Science and Technology, 2nd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; ISBN 9780470673423.

- Marsh, K.; Bugusu, B. Food Packaging? Roles, Materials, and Environmental Issues. J. Food Sci. 2007, 72, R39–R55.

- ISO 5801:2007 Industrial Fans Performance (Testing Using Standardized Airways). Available online: https://www.iso.org/obp/ui/#iso:std:iso:5801:ed-2:v1:en (accessed on 2 February 2022).

- Detzel, A.; Bodrogi, F.; Kauertz, B.; Bick, C.; Welle, F.; Schmid, M.; Schmitz, K.; Müller, K.; Käb, H. Biobasierte Kunststoffe als Verpackung von Lebensmitteln; Bundesministerium für Ernährung und Landwirtschaft: Heidelberg, Germany, 2018; Available online: https://www.ifeu.de/fileadmin/uploads/Endbericht-Bio-LVp_20180612.pdf (accessed on 27 September 2021).

- Carlsson, D.J.; Wiles, D.M. Composites, Fabrication to Die Design. In Encyclopedia of Polymer Science and Engineering, 2nd ed.; Mark, H., Bikales, N.M., Overberger, C.G., Menges, G., Eds.; John Wiley & Sons: New York, NY, USA, 1986; p. 665.

- Fellows, P. Food Processing Technology: Principles and Practice, 3rd ed.; Woodhead Publishing Limited, CRC Press: Cambridge, UK, 2009; ISBN 1615830413.

- Yam, K.L. (Ed.) The Wiley Encyclopedia of Packaging Technology, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2009; ISBN 0470087048.

- Commission Regulation (EU) No 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food Text with EEA Relevance; European Commission: Brussels, Belgium, 2011.

- Commission Regulation (EC) No 2023/2006 of 22 December 2006 on Good Manufacturing Practice for Materials and Articles Intended to Come into Contact with Food (Text with EEA Relevance); European Commission: Brussels, Belgium, 2006.

- BFR. Database BfR Recommendations on Food Contact Materials: Recommendations. Available online: https://bfr.ble.de/kse/faces/DBEmpfehlung_en.jsp (accessed on 3 February 2022).

- EDQM Council of Europe. Food Contact Materials and Articles. Available online: https://www.edqm.eu/en/food-contact-materials-and-articles (accessed on 11 October 2021).

- SR 817. 023.21—Verordnung des EDI vom 16. Dezember 2016 über Materialien und Gegenstände, die Dazu Bestimmt Sind, mit Lebensmitteln in Berührung zu Kommen (Bedarfsgegenständeverordnung): Bedarfsgegenständeverordnung; Eidgenössische Departement des Innern: Switzerland, 2016.

- European Printing Ink Association EuPIA. EuPIA Guideline on Printing Inks Applied to Food Contact Materials. 2020. Available online: https://www.eupia.org/fileadmin/Documents/Food_contact_material/2020-12-22_EuPIA_Guideline_on_Printing_Inks_applied_to_Food_Contact_Materials.pdf (accessed on 3 February 2022).

- Barone, C.; Bolzoni, L.; Caruso, G.; Salvatore, P. (Eds.) Food Packaging Hygiene; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 9783319148267.

- Belitz, H.-D.; Grosch, W.; Schieberle, P. Cereals and Cereal Products. In Food Chemistry, 3rd ed.; Belitz, H.-D., Grosch, W., Schieberle, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2004; pp. 673–746. ISBN 978-3-540-40818-5.

- Smith, J.P.; Daifas, D.P.; El-Khoury, W.; Koukoutsis, J.; El-Khoury, A. Shelf Life and Safety Concerns of Bakery Products—A Review. Crit. Rev. Food Sci. Nutr. 2004, 44, 19–55.

- Wolf, B. Confectionery and Sugar-Based Foods. Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-0-08-100596-5.

- Subramaniam, P. The Stability and Shelf Life of Confectionery Products. In Stability and Shelf Life of Food, 2nd ed.; Subramaniam, P., Wareing, P., Eds.; Elsevier Science & Technology: Cambridge, UK, 2016; ISBN 9780081004364.

- Lusas, E.W.; Rooney, L.W. (Eds.) Snack Foods Processing; CRC Press LLC: Boca Raton, FL, USA, 2001; ISBN 1566769329.

- European Commission. Guidance Document Describing the Food Categories in Part E of Annex II to Regulation (EC) No 1333/2008 on Food Additives. 2017. Available online: https://ec.europa.eu/food/system/files/2017-09/fs_food-improvement-agents_guidance_1333-2008_annex-2.pdf (accessed on 4 February 2022).

- FAO. Cereal Supply and Demand Brief. Available online: http://www.fao.org/worldfoodsituation/csdb/en/ (accessed on 4 October 2021).

- EUROSTAT. Prodcom Annual Data. 2020. Available online: https://ec.europa.eu/eurostat/web/prodcom/data/excel-files-nace-rev.2 (accessed on 4 October 2021).

- Regulation (EC) No 178/2002 of the European Parliament and of the Council of 28 January 2002 Laying Down the General Principles and Requirements of Food Law, Establishing the European Food Safety Authority and Laying Down Procedures in Matters of Food Safety; EC: Brussels, Belgium, 2002.

- Regulation (EC) No 1331/2008 of the European Parliament and of the Council of 16 December 2008 Establishing a Common Authorisation Procedure for Food Additives, Food Enzymes and Food Flavourings (Text with EEA Relevance); EC: Brussels, Belgium, 2008.

- Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the Provision of Food Information to Consumers, Amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and Repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004 Text with EEA relevance; EC: Brussels, Belgium, 2011.

- Commission Regulation (EC) No 2073/2005 of 15 November 2005 on Microbiological Criteria for Foodstuffs (Text with EEA Relevance); EC: Brussels, Belgium, 2005.

- Regulation (EC) No 852/2004 of the European Parliament and of the Council of 29 April 2004 on the Hygiene of Foodstuffs; EC: Brussels, Belgium, 2004.

- Robertson, G.L. (Ed.) Food Packaging and Shelf Life: A Practical Guide; CRC Press: Boca Raton, FL, USA, 2009; ISBN 9781420078459.

- Subramaniam, P.; Wareing, P. (Eds.) Stability and Shelf Life of Food, 2nd ed.; Elsevier Science & Technology: Cambridge, UK, 2016; ISBN 9780081004364.

- Kong, F.; Singh, R.P. Chemical Deterioration and Physical Instability of Foods and Beverages. In Stability and Shelf Life of Food, 2nd ed.; Subramaniam, P., Wareing, P., Eds.; Elsevier Science & Technology: Cambridge, UK, 2016; pp. 43–76. ISBN 9780081004364.

- Fabra, M.J.; Talens, P.; Moraga, G.; Martínez-Navarrete, N. Sorption isotherm and state diagram of grapefruit as a tool to improve product processing and stability. J. Food Eng. 2009, 93, 52–58.

- Lianou, A.; Panagou, E.Z.; Nychas, G.-J.E. Microbiological spoilage of foods and beverages. In The Stability and Shelf Life of Food, 2nd ed.; Subramaniam, P., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 3–42.

- Schmidt, S.J.; Fontana, A.J. Appendix E: Water Activity Values of Select Food Ingredients and Products. In Water Activity in Foods: Fundamentals and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; pp. 407–420.

- Ergun, R.; Lietha, R.; Hartel, R.W. Moisture and Shelf Life in Sugar Confections. Crit. Rev. Food Sci. Nutr. 2010, 50, 162–192.

- Bussiere, G.; Serpelloni, M. Confectionery and Water Activity Determination of AW by Calculation. In Properties of Water in Foods: In Relation to Quality and Stability; Simatos, D., Multon, J.L., Eds.; Springer: Dordrecht, The Netherlands, 1985; pp. 627–645. ISBN 978-94-010-8756-8.

- Subramaniam, P.J. Shelf-Life Prediction and Testing. In Science and Technology of Enrobed and Filled Chocolate, Confectionery and Bakery Products; Talbot, G., Ed.; CRC Press: Boca Raton, FL, USA, 2009; pp. 233–254. ISBN 9781845693909.

- Cauvain, S.P.; Young, L.S. Bakery Food Manufacture and Quality: Water Control and Effects, 2nd ed.; Wiley-Blackwell: Chichester, UK, 2008; ISBN 9781444301083.

- Dury-Brun, C.; Jury, V.; Guillard, V.; Desobry, S.; Voilley, A.; Chalier, P. Water barrier properties of treated-papers and application to sponge cake storage. Food Res. Int. 2006, 39, 1002–1011.

- Davidson, I. Biscuit, Cookie and Cracker Production: Process, Production and Packaging Equipment, 2nd ed.; Academic Press, Elsevier: Amsterdam, The Netherlands, 2018; ISBN 0128155795.

- Pekmez, H. Properties of Flour used in Flat Bread (Gaziantep pita) Production. Turk. J. Agric. Food Sci. Technol. 2019, 7, 209–213.

- Taoukis, P.; Labuza, T.; Sam Saguy, I. Kinetics of Food Deterioration and Shelf-Life Prediction. Handbook of Food Engineering Practice; CRC Press: New York, NY, USA, 1997.

- Costa, A.L.C. Combination of Process Technology and Packaging Conditions to Improve the Shelf Life of Fresh Pasta. J. Food Process. Technol. 2014, 5.

- Machálková, L.; Hřivna, L.; Nedomová, Š.; Jůzl, M. The effect of storage temperature on the quality and formation of blooming defects in chocolate confectionery. Potravinarstvo Slovak J. Food Sci. 2015, 9.

- Jaroni, D.; Ravishankar, S.; Juneja, V. Microbiology of Ready-to-Eat Foods. In Ready-to-Eat Foods, 1st ed.; Hwang, A., Huang, L., Eds.; CRC Press: Boca Raton, FL, USA, 2010; pp. 1–60.

- Valerio, F.; de Bellis, P.; Di Biase, M.; Lonigro, S.L.; Giussani, B.; Visconti, A.; Lavermicocca, P.; Sisto, A. Diversity of spore-forming bacteria and identification of Bacillus amyloliquefaciens as a species frequently associated with the ropy spoilage of bread. Int. J. Food Microbiol. 2012, 156, 278–285.

- Pepe, O.; Blaiotta, G.; Moschetti, G.; Greco, T.; Villani, F. Rope-producing strains of Bacillus spp. from wheat bread and strategy for their control by lactic acid bacteria. Appl. Environ. Microbiol. 2003, 69, 2321–2329.

- Galić, K.; Gabrić, D.; Ćurić, D. Packaging and the Shelf Life of Bread; Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2019.

- Omedi, J.O.; Huang, W.; Zhang, B.; Li, Z.; Zheng, J. Advances in present-day frozen dough technology and its improver and novel biotech ingredients development trends—A review. Cereal. Chem. 2018, 96, 34–56.

- Recanati, F.; Marveggio, D.; Dotelli, G. From beans to bar: A life cycle assessment towards sustainable chocolate supply chain. Sci. Total Environ. 2018, 613–614, 1013–1023.

- Neira, D.P. Energy sustainability of Ecuadorian cacao export and its contribution to climate change. A case study through product life cycle assessment. J. Clean. Prod. 2016, 112, 2560–2568.

- Büsser, S.; Jungbluth, N. LCA of Chocolate Packed in Aluminium Foil Based Packaging, Switzerland. 2009. Available online: http://www.alufoil.org/files/alufoil/sustainability/ESU_-_Chocolate_2009_-_Exec_Sum.pdf (accessed on 4 February 2022).

- Boakye-Yiadom, K.; Duca, D.; Pedretti, E.F.; Ilari, A. Environmental Performance of Chocolate Produced in Ghana Using Life Cycle Assessment. Sustainability 2021, 13, 6155.

- Pérez-Neira, D.; Copena, D.; Armengot, L.; Simón, X. Transportation can cancel out the ecological advantages of producing organic cacao: The carbon footprint of the globalized agrifood system of ecuadorian chocolate. J. Environ. Manag. 2020, 276, 111306.

- Bianchi, F.R.; Moreschi, L.; Gallo, M.; Vesce, E.; Del Borghi, A. Environmental analysis along the supply chain of dark, milk and white chocolate: A life cycle comparison. Int. J. Life Cycle Assess. 2020, 26, 807–821.

- Miah, J.; Griffiths, A.; McNeill, R.; Halvorson, S.; Schenker, U.; Espinoza-Orias, N.; Morse, S.; Yang, A.; Sadhukhan, J. Environmental management of confectionery products: Life cycle impacts and improvement strategies. J. Clean. Prod. 2018, 177, 732–751.

- PlascticsEurope. Plasctics—The Facts. 2020. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2020/ (accessed on 19 January 2022).

- Nilsson, K.; Sund, V.; Florén, B. Environmental Impact of the Consumption of Sweets, Crisps and Soft Drinks, Copenhagen. 2011. Available online: http://www.diva-portal.org/smash/get/diva2:702819/FULLTEXT01.pdf (accessed on 17 February 2022).

- Konstantas, A.; Stamford, L.; Azapagic, A. Evaluation of environmental sustainability of biscuits at the product and sectoral levels. J. Clean. Prod. 2019, 230, 1217–1228.

- Morris, B. Examples of Flexible Packaging Film Structures. The Science and Technology of Flexible Packaging; Elsevier: Amsterdam, The Netherlands, 2017; pp. 697–709. ISBN 9780323242738.

- Kägi, T.; Wettstein, D.; Dinkel, F. Comparing rice products: Confidence intervals as a solution to avoid wrong conclusions in communicating carbon footprints. In Proceedings of the 7th International Conference on Life Cycle Assessment in the Agrifood Sector, Bari, Italy, 24 September 2010; pp. 229–233.

- Nunes, F.A.; Seferin, M.; Maciel, V.G.; Flôres, S.H.; Ayub, M.A.Z. Life cycle greenhouse gas emissions from rice production systems in Brazil: A comparison between minimal tillage and organic farming. J. Clean. Prod. 2016, 139, 799–809.

- Urbelis, J.H.; Cooper, J.R. Migration of food contact substances into dry foods: A review. Food Addit. Contam. Part A 2021, 38, 1044–1073.

- Forsido, S.F.; Welelaw, E.; Belachew, T.; Hensel, O. Effects of storage temperature and packaging material on physico-chemical, microbial and sensory properties and shelf life of extruded composite baby food flour. Heliyon 2021, 7, e06821.

- Monahan, E.J. Packaging of ready-to-eat breakfast cereals. Cereal Foods World 1988, 33, 215–221.

- Sakamaki, C.; Gray, J.I.; Harte, B.R. The influence of selected barriers and oxygen absorbers on the stability of oat cereal during storage. J. Packag. Technol. 1988, 2, 98–103.

- Jeswani, H.K.; Burkinshaw, R.; Azapagic, A. Environmental sustainability issues in the food–energy–water nexus: Breakfast cereals and snacks. Sustain. Prod. Consum. 2015, 2, 17–28.

- Sieti, N.; Rivera, X.C.S.; Stamford, L.; Azapagic, A. Environmental impacts of baby food: Ready-made porridge products. J. Clean. Prod. 2018, 212, 1554–1567.

- Cimini, A.; Cibelli, M.; Moresi, M. Cradle-to-grave carbon footprint of dried organic pasta: Assessment and potential mitigation measures. J. Sci. Food Agric. 2019, 99, 5303–5318.

- Röös, E.; Sundberg, C.; Hansson, P.-A. Uncertainties in the carbon footprint of refined wheat products: A case study on Swedish pasta. Int. J. Life Cycle Assess. 2011, 16, 338–350.

- Saget, S.; Costa, M.P.; Barilli, E.; de Vasconcelos, M.W.; Santos, C.S.; Styles, D.; Williams, M. Substituting wheat with chickpea flour in pasta production delivers more nutrition at a lower environmental cost. Sustain. Prod. Consum. 2020, 24, 26–38.

- Nette, A.; Wolf, P.; Schlüter, O.; Meyer-Aurich, A. A Comparison of Carbon Footprint and Production Cost of Different Pasta Products Based on Whole Egg and Pea Flour. Foods 2016, 5, 17.

- Park, C.; Szabo, R.; Jean, A. A Survey of Wet Pasta Packaged Under a C02:N2 (20:80) Mixture for Staphylococci and their Enterotoxins. Can. Inst. Food Sci. Technol. J. 1988, 21, 109–111.

- Sanguinetti, A.; Del Caro, A.; Mangia, N.; Secchi, N.; Catzeddu, P.; Piga, A. Quality Changes of Fresh Filled Pasta During Storage: Influence of Modified Atmosphere Packaging on Microbial Growth and Sensory Properties. Food Sci. Technol. Int. 2011, 17, 23–29.

- Rachtanapun, P.; Tangnonthaphat, T. Effects of packaging types and storage temperatures on the shelf life of fresh rice noodles under vacuum conditions. Chiang Mai J. Sci. 2011, 38, 579–589.

- Espinoza-Orias, N.; Stichnothe, H.; Azapagic, A. The carbon footprint of bread. Int. J. Life Cycle Assess. 2011, 16, 351–365.

- Jensen, J.K.; Arlbjørn, J.S. Product carbon footprint of rye bread. J. Clean. Prod. 2014, 82, 45–57.

- Svanes, E.; Oestergaard, S.; Hanssen, O.J. Effects of Packaging and Food Waste Prevention by Consumers on the Environmental Impact of Production and Consumption of Bread in Norway. Sustainability 2018, 11, 43.

- Williams, H.; Wikström, F. Environmental impact of packaging and food losses in a life cycle perspective: A comparative analysis of five food items. J. Clean. Prod. 2011, 19, 43–48.

- Korsaeth, A.; Jacobsen, A.Z.; Roer, A.-G.; Henriksen, T.M.; Sonesson, U.; Bonesmo, H.; Skjelvåg, A.O.; Strømman, A.H. Environmental life cycle assessment of cereal and bread production in Norway. Acta Agric. Scand. Sect. A Anim. Sci. 2012, 62, 242–253.

- Cauvain, S.P.; Young, L.S. Chemical and physical deterioration of bakery products. In Chemical Deterioration and Physical Instability of Food and Beverages; Skibsted, L., Risbo, J., Andersen, M., Eds.; Woodhead Publishing: Washington, DC, USA, 2010; pp. 381–412. ISBN 9781845699260.

- Chinnadurai, K.; Sequeira, V. Packaging of Cereals, Snacks, and Confectionery. Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-0-08-100596-5.

More

Information

Subjects:

Agriculture, Dairy & Animal Science

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

9.3K

Revisions:

9 times

(View History)

Update Date:

29 Mar 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No