Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Petter Kyösti | + 2498 word(s) | 2498 | 2022-01-21 07:12:49 | | | |

| 2 | Jason Zhu | Meta information modification | 2498 | 2022-01-24 04:30:11 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kyösti, P. SOA-Based Platform Example. Encyclopedia. Available online: https://encyclopedia.pub/entry/18620 (accessed on 07 February 2026).

Kyösti P. SOA-Based Platform Example. Encyclopedia. Available at: https://encyclopedia.pub/entry/18620. Accessed February 07, 2026.

Kyösti, Petter. "SOA-Based Platform Example" Encyclopedia, https://encyclopedia.pub/entry/18620 (accessed February 07, 2026).

Kyösti, P. (2022, January 21). SOA-Based Platform Example. In Encyclopedia. https://encyclopedia.pub/entry/18620

Kyösti, Petter. "SOA-Based Platform Example." Encyclopedia. Web. 21 January, 2022.

Copy Citation

There are considerable potential to save engineering effort, time and costs during the life-cycle of professional automation systems if using a SOA-based architecture supporting microservices as part of the platform baseline.

SOA-Based Platform

Architecture

Case

micro services

automation systems

life-cycle

development operation & maintenance

monolith

1. A High-Level Architecture Overview of an Example SOA-Based Platform

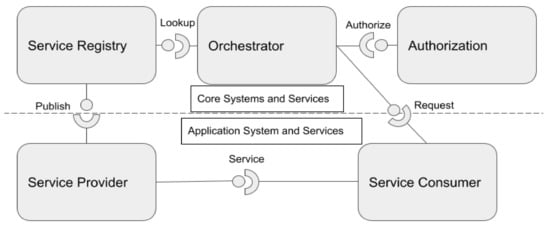

Below, there is an example of how an SOA-based platform, also based on microservices, can be embodied in terms of overall architecture and its main components, and relations in between these. Figure 1 outlines the overall architecture of the Arrowhead Framework [1]. The overall architecture encompasses a small number of necessary core systems and services, including an authorization system (for users and services), a service registry (where services can be registered and looked up), and an orchestration system (in order to maintain system connections). Further, there is an application systems and services part, which comprises the actual business logic and provisioning, which differ for each context. In addition, the SOA principle is based on the foundation of the three Ls: Lookup (discover/set presence), Loosely coupled (autonomies and distributed components), and Late binding (dynamic system of system compositions) supported by strictly defined service contracts and architectural methods.

Figure 1. Outline of general architecture—Arrowhead Framework.

A service can be a provider, consumer or both a provider and consumer. The service registry enables selection of the desired service from a range of many similar services. However, firstly, the orchestrator manages the system connection and ensures that there is an authorization to use the service wanted. If wanted, a minimum cybersecurity requirement baseline, such as authentication level and encryption algorithm with key length, can be part of the authorization scheme or else disqualify the service request connection.

2. Results from the Five Cases—Visualization with Summary of Improvements

The results from the case study and its five cases, plus a summary of the improvements perceived, are visualized in Table 2 in order to provide a comprehensive overview. Additional details on the results are available in the following subsections. Within Table 2, an “x” means the case finds significant improvements during that phase of the lifecycle. Further, an “o” is the same as an “x” but multiple use cases can be part of this entry.

Table 2. Visualization of results and summary of improvements.

| Phase of Lifecycle/Case | Arrowhead Tools (Multiple Use Cases) | LKAB | Sinetiq AB | Smart Recycling AB | ThingWave AB |

|---|---|---|---|---|---|

| Business development | x | x | x | x | |

| Requirement engineering | x | ||||

| Design | o | x | x | x | |

| Development | o | x | x | x | |

| Piloting/early test at customers | o | x | x | x | |

| Test/QA | o | x | x | x | |

| Procurement (with customization) | x | ||||

| Installation/Commissioning | o | x | x | x | |

| Operations (with maintenance and upgrades) | x | x | x | x | |

| De-commissioning, repurposing, down-cycling or re-cycling etc. | |||||

| Improvement | The results are from an RDI project, and the minimum requirement was a time improvement of 20–50% concerning the specific part/phase—which was surpassed by most of the use cases. The exceptional use cases had improvements of 83% and 96% for their limited part of the lifecycle. Thus, in general, there were time improvements of at least 50% | Do not have any hard numbers yet, but will get more agile, add more value to processes faster and “we do not want to go back again to 1-to-1 integrations!” | The development time decreases with a magnitude (e.g., what took hours takes minutes, what took weeks takes days, and what took years takes months) | Based on 6 larger development projects—50–75% improvement in effort from using the SOA-based platform approach with changed development processes/practices | General improvement from business development to end of test/QA is 1:4, i.e., about 75% time/effort improvement. Concerning the operations with maintenance and upgrades, the more extensive installation it is, the more improvement there will be. Thus, the time/effort improvement numbers scale beneficially with the number of sensors and actuators, etc. |

Thus, the use of the SOA-based platforms varies somewhat among the cases, depending on the focus and targeted problems. However, using pattern matching [2], it is clear that the companies who develop solutions/products, etc., find that there is a clear and significant benefit during the following phases: business development, design/development/piloting/test, installation/commissioning, and operations. LKAB, a mining company, sees the main benefits at the start and end of the lifecycle, where LKAB also gets the most value due to the fact that the length of the operations phase is commonly the longest phase of the lifecycle. Arrowhead Tools, which is a different being compared to the other case organizations, places more focus on the engineering phases of the lifecycle, as well as on the following operations phase. All cases except LKAB, which has yet not measured any hard data concerning improvements, indicates that there is an overall minimum improvement of approximately 50% and, on the upper side, a change in magnitude. In addition, although without any hard data to support the views, LKAB states that “we do not want to go back again to 1-to-1 integrations!” which supports the contention that there is a clear benefit/improvement from using an SOA-based platform supporting microservices.

3. Additional Details on the Results from the Arrowhead Tools Case (Comprising More Than 30 Use Cases)

The Arrowhead Tools project continues to add necessary tools to the Arrowhead Framework to enable more companies and organizations to use the Arrowhead Framework (platform) while building and operating automation solutions of various kinds where security, integrations, and interoperability between systems-of-systems are key for success. During the project, comprising more than 30 relevant use cases, the focus has been to use the Arrowhead Framework to build various tools to increase the usability and enable more organizations and companies to use the platform. The areas of interest have been mainly the 4 development-related phases (i.e., “engineering work”) and the operations phase later on. The measurements and estimated improvements have been recorded in two project deliverables and show, overall, very promising results. However, to be able to achieve the results, there is an investment required in skills and competencies to be able to understand the concept, how to further develop it, and how to best use it during the whole lifecycle. Nevertheless, if the investment is made, it seems like the ones who have started do not want to go back to the old traditional way of development of automation solutions or to integrate various types of systems. As the use cases have spanned a number of manufacturing and process industries, e.g., manufacturing and production of vehicles, bearings, semiconductors, and consumer products, the generalizability level of the Arrowhead Framework (platform) with the new tools is deemed as high.

4. Additional Details on the Results from the LKAB Case

LKAB develops its own SOA-based platform, LOMI, with functionalities such as: message bus, container environment, and integration services (with low code integration), more with the intent to get real-time access to (streaming) data from the mining processes for exchange with other processes and for management decision-support purposes. The intent is to follow the main industrial standards and thus increase interoperability to connected mining equipment and software solutions from third parties. The SOA-based LOMI and standards provide loose binding, such as work-order systems that can be independent of the maintenance system used and to ensure that there is the flexibility of having systems on premise, in the cloud or in hybrids of these. One of the main benefits of LOMI is that LKAB can be more agile and can make changes and add additional requirements/functionality “as the show goes on”, and add more value to the processes faster. Cloud technology, model-based development, design-by-contract, and increased use of modeling/simulations are supporting improvements from LOMI as well. LKAB considers that the quality of data will be of paramount importance, as more and more is based on data at the same time as software increasingly takes over functionality from hardware. In the future, LKAB wants all hardware and software added to the work processes to be “Internet or IoT-ready” in terms of plug-and-play, security, safety, secure updates of software, self-configuration, fleet management, etc. As LKAB procures a lot of software and hardware, LKAB has started to require, instead of monoliths, that the architecture is future-proofed by using SOA principles and microservices in order to avoid costly and time-consuming changes and integrations. To facilitate all this, LKAB will transform the IT/OT-infrastructure for preparing additions of the Internet/IoT-ready hardware and software to come. LKAB anticipates that most benefits/improvements will be realized in the operations phase where maintenance and upgrades are made continuously, and where improved availability and less testing are efficiency boosters for the mining processes. Here, it is also necessary to keep the hardware/software/service providers data apart and also secure LKAB’s own data. All the above, together with an increasing use of digital twins enabled, will make it easier to change and make additions to the mining processes.

5. Additional Details on the Results from the Sinteq AB Case

Sinetiq AB has made its own cloud service/IoT platform, based on ideas and concepts from the Arrowhead Framework, but is not limited to using only this. The main problems addressed in customer cases are to help customers to get more SOA-ified, gain control of the present and future needs, and eventually, to meet the future with more flexibility and agility. Examples of applications and integrations built on the platform include: vehicle part manufacturing process, sensor information systems, sensor intelligence systems, integration of monolith systems with other systems, verification, and compliance tool for integrations and products. The main benefits can be seen in the ability to make advanced prototypes for customer integration problems really quickly (i.e., a magnitude faster than with traditional 1-to-1 integrations), and then to smoothly replace the prototypes with the real integrations with desired level of quality. The use of microservices enables de-coupling and thus, faster development and later changes as well as an efficient modeling for calculating the allocation of processing power to meet customer requirements concerning speed and availability. In addition, the increased flexibility enables the mixing of own components/services with off-the-shelf or customized ones from third parties. The possibility for rapid prototyping and agility in development are important factors in early business development, as a few examples can be realized, and then the customers learn the difference compared to the use of monoliths and the problems related to such. Sinetiq AB sees the initial documentation of interfaces and service definitions as the foundation for the subsequent efficient development-related phases, where development and tests get streamlined and only need to focus on what has been changed and the dependencies thereof. This also makes it very efficient to integrate to one or many systems at the same time. Sinetiq AB plans to augment the platform with components to monitor flow through services/nodes to measure if sufficient or when quality is too low, and also develop test tools with digital twins and simulation possibilities for services. Sinetiq AB considers that a system will never get finalized, and trying to make it all perfect from the start is not feasible and thus, it is better to build it piece by piece and continuously improve these pieces.

6. Additional Details on the Results from the Smart Recycling AB Case

Smart Recycling AB has made its own cloud service/IoT platform, based on ideas and concepts from the Arrowhead Framework, and uses it, for instance, to build the service of measuring and trending the filling level of recycling containers for glass, metals, plastics, and paper, spanning from the sensors deployed, communications, security, data collection and analysis, and visualization of data and results. The visualization provides decision-making support to operators responsible for emptying the recycling containers before they become overfilled or to not empty them until properly filled up. Data mining employed enables operators to further understand the filling variations/patterns during a year when there is a frequent need or less frequent need to empty the containers. Some lessons learned from the development are that the strict rule to define service contracts/definitions combined with faster development has made the company competitive. In addition, the fleet management functionality, the capacity to manage mass-deployed sensors over vast geographical areas, continuous improvements to remove complexity and build in everything necessary into the sensor package, have streamlined it all further. Some of the issues overcome were related to: efficient infrastructure, getting the mobile communications to work on a long-term basis (low battery consumption at end points), to find new skilled employees, and to develop existing employees to acquire the required skills and competencies. Additional tough challenges to overcome were to redefine the work processes (from traditional development and business development to agile) and to set up service/support for national/international coverage along with finding a sustainable business model.

7. Additional Details on the Results from the Thingwave AB Case

ThingWave AB has made its own IoT platform, based on ideas and concepts from the Arrowhead Framework, and uses it to build a number of customer offerings regarding remote monitoring and management of industrial processes and critical infrastructures. Examples of offerings are ground support monitoring (IoT enabled rock bolts and seismic sensing for underground cavities), digital twins, smart ventilation, and condition monitoring for industrial machinery. The investment made in the development of the IoT platform has been significant for an SME, but now it pays off in terms of business development wins where prototypes and integrations between systems can be shown to work with about 25% of the effort expected by customers. The development phases are also considerably faster by using strict service descriptions, microservices, and new own developed communications protocols for fast and efficient sensor communication in order to reduce power consumption and improve data rate. This also enables connection of machines and equipment not yet connected (having communications interfaces) to remote monitoring and management. ThingWave AB uses more and more IT-equipment in OT-environments (production and distribution), which is a benefit due to lower prices, and these are faster/easier to replace than vendor-specific OT-equipment. Thus, ThingWave AB is not interested in going back to traditional hard-coded development and integrations with hard dependencies to vendor-specific OT-equipment or systems. The agile process and microservices are a great benefit, as customers can, after a prototype is working, quickly replace it with a newly tested and verified microservice, which is put into production, due to the isolation and limited dependencies to others. Thus, the test and verification effort (i.e., quality assurance) has also been speeded up, and fewer bugs slip through and are faster to rectify if needed. Regarding the installation/commissioning and operations phases, it is within these areas that ThingWave AB sees the greatest potential to streamline the efforts required in terms of hands-on activities, and to operate and maintain an automation solution and its integrations. Remote monitoring and fleet management functionality, such as: plug-and-play, self-configuration, group configurations, secure upgrading of software, etc., all reduce the need to walk around a mine, mill or factory in order to ensure that all software and configurations are up-to-date and working.

References

- Arrowhead Framework. Available online: https://www.arrowhead.eu/eclipse-arrowhead (accessed on 8 December 2021).

- Miles, M.; Huberman, M. An Expanded Sourcebook—Qualitative Data Analysis, 2nd ed.; Sage Publications: Thousand Oaks, CA, USA, 1994.

More

Information

Subjects:

Engineering, Manufacturing

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

878

Revisions:

2 times

(View History)

Update Date:

24 Jan 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No