| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Chunming Tan | + 3248 word(s) | 3248 | 2021-09-17 09:46:16 | | | |

| 2 | Amina Yu | -51 word(s) | 3197 | 2022-02-17 03:15:49 | | |

Video Upload Options

Antimicrobial packaging is a robust technology to provide fresher, safer, and higher quality food products, which concerns about foodborne pathogenic and spoilage microorganisms. It is a form of active packaging (including oxygen scavengers, moisture absorbers, ultraviolet barriers, and other mechanisms delivering antioxidant, flavoring, or antimicrobial activity), and the packaging material interacts with the packaged food in a desirable way. Antimicrobial packaging stands out as an emerging technology that not only prolongs the shelf life of food products but also helps maintain their quality.

1. Introduction

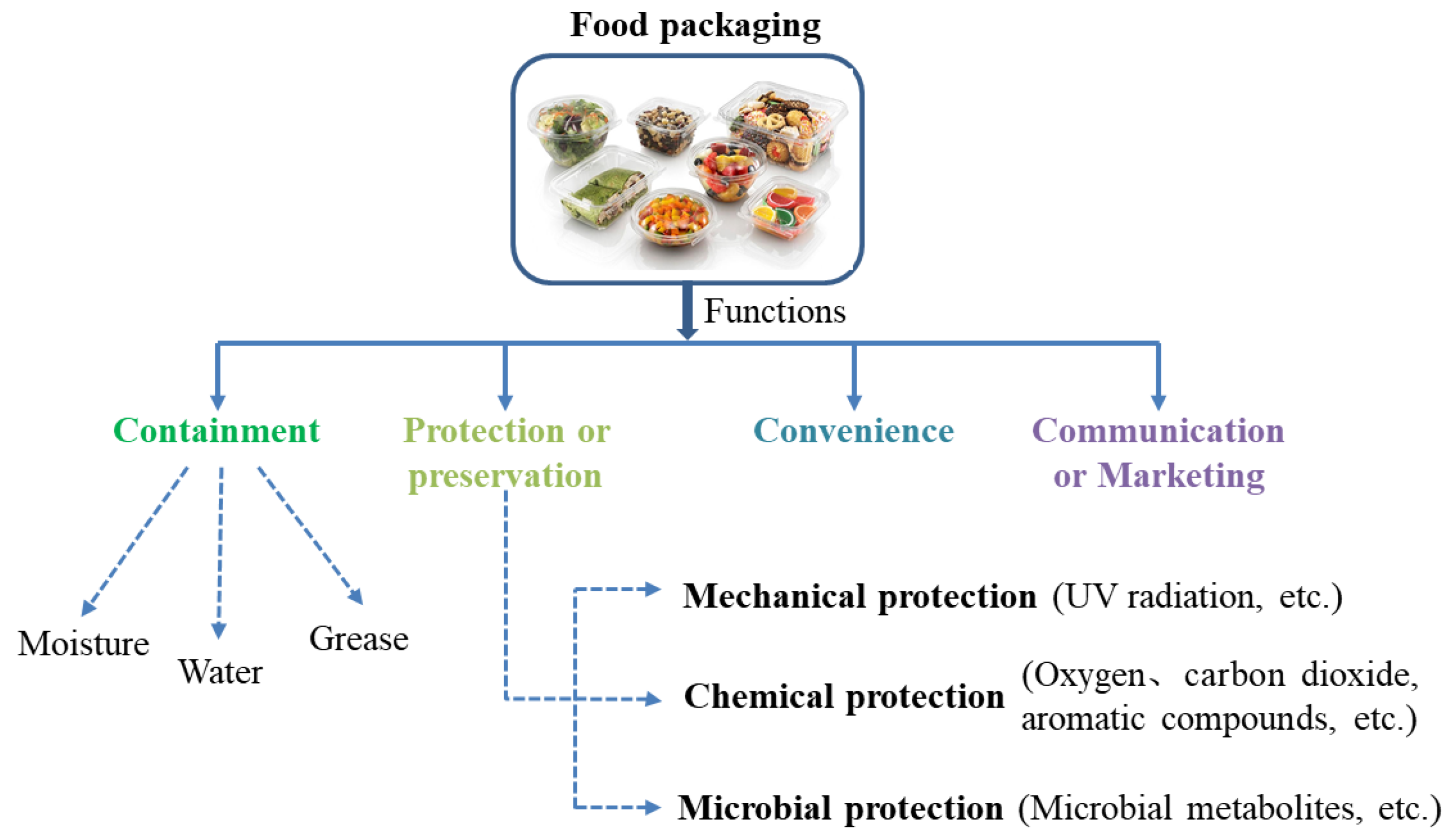

The essential functions of packaging are coverage and conservation of foodstuffs, retaining the food safety, quality, and increasing the shelf life of food products during transport, storage, and marketing. It decreases post contamination and protects them from physical, chemical, environmental, and microbial hazards [1][2] ( Figure 1 ). Packaging also provides information regarding products, simplifies their end-use suitability and communication (marketability and acceptability), and facilitates the food control process from distribution to the consumer’s table [3][4]. Food contamination not only creates the problems of food insecurity and economic loss, but also contributes to food waste, which is another global environmental problem [5]. Furthermore, foodborne pathogens denote a major threat to public health; it is a critical reason for illnesses, hospitalizations, and deaths of people. In the United States (2018), the number of cases of foodborne illness was 35,027; outbreaks are frequently reported every month with the number of 204 in April [6]. Al-Tayyar et al. [7] reported that the United States foodborne illness cost is approximately 152 billion dollars annually for long term health and immediate medical care, among which ¼ of expenditures are caused due to foodborne illness linked with the use of processed, canned, and fresh products. The food industries and retailers have to face product degradation or loss and pay millions of dollars as microbiological contamination costs. Tamayo et al. [8] reported that Staphylococcus aureus, Listeria monocytogenes, Toxoplasma gondii, Campylobacter spp. , and Salmonella spp. are the widely spread pathogens; they cause illness, hospitalizations, or even deaths among human beings when contamination of food is caused. In addition, food spoilage is another troubling issue faced by the food industry, as it negatively affects the food quality and it could lead to huge economic losses for producers, retailers, and consumers [9]. The cross-contamination of spoilage microorganisms on raw materials or processed foodstuffs can result in changes in the nutritional and sensory characteristics of food. It causes approximately 1.3 billion tons of food waste every year, and the heavy expenses in medical care account for more than 77.1 billion dollars annually, only in the USA [10][11]. The microbial contamination of foods can occur anywhere when food is kept in an external environment, such as stages of slaughtering, distribution, shipping, storage, and retail display [7]. Therefore, effective packaging is a compelling obstacle for shielding food items from outside contaminants and can maintain its quality.

There are diverse materials applicable for packaging, among them plastics for food packaging are the most and reached 129 million tons globally in 2015, and were expected to reach USD 262 billion by 2020 [2][12][13]. Plastics have been extracted from non-renewable resources of fossil fuels since the middle of the twentieth century and they face difficulty in recycling and disposal [2][14]. Due to organic materials being contaminated and present on food packaging plastics, thus plastic recycling is not suitable for food packaging systems [15]. Sharma et al. [2] indicated approximately 4.8–12.7 million tons of plastics were thrown in the ocean during the year 2010, and more than 30% of the waste produced by plastic processing was landfilled in the year 2014. Therefore, the use of non-biodegradable and non-renewable materials (e.g., cans, plastics, glass bottles, paper bags, and metals) in packaging applications has caused numerous environmental concerns about their decomposition and overexploitation of natural resources and thus there is demand for seeking a suitable alternative for traditional packaging materials [4][16]. Biopolymers have developed widespread attention for food packaging applications, since they are biodegradable, renewable, and have a low carbon footprint [14][17]. They provide a great opportunity to reduce the extensive use of fossil fuels and develop biobased food packaging materials [18], addressing the environmental problems and contribute significantly to sustainable development [19]. Studies have reported that the application of biopolymer-based materials can reduce packaging waste and solve the waste disposal problems to a certain extent [16][20] and have the potential to be an alternative for synthetic plastic packaging materials, especially for single-use and short-lived food packaging purposes [2][17][21]. Abdul Khalil et al. [16] indicated that bio-based materials successfully address concerns regarding cost, energy consumption, recycling procedure, and sustainability when compared to synthetic plastics. At present, various bio-based polymers have been used in food packaging materials, including polysaccharide-, protein-, and lipid-based materials [2][7]. Among them, coatings are provided via biopolymers which can be applied directly in a liquid form on foodstuffs via immersion, spraying, and brushing, etc. [22], and the carbohydrate and protein-based packaging films have good mechanical characteristics and are generally considered as effective oxygen hinderers below intermediate humidity, but their physical features (like water vapor barrier), mechanical properties, and antimicrobial activity are still poor; thus, they are hard to use in industries [1][7]. Therefore, the combination of polysaccharides with other polymers offers a new way for the development of various tailor-made packaging and coating materials for medical and food purposes [3][23].

However, compared with petroleum-based materials, weak mechanical and barrier properties of biopolymer-based packaging materials limited their widespread application in the industry [16][18]. Therefore, greater efforts are underway to improve the properties of bioplastics to make them suitable and successful for practical use in food packaging. Abdul Khalil et al. [16] reported that various methods have been proposed for this purpose, such as the addition of plasticizer and nanomaterials, chemical modification of polymer, treatment of gamma irradiation, etc. In recent years, biopolymer-based nanocomposite packaging materials have been widely considered due to their good mechanical, thermal, chemical resistance, biodegradable, antimicrobial, and gas barrier properties [2]. Bio-nanocomposites are novel materials with two or more phases (continuous and discontinuous), and the nanoparticles can interact with other matter at the atomic, molecular, or macromolecular level thus changing functional properties. The continuous phase is biopolymers such as polysaccharides, proteins, lipids, nucleic acids, etc., while the discontinuous phase is filler such as silicates, carbon nanotubes, silver/silver oxide (Ag/AgO), zinc oxide (ZnO), titanium dioxide (TiO 2), etc. [17]. Among the metal oxides, ZnO is one of the most broadly utilized materials in different fields because of its antimicrobial activity and photocatalytic properties, such as zinc oxide nanoparticles (ZnO-NPs) and ZnO-SiO 2 nanocomposites [24]. These nanoparticles are also biocompatible with cells so they can be used as a defense against food pathogens [7][25].

Antimicrobial packaging is a robust technology to provide fresher, safer, and higher quality food products, and some new technologies have been studied which are associated with foodborne pathogenic and spoilage microorganisms. It is a form of active packaging (including oxygen scavengers, moisture absorbers, ultraviolet barriers, and other mechanisms delivering antioxidant, flavoring, or antimicrobial activity), and the packaging material interacts with the packaged food in a desirable way [11][26]. Antimicrobial packaging stands out as an emerging technology that not only prolongs the shelf life of food products but also helps maintain their quality [27]. The antimicrobial active packaging forms including directly fixing the antibacterial agents into a polymer matrix, using the inherently antimicrobial activity of polymers, coating it onto the packaging surface, or immobilizing it in pouches and pads via ion or covalent linkages [28]. Many types of antibacterial agents that are used in food packaging include natural antibacterial agents (e.g., chitosan, nisin, lysozyme, plant essential oils, tea polyphenols, etc.), organic synthetic antibacterial agents (such as chloramphenicol and nalidixic acid), and inorganic antibacterial agents (some of the oxidized nanoparticles) [29][30][31][32]. Many inorganic and metal nanoparticles have been implemented to synthesize active food packaging materials and to extend the shelf life of foodstuffs [33]. However, it is noteworthy that the compatibility between nanomaterials and polymer matrices is considered the biggest challenge for the preparation of bio-nanocomposites.

2. Types of Bio-Based Materials in Antimicrobial Food Packing

Starch, another widely explored naturally renewable carbohydrate polymer (extracted from rice, maize, corn, wheat, barley, potato, vegetables, soya and so on), contains amylose (linear molecules linked to each other through α-1, 4 glycosidic bonds) and amylopectin (a branched-chain molecule with branches occurring at α-1, 6 bonds) [19]. They are mainly used as raw material in the production of biodegradable films or bio-plastics due to their non-toxic, biodegradable features, low cost, plasticity, and ready accessibility for industries [34]. The starch-based films commonly possess high properties of an oxygen barrier, but they have poor properties of moisture barrier, while the addition of chitosan in starch can change the sensitivity of water and enhance the mechanical and barrier features of starch films [35]. Starch and its derivatives are the most general kind that has been explored to prepare bio-nanocomposite materials for food packaging applications [36], and the cheaper food spoilage detecting packaging materials can be produced using a conducting biodegradable polymer material. However, more research is required on starch that focuses on decreasing retrogradation and reducing water absorption of the material to maintain stiffness and mechanical strength during storage, making the food packaging material simpler, cheaper, more active, yet smarter, where the consumer is able to assess the quality, safety, shelf life, and nutritional values of the contents of the packet.

Bio-nanocomposites are a new generation of nano food packaging materials that are highly useful to inhibit the growth of microorganisms and further lead to the increase in the shelf life of food products and maintaining product quality and safety during transport, storage, and marketing. Bio-nanocomposites mainly comprise bio-based polymeric matrices that are reinforced with nanofillers or nanoparticles, and they generally possess better characteristics (for example, antimicrobial, stable under high temperature and pressures) in comparison to traditional bio-based polymers [37]. Sharma et al. [2] and Zubair and Ullah [17] reported that bio-composites can be modified via fusion of nanofillers such as montmorillonite (MMT), Ag/AgO, ZnO/ZnO 2, TiO 2, and SiO 2 and biodegradable polymers including PLA, polyhydroxylbutyrate (PHB), polybutylene succinate (PBS), polyvinyl alcohol (PVA), and poly-caprolactone (PCL), along with natural biopolymers such as polysaccharides, proteins, lipids, nucleic acids and so on. At present, there are various antimicrobial bio-nanocomposites that can inhibit the growth of microorganisms (pathogens and spoilage bacteria) on food surfaces and thus increase their shelf life, such as PLA/halloysite, PLA/Ag-NPs, hydroxyapatite/TiO 2, layered silicate, chitosan/Ag-NPs, and cellulose nanocomposites. These versatile materials have good mechanical, thermal, and chemical resistance and barrier (oxygen, carbon dioxide, moisture, flavors, and grease), antimicrobial, and biodegradable properties [21][38][39][40], and they are also easy to process and have a low cost. Therefore, bio-nanocomposites have been considered as a promising alternative and a new generation of antimicrobial food packaging materials which are high-performance and eco-friendly have been used to inhibit the growth of contaminant microorganisms and further maintain food quality and safety during storage.

According to the type of applied filler with antimicrobial properties, different types of antimicrobial bio-nanocomposites that are used in food packaging can be classified as follows: (ⅰ) clay and silicate-based bio-nanocomposites, (ⅱ) biopolymer-based bio-nanocomposites, (ⅲ) metallic-based bio-nanocomposites, (ⅳ) nano cellulose-based bio-nanocomposites, and (ⅴ) layered double hydroxide-based bio-nanocomposites.

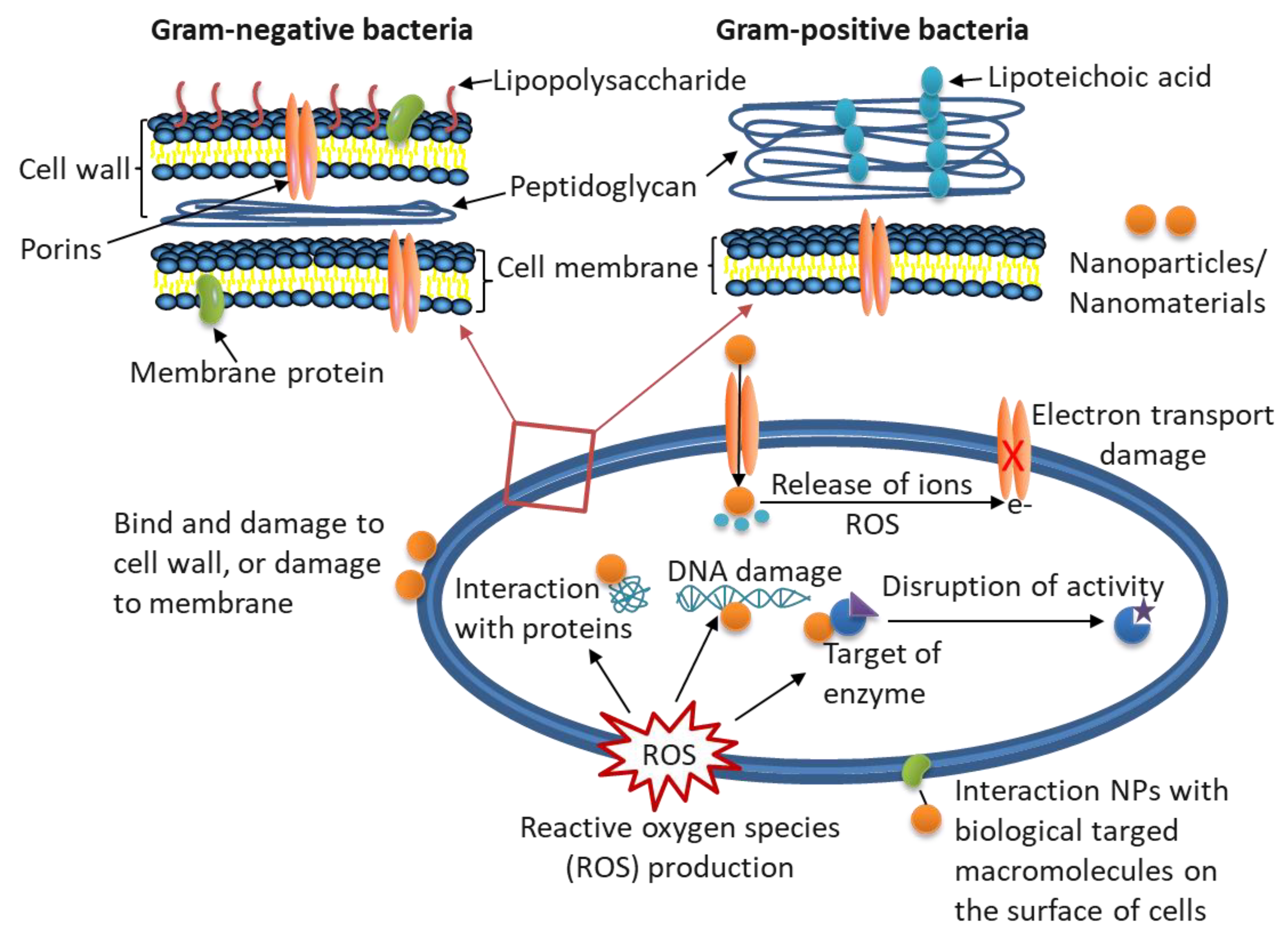

Currently, there are several mechanisms that can be used to explain the antimicrobial activity of these NPs, including interacting directly with the microbial cells, oxidizing cell components, producing secondary products, and dissolving heavy metal ions that cause damage [32][33][41], as shown in Figure 2, and many investigations have been performed on antimicrobial carriers, antimicrobial agents, growth inhibitors, and antimicrobial packaging films due to the nanoparticles or nanocomposite materials with antimicrobial activity. They have potential applications in food packaging, such as cheese, poultry, bread, fruits and vegetables, meat products, and fish products [2].

Figure 2. The potential antimicrobial mechanisms of nanoparticles/nanomaterials in food packaging (modified from Jamróz et al. [41]).

3. Application of Novel Bio-Based Antimicrobial Materials in Food Products

With the continuous improvement of living standards, food is required to have higher quality and longer shelf life. Food or beverage contamination and spoilage are always a concern in the food industry. In order to prevent foodborne pathogens and spoilage microorganisms, foodstuffs need suitable packaging during transport, storage, and marketing. Traditionally, the food is packaged with plastic that is extracted from non-renewable resources of fossil fuels; they are rarely recyclable and face hardship in a disposal [2]. Therefore, the bio-based materials have become promising alternative materials since they are biodegradable, renewable, and eco-friendly [17]. At present, various novel bio-based antimicrobial materials have been used in food packaging, including biopolymer materials, nanoparticles/nanofillers, bio-based composites, and bio-nanocomposites. For instance, the polymer nanocomposite MMT of clay is a novel material for food packaging on the market, which can decrease the gas transmission rate resulting in keeping the freshness and prolonging the shelf life of oxygen-sensitive food products [42]. Sarojini et al. [43] studied the biological effects of mahua oil-based polyurethane/CS/ZnO-NPs nanocomposites for food packaging, which showed good anti-bacterial properties against Gram-positive and Gram-negative bacteria in carrot and improved the mechanical property. Ag-NPs have been used in fruit preservation due to their ability to catalyze the absorption and decomposition of ethylene emitted from fruit metabolism and their broad-spectrum inhibitory activities [2]. Badawy et al. [44] stated that CS-NPs-loaded monoterpenes exhibited a high antibacterial effect on Salmonella typhimurium and E. coli in minced meat, and with the antioxidant property thus extended the shelf life. In addition, bio-nanocomposites of moringa oil/CS-NPs-embedded gelatin nanofibers possessed high antibacterial activity against L. monocytogenes and S. aureus, and without any effect on the sensory quality of cheese [45]. Table 1 provides an overview of different types of novel bio-based antimicrobial materials in food packaging applications.

| Type of Materials | Food Product | Characteristics | References |

|---|---|---|---|

| Chitosan/carboxymethyl cellulose/ZnO-NPs | Egyptian soft white cheese | Antibacterial activity against Gram-positive (S. aureus), Gram-negative (P. aeruginosa, E. coli) bacteria and fungi (C. albicans); increasing the shelf life of white soft cheese. | [23] |

| Calcium alginate film loaded with ZnO-NPs | Ready-to-eat poultry meat | Antibacterial activity against S. typhimurium and S. aureus. | [46] |

| PLA/ZnO:Cu/Ag bio-nanocomposites | Food simulants (distilled water, 10% ethanol, and 3% acetic acid) | Good mechanical, thermal, and barrier properties to ultraviolet light, water vapor, oxygen, and carbon dioxide; antibacterial activity and low migration of nanoparticles into food simulants. | [47] |

| PVA/CS/ZnO-SiO2 | Bread | Displayed superior antibacterial activity against Gram-positive bacteria (S. aureus, S33R) as well as Gram-negative bacteria (E. coli, IRAQ 3); greatly improved visual appearance of the bread, increase in shelf life. | [24] |

| ZnO-NPs/neem oil/CS | Carrot | The tensile strength, elongation, film thickness, and film transparency were improved; antibacterial activity against E. coli. | [48] |

| Mahua oil-based polyurethane/CS/nano ZnO composite film | Carrot | Improved the mechanical property and reduced the permeability of oxygen and moisture; excellent anti-bacterial properties against Gram-positive and Gram-negative bacteria, reducing bacterial contamination; enhances the shelf life of carrot. | [43] |

| CS/PVA/TiO2 bio-nanocomposite | Soft white cheese | Effective antibacterial activity against Gram-positive (S. aureus) and Gram-negative (P. aeruginosa, E. coli) bacteria and fungi (C. albicans); extension in shelf life. | [49] |

| Cellulose acetate (CA)/Cu-NPs | Food simulants | Antibacterial activity against S. aureus, P. aeruginosa, C. albicans, and A. niger; CA film with 6% exhibited lower activity than film with 2% Cu-NPs; enhancement of thermal stability. | [50] |

| Poly(glycidyl methacrylate covinyl ferrocene); graphene oxide/Fe3O4-NPs | Fish | An effective platform to produce reliable xanthine biosensor; fish meat freshness control. | [51] |

| CS-NPs-loaded monoterpenes | Minced meat | Exhibited good in vivo antimicrobial (against S. typhimurium and E. coli) and antioxidant property; extension in shelf life. | [44] |

| Corn starch/talc NPs | Tomato | Improvement in strength, tightness, and barrier properties; reduction in water vapor and oxygen permeability. | [52] |

| ε-Poly-lysine/CS-nanofibers | Chicken | Exhibited antibacterial effect on S. typhimurium and S. enteritidis on chicken; increasing the shelf life and maintaining the quality of the packed food. | [53] |

| Moringa oil/CS-NPs-embedded gelatin nanofibers | Cheese | Possessed high antibacterial activity against L. monocytogenes and S. aureus, without any effect on the sensory quality of cheese. | [45] |

| Pectin/ LDH-salicylate | Fresh apricot | Improved elongation at break point for pectin; improved water vapor barrier properties; extension in shelf life. | [54] |

| Starch nanocomposite films containing nanoclay (halloysite) and nisin | Soft cheese | Mechanical properties were improved with halloysite addition; antimicrobial activity against L. monocytogenes, Clostridium perfringens, and S. aureus. | [55] |

| Quaternary ammonium salt-modified CS and PVA | Strawberries | Highly efficient antifogging and antibacterial activity (against E. coli, S. aureus, and Botrytis cinerea). | [56] |

| Thyme EOs and MMT based sweet potato starch films | Baby spinach leaves | Antibacterial activity against E. coli and S. Typhi on fresh baby spinach leaves; extension in shelf life. | [57] |

| Addition of MMT to WPI matrix | Food simulants (water, 3% acetic acid, 15% ethanol, olive oil) | Increased tensile strength of the WPI film, and swelling of the WPI film was reduced. | [58] |

| Alginate/nano-Ag coating | Shiitake mushroom (Lentinus edodes) | Reduced mesophilic, pseudomonad, yeasts and molds counts; spoilage reduction, improvement of sensory attributes, lower weight loss. | [59] |

| Shirazi balangu seed mucilage edible coating |

Beef slices | Enhancement of the shelf life of beef by preventing lipid oxidation and microbial spoilage. |

[60] |

| Tilapia skin gelatin incorporated with ethanolic extract from coconut husk/Cloisite Na+ nanoclay | Meat powder | Lower lipid oxidation products; improved moisture barrier properties; extension in shelf life. | [61] |

| Nanoemulsion coating of CS/mandarin EOs | Green beans | Antimicrobial activity in L. monocytogenes; exhibited a slight antagonistic effect and had a slight detrimental impact on color properties when combined with pulsed light, but promising with high hydrostatic pressure. | [62] |

It should be noted that antibacterial bio-polymer is usually effective for some specific microorganisms, and not all microorganisms can degrade biopolymers. Antibacterial materials have their own antibacterial spectrum. The degradation of biodegradable polymers disposed in environments (e.g., landfills) is often induced by microorganisms (e.g., bacteria, fungi) via enzymatic catalysis processes. Furthermore, the polymer chains may also be broken down by nonenzymatic processes like chemical hydrolysis. This dilemma between biodegradable behavior and antimicrobial activity can be addressed well as long as the appropriate materials are selected in a targeted manner.

4. Regulatory and Safety Issues of Antimicrobial Nanomaterials

The safety and environmental impacts of different antimicrobial nanomaterials in food packaging must be identified to the fullest degree possible. Nanomaterials can migrate from packaging materials to the packaged foodstuffs and drinks and may pose risks to human health, animals, and the environment [63][64]. The generation of reactive oxygen species (ROS) by nanomaterials has been seen in both in vitro and in vivo conditions [65]. They may lead to the generation of ROS in the intestinal (or other) cells of humans after ingestion of food in which NPs have moved from the materials used to protect the food, causing cellular perturbation along with DNA damage and apoptosis. In addition, the presence of ROS in wounds may hamper wound healing [41]. Low ROS concentration will activate the signaling pathways, whereas its higher concentration can cause damage to mitochondria, cell membrane and other macromolecules [65]. Reactive oxygen species (ROS) can also cause tissue degradation, which ultimately leads to carcinogenesis, aging, and other diseases [66]. Yet, the overall effects of nanomaterials on them are still not fully understood. Therefore, it is also highly recommended to study the migration path and pattern of NPs from nanocomposite packaging when in contact with food products and to establish an effective risk assessment system. Additionally, proper and validated procedures are lacking for all applications and characteristics; thus, safety decisions should be made with consideration of the nanoparticle size and the related safety evaluations, ultimately giving a clear answer as to whether and which nanomaterials can be a practicable substitute for traditional materials for food packaging application. Moreover, regulation and legislation still need a base to be developed.

References

- Youssef, A.M.; El-Sayed, S.M. Bionanocomposites materials for food packaging applications: Concepts and future outlook. Carbohyd. Polym. 2018, 193, 19–27.

- Sharma, R.; Jafari, S.M.; Sharma, S. Antimicrobial bio-nanocomposites and their potential applications in food packaging. Food Control. 2020, 112, 107086.

- Youssef, A.M.; Assem, F.M.; Abdel-Aziz, M.E.; Elaaser, M.; Ibrahim, O.A.; Mahmoud, M.; Abd El-Salam, M.H. Development of bionanocomposite materials and its use in coating of Ras cheese. Food Chem. 2019, 270, 467–475.

- Milani, J.M.; Tirgarian, B. An overview of edible protein-based packaging: Main sources, advantages, drawbacks, recent progressions and food applications. J. Packag. Technol. Res. 2020, 4, 103–115.

- Illikoud, N.; Rossero, A.; Chauvet, R.; Courcoux, P.; Pilet, M.-F.; Charrier, T.; Emmanuel, J.; Zagorec, M. Genotypic and phenotypic characterization of the food spoilage bacterium Brochothrix thermosphacta. Food Microbiol. 2019, 81, 22–31.

- CDC. National Outbreak Reporting System Dashboard; U.S. Department of Health and Human Services: Atlanta, GA, USA, 2018.

- Al-Tayyar, N.A.; Youssef, A.M.; Al-hindi, R. Antimicrobial food packaging based on sustainable bio-based materials for reducing foodborne pathogens: A review. Food Chem. 2020, 310, 1–17.

- Tamayo, L.; Azócar, M.; Kogan, M.; Riveros, A.; Páez, M. Copper-polymer nanocomposites: An excellent and cost-effective biocide for use on antibacterial surfaces. Mater. Sci. Eng. 2016, 69, 1391–1409.

- Odeyemi, O.A.; Alegbeleye, O.O.; Strateva, M.; Strateva, D. Understanding spoilage microbial community and spoilage mechanisms in foods of animal origin. Compr. Rev. Food Sci. Food Saf. 2020, 19, 311–331.

- Scharff, R.L. Economic burden from health losses due to foodborne illness in the United States. J. Food Prot. 2012, 75, 123–131.

- Otoni, C.G.; Espitia, P.J.P.; Avena-Bustillos, R.J.; Mchugh, T.H. Trends in antimicrobial food packaging systems: Emitting sachets and absorbent pads. Food Res. Int. 2016, 83, 60–73.

- Gan, I.; Chow, W.S. Antimicrobial poly (lactic acid)/cellulose bionanocomposite for food packaging application: A review. Food Packag. Shelf. 2018, 17, 150–161.

- Pilevar, Z.; Bahrami, A.; Beikzadeh, S.; Hosseini, H.; Jafari, S.M. Migration of styrene monomer from polystyrene packaging materials into foods: Characterization and safety evaluation. Trends Food Sci. Tech. 2019, 91, 248–261.

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689.

- Ingrao, C.; Gigli, M.; Siracusa, V. An attributional life cycle assessment application experience to highlight environmental hotspots in the production of foamy polylactic acid trays for fresh-food packaging usage. J. Clean. Prod. 2017, 150, 93–103.

- Abdul Khalil, H.P.S.; Davoudpour, Y.; Saurabh, C.K.; Hossain, M.S.; Adnan, A.S.; Dungani, R.; Paridah, M.T.; Sarker, M.Z.I.; Fazita, M.R.N.; Syakir, M.I.; et al. A review on nanocellulosic fibres as new material for sustainable packaging: Process and applications. Renew. Sustain. Energy Rev. 2016, 64, 823–836.

- Zubair, M.; Ullah, A. Recent advances in protein derived bionanocomposites for food packaging applications. Crit. Rev. Food Sci. Nutr. 2020, 60, 406–434.

- Tang, X.Z.; Kumar, P.; Alavi, S.; Sandeep, K.P. Recent advances in biopolymers and biopolymer-based nanocomposites for food packaging materials. Crit. Rev. Food Sci. 2012, 52, 426–442.

- Prabhu, T.N.; Prashantha, K. A review on present status and future challenges of starch based polymer films and their composites in food packaging applications. Polym. Compos. 2016, 39, 2499–2522.

- Davis, G.; Song, J. Biodegradable packaging based on raw materials from crops and their impact on waste management. Ind. Crop. Prod. 2006, 23, 147–161.

- Vahedikia, N.; Garavand, F.; Tajeddin, B.; Cacciotti, I.; Jafari, S.M.; Omidi, T.; Zahedi, Z. Biodegradable zein film composites reinforced with chitosan nanoparticles and cinnamon essential oil: Physical, mechanical, structural and antimicrobial attributes. Colloid. Surf. B 2019, 177, 25–32.

- Hassan, B.; Chatha, S.A.S.; Hussain, A.I.; Zia, K.M.; Akhtar, N. Recent advances on polysaccharides, lipids and protein based edible films and coatings: A review. Int. J. Biol. Macromol. 2018, 109, 1095–1107.

- Youssef, A.M.; El-Sayed, S.M.; El-Sayed, H.S.; Salama, H.H.; Dufresne, A. Enhancement of Egyptian soft white cheese shelf life using a novel chitosan/carboxymethyl cellulose/zinc oxide bionanocomposite film. Carbohyd. Polym. 2016, 151, 9–19.

- Al-Tayyar, N.A.; Youssef, A.M.; Al-hindi, R. Antimicrobial packaging efficiency of ZnO-SiO2 nanocomposites infused into PVA/CS film for enhancing the shelf life of food products. Food Packag. Shelf. 2020, 25, 100523.

- Venkatasubbu, G.D.; Baskar, R.; Anusuya, T.; Seshan, C.A.; Chelliah, R. Toxicity mechanism of titanium dioxide and zinc oxide nanoparticles against food pathogens. Colloid. Surf. B 2016, 148, 600–606.

- Vilela, C.; Kurek, M.; Hayouka, Z.; Rocker, B.; Yildirim, S.; Antunes, M.D.C.; Nilsen-Nygaard, J.; Pettersen, M.K.; Freire, C.S.R. A concise guide to active agents for active food packaging. Trends Food Sci. Tech. 2018, 80, 212–222.

- Zanetti, M.; Carniel, T.K.; Dalcanton, F.; dos Anjos, R.S.; Riella, H.G.; de Araújo, P.H.; de Oliveira, D.; Fiori, M.H. Use of encapsulated natural compounds as antimicrobial additives in food packaging: A brief review. Trends Food Sci. Tech. 2018, 81, 50–61.

- Appendini, P.; Hotchkiss, J.H. Review of antimicrobial food packaging. Innov. Food Sci. Emerg. 2002, 3, 113–126.

- Ju, J.; Wang, C.; Qiao, Y.; Li, D.; Li, W. Effects of tea polyphenol combined with nisin on the quality of weever (Lateolabrax japonicus) in the initial stage of fresh-frozen or chilled storage state. J. Aquat. Food Prod. T. 2017, 26, 543–552.

- Ju, J.; Xu, X.; Xie, Y.; Guo, Y.; Cheng, Y.; Qian, H.; Yao, W. Inhibitory effects of cinnamon and clove essential oils on mold growth on baked foods. Food Chem. 2017, 240, 850–855.

- Ju, J.; Chen, X.; Xie, Y.; Yu, H.; Guo, Y.; Cheng, Y.; Qian, H.; Yao, W. Application of essential oil as a sustained release preparation in food packaging. Trends Food Sci. Tech. 2019, 92, 22–32.

- Khaneghah, A.M.; Hashemi, S.M.B.; Limbo, S. Antimicrobial agents and packaging systems in antimicrobial active food packaging: An overview of approaches and interactions. Food Bioprod. Process. 2018, 111, 1–19.

- Hoseinnejad, M.; Jafari, S.M.; Katouzian, I. Inorganic and metal nanoparticles and their antimicrobial activity in food packaging applications. Crit. Rev. Microbiol. 2018, 44, 161–181.

- Babu, R.P.; O’Connor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8.

- Ren, L.; Yan, X.; Zhou, J.; Tong, J.; Su, X. Influence of chitosan concentration on mechanical and barrier properties of corn starch/chitosan films. Int. J. Biol. Macromol. 2017, 105, 1636–1643.

- Othman, S.H. Bio-nanocomposite materials for food packaging applications: Types of bio-based polymer and nano-sized filler. Agric. Agric. Sci. Procedia 2014, 2, 296–303.

- Maftoonazad, N.; Ramaswamy, H. Novel techniques in food processing: Bionanocomposites. Curr. Opin. Food Sci. 2018, 23, 49–56.

- Tabatabaei, R.H.; Jafari, S.M.; Mirzaei, H.; Nafchi, A.M.; Dehnad, D. Preparation and characterization of nano-SiO2 reinforced gelatin-k-carrageenan biocomposites. Int. J. Biol. Macromol. 2018, 111, 1091–1099.

- Khanzadi, M.; Jafari, S.M.; Mirzaei, H.; Chegini, F.K.; Maghsoudlou, Y.; Dehnad, D. Physical and mechanical properties in biodegradable films of whey protein concentrate-pullulan by application of beeswax. Carbohyd. Polym. 2015, 118, 24–29.

- Rhim, J.W.; Wang, L.F.; Hong, S.I. Preparation and characterization of agar/silver nanoparticles composite films with antimicrobial activity. Food Hydrocolloid. 2013, 33, 327–335.

- Jamróz, E.; Kulawik, P.; Kopel, P. The effect of nanofillers on the functional properties of biopolymer-based films: A review. Polymers 2019, 11, 675.

- Silvestre, C.; Duraccio, D.; Cimmino, S. Food packaging based on polymer nanomaterials. Prog. Polym. Sci. 2011, 36, 1766–1782.

- Sarojini, K.S.; Indumathi, M.P.; Rajarajeswari, G.R. Mahua oil-based polyurethane/chitosan/nano ZnO composite films for biodegradable food packaging applications. Int. J. Biol. Macromol. 2019, 124, 163–174.

- Badawy, M.E.I.; Lotfy, T.M.R.; Shawir, S.M.S. Facile synthesis and characterizations of antibacterial and antioxidant of chitosan monoterpene nanoparticles and their applications in preserving minced meat. Int. J. Biol. Macromol. 2020, 156, 127–136.

- Lin, L.; Gu, Y.; Cui, H. Moringa oil/chitosan nanoparticles embedded gelatin nanofibers for food packaging against Listeria monocytogenes and Staphylococcus aureus on cheese. Food Packag. Shelf 2019, 19, 86–93.

- Akbar, A.; Anal, A.K. Zinc oxide nanoparticles loaded active packaging, a challenge study against Salmonella typhimurium and Staphylococcus aureus in ready-to-eat poultry meat. Food Control. 2014, 38, 88–95.

- Vasile, C.; Rapa, M.; Ștefan, M.; Stan, M.; Macavei, S.; Darie-Nita, R.N.; Barbu-Tudoran, L.; Vodnar, D.C.; Popa, E.E.; Ștefan, R.; et al. New PLA/ZnO:Cu/Ag bionanocomposites for food packaging. Express Polym. Lett. 2017, 7, 531–544.

- Sanuja, S.; Agalya, A.; Umapathy, M. Synthesis and characterization of zinc oxide–neem oil– chitosan bio-nanocomposite for food packaging application. Int. J. Biol. Macromol. 2015, 74, 76–84.

- Youssef, A.M.; El-Sayed, S.M.; Salama, H.H.; El-Sayed, H.S.; Dufresne, A. Evaluation of bionanocomposites as packaging material on properties of soft white cheese during storage period. Carbohyd. Polym. 2015, 132, 274–285.

- Abou-Yousef, H.; Saber, E.; Abdel-Aziz, M.S.; Kamel, S. Efficient alternative of antimicrobial nanocomposites based on cellulose acetate/Cu-NPs. Soft Mater. 2018, 16, 141–150.

- Dervisevic, M.; Custiuc, E.; Çevik, E.; Durmus, Z.; Şenel, M.; Durmus, A. Electrochemical biosensor based on REGO/Fe3O4 bionanocomposite interface for xanthine detection in fish sample. Food Control. 2015, 57, 402–410.

- López, O.V.; Castillo, L.A.; García, M.A.; Villar, M.A.; Barbosa, S.E. Food packaging bags based on thermoplastic corn starch reinforced with talc nanoparticles. Food Hydrocolloid. 2015, 43, 18–24.

- Lin, L.; Xue, L.; Duraiarasan, S.; Haiying, C. Preparation of ε-polylysine/chitosan nanofibers for food packaging against Salmonella on chicken. Food Packag. Shelf 2018, 17, 134–141.

- Gorrasi, G.; Bugatti, V. Edible bio-nano-hybrid coatings for food protection based on pectins and LDH-salicylate: Preparation and analysis of physical properties. LWT Food Sci. Technol. 2016, 69, 139–145.

- Meira, S.M.M.; Zehetmeyer, G.; Scheibel, J.M.; Werner, J.O.; Brandelli, A. Starch-halloysite nanocomposites containing nisin: Characterization and inhibition of Listeria monocytogenes in soft cheese. LWT-Food Sci. Technol. 2016, 68, 226–234.

- Min, T.; Zhu, Z.; Sun, X.; Yuan, Z.; Zha, J.; Wen, Y. Highly efficient antifogging and antibacterial food packaging film fabricated by novel quaternary ammonium chitosan composite. Food Chem. 2020, 308, 125682.

- Issa, A.; Ibrahim, S.A.; Tahergorabi, R. Impact of sweet potato starch-based nanocomposite films activated with thyme essential oil on the shelf-life of baby spinach leaves. Foods 2017, 6, 43.

- Wakai, M.; Almenar, E. Effect of the presence of montmorillonite on the solubility of whey protein isolate films in food model systems with different compositions and pH. Food Hydrocolloid. 2015, 43, 612–621.

- Jiang, T.; Feng, L.; Wang, Y. Effect of alginate/nano-Ag coating on microbial and physicochemical characteristics of shiitake mushroom (Lentinus edodes) during cold storage. Food Chem. 2013, 141, 954–960.

- Behbahani, B.A.; Fooladi, A.A.I. Shirazi balangu (Lallemantia royleana) seed mucilage: Chemical composition, molecular weight, biological activity and its evaluation as edible coating on beefs. Int. J. Biol. Macromol. 2018, 114, 882–889.

- Nagarajan, M.; Benjakul, S.; Prodpran, T.; Songtipya, P. Properties and characteristics of nanocomposite films from tilapia skin gelatin incorporated with ethanolic extract from coconut husk. J. Food Sci. Tech. 2015, 52, 7669–7682.

- Donsì, F.; Marchese, E.; Maresca, P.; Pataro, G.; Vu, K.D.; Salmieri, S.; Lacroix, M.; Ferrari, G. Green beans preservation by combination of a modified chitosan based-coating containing nanoemulsion of mandarin essential oil with high pressure or pulsed light processing. Postharvest Biol. Tec. 2015, 106, 21–32.

- Dimitrijevic, M.; Karabasil, N.; Boskovic, M.; Teodorovic, V.; Vasilev, D.; Djordjevic, V.; Kilibardac, N.; Cobanovic, N. Safety aspects of nanotechnology applications in food packaging. Procedia Food Sci. 2015, 5, 57–60.

- Huang, J.Y.; Li, X.; Zhou, W. Safety assessment of nanocomposite for food packaging application. Trends Food Sci. Tech. 2015, 45, 187–199.

- Ranjan, S.; Dasgupta, N.; Singh, S.; Gandhi, M. Toxicity and regulations of food nanomaterials. Environ. Chem. Lett. 2019, 17, 929–944.

- Luo, C.; Urgard, E.; Vooder, T.; Metspalu, A. The role of COX-2 and Nrf2/ARE in anti-inflammation and antioxidative stress: Aging and anti-aging. Med. Hypotheses 2011, 77, 174–178.