Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mohsen Mousavi | + 2171 word(s) | 2171 | 2022-01-03 07:59:44 | | | |

| 2 | Conner Chen | Meta information modification | 2171 | 2022-01-27 02:01:05 | | | | |

| 3 | Lindsay Dong | Meta information modification | 2171 | 2022-03-28 05:48:25 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Mousavi, M. Composite Structures. Encyclopedia. Available online: https://encyclopedia.pub/entry/18810 (accessed on 08 February 2026).

Mousavi M. Composite Structures. Encyclopedia. Available at: https://encyclopedia.pub/entry/18810. Accessed February 08, 2026.

Mousavi, Mohsen. "Composite Structures" Encyclopedia, https://encyclopedia.pub/entry/18810 (accessed February 08, 2026).

Mousavi, M. (2022, January 26). Composite Structures. In Encyclopedia. https://encyclopedia.pub/entry/18810

Mousavi, Mohsen. "Composite Structures." Encyclopedia. Web. 26 January, 2022.

Copy Citation

Common types of engineering materials include metals, polymers, ceramics, and composites. Among these, composite materials are often a better alternative for traditional materials, such as metals, ceramics, and polymers due to their light weight, corrosion resistance, high strength and stiffness, ability to withstand high temperatures, and simple manufacturing process. Composite structures are used in a range of different industries from aerospace, marine, aviation, transport, and sports/leisure to civil engineering. For example, advanced composite materials have been used in different structures regarding the above industries, such as rotor blades, aircraft main body, and wing skins.

composite structures

1. Composite Structures

Common types of engineering materials include metals, polymers, ceramics, and composites. Among these, composite materials are often a better alternative for traditional materials, such as metals, ceramics, and polymers due to their light weight, corrosion resistance, high strength and stiffness, ability to withstand high temperatures, and simple manufacturing process [1][2]. Composite structures are used in a range of different industries from aerospace, marine, aviation, transport, and sports/leisure to civil engineering. For example, advanced composite materials have been used in different structures regarding the above industries, such as rotor blades, aircraft main body, and wing skins.

Laminated composites usually consists of a couple of ply termed as lamina. Each lamina generally consists of two substances: (1) the matrix, and (2) the reinforcement material or fiber, which is immersed in the matrix. Generally, composite materials are made of a base material (matrix) and a reinforcement material (fiber) [2][3][4]. Fiber-reinforced composite (FRC) materials are composed of high-strength fibers that are embedded in a matrix for two main reasons: (1) to hold the fibers in place and (2) to prevent the fibers from exposure to destructive environmental conditions, such as humidity. The different types of composite textures pertain to fibrous composites, laminated composites, particulate composites, symmetric laminates, and unsymmetrical laminates.

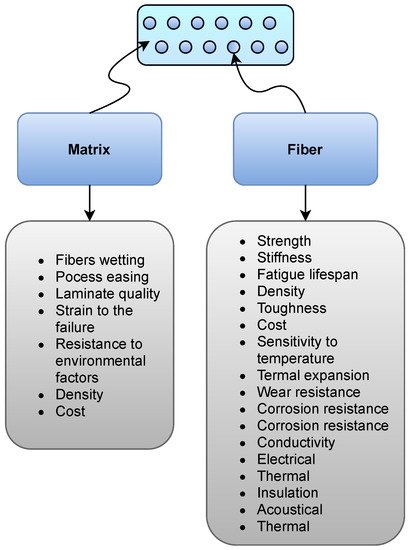

Figure 1 shows the contributions of the matrix and fiber to different properties of a ply in composite laminates.

Figure 1. The contributions of matrix and fibers to different properties of a ply.

-

Fibrous Composites:Fibrous composite is a type of composite materials that includes fibers integrated with a matrix, owing its remarkable stiffness and strength to the fibers. Fibers can be classified based on their length into long and short fibers. While long fibers are usually produced in straight form or woven form, short fibers, also known as whiskers, possess better strength and stiffness properties. The geometrical properties of a fiber are usually characterised by a high length-to-diameter ratio as well as its near crystal-sized diameter. The effectiveness of a fiber is, however, determined by its strength-to-density and stiffness-to-density ratios. Fibers can effectively improve the fracture resistance of the matrix [5], and the long-dimension reinforcement made by fibers stalls the growth of the cracks initiating normal to the direction of reinforcement.

-

Laminated Composites:Laminated composites consist of several layers of different materials (at least two) bonded together. Since layers are usually very thin individually, they are combined through lamination to achieve a material with better mechanical properties. Various orientations of the layers are typically used to form a multiply laminated composite suitable for engineering applications. Some examples of laminated composites include bimetals, clad metals, laminated glass, plastic-based laminates, and fibrous composite laminates [6].A hybrid class of composites, called laminated fiber-reinforced composites, involves both fibrous composites and lamination techniques. The fiber direction of each layer of fiber-reinforced composites is typically oriented in a direction different from the direction of other layers in order to achieve strength and stiffness in different directions. Thus, the layering of such composites can be tailored based on specific design requirements [7].

-

Particulate Composites:Particulate composites, such as concrete, consist of particles of different materials with different shapes, sizes, or configurations that are randomly suspended in a matrix. However, unlike fibers, particulate composites are not usually of long dimensions (with the exception of platelets) but instead are regarded as isotropic materials. Similar to a matrix, particles can be composed of different types of materials, including metallic and nonmetallic. As such, there are four possible combinations of fibers and matrices in terms of the type of material used in each one: (1) metallic particles in nonmetallic matrix, (2) nonmetallic particles in metallic matrix (metal matrix composites), (3) nonmetallic particles in nonmetallic matrix, and (4) metallic particles in metallic fibers. Particulate composites are meant to reduce the cost of integrating composites with fibers [8]. Notwithstanding, they typically do not exhibit the strong load-bearing capability of fibrous composites and are not typically resistant to fracture.

-

Symmetric Laminates:Symmetric laminates are a laminated composite that is symmetric in geometry and material with respect to the geometrical middle surface. Therefore, the layers that make up a symmetric pair possess the same properties. Symmetric laminates are more common compared with unsymmetrical laminates [9].

-

Unsymmetrical Laminates:Unsymmetrical laminates are not symmetric with respect to their middle surface. They are used in many applications, depending on the design requirements [10].

Often times, various types of composite textures can be mixed to obtain six different kinds of composite materials as follows:

-

Symmetric–fibrous composites;

-

Symmetric–laminated composites;

-

Symmetric–particulate composites;

-

Unsymmetrical–fibrous composites;

-

Unsymmetrical–laminated composites; and

-

Unsymmetrical–particulate composites.

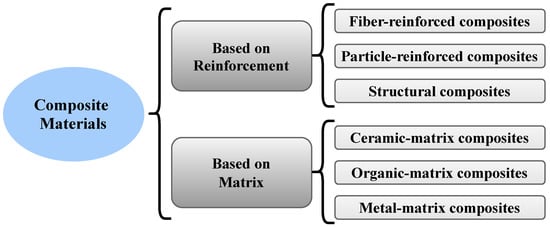

The load is mainly carried by the fibers that act as reinforcement, while the roles of the matrix are (1) to hold the fibers in place and (2) to transmit the load to the fibers. Typically, fibers are composed of carbon, glass, aramid, boron, and silicon carbide, whereas the matrices are usually made from polymers such as epoxies and polyimides [10]. Figure 2 shows the classification of composite materials based on the type of reinforcement and matrix. Therefore, the properties of a composite are generally determined by the following factors:

Figure 2. The classification of the composite material.

-

Fiber properties;

-

Matrix properties;

-

Fiber Volume Fraction (FVF), which is defined as the ratio of fiber to matrix; and

-

Arrangement of fibers in the composite, such as geometry and orientation.

The density, stiffness, and strength of the matrix is lower than those of the fibers. The combination of the matrix and fibers usually offers very high strength and stiffness while maintaining low density [4].

For further details about the classification of composite structures, the readers are referred to [11][12][13][14].

2. Failure Mechanisms of Composite Structures

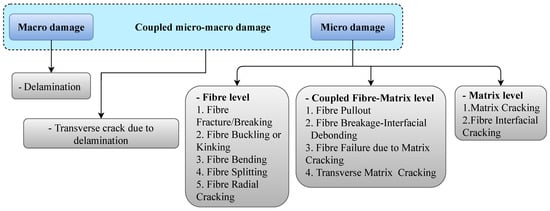

Various types of defects can occur in composite structures, which can be classified based on the size and component of the effected composite structure, as illustrated in Figure 3. Some of the most critical types of damage are those caused by cyclic loading (fatigue damage) or impact loading. Such damage can significantly reduce the residual strength in a part of a composite structure, depending on their type and size [14]. Damage can occur in a composite structure in different forms, ranging from defects in the matrix or fiber to other forms of damage such as a breakage of elements or failure of attachments that are either bonded or bolted to the body of the structure [15]. The extent of damage determines the remaining service life of a composite component and is thus considered a factor to identify the damage tolerance of the component. While some types of damage can have very little effect on the residual strength, they can become more severe over time when combined with other factors, such as environmental and operational effects [16][17].

Figure 3. Types of damage in composite structures.

Impact damage can reduce the compression, shear, and tensile strength of composite materials. As such, the compressive residual strength of the laminated composite material is dependent on the extent of delamination and fiber failure produced by transverse impacts. Fiber failure can subsequently affect the tensile residual strength of the material. However, the effect of impact damage can vary based on the specific design and application of the composite member. For example, in aircraft systems, impact damage can decline the resistance and integrity of composite components to the environmental factors, such as moisture. As such, the core of sandwich panels with thin face sheets may be subjected to moisture after the impact, or the impact can bring about fuel leaks in stiffened wing panels. Therefore, a good understanding of these effects can guarantee a safe and economic application of composite materials.

Table 2 lists some studies that investigate common failure mechanisms in composite structures.

Table 2. Some common failure mechanisms along with recommended damage detection methods in composite structures.

| Refs | Failure | Description | Method |

|---|---|---|---|

| [18] | Matrix cracking | An NDE method based on propagation of ultrasonic Lamb wave in polymeric composites that is capable of detecting and classifying matrix cracking in the material using artificial intelligence was developed | Method based on guided wave propagation and artificial neural networks |

| [19] | Fiber cracking | A mixed-mode I/II crack detection criterion was developed for fracture detection of orthotropic materials with arbitrary crack-fiber angle | Augmented Strain Energy Release Rate (ASER) |

| [20] | Delamination | An image processing methodology, based on digital radiography, was developed to characterize the drilling-induced delamination damage | Image processing |

3. Environmental Variations Effects

One pertinent factor to be considered when designing a composite component is the environment that the component is exposed to during service time. This is mainly due to the fact that the performance of composite members is significantly affected by environmental factors. There are several environmental factors that can have such effects, with temperature and moisture being the most important for polymer composites. For example, the modulus and strength of the polymer matrix are highly affected by temperature variations, which can further affect the mechanical properties of the lamina and laminate. While the modulus and strength of the matrix can be reduced by elevated temperature, extreme cold conditions can trigger brittle behaviour in some resin systems [25][26][27][28]. However, the extent of this event highly depends on the type of resin and, more generally, all other materials used in the design of the composite component. For example, the effect of temperature on glass or carbon fibers is less than that on some organic fibers, such as aramid. Likewise, increased moisture content can decrease some mechanical properties of materials, such as the resin’s modulus and strength. Moreover, matrix swelling is another effect caused by moisture uptake, resulting in increased residual stresses within the laminate. Except for most spacecrafts, moisture swelling effects are not as severe as those pertaining to temperature and, therefore, are usually neglected at the design stage.

Table 3 outlines the effect of different environmental, operational, and damage mechanisms on the mechanical properties of composite structures based on reviewing References [11][12][29][30][31]. For instance, the composite material stiffness is highly sensitive to the temperature and moisture variations as well as the presence of fiber cracks. Another factor that is highly sensitive to moisture, as an environmental effect, is the mass of composite components. As such, the boundary formation is the item least influenced by the environmental variations, i.e., temperature and humidity. The mechanical load and electromagnetic radiation have relatively moderate effects on composite material conductivity. However, their impact on other mechanical properties of the composite structure is negligible.

Table 3. Influence of environmental conditions on local properties of composite structures. (+) strong, (∘) average, and (−) weak influence. (Dl) Delamination, (T) Temperature, (Dt) Dirt, (M) Moisture, (ER) Electromagnetic Radiation, and (ML) Mechanical Load.

| Condition Influence | Notch | Matrix Crack | Fiber Crack | Dl | T | Dt | M | ER | ML |

|---|---|---|---|---|---|---|---|---|---|

| Material Stiffness | ∘ | ∘ | + | ∘ | + | − | + | − | − |

| Mass | − | − | − | − | − | + | + | − | − |

| Damping | − | ∘ | ∘ | ∘ | ∘ | + | ∘ | − | − |

| Material Conductivity | + | ∘ | + | ∘ | ∘ | − | ∘ | ∘ | ∘ |

| Boundary Formation | + | − | − | + | − | ∘ | − | − | − |

Table 4 indicates the review of several studies on the environmental and operational effects on different types of structures. Some further references on this topic include [32][33][34][35].

Table 4. Some references studying the environmental and operational effects.

| Effect | Refs | Description |

|---|---|---|

| Temperature effects | [36] | Vibration tests conducted on five bridges in the UK indicated that bridge responses are sensitive to the structural temperature |

| [37] | The movement of a point in the experimental model with respect to its expected location in the analytical model confirmed a significant expansion of the bridge deck due to the elevated temperature. | |

| [38] | A 5% variation in the first mode frequency of the bridge, during the 24 h cycle, was detected | |

| [39] | The frequency–temperature and displacement–temperature correlations using long-term monitoring data were investigated | |

| [40] | Dempster–Shafer data fusion technique was employed to investigate the correlation between modal data and temperature | |

| [41] | The regression analysis in conjunction with Principal Component Analysis (PCA) was employed to purify natural frequency from the environmental and operational variations effects | |

| [42] | The back-propagation neural network (BPNN)-based approach was employed to clean the identified natural frequencies from temperature effects | |

| Boundary condition effects | [43] | The effect of crack and beam lengths on the natural frequencies was investigated |

| [44] | The changes in the natural frequencies caused by the freezing bridge supports were investigated | |

| Mass loading effects | [45] | It was noted that heavy traffic on a 46 m long, simply supported plate girder bridge decreased the natural frequencies of the bridge by 5.4% |

| [46] | The effect of the traffic mass on the damping ratios becomes evident when the vibration of the deck due to the traffic exceeds a certain level | |

| Wind-induced variation effect | [47] | The alleviated wind velocity can reduce the natural frequency and decrease the modal damping of a suspension bridge |

| [48] | A quadratic function can be established to map the vertical amplitude of the bridge response to the wind speed. It was also noted that the damping ratio is dependent on the vibration amplitude |

References

- Brugo, T.M.; Maccaferri, E.; Cocchi, D.; Mazzocchetti, L.; Giorgini, L.; Fabiani, D.; Zucchelli, A. Self-sensing hybrid composite laminate by piezoelectric nanofibers interleaving. Compos. Part B Eng. 2021, 212, 108673.

- Mukhopadhyay, T.; Naskar, S.; Chakraborty, S.; Karsh, P.; Choudhury, R.; Dey, S. Stochastic oblique impact on composite laminates: A concise review and characterization of the essence of hybrid machine learning algorithms. Arch. Comput. Methods Eng. 2021, 28, 1731–1760.

- Ali, Z.A.A.A.; Kadhim, A.A.; Al-Khayat, R.H.; Al-Waily, M. Review Influence of Loads upon Delamination Buckling in Composite Structures. J. Mech. Eng. Res. Dev. 2021, 44, 392–406.

- Bezzie, Y.M.; Paramasivam, V.; Tilahun, S.; Selvaraj, S.K. A review on failure mechanisms and analysis of multidirectional laminates. Mater. Today Proc. 2021, 46, 7380–7388.

- Rehman, A.; Houshyar, S.; Wang, X. Nanodiamond-Based Fibrous Composites: A Review of Fabrication Methods, Properties, and Applications. ACS Appl. Nano Mater. 2021, 4, 2317–2332.

- Khan, R. Fiber bridging in composite laminates: A literature review. Compos. Struct. 2019, 229, 111418.

- Boursier Niutta, C.; Tridello, A.; Paolino, D.S.; Belingardi, G. Residual Properties in Damaged Laminated Composites through Nondestructive Testing: A Review. Materials 2021, 14, 4513.

- Luo, Y. Isotropized Voigt-Reuss model for prediction of elastic properties of particulate composites. Mech. Adv. Mater. Struct. 2021, 28, 1–13.

- Pastorino, D.; Blázquez, A.; López-Romano, B.; París, F. Closed-form methodology for the bending of symmetric composite plates with cutouts and non-uniform lay-up. Compos. Struct. 2021, 271, 114052.

- Kumar, A.P.; Anilkumar, P.; Haldar, A.; Scheffler, S.; Jansen, E.; Rao, B.; Rolfes, R. Tailoring bistability in unsymmetrical laminates using an additional composite strip. Thin-Walled Struct. 2021, 168, 108212.

- Rajan, G.; Prusty, B.G. Structural Health Monitoring of Composite Structures Using Fiber Optic Methods; CRC Press: Boca Raton, FL, USA, 2016.

- Cardarelli, F. Materials Handbook; Springer: Berlin/Heidelberg, Germany, 2018.

- Peters, S.T. Handbook of Composites; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013.

- Senthilkumar, M.; Sreekanth, T.; Manikanta Reddy, S. Nondestructive health monitoring techniques for composite materials: A review. Polym. Polym. Compos. 2021, 29, 528–540.

- Nsengiyumva, W.; Zhong, S.; Lin, J.; Zhang, Q.; Zhong, J.; Huang, Y. Advances, limitations and prospects of nondestructive testing and evaluation of thick composites and sandwich structures: A state-of-the-art review. Compos. Struct. 2021, 256, 112951.

- Venkatesan, K.; Stoumbos, T.; Inoyama, D.; Chattopadhyay, A. Computational analysis of failure mechanisms in composite sandwich space structures subject to cyclic thermal loading. Compos. Struct. 2021, 256, 113086.

- Zhang, P.; Feng, Y.; Bui, T.Q.; Hu, X.; Yao, W. Modelling distinct failure mechanisms in composite materials by a combined phase field method. Compos. Struct. 2020, 232, 111551.

- Mardanshahi, A.; Nasir, V.; Kazemirad, S.; Shokrieh, M. Detection and classification of matrix cracking in laminated composites using guided wave propagation and artificial neural networks. Compos. Struct. 2020, 246, 112403.

- Fakoor, M. Augmented strain energy release rate (ASER): A novel approach for investigation of mixed-mode I/II fracture of composite materials. Eng. Fract. Mech. 2017, 179, 177–189.

- Machado, C.M.; Silva, D.; Vidal, C.; Soares, B.; Teixeira, J.P. A new approach to assess delamination in drilling carbon fibre-reinforced epoxy composite materials. Int. J. Adv. Manuf. Technol. 2021, 112, 3389–3398.

- Bak, B.L.; Sarrado, C.; Turon, A.; Costa, J. Delamination under fatigue loads in composite laminates: A review on the observed phenomenology and computational methods. Appl. Mech. Rev. 2014, 66, 060803.

- Liu, P.; Zheng, J. Recent developments on damage modeling and finite element analysis for composite laminates: A review. Mater. Des. 2010, 31, 3825–3834.

- Galos, J. Thin-ply composite laminates: A review. Compos. Struct. 2020, 236, 111920.

- Zimmermann, N.; Wang, P.H. A review of failure modes and fracture analysis of aircraft composite materials. Eng. Fail. Anal. 2020, 115, 104692.

- Gorgin, R.; Luo, Y.; Wu, Z. Environmental and operational conditions effects on Lamb wave based structural health monitoring systems: A review. Ultrasonics 2020, 105, 106114.

- Wen, T.; Ratner, A.; Jia, Y.; Shi, Y. Parametric Study of Environmental Conditions on The Energy Harvesting Efficiency for The Multifunctional Composite Structures. Compos. Struct. 2021, 255, 112979.

- Min, R.; Liu, Z.; Pereira, L.; Yang, C.; Sui, Q.; Marques, C. Optical fiber sensing for marine environment and marine structural health monitoring: A review. Opt. Laser Technol. 2021, 140, 107082.

- Budhe, S.; Banea, M.; De Barros, S. Bonded repair of composite structures in aerospace application: A review on environmental issues. Appl. Adhes. Sci. 2018, 6, 1–27.

- Amsc, N.; CMPS, A.A. Polymer Matrix Composites Materials Usage, Design, and Analysis In Composite Materials Handbook; SAE International: Warrendale, PA, USA, 2002.

- Tsai, S.W.; Hahn, H.T. Introduction to Composite Materials; Routledge: London, UK, 2018.

- Clyne, T.W.; Hull, D. An introduction to composite materials; Cambridge University Press: Cambridge, UK, 2019.

- Mousavi, M.; Gandomi, A.H.; Wahab, M.A. Structural damage identification under non-linear EOV effects using genetic programming. In Proceedings of the Genetic and Evolutionary Computation Conference Companion, Lille, France, 10–14 July 2021; pp. 317–318.

- Mousavi, M.; Gandomi, A.H. Deep learning for structural health monitoring under environmental and operational variations. In Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure, and Transportation XV; International Society for Optics and Photonics: Bellingham, WA, USA, 2021; Volume 11592, p. 115920H.

- Mousavi, M.; Gandomi, A.H. Structural health monitoring under environmental and operational variations using MCD prediction error. J. Sound Vib. 2021, 512, 116370.

- Mousavi, M.; Gandomi, A.H. Prediction error of Johansen cointegration residuals for structural health monitoring. Mech. Syst. Signal Process. 2021, 160, 107847.

- Wood, M.G. Damage Analysis of Bridge Structures Using Vibrational Techniques. Ph.D. Thesis, Aston University, Birmingham, UK, 1992.

- Moorty, S.; Roeder, C.W. Temperature-dependent bridge movements. J. Struct. Eng. 1992, 118, 1090–1105.

- Farrar, C.R.; Doebling, S.W. An Overview of Modal-Based Damage Identification Methods; Office of Scientific and Technical Information: Washington, DC, USA, 1997.

- Askegaard, V.; Mossing, P. Long term observation of RC-bridge using changes in natural frequency. Nord. Concr. Res. 1988, 20–27. Available online: http://pascal-francis.inist.fr/vibad/index.php?action=getRecordDetail&idt=7253872 (accessed on 20 December 2021).

- Yang, D.; Youliang, D.; Aiqun, L. Structural condition assessment of long-span suspension bridges using long-term monitoring data. Earthq. Eng. Eng. Vib. 2010, 9, 123–131.

- Bao, Y.; Xia, Y.; Li, H.; Xu, Y.L.; Zhang, P. Data fusion-based structural damage detection under varying temperature conditions. Int. J. Struct. Stab. Dyn. 2012, 12, 1250052.

- Magalhães, F.; Cunha, Á.; Caetano, E. Vibration based structural health monitoring of an arch bridge: From automated OMA to damage detection. Mech. Syst. Signal Process. 2012, 28, 212–228.

- Zhou, H.; Ni, Y.; Ko, J. Constructing input to neural networks for modeling temperature-caused modal variability: Mean temperatures, effective temperatures, and principal components of temperatures. Eng. Struct. 2010, 32, 1747–1759.

- Cawley, P. Long range inspection of structures using low frequency ultrasound. In Structural Damage Assessment Using Advanced Signal Processing Procedures; University of Sheffield: Sheffield, UK, 1997; pp. 1–17.

- Alampalli, S. Influence of in-service environment on modal parameters. Proc. SPIE 1998, 1, 111–116.

- Kim, C.; Kim, N.; Yoon, J.; Jung, D. Effect of vehicle mass on the measured dynamic characteristics of bridges from traffic-induced vibration test. Proc. SPIE 2001, 2, 1106–1111.

- Zhang, Q.; Fan, L.; Yuan, W. Traffic-induced variability in dynamic properties of cable-stayed bridge. Earthq. Eng. Struct. Dyn. 2002, 31, 2015–2021.

- Abe, M.; Fujino, Y.; Yanagihara, M.; Sato, M. Monitoring of hakucho suspension bridge by ambient vibration measurement. In Proceedings of the Nondestructive Evaluation of Highways, Utilities, and Pipelines IV, Newport Beach, CA, USA, 6–8 March 2000; International Society for Optics and Photonics: Bellingham, WA, USA, 2000; Volume 3995, pp. 237–244.

More

Information

Subjects:

Engineering, Civil

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

6.4K

Revisions:

3 times

(View History)

Update Date:

28 Mar 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No