| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Stavros Yannopoulos | + 2373 word(s) | 2373 | 2020-08-28 14:00:51 | | | |

| 2 | Peter Tang | Meta information modification | 2373 | 2020-09-12 05:59:50 | | | | |

| 3 | Peter Tang | Meta information modification | 2373 | 2020-10-27 10:13:14 | | |

Video Upload Options

Agricultural drainage plays an important role worldwide in food production and conservation of soil resources, while safeguarding investments in agricultural production and irrigation projects. It can improve crop yields and land productivity, especially on poorly drained soils and in cases of prolonged waterlogging. Both the subsurface drainage materials and the installation techniques used have a long history dating to prehistoric times. Over time, new subsurface drainage materials, installation techniques and modernized equipment developed continuously to take advantage of technological advances provided through research and development, while the planning and organization of the implementation process improved.

1. Introduction

The importance of adequate drainage of agricultural lands has long been recognized, given the fact that drainage is probably as old as agriculture itself, dating from antiquity. In antiquity, serious drainage problems occurred in irrigated areas in several regions of the world, just as today. This is probably the reason for the decline and disappearance of some ancient irrigation-based civilizations (e.g., Mesopotamians) as they failed to confront the hazards due to poor land drainage [1]. Nowadays, in several regions of the world, some agricultural lands (e.g., coastal plains, river valleys, and inland plains) have limited natural drainage capacity due to poorly drained root zone soils and or shallow water tables. To provide a root environment suitable for maximum crop production in these conditions, artificial drainage is required to control root zone waterlogging and salt accumulation, or to prevent surface flooding during periods of high rainfall [2]. More specifically, land drainage is part of agricultural water management to enhance crop growth and maintain soil productivity. In particular, the direct goals of a land drainage system are: (a) removal of the excess of surface and subsurface water; (b) maintenance of groundwater levels for adequate root zone aeration and trafficability; (c) removal of excess soluble salts from the root zone associated with the applied irrigation water or upward flowing shallow groundwater.

There are two major types of drainage systems for controlling water table levels and for removing excess water from a field, namely open ditches of various sizes and shapes (surface drainage) and subsurface piping (subsurface drainage). The choice depends on the type of drainage problem encountered and the soil’s physical properties. Consequently, the solution may be a surface drainage system, a subsurface drainage system, or as is often the case, a combination of the two. For centuries, engineers and inventors tried to develop rapid and low cost techniques for subsurface drainage. Though many ideas were considered, only a few found widespread applications. The selection of the appropriate drainage materials (i.e., pipes and envelopes) depends mainly on their availability, durability, and cost [3]. Over time, new drainage materials, installation techniques and modernized equipment developed continuously to take advantage of technological advances provided through research and development, while the planning and organization of the implementation process also improved.

2. Evolution of Drainpipe Materials

A surface drainage system is composed of field drains that collect excess water from the land surface and root zone, conduct it to lateral ditches, which then flow to a main ditch, and finally, the drainage outlet, usually a natural waterway [4]. Similarly, a subsurface drainage system may use buried perforated pipes or tiles that collect drainage water and move it through the underground pipe system to the main drains that provide an outlet for the water captured from the root zone [5]. In general, subsurface drainage of agricultural lands likely began with the excavation of relatively shallow open ditches that accepted surface runoff and lateral discharge of shallow groundwater. In this way, these drains operated, at the same time, like a system of surface and subsurface drainage. Over the centuries, drainage pipes have been made from wood boards or box drains, bricks, ceramic tiles, clay tiles, concrete tiles, bituminized fiber perforated pipes, rigid plastic perforated pipes, corrugated wall metal conduits, perforated smooth plastic pipes or corrugated plastic pipes. In fact, historically, a “subsurface drainage system” was referred to as a “tile drainage system” due to the widespread use of buried clay/ceramic tile pipes for drainage systems. Nowadays, corrugated plastic pipes are frequently used, although clay and concrete pipes installed in the 1940s and 1950s are still used in irrigated agriculture. In any case, their application is determined by local economic factors. Undoubtedly, in the last several decades, there have been several advances in drainage installation equipment, materials, techniques, and technology, that improved installation quality in many parts of the world. Currently, corrugated plastic pipes are commonly used in irrigated agriculture in most regions of the world.

2.1. Drainage Pipes over Antiquity

Drainage systems have a long history of application, when agricultural drainage appeared for the first time in the Mesopotamia, approximately 9000 years ago; pipes were nonexistent [6]. Due to the lack of the drainage pipes, the early subsurface drains probably were trenches partially filled with highly permeable materials, such as gravel and stones, or permeable, voluminous substances such as bundles of small trees and shrubs tied together at the bottom of the trench [3]. Perhaps the oldest known drainpipes were discovered in the Lower Indus river valley, which were fabricated about 2000 BC [7], or are approximately 4000 years old. Additionally, underground bamboo sticks with holes were used as drains in ancient times in China [8]. About 400 BC, the Egyptians and Greeks drained land using a system of surface ditches to drain individual land parcels [9].

2.2. Drainage Pipes from Antiquity until about 1700

The Romans used open drains to remove ponded surface water and closed drains for removing surplus water from the soil itself. In addition, it seems they have applied clay-ware tiles for drainage purposes [10]. As Schwab and Fouss [11] pointed out, the first subsurface drain materials were probably bundles of brush tied together at the bottom of a trench or gravel and stones. Clay-ware tiles dating from the 1st century AD are shown in Figure 1.

Figure 1. Roman clay ware tiles [12].

In Europe, clay tiles have been used since the beginning of Christian Era [13]. By placing a modified form of medieval clay roofing tiles in a trench, French farmers are considered the first to use clay roofing tiles for farm drainage purposes. This type of tile drainage was used at least into the 14th or 15th centuries [9]. In addition, subsurface drainage conduits made of sticks, brush and stones were generally used in Europe until at least the end of the 17th century [9]. Davidson [14] stated that land drainage by means of tile was introduced in Europe as early as 1620, but it did not come into general use until about 1850. The tile drainage pipes discovered in 1620 were located in the garden of a convent in Maubeuge, France. Each tile was about 25.40 cm (10 in) long and 10.14 cm (4 in) in diameter. The tiles had been laid in the soil in such a manner as to form a drain system at a depth of 121.92 cm (4 feet). Each tile at one end had formed into a funnel-shape, and the other tapered into a cone (Figure 2). They were made by hand of an argilo-siliceous clay, which was very hard, then glazed in burning, and turned on a lathe [15]. It is not exactly known when these tiles were placed there [16]. Tile making machines were introduced in about 1848, and from this time on, tile drainage increased rapidly.

Figure 2. Pipe drainage discovered in Maubeuge, France in 1620 [15].

During the 17th century, installation of subsurface drainage systems in the United Kingdom included trenches filled with bushes or stones that were further developed on a larger scale across the Netherlands [17]. In the Midwestern United States (Midwest), subsurface drainage lines began to be installed in the late 1800s (earlier in New England). Most of these tile drains were pipes or sections of clay, concrete, or wood that were installed between 1870 and 1920, and again, between 1945 and 1960 [18][19].

2.3. Drainage Pipes from 1700 until 1940s

Whilst the clay working industry is an ancient industry dating to unrecorded history, the first clay drainpipes were used on the estate of Sir James Graham in Northumberland in England in 1810, and they appear to have been the standard tile for about thirty years [16][20]. The invention of clay pipes marked an important epoch in the history of drainage [19]. The earliest form of tiles introduced for drainage purposes was the horseshoe shaped tile, so called due from its shape. Sometimes, these tiles were used without any sole at the bottom of the drain (Figure 3). In this way, the water can run freely on the ground. The tiles formed a simple arch or tunnel when placed open side down and end-to-end along the bottom of a trench, and then, they were covered with excavated soil. However, this form of drain tile was short-lived because the drainage systems failed in time.

Figure 3. Horseshoe tile [21].

Later, horseshoe tiles were placed on a flat piece of burned clay or pallet (sole) running the length of the tile and a width one inch wider than the tile. The pallet was used to stabilize the trench bottom soils and to create a closed conduit for the water to flow through (Figure 4). These tiles were handmade, and consequently, very costly [9]. Weaver [13] reported on the use of horseshoe tiles laid in 1760 on the Granbury estate in Suffolk, England.

Figure 4. Horseshoe shaped tiles and soles properly placed [22].

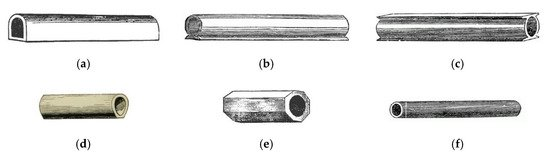

Clay pipes were made in a variety of shapes, as shown in Figure 5. Moreover, many shapes of tiles and pipes can be found in the catalogue of the Museum of English Rural Life, donated by the Ministry of Agriculture Fisheries and Food Land Drainage and Water Supplies Division [23].

Figure 5. Clay pipes of variety of shapes: (a) Horseshoe tile and sole in one [15]; (b) Sole tile [21]; (c) Double sole tile [21]; (d) Tile with a flat base [24]; (e) Octagonal pipe tile [15] and (f) Cylindrical drainage tile [21]. (Processing has been made by Stavros I. Yannopoulos).

Cylindrical drainage pipes were first manufactured by John Reade, a gardener in the village of Horsemonden in the county of Kent in England in 1810. His handmade tiles were a great improvement over the old brush and stone drains and proved more popular than horseshoe drains [9]. However, no special attention was given to these pipes until they were exhibited by John Reade in the Royal Agricultural Society’s Show in Derby, England, in 1843 [22][25]. As Mitchell [26] stated, while the cylindrical pipes were being used locally some twenty years earlier (about since 1823), it is thought they were first introduced about the year 1843.

The revolution in drainage construction dates back to 1845, when Thomas Scragg invented an extruding machine that produced round clay pipes quickly, reducing significantly their cost of production [9][27][28][29][30]. This invention constituted an important factor in spreading the use of the drainage worldwide. From England, the mechanical production of clay drainpipes spread over Europe and to the USA in the mid-19th century [31]. For the next century, ceramic (tile) pipes became the basic means of drainage in several countries, such as Jordan, Spain, Pakistan, and a number of other countries.

In 1830, for the first time, Portland cement was used to make drain tiles by hand [1]. The manufacturing of concrete drainpipes started in the USA in 1862, when David Ogden developed a suitable machine for making drainpipes from cement and sand [14]. This machine could make pipe with an inside diameter of 5.715 cm (2.25 in) to 60.96 cm (24 in). Obviously, the use of concrete drain tiles dominated in areas where good clay was not available, while in the other areas, economic factors determined the choice of which material was used.

For many years, both clay and concrete pipes were the main drainage materials for the practice of subsurface drainage systems, and they were used extensively in irrigated areas. However, as Fouss [32] pointed out, “these products today are much improved over the tile used in the early 1900s”. The choice between the two tubes is largely dependent on the delivery price at the place of installation [2].

Some disadvantages of these drainpipes are: (a) the production of clay and concrete drainpipes needed considerable labor, and (b) the protection of drainpipes against sedimentation with envelope materials is difficult to apply. However, the durability of clay pipes was very important, as they can be used in almost all circumstances. Use of concrete drainpipes in acid and high sulfate soils requires special highly resistant cement and high-density concrete should be used in order to withstand sulfate degradation of the pipes.

2.4. Drainage Pipes from 1940s Until Today

In the 1940s, an interesting breakthrough in pipe drainage technology took place, when rigid plastic and bituminous fiber pipes were introduced [8]. This was followed by the 1960s, when smooth plastic drainpipes were introduced that never found widespread use due to the introduction of corrugated plastic drainpipes in 1963, which overcame the disadvantages of the smooth plastic pipes. Gradually, corrugated plastic drainpipes started to replace the clay and concrete drainpipes [3]. Since the 1980s, corrugated high density polyethylene (HDPE) and corrugated polyvinyl chloride (PVC) pipes are the preferred standards for drainage pipes [8][33].

Nowadays, the corrugated plastic drains are made of PVC, high density polyethylene (HDPE) and polypropylene (PP). Since the 1980s, corrugated high density polyethylene (HDPE) and corrugated polyvinyl chloride (PVC) pipes are the preferred standards for drainage pipes [8][33]. The choice of one of these materials is determined by economic factors. It is worth noting that while PVC and HDPE, as raw materials, have different physical properties, it is possible to make durable pipes of good quality from either materials. In the United Kingdom, drains are made of HDPE and a minority of PP, while in the rest Europe, corrugated drains are mainly made of PVC. In the USA and Canada, most drainpipes are made of HDPE, mainly because of the low price of the raw material [3].

3. Conclusion

Over the last two centuries, there has been considerable progress made by engineers and scientists in the field of drainage. It is worth noting that, since the 1950s, the new types of installation equipment, materials and techniques were revolutionary for the drainage industry and contributed to the improvements of the drainage systems’ installation quality and durability. Subsurface drainage methods, materials, technologies, and installation were modernized much more through innovative research and development between 1960 and 1975 than during the previous centuries. In particular, since the 1960s and thereafter, drainage technology has changed rapidly, with enormous improvements in drainage tubing, machinery and methods of installation, drainage envelopes (natural and manufactured), and techniques for quality assurance and control.

References

- Donnan, W.W. An Overview of Drainage Worldwide. In Proceedings of the 3rd National Drainage Symposium on Drainage for Increased Crop Production and a Quality Environment. Chicago, IL, USA, 13–14 December 1976; American Society of Agricultural Engineers (ASAE) Publication 1–77: St. Joseph, MI, USA, 1976; pp. 6–9.

- Luthin, J.N. Drainage of Irrigated Lands. In Drainage of Agricultural Lands; Luthin, J.N., Ed.; American Society of Agronomy: Madison, WI, USA, 1957; Volume 7, pp. 344–371.

- Stuyt, L.C.; Dierickx, W.; Martínez Beltrán, J. Materials for Subsurface Land Drainage Systems; Paper No. 60 Rev. 1; Food and Agricultural Organization of the United States: Rome, Italy, 2005.

- Ogrosky, H.O.; Mockus, V. Chapter 21. Hydrology of Agricultural Lands. In Handbook of Applied Hydrology; Chow, V.T., Ed.; McGraw-Hill Publ. Co.: New York, NY, USA, 1964; pp. 21.1–21.97.

- van der Gulik, T.W.; Christl, L.H.; Coote, D.R.; Madramootoo, C.A.; Nyvall, T.J.; Sopuck, T.J.V. Chapter 10. Managing Excess Water. In The Health of Our Water: Toward Sustainable Agriculture in Canada; Coote, D.R., Gregorich, L.J., Eds.; Research Planning and Coordination Directorate, Research Branch, Agriculture and Agri-Food Canada: Ottawa, ON, Canada, 2000; Publication No. 2020/E; pp. 121–129.

- van Schilfgaarde, J. Drainage yesterday, today, and tomorrow. In Proceedings of the American Society of Agricultural Engineers (ASAE) National Drainage Symposium; Chicago, IL, USA, 6–7 December 1971; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1971.

- Ami, S.R. Drainage Pipe Testing Manual; Canadian International Development Agency (CIDA): Hull, QC, Canada, 1987.

- Nijland, H.J.; Croon, F.W.; Ritzema, H.P. Subsurface Drainage Practices: Guidelines for the Implementation, Operation and Maintenance of Subsurface Pipe Drainage Systems; ILRI Publication No. 60; Alterra: Wageningen, The Netherlands, 2005.

- Beauchamp, K.H. Chapter 2. A History of Drainage and Drainage Methods. In Farm Drainage in the United States: History, Status, and Prospects; Miscellaneous Publication No. 1455; Pavelis, G.A., Ed.; Economic Research Service: Washington, DC, USA, 1987; pp. 13–29.

- Wesseling, J. The development of drainage in humid temperate regions. In Proceedings of the Symposium of the 25th International Course on Land Drainage: Twenty-Five Years of Drainage Experience, Wageningen, The Netherlands, 24–28 November 1986; International Institute for Land Reclamation and Improvement (ILRI): Wageningen, The Netherlands, 1987; pp. 14–20.

- Schwab, G.O.; Fouss, J.L. Drainage materials. In Agricultural Drainage; Skaggs, R.W., van Schilfgaarde, J., Eds.; American Society of Agronomy: Madison, WI, USA, 1999; Agronomy Monograph No. 38; pp. 911–926.

- Scherer, T.F. Welcome to the North Dakota–Minnesota Subsurface Drainage Forum; University of Minnesota, NDSU Extension Agricultural Services: Minneapolis, MN, USA, 2003. Available online: http://www.ag.ndsu.edu/waterquality/documents/History_of_Drainage.pdf (accessed on 21 January 2018).

- Weaver, M.M. History of Tile Drainage; Private Publication: Waterloo, NY, USA, 1964.

- Davidson, B. Agricultural Engineering; Webb Publ. Co.: St. Paul, MI, USA; 1913.

- Klippart, J.H. Principles and Practice of Land Drainage, 3rd ed.; Robert Clark & Co.: Cincinnati, OH, USA, 1888.

- Powers, W.L.; Teeter, T.A.H. Land Drainage; John Wiley & Sons Inc.: New York, NY, USA, 1922.

- van de Ven, G.P. Man-Made Lowlands: History of Water Management and Land Reclamation in The Netherlands, 4th ed.; Uitgeverij Matrijs: Utrecht, The Netherlands, 2004.

- Zucker, L.A.; Brown, L.C. Agricultural Drainage: Water Quality Impacts and Subsurface Drainage Studies in the Midwest; Ohio State University: Columbus, OH, USA, 1998; Ohio State University Extension Bulletin no. 871.

- Blann, K.L.; Anderson, J.L.; Sands, G.R.; Vondracek, B. Effects of Agricultural Drainage on Aquatic Ecosystems: A Review. Crit. Rev. Environ. Sci. Technol. 2009, 39, 909–1001.

- Elliott, C.G. Engineering for Land Drainage. A Manual for the Reclamation of Lands Injured by Water, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1912.

- Waring, G.E., Jr. Draining for Profit, and Draining for Health; Orange Judd & Company: New York, NY, USA, 1867.

- French, H.F. Farm Drainage: The Principles, Processes, and Effects of Draining Land with Stones, Wood, Plows, and Open Ditches, and Especially With Tiles; C.M. Sexton Barker & Co.: New York, NY, USA, 1860.

- Field Drainage Tiles and Pipes. Available online http://www.collectionsgateway.org.uk/collections/8/field_drainage_tiles.pdf (accessed on 30 September 2019).

- Barral, J.A. Drainage des Terres Arables, 2nd ed.; Tome I; Librairie Agricole de la Maison Rustique: Paris, France, 1856.

- Gisborne, T. Essays on Agriculture, 3rd ed.; John Murray, London, UK, 1854.

- Mitchell, G.S. A Handbook of Land Drainage: Principally based upon the Requirements of the Syllabus Issued by the Surveyors’ Institution, 3rd ed.; Land Agents’ Record Publ.: London, UK, 1899.

- Robinson, M. Impact of Improved Land Drainage on River Flows; Report No. 113; Institute of Hydrology: Wallingford, UK, 1990.

- Minaev, I.V.; Maslov, B.S. History of Land Improvement. In Agricultural Land Improvement: Amelioration and Reclamation; Maslov, B.S., Ed.; Encyclopedia of Life Support Systems (EOLSS); Eolss Publ. Co., Ltd.: Oxford, UK, 2009; Volume 1, pp. 95–116.

- Maslov, B.S. Drainage of Farmalnds. In Agricultural Land Improvement: Amelioration and Reclamation; Maslov, B.S., Ed.; Encyclopedia of Life Support Systems (EOLSS); Eolss Publ. Co., Ltd.: Oxford, UK, 2009; Volume 2, pp. 1–50.

- Robinson, M. The extent of farm underdrainage in England and Wales, prior to 1939. Agric. Hist. Rev. 1986, 34, 77–85.

- Nosenko, P.P.; Zonn, I.S. Land Drainage in the World. ICID Bull. 1976, 25, 65–70.

- Fouss, J.L. Drain Tube Materials and Installation. In Drainage for Agriculture; van Schilfgaarde, J., Ed.; American Society of Agronomy: Madison, WI, USA, 1974; Agronomy No. 17; pp. 147–177.

- Vlotman, W.F.; Willardson, L.S.; Dierickx, W. Envelope Design for Subsurface Drains; Publication No. 56; International Institute for Land Reclamation (ILRI): Wageningen, The Netherlands, 2000.