| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Rui A. Lima | + 2417 word(s) | 2417 | 2022-01-24 03:59:46 | | | |

| 2 | Yvaine Wei | -94 word(s) | 2323 | 2022-02-08 02:17:11 | | |

Video Upload Options

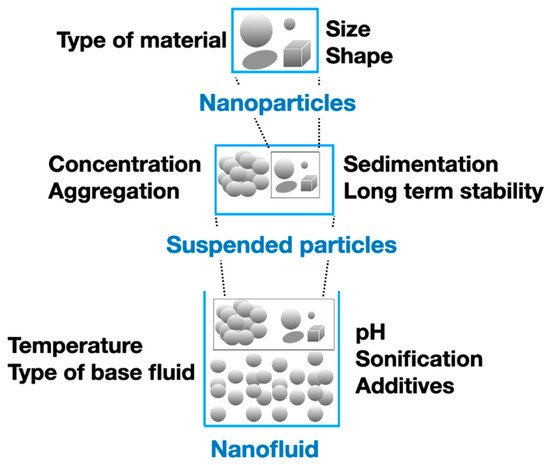

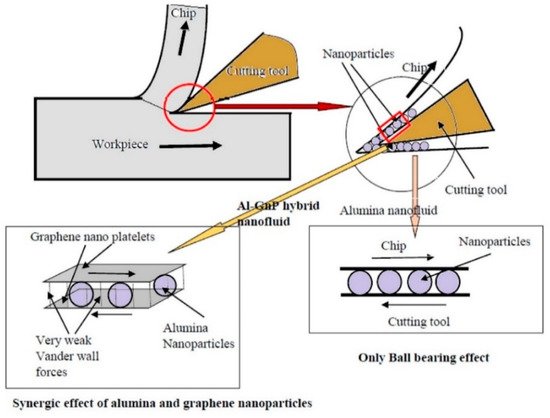

The nanofluids (NFs) are known as a colloidal suspension where nanoparticles (NPs) are dispersed in conventional base fluids (BFs). This suspension has been frequently used to improve the heat transfer (HT) capacity of a fluid by studying their thermophysical properties. The NFs thermal properties and their applications are being used in different fields of engineering, ranging from machining to renewable energies. In machining, NFs play a prominent role in the processes of turning, milling, drilling, and grinding, being responsible for their optimization as well as improving the useful life of the tools and reducing costs. In the solar energy field, NFs have been used in the thermal management of the panels, controlling and homogenizing the operating temperature of these systems. In the biomedical area, the advantages of using NFs come from the treatment of cancer cells, the development of vaccines before the improvement of diagnostic imaging, and many others.

1. Introduction

2. Thermal Properties

3. Stability of Nanofluids

4. Nanofluid Application in Machining

5. Solar Panels and Collectors

6. Biomedicine

-

Reduction of toxicity and side effects of conventional drugs by increasing their efficiency;

-

Specific binding to target cells;

-

Improvement of solubility, stability, tumor aggregation, and half-life of conventional drugs;

-

Release of the loaded drug through a stimuli-responsive mechanism;

-

Increase the area of interaction for encapsulated drugs or drugs attached to biomacromolecules;

-

Overcoming drug resistance by delivering several active agents to specific cellular target sites;

-

Overcoming biological barriers;

-

Improvement of diagnostic and imaging sensitivity;

-

Assessment of drug efficiency in real-time by linking imaging molecules and active anticancer components;

-

Contribution to the development of new vaccines;

-

Improving the diagnostic and imaging of cancer using smaller devices.

References

- Sajid, M.U.; Ali, H.M. Recent Advances in Application of Nanofluids in Heat Transfer Devices: A Critical Review. Renew. Sustain. Energy Rev. 2019, 103, 556–592.

- Saidur, R.; Leong, K.Y.; Mohammed, H.A. A Review on Applications and Challenges of Nanofluids. Renew. Sustain. Energy Rev. 2011, 15, 1646–1668.

- Qiu, L.; Zhu, N.; Feng, Y.; Michaelides, E.E.; Żyła, G.; Jing, D.; Zhang, X.; Norris, P.M.; Markides, C.N.; Mahian, O. A Review of Recent Advances in Thermophysical Properties at the Nanoscale: From Solid State to Colloids. Phys. Rep. 2020, 843, 1–81.

- Hwang, Y.; Lee, J.K.; Lee, C.H.; Jung, Y.M.; Cheong, S.I.; Lee, C.G.; Ku, B.C.; Jang, S.P. Stability and Thermal Conductivity Characteristics of Nanofluids. Thermochim. Acta 2007, 455, 70–74.

- Mamat, H. Nanofluids: Thermal Conductivity and Applications. Ref. Modul. Mater. Sci. Mater. Eng. 2019.

- Choi, S.U.S.; Esatman, J.A. Enhancing Thermal Condutivity of Fluids with Nanoparticles. In Proceedings of the Asme International Mechanical Engineering Congress & Exposition, San Francisco, CA, USA, 12–17 November 1995; ASME Publ-Fed: New York, NY, USA, 1995; pp. 99–106.

- Li, Y.; Zhou, J.; Tung, S.; Schneider, E.; Xi, S. A Review on Development of Nanofluid Preparation and Characterization. Powder Technol. 2009, 196, 89–101.

- Ali, A.R.I.; Salam, B. A Review on Nanofluid: Preparation, Stability, Thermophysical Properties, Heat Transfer Characteristics and Application. SN Appl. Sci 2020, 2, 1–17.

- Parsa, S.M.; Rahbar, A.; Koleini, M.H.; Aberoumand, S.; Afrand, M.; Amidpour, M. A Renewable Energy-Driven Thermoelectric-Utilized Solar Still with External Condenser Loaded by Silver/Nanofluid for Simultaneously Water Disinfection and Desalination. Desalination 2020, 480, 114354.

- Ahmad, S.H.A.; Saidur, R.; Mahbubul, I.M.; Al-Sulaiman, F.A. Optical Properties of Various Nanofluids Used in Solar Collector: A review. Renew. Sustain. Energy Rev. 2017, 73, 1014–1030.

- Hassan, Y.M.; Guan, B.H.; Zaid, H.M.; Hamza, M.F.; Adil, M.; Adam, A.A.; Hastuti, K. Application of Magnetic and Dielectric Nanofluids for Electromagnetic-Assistance Enhanced Oil Recovery: A Review. Crystals 2021, 11, 106.

- Souza, R.R.; Gonçalves, I.M.; Rodrigues, R.O.; Minas, G.; Miranda, J.M.; Moreira, A.L.N.; Lima, R.; Coutinho, G.; Pereira, J.E.; Moita, A.S. Recent Advances on the Thermal Properties and Applications of Nanofluids: From Nanomedicine to Renewable Energies. Appl. Therm. Eng. 2021, 201, 117725.

- Freitas, E.; Pontes, P.; Cautela, R.; Bahadur, V.; Miranda, J.; Ribeiro, A.P.C.; Souza, R.R.; Oliveira, J.D.; Copetti, J.B.; Lima, R. Pool Boiling of Nanofluids on Biphilic Surfaces: An Experimental and Numerical Study. Nanomaterials 2021, 11, 125.

- Junankar, A.A.; Purohit, J.K.; Bhende, N.V. Effective Utilization of Nanofluids for Machining Process Enhancement. AIP Conf. Proc. 2019, 2148, 030040.

- Wong, K.V.; Leon, O. De Applications of Nanofluids: Current and Future. Adv. Mech. Eng. 2010, 2, 519659.

- Felton, E.J.; Reich, D.H. Biological Applications of Multifunctional Magnetic Nanowires. In Biomedical Applications of Nanotechnology; John Wiley and Sons: Hoboken, NJ, USA, 2007; pp. 1–22.

- Ali, A.J.; Eddin, B.E.; Chaichan, M.T. An Investigation of Effect of Hematocrit on Thermal Conductivity of a Bio-Nanofluid (MWCNT or SWCNT with Blood). Therm. Sci. Eng. Prog. 2021, 25, 100985.

- Gonçalves, I.; Souza, R.; Coutinho, G.; Miranda, J.; Moita, A.; Pereira, J.E.; Moreira, A.; Lima, R. Thermal Conductivity of Nanofluids: A Review on Prediction Models, Controversies and Challenges. Appl. Sci 2021, 11, 2525.

- Saleman, A.R.B.; Chilukoti, H.K.; Kikugawa, G.; Shibahara, M.; Ohara, T. A Molecular Dynamics Study on the Thermal Transport Properties and the Structure of the Solid–Liquid Interfaces between Face Centered Cubic (FCC) Crystal Planes of Gold in Contact with Linear Alkane Liquids. Int. J. Heat Mass Transf. 2017, 105, 168–179.

- Xu, G.; Fu, J.; Dong, B.; Quan, Y.; Song, G. A Novel Method to Measure Thermal Conductivity of Nanofluids. Int. J. Heat Mass Transf. 2019, 130, 978–988.

- Wang, X.; Xu, X.; Choi, S.U.S. Thermal Conductivity of Nanoparticle-Fluid Mixture. J. Thermophys. Heat Transf. 1999, 13, 474–480.

- Amiri, A.; Shanbedi, M.; Dashti, H. Thermophysical and Rheological Properties of Water-Based Graphene Quantum Dots Nanofluids. J. Taiwan Inst. Chem. Eng. 2017, 76, 132–140.

- Alshayji, A.; Asadi, A.; Alarifi, I.M. On the Heat Transfer Effectiveness and Pumping Power Assessment of a Diamond-Water Nanofluid Based on Thermophysical Properties: An Experimental Study. Powder Technol. 2020, 373, 397–410.

- Fuskele, V.; Sarviya, R.M. Recent Developments in Nanoparticles Synthesis, Preparation and Stability of Nanofluids. Mater. Today Proc. 2017, 4, 4049–4060.

- Lomascolo, M.; Colangelo, G.; Milanese, M.; De Risi, A. Review of Heat Transfer in Nanofluids: Conductive, Convective and Radiative Experimental Results. Renew. Sustain. Energy Rev. 2015, 43, 1182–1198.

- Souza, R.R.; Faustino, V.; Oliveira, J.D.; Gonçalves, I.M.; Miranda, J.M.; Moita, A.S.; Moreira, A.L.N.; Teixeira, J.C.F.; Bañobre-López, M.; Lima, R. A Novel and Extremely Stable Nanofluid Based on Iron Oxide Nanoparticles: Experimental Investigations on the Thermal Performance. Therm. Sci. Eng. Prog. 2021, 26, 101085.

- Mukherjee, S.; Mishra, P.C.; Chaudhuri, P. Stability of Heat Transfer Nanofluids—A Review. ChemBioEng Rev. 2018, 5, 312–333.

- Wen, D.; Ding, Y. Experimental Investigation into the Pool Boiling Heat Transfer of Aqueous Based γ-Alumina Nanofluids. J. Nanopart. Res. 2005, 7, 265–274.

- Yu, H.; Hermann, S.; Schulz, S.E.; Gessner, T.; Dong, Z.; Li, W.J. Optimizing Sonication Parameters for Dispersion of Single-Walled Carbon Nanotubes. Chem. Phys. 2012, 408, 11–16.

- Lee, J.; Mudawar, I. Assessment of the Effectiveness of Nanofluids for Single-Phase and Two-Phase Heat Transfer in Micro-Channels. Int. J. Heat Mass Transf. 2007, 50, 452–463.

- Sadeghinezhad, E.; Mehrali, M.; Saidur, R.; Mehrali, M.; Latibari, S.T.; Akhiani, A.R.; Metselaar, H.S.C. A Comprehensive Review on Graphene Nanofluids: Recent Research, Development and Applications. Energy Convers. Manag. 2016, 111, 466–487.

- Dhar, N.R.; Islam, M.W.; Islam, S.; Mithu, M.A.H. The Influence of Minimum Quantity of Lubrication (MQL) on Cutting Temperature, Chip and Dimensional Accuracy in Turning AISI-1040 Steel. J. Mater. Process. Technol. 2006, 171, 93–99.

- Shokoohi, Y.; Khosrojerdi, E.; Rassolian Shiadhi, B.H. Machining and Ecological Effects of a New Developed Cutting Fluid in Combination with Different Cooling Techniques on Turning Operation. J. Clean. Prod. 2015, 94, 330–339.

- Goindi, G.S.; Sarkar, P. Dry Machining: A Step towards Sustainable Machining–Challenges and Future Directions. J. Clean. Prod. 2017, 165, 1557–1571.

- Braga, D.U.; Diniz, A.E.; Miranda, G.W.A.; Coppini, N.L. Using a Minimum Quantity of Lubricant (MQL) and a Diamond Coated Tool in the Drilling of Aluminum-Silicon Alloys. J. Mater. Process. Technol. 2002, 122, 127–138.

- Kadirgama, K. A Comprehensive Review on the Application of Nanofluids in the Machining Process. Int. J. Adv. Manuf. Technol. 2021, 47, 2669–2681.

- Hemmat Esfe, M.; Bahiraei, M.; Mir, A. Application of Conventional and Hybrid Nanofluids in Different Machining Processes: A Critical Review. Adv. Colloid Interface Sci. 2020, 282, 102199.

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Progress of Nanofluid Application in Machining: A Review. Mater. Manuf. Process. 2015, 30, 813–828.

- Daungthongsuk, W.; Wongwises, S. A Critical Review of Convective Heat Transfer of Nanofluids. Renew. Sustain. Energy Rev. 2007, 11, 797–817.

- Kakaç, S.; Pramuanjaroenkij, A. Review of Convective Heat Transfer Enhancement with Nanofluids. Int. J. Heat Mass Transf. 2009, 52, 3187–3196.

- Rahman, S.S.; Ashraf, M.Z.I.; Amin, A.N.; Bashar, M.S.; Ashik, M.F.K.; Kamruzzaman, M. Tuning Nanofluids for Improved Lubrication Performance in Turning Biomedical Grade Titanium Alloy. J. Clean. Prod. 2019, 206, 180–196.

- Roy, S.; Ghosh, A. High Speed Turning of AISI 4140 Steel Using Nanofluid through Twin Jet SQL System. In Proceedings of the ASME 2013 International Manufacturing Science and Engineering Conference Collocated with the 41st North American Manufacturing Research Conference, MSEC 2013, Madison, WI, USA, 10–14 June 2013; Volume 2.

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R.; Singh, R.K.; Singh, M. Novel Uses of Alumina/Graphene Hybrid Nanoparticle Additives for Improved Tribological Properties of Lubricant in Turning Operation. Tribol. Int. 2018, 119, 99–111.

- Ebaid, M.S.Y.; Al-busoul, M.; Ghrair, A.M. Performance Enhancement of Photovoltaic Panels Using Two Types of Nanofluids. Heat Transf. 2020, 49, 2789–2812.

- Kasaeian, A.; Eshghi, A.T.; Sameti, M. A Review on the Applications of Nanofluids in Solar Energy Systems. Renew. Sustain. Energy Rev. 2015, 43, 584–598.

- Shin, D.; Banerjee, D. Enhancement of Specific Heat Capacity of High-Temperature Silica-Nanofluids Synthesized in Alkali Chloride Salt Eutectics for Solar Thermal-Energy Storage Applications. Int. J. Heat Mass Transf. 2011, 54, 1064–1070.

- Khanafer, K.; Vafai, K. A Review on the Applications of Nanofluids in Solar Energy Field. Renew. Energy 2018, 123, 398–406.

- Abdolbaqi, M.K.; Azmi, W.H.; Mamat, R.; Sharma, K.V.; Najafi, G. Experimental Investigation of Thermal Conductivity and Electrical Conductivity of BioGlycol-Water Mixture Based Al2O3 Nanofluid. Appl. Therm. Eng. 2016, 102, 932–941.

- Paul, G.; Chopkar, M.; Manna, I.; Das, P.K. Techniques for Measuring the Thermal Conductivity of Nanofluids: A Review. Renew. Sustain. Energy Rev. 2010, 14, 1913–1924.

- Riahi, A.; Khamlich, S.; Balghouthi, M.; Khamliche, T.; Doyle, T.B.; Dimassi, W.; Guizani, A.; Maaza, M. Study of Thermal Conductivity of Synthesized Al2O3-Water Nanofluid by Pulsed Laser Ablation in Liquid. J. Mol. Liq. 2020, 304.

- Agarwal, R.; Verma, K.; Agrawal, N.K.; Singh, R. Comparison of Experimental Measurements of Thermal Conductivity of Fe2O3 Nanofluids Against Standard Theoretical Models and Artificial Neural Network Approach. J. Mater. Eng. Perform. 2019, 28, 4602–4609.

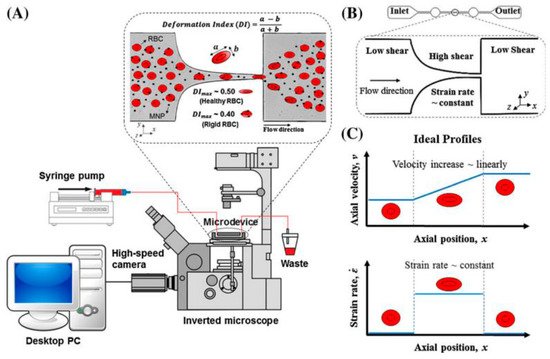

- Rodrigues, R.O.; Sousa, P.C.; Gaspar, J.; Bañobre-López, M.; Lima, R.; Minas, G. Organ-on-a-Chip: A Preclinical Microfluidic Platform for the Progress of Nanomedicine. Small 2020, 16, 2003517.

- Seeta Rama Raju, G.; Benton, L.; Pavitra, E.; Yu, J.S. Multifunctional Nanoparticles: Recent Progress in Cancer Therapeutics. Chem. Commun. 2015, 51, 13248–13259.

- Lungu, I.I.; Grumezescu, A.M.; Volceanov, A.; Andronescu, E. Nanobiomaterials Used in Cancer Therapy: An up-to-Date Overview. Molecules 2019, 24, 3547.

- Patra, J.K.; Das, G.; Fraceto, L.F.; Campos, E.V.R.; Rodriguez-Torres, M.D.P.; Acosta-Torres, L.S.; Diaz-Torres, L.A.; Grillo, R.; Swamy, M.K.; Sharma, S.; et al. Nano Based Drug Delivery Systems: Recent Developments and Future Prospects. J. Nanobiotechnol. 2018, 16, 71.

- Zhu, D.; Long, Q.; Xu, Y.; Xing, J. Evaluating Nanoparticles in Preclinical Research Using Microfluidic Systems. Micromachines 2019, 10, 414.

- Rodrigues, R.O.; Baldi, G.; Doumett, S.; Garcia-Hevia, L.; Gallo, J.; Bañobre-López, M.; Dražić, G.; Calhelha, R.C.; Ferreira, I.C.F.R.; Lima, R.; et al. Multifunctional Graphene-Based Magnetic Nanocarriers for Combined Hyperthermia and Dual Stimuli-Responsive Drug Delivery. Mater. Sci. Eng. C 2018, 93, 206–217.

- Demetzos, C. Application of Nanotechnology in Imaging and Diagnostics. In Pharmaceutical Nanotechnology; Springer: Singapore, 2016; pp. 65–75.

- Yang, S.; Chen, L.; Zhou, X.; Sun, P.; Fu, L.; You, Y.; Xu, M.; You, Z.; Kai, G.; He, C. Tumor-Targeted Biodegradable Multifunctional Nanoparticles for Cancer Theranostics. Chem. Eng. J. 2019, 378, 122171.

- Kung, C.T.; Gao, H.; Lee, C.Y.; Wang, Y.N.; Dong, W.; Ko, C.H.; Wang, G.; Fu, L.M. Microfluidic Synthesis Control Technology and Its Application in Drug Delivery, Bioimaging, Biosensing, Environmental Analysis and Cell Analysis. Chem. Eng. J. 2020, 399, 125748.

- Carvalho, V.; Gonçalves, I.; Lage, T.; Rodrigues, R.O.; Minas, G.; Teixeira, S.F.C.F.; Moita, A.S.; Hori, T.; Kaji, H.; Lima, R.A. 3D Printing Techniques and Their Applications to Organ-on-a-Chip Platforms: A Systematic Review. Sensors 2021, 21, 3304.

- Madamsetty, V.S.; Mukherjee, A.; Mukherjee, S. Recent Trends of the Bio-Inspired Nanoparticles in Cancer Theranostics. Front. Pharmacol. 2019, 10, 1264.

- Rodrigues, R.O.; Bañobre-López, M.; Gallo, J.; Tavares, P.B.; Silva, A.M.T.; Lima, R.; Gomes, H.T. Haemocompatibility of Iron Oxide Nanoparticles Synthesized for Theranostic Applications: A High-Sensitivity Microfluidic Tool. J. Nanopart. Res. 2016, 18, 194.