Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Agnieszka Lekawa-Raus | + 2405 word(s) | 2405 | 2022-02-22 11:01:43 | | | |

| 2 | Beatrix Zheng | -5 word(s) | 2400 | 2022-03-01 11:22:23 | | | | |

| 3 | Beatrix Zheng | Meta information modification | 2400 | 2022-03-02 07:22:49 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Lekawa-Raus, A. Enriching WPCs and NFPCs with Carbon Nanomaterials. Encyclopedia. Available online: https://encyclopedia.pub/entry/20036 (accessed on 07 February 2026).

Lekawa-Raus A. Enriching WPCs and NFPCs with Carbon Nanomaterials. Encyclopedia. Available at: https://encyclopedia.pub/entry/20036. Accessed February 07, 2026.

Lekawa-Raus, Agnieszka. "Enriching WPCs and NFPCs with Carbon Nanomaterials" Encyclopedia, https://encyclopedia.pub/entry/20036 (accessed February 07, 2026).

Lekawa-Raus, A. (2022, March 01). Enriching WPCs and NFPCs with Carbon Nanomaterials. In Encyclopedia. https://encyclopedia.pub/entry/20036

Lekawa-Raus, Agnieszka. "Enriching WPCs and NFPCs with Carbon Nanomaterials." Encyclopedia. Web. 01 March, 2022.

Copy Citation

Carbon nanotubes (CNTs) and graphene, with their unique mechanical, electrical, thermal, optical, and wettability properties, are very effective fillers for many types of composites. Recently, a number of studies have shown that CNTs and graphene may be integrated into wood–plastic composites (WPCs) and natural-fibre-reinforced polymer composites (NFPCs) to improve the existing performance of the WPCs/NFPCs as well as enabling their use in completely new areas of engineering.

wood–plastic composites

natural fibre–plastic composites

carbon nanotubes

MWCNTs

graphene

graphene oxide

graphene nanoplatelets

hybrid composites

1. Introduction

Wood–plastic composites (WPCs) entered the market in the 1990s; they are usually composed of up to 50% w/w of wood flour, thermoplastic polymers (polypropylene, polyethylene, polyvinyl chloride etc.), and small amounts of additives such as dyes or coupling agents [1]. WPCs are most often used in construction and flooring, replacing lumber, wood-based boards (WBBs), ceramic tiles, or metals. WPCs can be designed for specific performance requirements, taking into account the advantages of the natural strength of the wood and the hydrophobic characteristics of the plastic component. The possibility of use of wood waste fillers as well as waste and recycled plastics reduces the environmental impact of the material, and also improves the circular economy [2][3][4]. Other advantages of WPCs are their ease of maintenance, improved durability, and substantial service lifetime [5]. The large weight share of polymers enables the shaping of WPC elements by moulding. Moulding allows the formation of complex shapes that would be very costly or even impossible to produce with pure lumber, wood-based boards (WBBs), or stone/ceramics. Furthermore, ready-made WPCs may be further shaped using the same tools as conventional lumber.

However, WPCs are also not free from disadvantages. The large weight share of the polymer matrix also predetermines the mechanical properties of the WPCs, which are close to those of their base polymers; therefore, they are poorer than (for example) raw wood. Another negative property that has been observed in WPCs is their susceptibility to environmental degradation. This type of degradation can occur as a result of various factors, including temperature, air quality, moisture (the polymer matrix does not fully exclude water interaction), microorganisms, light, high-energy radiation, chemical agents, and mechanical stress [6][7]. These factors can decrease the aesthetic quality (discoloration) and mechanical strength of WPCs [1][8][9]. Moreover, evidence has been seen of the presence of fungal attack on WPC boards that are exposed to natural weathering [10][11].

Even taking account of these issues, the current wide use of WPCs, coupled with their composite nature, favours the development of research in this area. Very often, the studies are extended to the use of other cellulose-rich materials (e.g., milled straw, plant shells, or bamboo) as fillers [12]. The latter composites are referred to as natural fibre–polymer composites (sometimes WPCs are classified as subgroup of NFPCs). NFPCs are not yet widely applied, as up to this point their performance has often been found to be less than satisfactory [12]. However, new studies in this area show very encouraging results [13][14][15][16][17][18]. Other studies focus mainly on the improvement of the performance of the WPCs, utilisation of new types of matrices, new manufacturing techniques, and an increase in the range of applications [19][20][21][22][23]. One of the notable interesting areas of study is in the enrichment of the WPC and NFPC composites with carbon nanomaterials, such as carbon nanotubes (CNTs) and graphene.

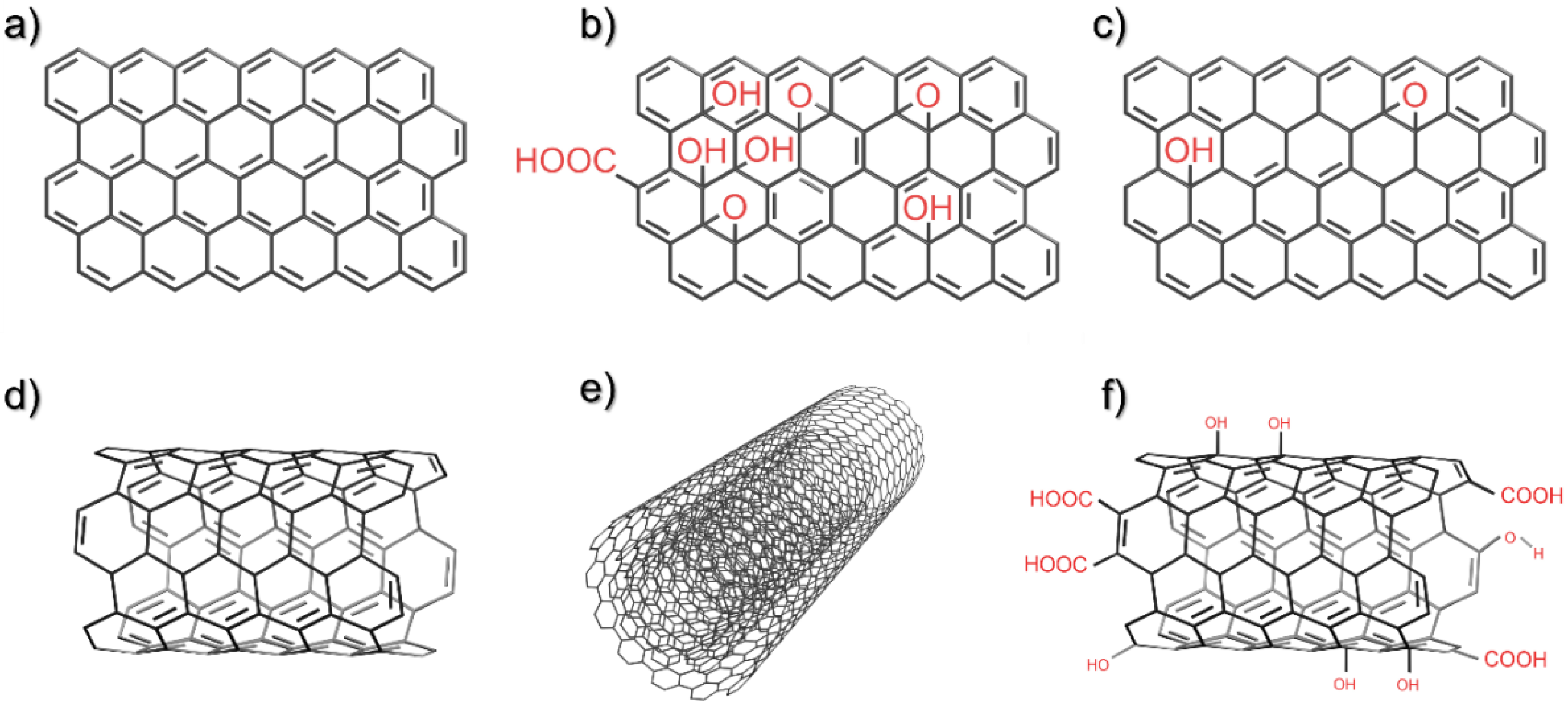

Both carbon nanotubes and graphene are nano-allotropes of pure carbon [24][25]. The structure of both is based on a planar hexagonal lattice of sp2-bonded carbon atoms (Figure 1a), i.e., every carbon atom forms a strong covalent bond with three neighbouring carbon atoms, and a much weaker pi bond is formed by the atoms laterally by their fourth available electrons distributed in pz orbitals perpendicular to the hexagonal plane. This atomic structure imparts both CNTs and graphene with extremely high mechanical strength and stiffness, as well as superior electrical and thermal conductivity [26]. Additionally, both of these nanomaterials are lightweight [27], superhydrophobic [28][29], chemically resistant [30], and environmentally friendly, as they may be synthesised from greenhouse gases such as methane or CO2 [31][32].

Figure 1. Structure of (a) graphene, (b) graphene oxide, (c) reduced graphene oxide, (d) single-walled carbon nanotube (e) multiwalled carbon nanotube, and (f) functionalised carbon nanotube. Annotation indicates where the structure is not pure carbon.

Graphene is a 2D structure that, in theory, is one atomic layer thick (Figure 1a). In practice, the name graphene often refers to the whole family of two-dimensional carbon nanomaterials. The material to mention first in the context of WPCs is graphene nanoplatelets (GNPs); these are multilayered pure graphene structures often produced by the exfoliation of graphite, or via the chemical vapour deposition (CVD) process. Although the properties of GNPs may not be superior to those of single-layer graphene, they are sufficient to improve the properties of many polymer composites [33]. GNPs are also quite inexpensive, easy to handle, and are produced and sold in large quantities. A further material is graphene oxide (GO) (Figure 1b), which is a disordered single- or multilayered graphene functionalised with epoxy bridges, hydroxyl groups, and carboxyl groups [34]. GO is electrically insulating, and has a much poorer mechanical performance than graphene/GNPs, but it is also a chemically active and hydrophilic structure; this enables dispersion in water and a uniform distribution in many polymers [35]. Finally, reduced graphene oxide (rGO) is a material formed by the chemical reduction of GO. This process partially restores the electrical and mechanical properties of the graphene via the removal of most of the functional groups and the recovery of the sp2 carbon–carbon bonds (Figure 1c) [36]. Often, the reduction process is performed after the composite manufacturing process, so as to benefit from the chemical reactivity of GO during manufacture and the electrical and mechanical properties of graphene in the final product.

Carbon nanotubes are one-dimensional structures of seamlessly rolled-up graphene sheets; they may be referred to as single-walled carbon nanotubes (SWCNTs) if made of a single layer of graphene (Figure 1d), or multiwalled carbon nanotubes (MWCNTs) if two or more SWCNTs are encapsulated within one another (Figure 1e). SWCNTs are often characterised as having better properties than MWCNTs, but the MWCNTs can be produced inexpensively and on a large scale [31]. The CNTs may also be produced in a functionalised form to facilitate the dispersion of these structures in polymer matrices (Figure 1f) [37]. As 1D structures, the CNTs have nanosized diameters, and are most often nano- or micrometre lengths. In composites, CNTs form percolation networks more easily than graphene, but in some processes it is more difficult to obtain their high loading fractions [38][39].

Both graphene and CNTs have been widely used in composites [40]; they have been tested as fillers in many types of matrices, including polymers [39][41], metals [42], and ceramics [43]. Polymer composites were actually the first major area in which CNTs and graphene found commercial applications. Both nanomaterials have been used to enhance mechanical properties [44], improve thermal stability [45], decrease flammability [46][47], introduce electrical and thermal conductivity [39], and much more [48]. The applications of these composites include strong and lightweight construction materials [43], electromagnetic shielding [49], antistatic surfaces [50], sensors [51], components such as supercapacitors, etc. [52]. It may therefore be expected that a combination of WPCs and other NFPCs with CNTs and/or graphene may produce materials with very interesting performance parameters, suitable for completely new applications.

2. Applications

As well as improving the performance of WPCs in current applications, the enhancement of WPCs with new functionalities can also be considered, allowing them to be used in completely new areas. For example, as indicated by Rajan et al. [53], an increase in the electrical conductivity may render the WPC’s surface antistatic and simply prevent static electricity buildup in WPC constructions, or it may enable the use of WPCs in electronic packaging. Another application in this area may be the electromagnetic shielding studied by Chen et al. [54].

Moreover, WPCs filled with CNMs could potentially be used as sensors for temperature, water, or bending [55], although to the best of human's knowledge they have not been tested for these applications to date.

Another property that may be utilised in new applications is thermal conductivity. Lu et al. [56] studied the thermal properties of wood–polymer composites enriched with GO, with a view to creating a solar thermal energy storage device. The authors designed a shape-stabilised phase change material (SSPCM) composed of polyethylene glycol (PEG)-based polyethylene glycol–polyurethane (PU), wood fibres, and graphene oxide. The PEG-based PU was used as a phase change material with a high energy storage density, with the wood fibres acting as a scaffold, while the GO enhancement increased the thermal conductivity and light absorption. As a result, a device with good thermal stability and a light–thermal conversion performance was produced.

3. Practical Considerations, Key Challenges, and Future Work

Currently, WPCs are widely applied, and are mostly used in indoor and outdoor furniture and flooring, frames, fences, etc. The general improvement in their properties, such as increasing their strength, or decreasing their water uptake or flammability, may definitely be of interest to the current industry. Naturally, the obstacles here may be the introduction of CNMs into industrial production and the price of the final product. However, an analysis of market reports for carbon nanotubes shows that the polymer-CNT composites currently constitute the largest share of the market [57]. This indicates that the polymer industry is already well acquainted with carbon nanomaterials and the developed procedures for their incorporation into polymers, and these could be transferred to the industrial WPC production lines.

The initial estimations of pricing indicate that, assuming the current market prices of CNTs, GNP, and GO, as presented in Table 1, for low weight percentages of CNMs the price of a 1 m2, 2 cm thick WPC would not be increased significantly. Conversely, for high weight percentages (10 wt.%), the current costs are estimated to be outside of commercial viability. However, taking into account that most studies use low filler contents, and that 1 m2 of WPC costs USD ~100, it can already be found that the use of CNTs and graphene is quite feasible.

Table 1. Estimated prices of CNM additives to WPC.

| CNM | Manufacturer | Price per 1 kg (USD) | Estimated Price of CNM per 1 m2 of 2 cm Thick WPC (USD) | |

|---|---|---|---|---|

| with 0.1 wt.% CNM | with 10 wt.% CNM | |||

| CNTs | Nanocyl SA | 120 | 1.44 | 144 |

| GNP | Cheap Tubes Inc. | 500 | 6.00 | 600 |

| GO | Graphenea | 3300 | 39.60 | 3960 |

However, before CNM-enriched WPCs or NFPCs can enter the market, there are still some significant scientific challenges that need to be addressed.

Going forward, in future studies, a much more pragmatic approach to experimental planning needs to be adopted. It would be useful to consider the vast corpus of knowledge gathered in the manufacture of pure CNM and polymer composites [58][59][60][61], and to combine this with the state-of-the-art expertise already existing in the production of high-performance WPCs and NFPCs [62][63][64]. Such analysis could potentially help with the choice of specific CNMs, wood particles, compatible polymers, and methods of manufacture, as well as avoiding such issues as agglomeration or poor adhesion of components. The performance of modelling studies could also provide valuable insight.

It would also be useful to look at aspects such as density, which is a very basic property of every composite. To date, only Kumar et al. [57] and Rajan et al. [53] have provided data showing density changes with the content of CNMs. Kumar et al. showed that the density decreases linearly with an increase in GPC content, while Rajan et al. found the opposite trend. These discrepancies may be related to many factors, including large variations in the density of the chosen CNMs and issues related to the manufacturing of the composites, e.g., the formation of voids in the composites. Analysis of the density data could therefore be useful in the analysis of the quality of the composites, as well as in understanding the mechanisms responsible for their formation.

Taking into account the practical applications of WPCs and NFPCs, it would be also necessary to perform more studies on the weathering of hybrid samples. Apart from the UV exposure tested by Peng et al. [65] and the full water immersion effects studied by several authors (Section 2.4), weather-related degradation agents may include heat, humidity, rain erosion, freezing, and thawing. All of these factors separately or acting collectively may impact the mechanical, physical, and chemical properties of hybrid composites and, therefore, may change their visual appearance (e.g., colour, gloss) and their surface topography (e.g., roughness, surface microstructure), as well as affecting their strength, stiffness, dimensional stability, and overall service lifetime. Other degradation factors that should be considered, and have not been taken into account thus far, include fungi and mould, as well as decay/staining by air pollutants and saltwater.

More studies should also look into the issue of biodegradation. The only study dealing with this aspect to date, by Yaghoobi et al. [66], showed that enriching NFPCs with MWCNTs decreases the rate of biodegradation. This could be a very beneficial phenomenon; however, it could also be considered as a drawback when targeting the production of biodegradable composites [67][68].

Finally, it may be interesting and helpful to test the hybrid composites for acoustic properties, coatability, oil staining susceptibility, wear patterns, sand erosion, and performance under drilling. All of these properties are dependent on the specific application of the designed composites.

4. Conclusions

In summary, to date, a large variety of studies on WPCs/NFPCs hybridised with carbon nanomaterials have been presented. The composites were prepared using different types and amounts of wood flour and other forms of natural fillers, such as oil palm shell powder, kenaf fibres, bamboo mats, etc. The matrices were based on both thermoplastic and thermoset polymers. The composites were prepared both with and without additives such as MAPP and MAPE compatibilizers or selected hardeners. Various types of manufacturing techniques were also used, including twin-screw extrusion, compression moulding, and laser sintering. The WPCs/NFPCs were hybridised with graphene nanoplatelets, graphene oxides, MWCNTs, and functionalised CNTs, as well as CNM masterbatches.

Inclusion of the CNMs in the WPCs and NFPCs enabled the introduction of a relative improvement in the mechanical properties of the studied composites, such as tensile strength, flexural strength, and impact strength. The hybridisation with CNMs also enabled an increase in thermal conductivity. Furthermore, the addition of CNMs rendered WPCs electrically conductive, improved their thermal stability and decreased their flammability, increased their photostability, decreased their water absorption, and improved their foaming efficiency. However, the analysis of the researches showed that the level of improvement differed significantly between the hybrid WPCs/NFPCs, and that in some cases the improvement of one parameter was detrimental to another.

References

- Xu, K.; Du, G.; Wang, S. Wood Plastic Composites: Their Properties and Applications. In Engineered Wood Products for Construction; IntechOpen: London, UK, 2021.

- Keskisaari, A.; Kärki, T. The use of waste materials in wood-plastic composites and their impact on the profitability of the product. Resour. Conserv. Recycl. 2018, 134, 257–261.

- Kazemi Najafi, S. Use of recycled plastics in wood plastic composites—A review. Waste Manag. 2013, 33, 1898–1905.

- Hao, X.; Sun, J.; Chen, C.; Zhou, H.; Li, Y.; Li, W.; Wang, Q.; Ou, R. Dimensional stability improvements of waste wood flour/HDPE composites via carbon black network embedding. Constr. Build. Mater. 2021, 299, 123955.

- Papadopoulos, A.N. Advances in Wood Composites. Polymers 2020, 12, 48.

- Tokiwa, Y.; Calabia, B.P.; Ugwu, C.U.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742.

- Brebu, M. Environmental degradation of plastic composites with natural fillers—A review. Polymers 2020, 12, 166.

- Badji, C.; Soccalingame, L.; Garay, H.; Bergeret, A.; Bénézet, J.-C. Influence of weathering on visual and surface aspect of wood plastic composites: Correlation approach with mechanical properties and microstructure. Polym. Degrad. Stab. 2017, 137, 162–172.

- Wang, H.; Zhang, X.; Guo, S.; Liu, T. A review of coextruded wood–plastic composites. Polym. Compos. 2021, 42, 4174–4186.

- Fabiyi, J.S.; McDonald, A.G.; Wolcott, M.P.; Griffiths, P.R. Wood plastic composites weathering: Visual appearance and chemical changes. Polym. Degrad. Stab. 2008, 93, 1405–1414.

- Homkhiew, C.; Ratanawilai, T.; Thongruang, W. Effects of natural weathering on the properties of recycled polypropylene composites reinforced with rubberwood flour. Ind. Crops Prod. 2014, 56, 52–59.

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947.

- Luhar, S.; Suntharalingam, T.; Navaratnam, S.; Luhar, I.; Thamboo, J.; Poologanathan, K.; Gatheeshgar, P. Sustainable and Renewable Bio-Based Natural Fibres and Its Application for 3D Printed Concrete: A Review. Sustainability 2020, 12, 10485.

- Fogorasi, M.S.; Barbu, I. The potential of natural fibres for automotive sector—Review. IOP Conf. Ser. Mater. Sci. Eng. 2017, 252, 012044.

- Avci, E.; Acar, M.; Gonultas, O.; Candan, Z. Manufacturing biocomposites using black pine bark and oak bark. BioResources 2018, 13, 15–26.

- Russita, M. Bahruddin Production of palm frond based wood plastic composite by using twin screw extruder. IOP Conf. Ser. Mater. Sci. Eng. 2018, 345, 12039.

- Burgada, F.; Fages, E.; Quiles-Carrillo, L.; Lascano, D.; Ivorra-Martinez, J.; Arrieta, M.P.; Fenollar, O. Upgrading Recycled Polypropylene from Textile Wastes in Wood Plastic Composites with Short Hemp Fiber. Polymers 2021, 13, 1248.

- Carus, M.; Eder, A.; Dammer, L.; Korte, H.; Scholz, L.; Essel, R.; Breitmayer, E.; Barth, M. Wood-Plastic Composites (WPC) and Natural Fibre Composites (NFC): European and Global Markets 2012 and Future Trends in Automotive and Construction. Plast. Addit. Compd. 2015, 4, 18–21.

- Bengtsson, M.; Oksman, K.; Stark, N.M. Profile extrusion and mechanical properties of crosslinked wood–thermoplastic composites. Polym. Compos. 2006, 27, 184–194.

- Mazela, B.; Hochmanska, P.; Letmann, M. Biological durability of wood plastic composites. Ann. Wars. Univ. Life Sci. SGGW Wood Technol. 2008, 64, 71–76.

- Michalska-Pożoga, I.; Czerwińska, E. Effect of screw-disc extrusion process on the level of microbiological contamination of wood-plastic composites (WPC). Drewno 2015, 58, 65–73.

- Hosseinihashemi, S.K.; Badritala, A. The influence of a treatment process on the reaction to water of durable and water resistant wood/plastic composites. Drewno 2017, 60, 21–34.

- Kajaks, J.; Kalnins, K.; Naburgs, R. Wood plastic composites (WPC) based on high-density polyethylene and birch wood plywood production residues. Int. Wood Prod. J. 2018, 9, 15–21.

- Mathur, R.B.; Singh, B.P.; Pande, S. Carbon Nanomaterials: Synthesis, Structure, Properties and Applications, 1st ed.; Dresselhaus, M., Dresselhaus, G., Avouris, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2001; ISBN 9781498702119.

- Mandal, M.; Maitra, A.; Das, T.; Das, C.K. Graphene and Related Two-Dimensional Materials; Ashutosh Tiwari, M.S., Ed.; Wiley Online Books: Hoboken, NJ, USA; Scrivener Publishing LLC: Beverly, MA, USA, 2015; ISBN 9781119131816.

- Allen, M.J.; Tung, V.C.; Kaner, R.B. Honeycomb Carbon: A Review of Graphene. Chem. Rev. 2010, 110, 132–145.

- Gorgolis, G.; Galiotis, C. Graphene aerogels: A review. 2D Mater. 2017, 4, 32001.

- Łukawski, D.; Lisiecki, F.; Dudkowiak, A. Coating Cellulosic Materials with Graphene for Selective Absorption of Oils and Organic Solvents from Water. Fibers Polym. 2018, 19, 524–530.

- Łukawski, D.; Lekawa-Raus, A.; Lisiecki, F.; Koziol, K.; Dudkowiak, A. Towards the development of superhydrophobic carbon nanomaterial coatings on wood. Prog. Org. Coat. 2018, 125, 23–31.

- Nine, M.J.; Cole, M.A.; Tran, D.N.H.; Losic, D. Graphene: A multipurpose material for protective coatings. J. Mater. Chem. A 2015, 3, 12580–12602.

- Xiong, G.Y.; Suda, Y.; Wang, D.Z.; Huang, J.Y.; Ren, Z.F. Effect of temperature, pressure, and gas ratio of methane to hydrogen on the synthesis of double-walled carbon nanotubes by chemical vapour deposition. Nanotechnology 2005, 16, 532–535.

- Bo, Z.; Yang, Y.; Chen, J.; Yu, K.; Cen, K. Nanoscale Plasma-enhanced chemical vapor deposition synthesis of vertically oriented graphene nanosheets. Nanoscale 2013, 5, 5180–5204.

- Mohan, V.B.; Lau, K.; Hui, D.; Bhattacharyya, D. Graphene-based materials and their composites: A review on production, applications and product limitations. Compos. Part B Eng. 2018, 142, 200–220.

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228.

- Huang, X.; Qi, X.; Boeya, F.; Zhang, H. Graphene-based composites. Chem. Soc. Rev. 2012, 41, 666.

- Pei, S.; Cheng, H.-M. The reduction of graphene. Carbon 2012, 50, 3210.

- Tasis, D.; Tagmatarchis, N.; Bianco, A.; Prato, M. Chemistry of carbon nanotubes. Chem. Rev. 2006, 106, 1105–1136.

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498.

- Chen, J.; Lekawa-Raus, A.; Trevarthen, J.; Gizewski, T.; Lukawski, D.; Hazra, K.; Rahatekar, S.S.; Koziol, K.K.K. Carbon nanotube films spun from a gas phase reactor for manufacturing carbon nanotube film/carbon fibre epoxy hybrid composites for electrical applications. Carbon 2019, 158, 282–290.

- Kinloch, I.; Suhr, J.; Lou, J.; Young, R.J.; Ayajan, P.M. Composites with carbon nanotubes and graphene: An outlook. Science 2018, 362, 6414.

- Lepak-Kuc, S.; Podsiadły, B.; Skalski, A.; Janczak, D.; Jakubowska, M.; Lekawa-Raus, A. Highly Conductive Carbon Nanotube-Thermoplastic Polyurethane Nanocomposite for Smart Clothing Applications and Beyond. Nanomaterials 2019, 9, 1287.

- Milowska, K.; Ghorbani-Asl, M.; Burda, M.; Wolanicka, L.; Catic, N.; Bristowe, P.; Koziol, K. Breaking the electrical barrier between copper and carbon nanotubes. Nanoscale 2017, 9, 8458.

- Ramírez, C.; Belmonte, M.; Miranzo, P.; Osendi, M.I. Applications of Ceramic/Graphene Composites and Hybrids. Materials 2021, 14, 2071.

- Wang, J.; Song, F.; Ding, Y.; Shao, M. The incorporation of graphene to enhance mechanical properties of polypropylene self-reinforced polymer composites. Mater. Des. 2020, 195, 109073.

- Kashiwagi, T.; Du, F.; Winey, K.I.; Groth, K.M.; Shields, J.R.; Bellayer, S.P.; Kim, H.; Douglas, J.F. Flammability properties of polymer nanocomposites with single-walled carbon nanotubes: Effects of nanotube dispersion and concentration. Polymer 2005, 46, 471–481.

- Łukawski, D.; Grześkowiak, W.; Mazela, B.; Lekawa, A.; Dudkowiak, A. The Influence of Surface Modification of Wood Particles with Carbon Nanotubes on Properties of Particleboard Glued with Phenyl-Formaldehyde Resin. Drewno 2019, 62, 93–105.

- Łukawski, D.; Grześkowiak, W.; Lekawa-Raus, A.; Widelicka, M.; Lisiecki, F.; Dudkowiak, A. Flame retardant effect of lignin/carbon nanotubes/potassium carbonate composite coatings on cotton roving. Cellulose 2020, 27, 7271–7281.

- Sreenivasulu, B.; Ramji, B.R.; Nagaral, M. A Review on Graphene Reinforced Polymer Matrix Composites. Mater. Today Proc. 2018, 5, 2419–2428.

- Barathi Dassan, E.G.; Anjang Ab Rahman, A.; Abidin, M.S.Z.; Akil, H.M. Carbon nanotube–reinforced polymer composite for electromagnetic interference application: A review. Nanotechnol. Rev. 2020, 9, 768–788.

- Wang, Q.; Wang, Y.; Meng, Q.; Wang, T.; Guo, W.; Wu, G.; You, L. Preparation of high antistatic HDPE/polyaniline encapsulated graphene nanoplatelet composites by solution blending. RSC Adv. 2017, 7, 2796–2803.

- Choi, J.H.; Lee, J.; Byeon, M.; Hong, T.E.; Park, H.; Lee, C.Y. Graphene-Based Gas Sensors with High Sensitivity and Minimal Sensor-to-Sensor Variation. ACS Appl. Nano Mater. 2020, 3, 2257–2265.

- Ke, Q.; Wang, J. Graphene-based materials for supercapacitor electrodes—A review. J. Mater. 2016, 2, 37–54.

- Rajan, R.; Näkki, J.; Layek, R.; Rainosalo, E. Wood plastic composites with improved electrical and thermal conductivity. Wood Sci. Technol. 2021, 55, 719–739.

- Chen, J.; Teng, Z.; Zhao, Y.; Liu, W. Electromagnetic interference shielding properties of wood–plastic composites filled with graphene decorated carbon fiber. Polym. Compos. 2018, 39, 2110–2116.

- Łukawski, D.; Dudkowiak, A.; Janczak, D.; Lekawa-Raus, A. Preparation and applications of electrically conductive wood layered composites. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105656.

- Lu, X.; Liang, B.; Sheng, X.; Yuan, T.; Qu, J. Enhanced thermal conductivity of polyurethane/wood powder composite phase change materials via incorporating low loading of graphene oxide nanosheets for solar thermal energy storage. Sol. Energy Mater. Sol. Cells 2020, 208, 110391.

- Market Analysis. Available online: https://www.gminsights.com/industry-analysis/carbon-nanotubes-market (accessed on 11 February 2022).

- Liu, F.; Hu, N.; Zhang, J.; Atobe, S.; Weng, S.; Ning, H.; Liu, Y.; Wu, L.; Zhao, Y.; Mo, F.; et al. The interfacial mechanical properties of functionalized graphene–polymer nanocomposites. RSC Adv. 2016, 6, 66658–66664.

- Niyobuhungiro, D.; Hong, L. Graphene Polymer Composites: Review on Fabrication Method, Properties and Future Perspectives. Adv. Sci. Technol. Res. J. 2021, 15, 37–49.

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367.

- Chen, J.; Yan, L.; Song, W.; Xu, D. Interfacial characteristics of carbon nanotube-polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 149–169.

- Yáñez-Pacios, A.J.; Martín-Martínez, J.M. Surface modification and adhesion of wood-plastic composite (WPC) treated with UV/ozone. Compos. Interfaces 2018, 25, 127–149.

- Rao, J.; Zhou, Y.; Fan, M. Revealing the Interface Structure and Bonding Mechanism of Coupling Agent Treated WPC. Polymers 2018, 10, 266.

- Hejna, A.; Przybysz-Romatowska, M.; Kosmela, P.; Zedler, Ł.; Korol, J.; Formela, K. Recent advances in compatibilization strategies of wood-polymer composites by isocyanates. Wood Sci. Technol. 2020, 54, 1091–1119.

- Peng, Y.; Li, X.; Wang, W.; Cao, J. Photodegradation of wood flour/polypropylene composites incorporated with carbon materials with different morphologies. Wood Mater. Sci. Eng. 2020, 15, 104–113.

- Yaghoobi, H.; Fereidoon, A. Preparation and characterization of short kenaf fiber-based biocomposites reinforced with multi-walled carbon nanotubes. Compos. Part B 2019, 162, 314.

- Sommerhubera, P.F.; Wenkera, J.L.; Rütera, S.; Krause, A. Life cycle assessment of wood-plastic composites: Analysing alternative materials and identifying an environmental sound end-of-life option. Resour. Conserv. Recycl. 2017, 117, 235.

- Winandy, J.E.; Stark, N.M.; Clemons, C.M. Considerations in recycling of wood-plastic composites. In Proceedings of the 5th Global Wood and Natural Fibre Composites Symposium, Kassel, Germany, 27–28 April 2004; p. 9.

More

Information

Subjects:

Materials Science, Paper & Wood; Nanoscience & Nanotechnology; Materials Science, Composites

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

846

Revisions:

3 times

(View History)

Update Date:

02 Mar 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No