| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Chang Xi | + 2056 word(s) | 2056 | 2022-02-14 09:02:35 | | | |

| 2 | Jason Zhu | -33 word(s) | 2023 | 2022-02-23 03:01:31 | | | | |

| 3 | Jason Zhu | Meta information modification | 2023 | 2022-02-23 03:08:11 | | | | |

| 4 | Jason Zhu | -3 word(s) | 2020 | 2022-02-25 08:41:25 | | |

Video Upload Options

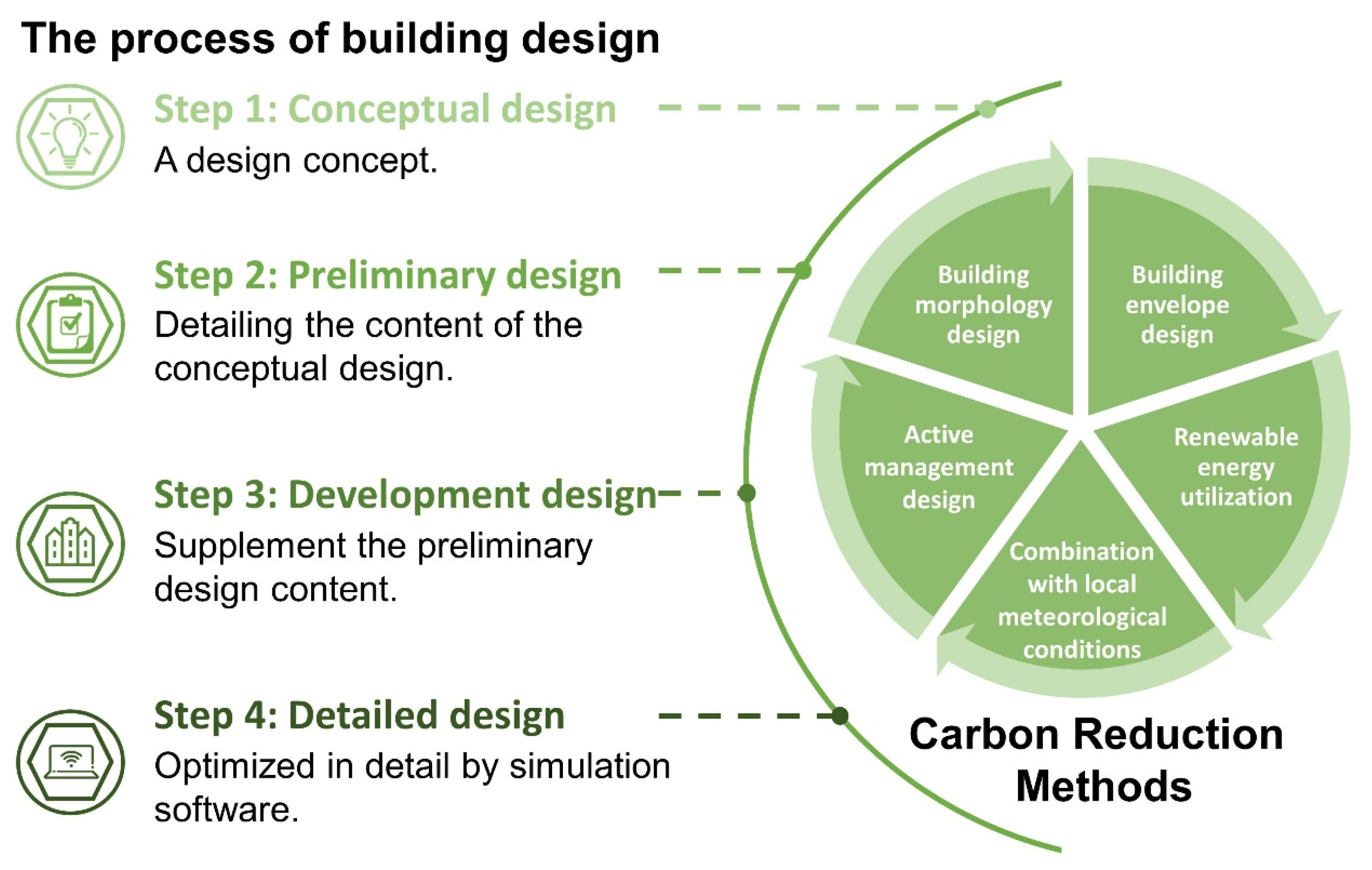

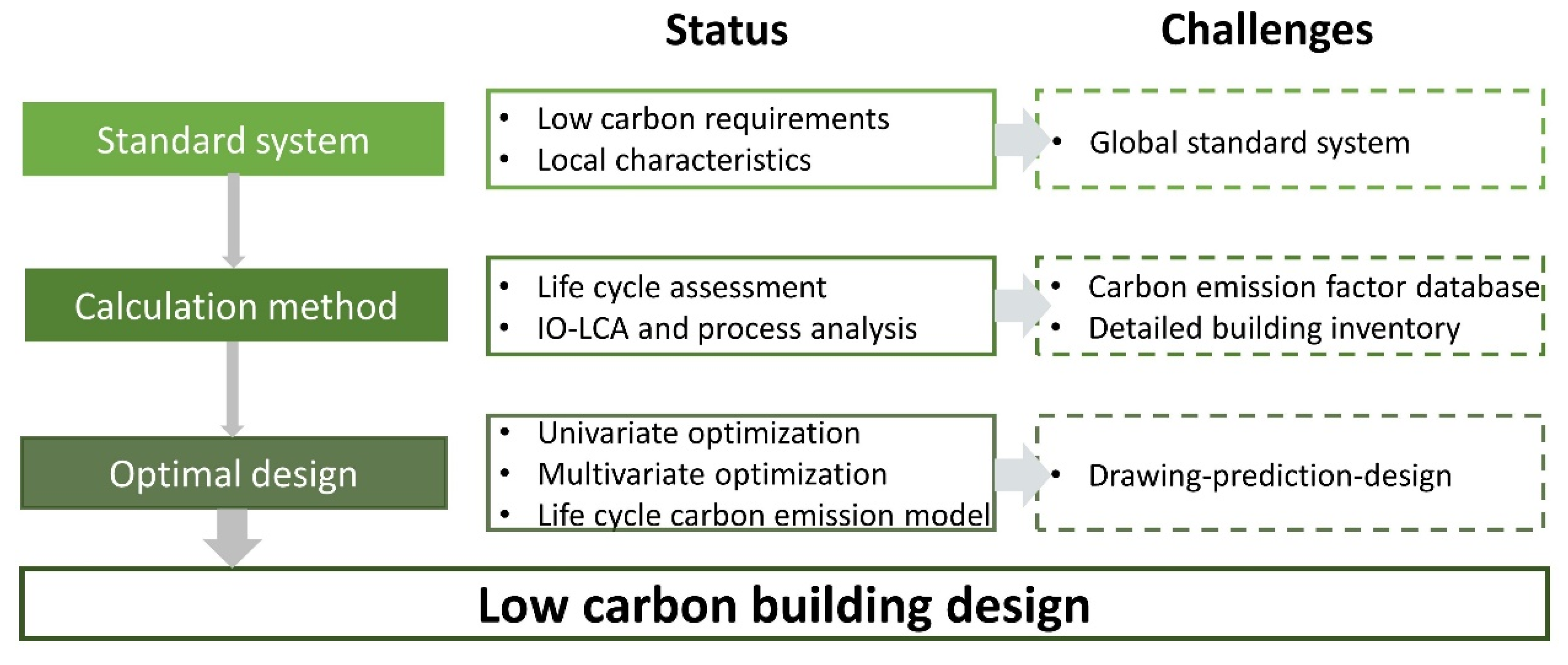

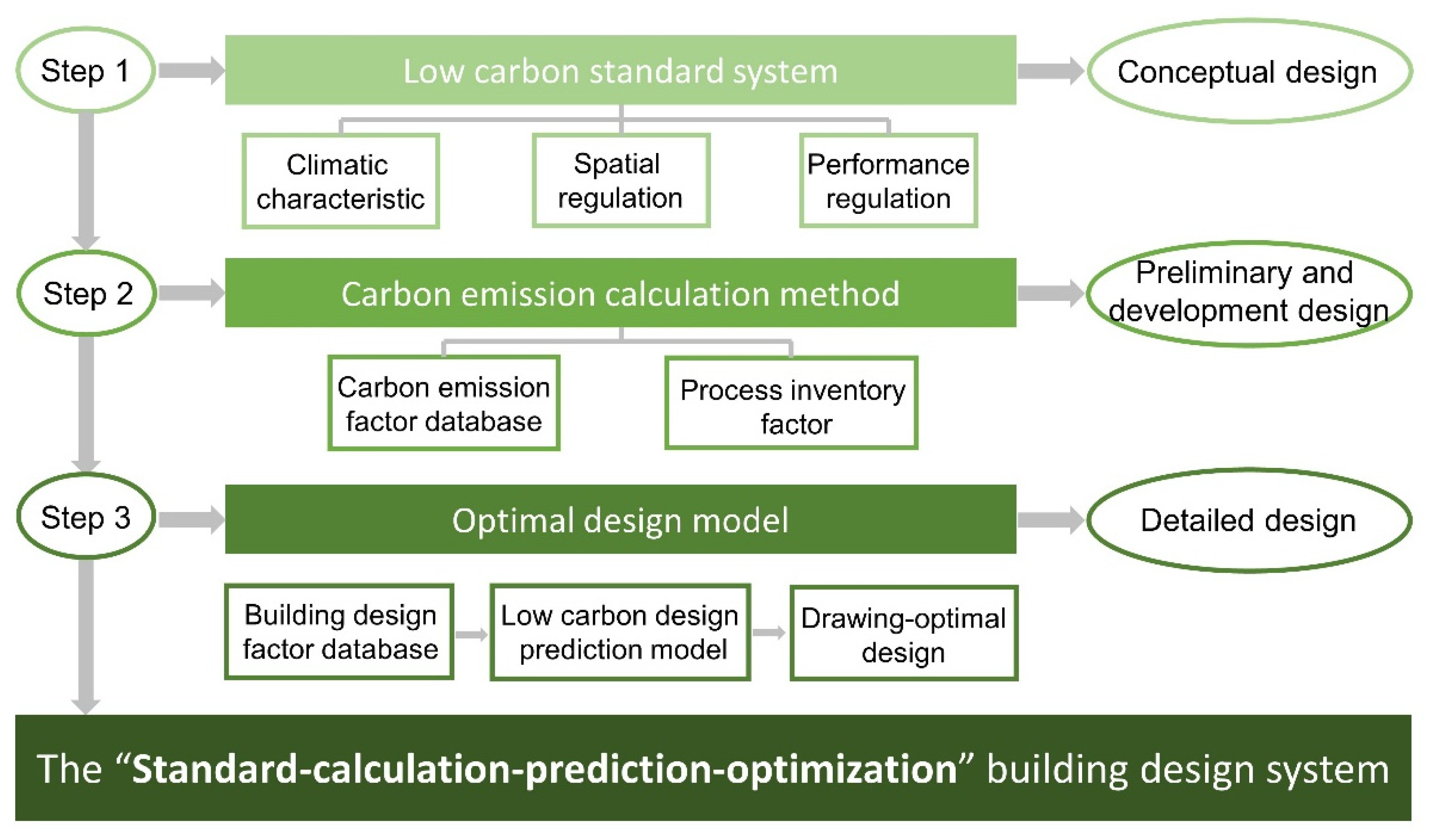

Excessive carbon emissions are causing the problems of global warming and the greenhouse effect, which urgently need to be controlled worldwide. It is crucial to reduce the carbon emissions of the construction industry as it is one of the main sources. Carbon is generated at all phases of the building life cycle, including in material production, building design, and building operation and maintenance. Notably, building design has various extents of influence on carbon emissions at each phase, for which a low carbon method urgently needs to be explored. The challenges of building design are as follows: lack of (1) a comprehensive standard system considering different factors, (2) lack of a carbon emission calculation method for the design phase, and a (3) no real-time optimization model aiming at carbon reduction. The path of “standard-calculation-prediction-optimization”(SCPO) for future building design is proposed to address these challenges. It takes standard system as the framework, the carbon calculation method as the foundation, the prediction model as the theory, and the low carbon building as the objective.

1. The Traditional Building Design Process

2. The Status of Low Carbon Building Design

3. The Challenges of Low Carbon Building Design

4. Possible Future Work

References

- Gao, H.; Koch, C.; Wu, Y.P. Building information modelling based building energy modelling: A review. Appl. Energy 2019, 238, 320–343.

- Braganca, L.; Vieira, S.M.; Andrade, J.B. Early stage design decisions: The way to achieve sustainable buildings at lower costs. Sci. World J. 2014, 365364.

- Cao, S.J.; Feng, Z.; Wang, J.; Ren, C.; Zhu, H.C.; Chen, G.; Mei, J. Ergonomics-oriented operation, maintenance and control of indoor air environment for public buildings. Chin. Sci. Bull. 2022, 67.

- Eikeland, P.O.; Skjærseth, J.B. The politics of low-carbon innovation: Implementing the European Union’s strategic energy technology plan. Energy Res. Soc. Sci. 2021, 76, 102043.

- Hu, M. 2019 energy benchmarking data for LEED-certified buildings in Washington, D.C.: Simulation and reality. J. Build. Eng. 2021, 42, 102475.

- MOHURD. Announcement on the Release of National Standards of General Specification for Energy Conservation and Renewable Energy Utilization in Buildings. Available online: http://www.mohurd.gov.cn/gongkai/fdzdgknr/zfhcxjsbwj/202110/20211013_762460.html (accessed on 8 September 2021).

- FORESTRY. The Announcement on the Issuance of the Implementation Plan for the In-Depth Development of Green Low-Carbon Leading Action for Public Institutions to Promote Carbon Peaking. Available online: http://www.forestry.gov.cn/zlszz/4262/20211123/110547204815318.html (accessed on 19 November 2021).

- ZJWSH. The 14th Five-Year Plan for Green Buildings in Shanghai. Available online: http://zjw.sh.gov.cn/ghjh/20211109/a3b03c1ee247418ebce706bd0b08da10.html (accessed on 9 November 2021).

- SCJST. “Fourteen Five” Construction Industry Development Plan of Sichuan Province. Available online: http://jst.sc.gov.cn/scjst/ghxx/2021/9/26/0f6d7763bd2b4f66b2cfeb568dfb66e1.shtml (accessed on 26 September 2021).

- CDZJ. The Notice on the Issuance of the “14th Five-Year Plan for the Development of the Construction Industry in Chengdu” by Chengdu Housing and Urban-Rural Development Bureau. Available online: http://cdzj.chengdu.gov.cn/cdzj/c131968/2021-11/15/content_8516cf63f9cf4195b6894ae4444e59a2.shtml (accessed on 15 November 2021).

- ZFCXJSTYN. Announcement on the Issuance of the “Fourteenth Five-Year Plan for the Development of Green Assembly Building Industry in Yunnan Province”. Available online: https://zfcxjst.yn.gov.cn/zhengfuwenjian8655/284647.html (accessed on 22 November 2021).

- ZFCXJWCQ. Announcement on the Issuance of the “Green Finance in Chongqing to Support the Green Development of the Construction Industry Pilot Program”. Available online: http://zfcxjw.cq.gov.cn/zwxx_166/gsgg/202111/t20211112_9968747.html (accessed on 12 November 2021).

- Wang, J.G.; Cao, S.J.; Yu, C.W. Development trend and challenges of sustainable urban design in the digital age. Indoor Built Environ. 2021, 30, 3–6.

- Meng, M.R.; Cao, S.J.; Kumar, P.; Tang, X.; Feng, Z. Spatial distribution characteristics of PM2.5 concentration around residential buildings in urban traffic-intensive areas: From the perspectives of health and safety. Saf. Sci. 2021, 141, 105318.

- Standard for building carbon emission calculation. GB/T 51366-2019MOHURD: Beijing, China, 2019.

- Alwisy, A.; BuHamdan, S.; Gul, M. Evidence-based ranking of green building design factors according to leading energy modelling tools. Sustain. Cities Soc. 2019, 47, 101491.

- Ali-Toudert, F.; Weidhaus, J. Numerical assessment and optimization of a low-energy residential building for Mediterranean and Saharan climates using a pilot project in Algeria. Renew. Energy 2017, 101, 327–346.

- Su, X.; Tian, S.C.; Shao, X.L.; Zhao, X. Embodied and operational energy and carbon emissions of passive building in HSCW zone in China: A case study. Energy Build. 2020, 222, 110090.

- Mao, X.K.; Wang, L.X.; Li, J.W.; Quan, X.L.; Wu, T.Y. Comparison of regression models for estimation of carbon emissions during building’s lifecycle using designing factors: A case study of residential buildings in Tianjin, China. Energy Build. 2019, 204, 109519.

- Dodoo, A.; Gustavsson, L.; Sathre, R. Lifecycle carbon implications of conventional and low-energy multi-storey timber building systems. Energy Build. 2014, 82, 194–210.

- Hong, J.K.; Shen, G.Q.; Feng, Y.; Lau, W.S.T.; Mao, C. Greenhouse gas emissions during the construction phase of a building: A case study in China. J. Clean. Prod. 2015, 103, 249–259.

- Huang, Y.A.; Weber, C.L.; Matthews, H.S. Categorization of scope 3 emissions for streamlined enterprise carbon footprinting. Environ. Sci. Technol. 2009, 43, 8509–8515.

- Guan, J.; Zhang, Z.H.; Chu, C.L. Quantification of building embodied energy in China using an input-output-based hybrid LCA model. Energy Build. 2016, 110, 443–452.

- Han, M.Y.; Chen, G.Q.; Shao, L.; Li, J.S.; Alsaedi, A.; Ahmad, B.; Guo, S.; Jiang, M.M.; Ji, X. Embodied energy consumption of building construction engineering: Case study in E-town, Beijing. Energy Build. 2013, 64, 62–72.

- Li, Y.L.; Han, M.Y.; Liu, S.Y.; Chen, G.Q. Energy consumption and greenhouse gas emissions by buildings: A multi-scale perspective. Build. Environ. 2019, 151, 240–250.

- Gan, V.J.L.; Chan, C.M.; Tse, K.T.; Lo, I.M.C.; Cheng, J.C.P. A comparative analysis of embodied carbon in high-rise buildings regarding different design parameters. J. Clean. Prod. 2017, 161, 663–675.

- Gan, V.J.L.; Cheng, J.C.P.; Lo, I.M.C.; Chan, C.M. Developing a CO2-e accounting method for quantification and analysis of embodied carbon in high-rise buildings. J. Clean. Prod. 2017, 141, 825–836.

- Marinova, S.; Deetman, S.; van der Voet, E.; Daioglou, V. Global construction materials database and stock analysis of residential buildings between 1970–2050. J. Clean. Prod. 2020, 247, 119146.

- Gan, V.J.L.; Cheng, J.C.P.; Lo, I.M.C. A comprehensive approach to mitigation of embodied carbon in reinforced concrete buildings. J. Clean. Prod. 2019, 229, 582–597.

- Kumanayake, R.; Luo, H.B.; Paulusz, N. Assessment of material related embodied carbon of an office building in Sri Lanka. Energy Build. 2018, 166, 250–257.

- Rock, M.; Hollberg, A.; Habert, G.; Passer, A. LCA and BIM: Visualization of environmental potentials in building construction at early design stages. Build. Environ. 2018, 140, 153–161.

- Mahmoud, S.; Ismaeel, W.S.E. Developing sustainable design guidelines for roof design in a hot arid climate. Archit. Sci. Rev. 2019, 62, 507–519.

- Rakotondramiarana, H.T.; Ranaivoarisoa, T.F.; Morau, D. Dynamic simulation of the green roofs impact on building energy performance, case study of Antananarivo, Madagascar. Buildings 2015, 5, 497–520.

- Feehan, A.; Nagpal, H.; Marvuglia, A.; Gallagher, J. Adopting an integrated building energy simulation and life cycle assessment framework for the optimisation of facades and fenestration in building envelopes. J. Build. Eng. 2021, 43, 103138.

- Yu, Z.; Zhang, W.L.; Fang, T.Y. Impact of building orientation and window-wall ratio on the office building energy consumption. Appl. Mech. Mater. 2013, 409-410, 606–611.

- Lartigue, B.; Lasternas, B.; Loftness, V. Multi-objective optimization of building envelope for energy consumption and daylight. Indoor Built Environ. 2014, 23, 70–80.

- Zhu, J.J.; Chew, D.A.S.; Lv, S.; Wu, W.W. Optimization method for building envelope design to minimize carbon emissions of building operational energy consumption using orthogonal experimental design (OED). Habitat Int. 2013, 37, 148–154.

- Xue, Q.W.; Wang, Z.J.; Chen, Q.Y. Multi-objective optimization of building design for life cycle cost and CO2 emissions: A case study of a low-energy residential building in a severe cold climate. Build. Simul.-China 2022, 15, 83–98.

- Zemero, B.R.; Tastes, M.E.D.; Bezerra, U.H.; Batista, V.D.; Carvalho, C.C.M.M. Methodology for preliminary design of buildings using multi-objective optimization based on performance simulation. J. Sol. Energy Eng.-Trans. ASME 2019, 141, 040801.

- Longo, S.; Montana, F.; Sanseverino, E.R. A review on optimization and cost-optimal methodologies in low-energy buildings design and environmental considerations. Sustain. Cities Soc. 2019, 45, 87–104.

- Xia, B.; Li, X. Analysis and comparison on the potential of low-carbon architectural design strategies. Sustain. Comput.-Inform. Syst. 2019, 21, 204–211.

- Fenner, A.E.; Kibert, C.J.; Li, J.X.; Razkenari, M.A.; Hakim, H.; Lu, X.S.; Kouhirostami, M.; Sam, M. Embodied, operation, and commuting emissions: A case study comparing the carbon hotspots of an educational building. J. Clean. Prod. 2020, 268, 122081.

- O’Neill, R.; Window, A.; Kenway, S.; Dargusch, P. Integrated operational and life-cycle modelling of energy, carbon and cost for building facades. J. Clean. Prod. 2021, 286, 125370.

- Yang, F.; Chou, J.M.; Dong, W.J.; Sun, M.Y.; Zhao, W.X. Adaption to climate change risk in eastern China: Carbon emission characteristics and analysis of reduction path. Phys. Chem. Earth 2020, 115, 102829.

- Han, X.J.; Yu, J.L.; Xia, Y.; Wang, J.J. Spatiotemporal characteristics of carbon emissions in energy-enriched areas and the evolution of regional types. Energy Rep. 2021, 7, 7224–7237.

- Cang, Y.J.; Luo, Z.X.; Yang, L.; Han, B. A new method for calculating the embodied carbon emissions from buildings in schematic design: Taking “building element” as basic unit. Build. Environ. 2020, 185, 107306.

- Pal, S.K.; Takano, A.; Alanne, K.; Siren, K. A life cycle approach to optimizing carbon footprint and costs of a residential building. Build. Environ. 2017, 123, 146–162.

- Nguyen, A.T.; Reiter, S.; Rigo, P. A review on simulation-based optimization methods applied to building performance analysis. Appl. Energy 2014, 113, 1043–1058.