Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Soumya Sarang | + 2366 word(s) | 2366 | 2021-12-15 10:26:00 | | | |

| 2 | Vicky Zhou | Meta information modification | 2366 | 2022-01-20 02:02:38 | | | | |

| 3 | Vicky Zhou | + 4 word(s) | 2370 | 2022-01-30 08:30:31 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Sarang, S. Optical Parametric Oscillators and Raman Lasers. Encyclopedia. Available online: https://encyclopedia.pub/entry/18509 (accessed on 07 February 2026).

Sarang S. Optical Parametric Oscillators and Raman Lasers. Encyclopedia. Available at: https://encyclopedia.pub/entry/18509. Accessed February 07, 2026.

Sarang, Soumya. "Optical Parametric Oscillators and Raman Lasers" Encyclopedia, https://encyclopedia.pub/entry/18509 (accessed February 07, 2026).

Sarang, S. (2022, January 19). Optical Parametric Oscillators and Raman Lasers. In Encyclopedia. https://encyclopedia.pub/entry/18509

Sarang, Soumya. "Optical Parametric Oscillators and Raman Lasers." Encyclopedia. Web. 19 January, 2022.

Copy Citation

Optical parametric oscillators (OPOs) and Raman lasers are two nonlinear-based laser technologies that extend the spectral range of conventional inversion lasers. Power and brightness scaling of lasers are significant for many applications in industry, medicine, and defense. Considerable advances have been made to enhance the power and brightness of inversion lasers.

optical parametric oscillators

diamond Raman lasers

power scaling

brightness scaling

1. Introduction

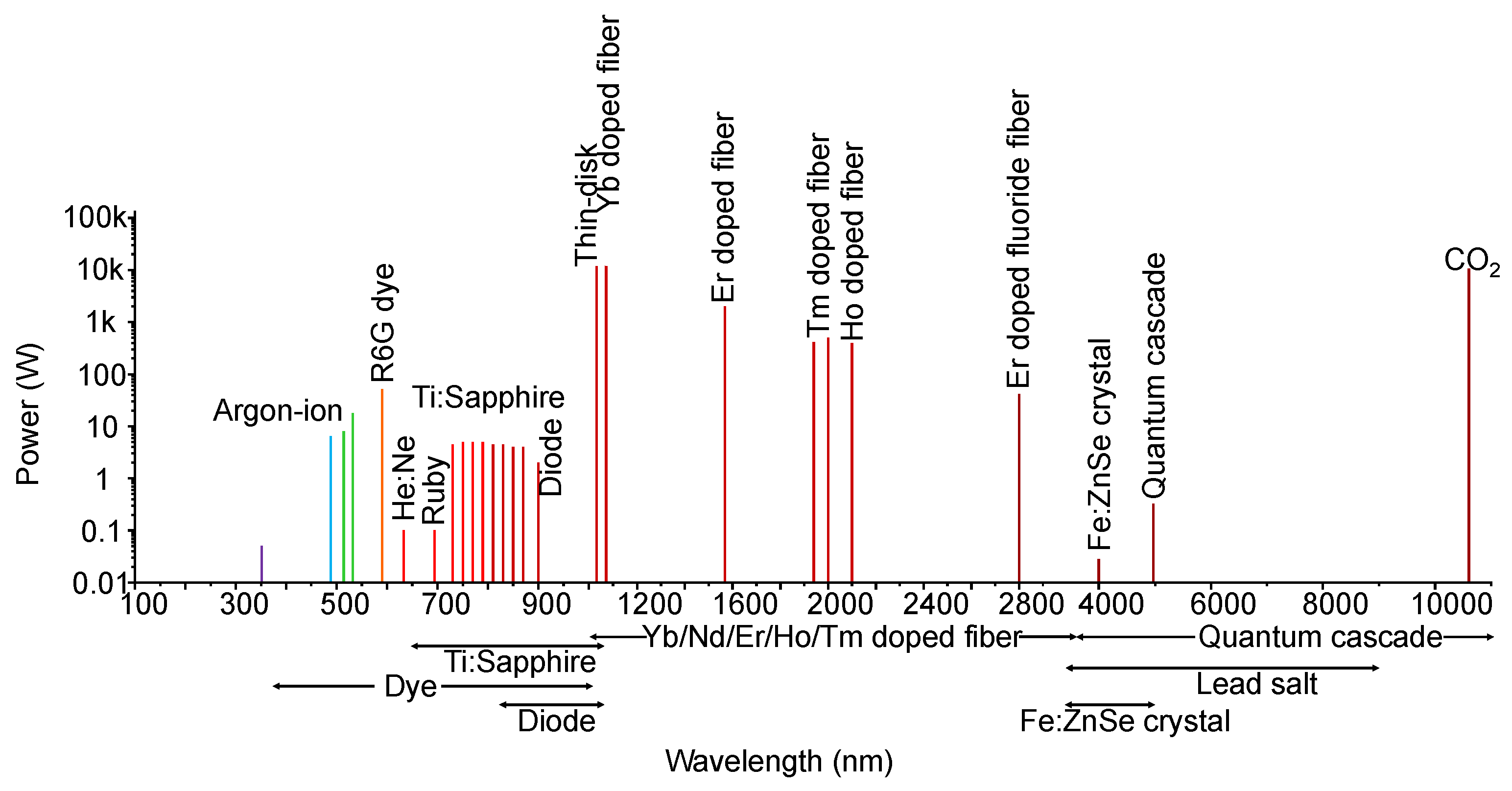

The wavelengths generated by inversion lasers are determined by energy level transitions in the gain material. These, and the availability of suitable efficient pumping manifolds, restrict the output of these lasers to specific bands of wavelengths, leaving “gaps” in the electromagnetic spectrum where no efficient inversion lasers have yet been demonstrated. Figure 1 illustrates such gaps in the blue region (400–440 nm), yellow-orange-red wavelengths (550–650 nm) in the visible region, and various regions of the infrared [1][2].

Figure 1. Wavelength and power of available inversion lasers.

Ion-lasers, Ti: Sapphire, dye, and semiconductor diode lasers are the most common commercially available continuous-wave (CW) lasers used for the visible spectral range [3][4][5][6][7][8][9]. However, the output power of single-laser sources is mostly limited to tens of watts. In near-IR spectral range from 1 to 2.5 µm, thin-disk lasers and rare earth doped-fiber lasers (such as ytterbium (Yb), erbium (Er), thulium (Tm), holmium (Ho)) are the prominent light sources providing extremely high powers with nearly diffraction-limited beam quality [10][11][12][13][14][15][16][17]. A Yb:YAG single-disk has delivered about 12 kW of CW output power at 1030 nm [13], whereas a single Yb-doped fiber has achieved about 6 kW of output power [18]. IPG Photonics offers commercial Yb-doped single-mode fiber of about 10 kW at 1074 nm with a beam quality of M2 = 1.05 [19]. Despite the availability of exceedingly powerful laser sources, there are still significant voids in this spectral region, particularly the “eye-safe” wavelengths from 1.4 to 1.8 µm. It is also evident from the figure that there are fewer sources catering to UV and mid-IR regions. The current mid-IR light sources are quantum-cascade semiconductor lasers, lead salt lasers, lasers doped with trivalent rare-earth ions, Cr:ZnS(e) and Fe:ZnS(e) lasers [20][21][22][23]. However, these lasers are limited in their spectral tunability, output power, and low beam quality.

The lack of efficient sources with wavelengths in these regions is significant for applications in many diverse areas such as in medical laser therapy, laser guide stars, directed energy, defense, remote sensing, LIDAR, optical communications, and material processing etc., [24][25][26][27][28]. Many of these applications require light sources with high output power, good beam quality, and minimal divergence. For example, free-space optical-communications, LIDAR, and remote sensing applications demand broad wavelength-tunable lasers to probe a wide range of molecules with different absorption peaks. Additionally, these lasers should have high optical power, good beam quality with minimum divergence to achieve high signal to noise ratio while covering large distances. Directed energy weapons necessitate high power lasers as high as 1 to multiple-100 kW depending on their operational impact [29]. Material processing applications such as cutting, welding, or drilling on metals require multi-kW output powers with moderate beam quality. On the other hand, drilling fine holes, remote welding, engraving, and micromachining require good beam quality for marking, high precision and high-value structures [30]. In many cases, these applications would benefit from sources at specific wavelengths, some of which, at present do not commercially exist. In addition to producing these inaccessible wavelengths, the sources for these applications need to be robust, stable, and amenable to power scaling.

Usually, enhancement of output power has been hindered by thermally induced effects in the gain medium such as stress, fracture, birefringence, and lensing in the laser material [31][32]. Another constraint of power scaling is preserving the brightness while elevating output power. Brightness is defined as the laser power divided by the product of beam mode area and solid angle of divergence. Higher brightness implies that the laser beam has high beam quality, minimal beam divergence, long focus field, and high power density [33]. Therefore, for applications requiring high-precision and accuracy, it is imperative that the brightness of lasers is simultaneously scaled with output power. However, in most lasers, one parameter has to be sacrificed for the improvement of the other. Thus, it is important to investigate the potential for increasing beam brightness for laser technologies.

Non-linear optics, in the form of second harmonic generation (and its derivatives of higher harmonics) [34], sum- and difference-frequency generation [35][36], parametric amplifiers [37], and stimulated Raman scattering (SRS) [38] help fill in some of the “gaps” in the spectrum, but with increased complexity and reduced efficiency [39][40][41]. OPOs and Raman lasers are two common sources that utilize nonlinear optical processes to access new spectral regions of interest. Sometimes, these lasers can employ other nonlinear processes such as frequency doubling and tripling, sum and difference frequency generation to access more wavelengths [42]. OPOs are attractive coherent light sources for producing narrow-linewidth, broadly tunable wavelengths from visible to the mid-IR [43][44][45][46]. Owing to thermal lensing in the gain media, these lasers were able to generate continuous-wave (CW) output power ranging from milliwatts to watts [43][47]. On the other hand, Raman lasers provide a practical alternative to OPOs as they do not require birefringent crystals or quasi-phase-matching conditions [48]. They are also efficient frequency converters generating high CW output powers and high brightness [49][50][51]. Recently, a quasi-CW diamond Raman laser (DRL) delivered 1.2 kW of output power at 1240 nm [52].

This review examines and compares the power scalability potential of Raman lasers with OPOs, the latter being an already mature and commercially available laser technology. We provide a short summary of the underlying gain process enabling these nonlinear frequency converters. We also analyze the cavity configurations of these lasers to evaluate the feasibility of these architectures for power scaling. The subsequent section reviews the stages of development in high-power CW OPOs and Raman lasers to identify the limiting effects in upscaling power. Furthermore, we summarize the evolution of these lasers in terms of brightness enhancement. Lastly, we will discuss why DRLs offer a strong potential to be a highly efficient and high brightness frequency converter.

2. Material Properties of OPO and Raman Crystals

In order to understand why specific crystalline nonlinear lasers worked much better than others, we need to investigate further the material properties of the gain media used.

The performance of OPOs depends on nonlinear optical (NLO) coefficients, transparency range and optical damage thresholds. In order to bring the CW lasing threshold to acceptable powers, a crystal with a large gain coefficient is required that can induce substantial nonlinearity at relatively low pump powers. It is also necessary that the crystal is highly transparent at the pump and output wavelengths. Moreover, a high optical damage threshold is essential for the crystal when scaling at higher powers.

The most popular crystal of choice for CW operation of OPOs is lithium niobate (LiNbO3, LN) owing to its large nonlinearity of 17.6 pm/V and wide acceptance angle in quasi-phase matched condition. However, its use in OPOs was reduced, as its low optical damage threshold and higher sensitivity to photorefractive damage adversely affected the performance of the lasers [53]. A solution to increase photorefractive damage was to heat the crystal but it led to a change in phase-matching, thereby complicating the cavity setup. Another method to eliminate the damage was by doping the crystal with MgO [53]. However, doping affected the crystal quality.

The development of periodically poled lithium niobate (PPLN) provided advantages over LN for OPOs. It enabled high gain, large effective nonlinear coefficient, and no spatial walk-off. It also made the crystal less susceptible to photorefractive damage. However, its coercive field is 21 kV/mm, which limited the crystal’s thickness to approximately 0.5 mm [54].

Borate-based crystals such as β-barium borate (BaB2O4, BBO) and lithium triborate (LiB3O5, LBO) were most commonly used for OPOs because of their moderate nonlinear coefficient, mechanical hardness, chemical stability, and high optical damage threshold [55][56]. They transmitted far into the ultraviolet spectrum than any other crystals. Furthermore, these crystals do not suffer from photorefractive damage. LBO provided an additional benefit over BBO as it enabled temperature tuning for non-critical phase matching resulting in a simple cavity alignment. Moreover, it has a smaller spatial walk-off angle. However, due to their lower nonlinear coefficients compared to other crystals, they were preferred for pulsed operation.

Potassium titanyl phosphate (KTiOPO4, KTP) is another commonly used gain crystal. It has a high nonlinear coefficient of 16.9 pm/V, a high optical damage threshold, and lower sensitivity to photorefractive effect [57][58]. It has a wide transparency range from ultraviolet to the mid-IR range with strong absorption at 2.8 and 3.4 µm. Moreover, another benefit of using the crystal is the easy attainment of the phase-matching through temperature tuning. Moreover, its low coercive field of 2 kV/mm allowed poling of thicker crystals [58]. Thus, KTP crystals of several millimeters (as large as 3 mm) are suitable for poling and consequently higher power generation [59]. Table 1 lists some important properties of popular nonlinear materials used for OPOs.

Table 1. Comparison of material properties of OPO crystals.

| Properties at Room Temperature | LBO [56] | LN [60] | KTP [57][58] | BBO [56] |

|---|---|---|---|---|

| Crystal structure | Orthorhombic | Trigonal | Orthorhombic | Trigonal |

| Optical transparency (µm) |

0.16–2.6 | 0.33–5.5 | 0.35–4.5 | 0.19–3.5 |

| NLO coefficients 1 (pm/V) | 1.02, 0.057, −0.95 |

5.7, 5.3, 17.6 |

1.9, 3.6, 2.5, 4.4, 16.9 |

2.3, −0.16 |

| Thermal conductivity (W/mK) | 3.5 | 5 | 2, 3, 3.3 2 |

1.2 |

| Thermal expansion coefficient 2 (10−5 K−1) |

10.8, −8.8, 3.4 |

0.2, 0.22 |

1.1, 0.9, 0.06 |

0.4, 3.6 |

| Thermo-optic coefficient (10−6 K−1) |

−9.3, −13.6 |

−0.87, 39.1 |

11, 13, 16 |

−9.3, −16.6 |

1 values for different susceptibility tensor elements dil; 2 values for principal axes.

In addition to the desirable properties discussed in OPO gain crystals, a Raman gain crystal should also possess good thermal properties. This is due to the fact that SRS is an inelastic nonlinear process and hence, there is heat deposition in the medium.

The initial popular choices for Raman crystals were barium nitrate, double tungstate crystals (such as KGW, KYW). Barium nitrate was selected as the gain medium for the first-ever CW external cavity Raman laser owing to its very high Raman gain coefficient [61]. But it has many disadvantages. It is hygroscopic and has a moderate optical damage threshold [62]. Furthermore, its low thermal conductivity limited the conversion efficiency of Raman lasers.

On the other hand, the thermal conductivity and transparency range of double tungstate crystals is better than barium nitrate. Additionally, its mechanical hardness and high optical damage threshold promote its use in Raman lasers. But it has a low Raman gain coefficient which constricts its implementation to mostly CW intracavity configuration. Moreover, the presence of several Raman modes also adversely affected the CW laser efficiency [63].

Another crystal that has a Raman gain coefficient comparable with barium nitrate is diamond. It possesses intrinsically extraordinarily high thermal conductivity, low thermal expansion, and high levels of hardness leading to high optical damage thresholds [64]. The combination of high gain coefficient and high damage threshold made it an outstanding candidate for realizing external cavity configurations.

With high optical transmissivity in the UV, visible, and mid-IR, its pure crystalline nature leads to low densities of microscopic scattering centers within the material resulting in low optical absorption losses, low birefringence and, unlike most doped oxide laser materials, high degrees of optical uniformity [49][65]. High quality diamond surfaces have been used for a number of industrial processes with the new availability of bulk single-crystalline diamond [66]. This form of diamond, fabricated by chemical vapor deposition (CVD) is the bedrock for the development of DRLs [67].

The primary challenge for using this crystal was its high birefringence and optical absorption [65]. Despite diamond being an optically isotropic crystal, it is susceptible to birefringence owing to the strain from grown-in defects during the CVD process [67][68]. Nitrogen impurities are responsible for optical absorption. The new advances in CVD technology led to the synthesis of high-optical-quality single-crystal diamonds with ultra-low birefringence and absorption coefficient. The Raman-grade diamond crystals manufactured by Element Six Ltd. have nitrogen impurities and absorption coefficients of approximately 20–40 ppb and 0.001–0.004 cm–1 (at 1064 nm), respectively [67]. It has a birefringence of typically <10–5 (in the visible and near-infrared range) perpendicular to the growth direction.

Table 2 summarizes some important properties of popular Raman crystals.

Table 2. Comparison of material properties of Raman crystals [64].

| Properties at Room Temperature | Diamond | BN | KGW | KYW [69][70] |

|---|---|---|---|---|

| Crystal structure | Cubic | Cubic | Monoclinic | Monoclinic |

| Optical transparency (µm) | 0.23–100 | 0.3–1.8 | 0.3–5 | 0.34–5.5 |

| Raman shift (cm−1) | 1332.3 | 1047.3 | 901, 768 1 |

905, 765 1 |

| Raman gain coefficient (cm/GW, @1064 nm) | 10 [71] | 11 | 3.3, 4.4 1 |

3.6, 3.6 1 |

| Raman linewidth FWHM (cm−1) | 1.5 | 0.4 | 7.8, 5.9 1 |

6–8 |

| Thermal conductivity (W/mK) | 2000 | 1.2 | 2.6, 3.8, 3.4 2 |

3.3 3 |

| Thermal expansion coefficient (10−6 K−1) | 1.1 | 13 [72] | 1.6–8.5 [73] | 2–8.5 [73] |

| Thermo-optic coefficient (10−6 K−1) | 15 | 20 | 0.4 | 0.4 |

1 values for two main Raman phonon modes; 2 values for three principal axes. 3 averaged over three principal axes.

3. Conclusions and Future Outlook

Thermal loading in the gain crystal was a critical challenge in the power scaling of OPOs and Raman lasers. However, in DRLs, this issue manifested only when output power exceeded the kilowatt level. They also exhibited the potential for extending the brightness range through their superior power handling capacity.

In conclusion, even though the OPOs are a mature nonlinear laser technology and more readily and commercially available, the path forward for power and brightness enhancement lies in the DRL technology.

Although the kilowatt demonstration of quasi-CW DRL witnessed thermal effects in the diamond crystal, the authors have not specified any material-cooling techniques in the paper. This raises an important question that is, how much power could be generated by the DRL with proper thermal management, before hitting the hard limits of thermal and mechanical stress in the crystal.

In the future, herein envisage continuous operation of a DRL to generate output powers in multi-kilowatts. We believe the thermal lensing that can be anticipated in CW regime would be similar to what is observed in a crystal for quasi-CW operation. Therefore, we will study and tailor thermal management strategies for the laser; laser cooling mounts, cooling techniques and coolants (such as cryogenics, liquid cooling). We will investigate the various factors (such as thermal resistance, heat transfer coefficient) determining the rapid dissipation of thermal load from the crystal. We will also investigate and endeavor to enhance the heat transfer coefficients in the cooling pipes using twisted or coiled tubes, finning or tube inserts.

DRLs with multi-kW output powers with high brightness can pave the way for directed energy and remote sensing applications. Through intracavity frequency doubling, novel wavelengths with high power, good beam-quality, narrow-linewidth can be obtained in the visible spectrum. These wavelengths are useful in applications such as laser guide stars, medical therapy etc. Moreover, Raman cascading or appropriate choice of pump wavelengths allows a convenient means of extending the near-IR wavelengths to “eye-safe” and mid-IR spectral ranges. These wavelengths are particularly significant for LIDAR applications. Furthermore, the study of cooling techniques and architectures could be adapted to other Raman crystals with high damage threshold and moderate thermal conductivity, thus providing an alternative approach to diamond.

References

- Geskus, D.; Jakutis-Neto, J.; Pask, H.M.; Wetter, N.U. Nonlinear Frequency Generation and Conversion: Materials, Devices, and Applications XIV; Ten Deep Blue to Cyan Emission Lines from an Intracavity Frequency Converted Raman Laser; International Society for Optics and Photonics: Bellingham, WA, USA, 2015.

- Mildren, R.P.; Convery, M.; Pask, H.M.; Piper, J.A.; Mckay, T. Efficient, all-solid-state, Raman laser in the yellow, orange and red. Opt. Express 2004, 12, 785–790.

- Hollberg, L. Precision Spectroscopy, Diode Lasers, and Optical Frequency Measurement; CW Dye Lasers; Diane Publishing Co.: Collingdale, PA, USA, 2000; p. 105.

- Miao, Z.W.; Yu, H.J.; Zhang, J.Y.; Zou, S.Z.; Zhao, P.F.; Lou, B.J.; Lin, X.C. Watt-level CW Ti: Sapphire oscillator directly pumped with green laser diodes module. IEEE Photonics Technol. Lett. 2020, 32, 247–250.

- Liu, H.; Sun, S.; Zheng, L.; Wang, G.; Tian, W.; Zhang, D.; Han, H.; Zhu, J.; Wei, Z. Review of laser-diode pumped Ti: Sapphire laser. Microw. Opt. Technol. Lett. 2021, 63, 2135–2144.

- M Squared SolsTiS. Available online: https://www.m2lasers.com/solstis.html (accessed on 24 October 2021).

- Photonics Solutions Ltd. Available online: https://www.photonicsolutions.co.uk/upfiles/PrismSeriesIonLasersDatasheetLG11Jun18.pdf (accessed on 24 October 2021).

- Anliker, P.; Luthi, H.; Seelig, W.; Steinger, J.; Weber, H.; Leutwyler, S.; Schumacher, E.; Woste, L. 33-W CW dye laser. IEEE J. Quantum Electron. 1977, 13, 547–548.

- Coherent INNOVA Series. Available online: https://www.coherent.com/lasers/ion/innova-series (accessed on 24 October 2021).

- Gottwald, T.; Kuhn, V.; Schad, S.S.; Stolzenburg, C.; Killi, A. Technologies for Optical Countermeasures X; and High-Power Lasers 2013: Technology and Systems; Recent Developments in High Power Thin Disk Lasers at TRUMPF Laser; International Society for Optics and Photonics: Bellingham, WA, USA, 2013.

- Stewen, C.; Contag, K.; Larionov, M.; Giesen, A.; Hugel, H. A 1-kW CW thin disc laser. IEEE J. Sel. Top. Quantum Electron. 2000, 6, 650–657.

- Wallace, J. High-Power Fiber Lasers: Kilowatt-Level Fiber Lasers Mature; Endeavor Business Media: Nashua, NH, USA, 2016.

- Papastathopoulos, E.; Baumann, F.; Bocksrocker, O.; Gottwald, T.; Killi, A.; Metzger, B.; Schad, S.S.; Speker, N.; Ryba, T.; Zaske, S. Solid State Lasers XXX: Technology and Devices; High-Power High-brightness Disk Lasers for Advanced Applications; International Society for Optics and Photonics: Bellingham, WA, USA, 2021.

- Jackson, S.D. Towards high-power mid-infrared emission from a fibre laser. Nat. Photonics 2012, 6, 423–431.

- Meleshkevich, M.; Platonov, N.; Gapontsev, D.; Drozhzhin, A.; Sergeev, V.; Gapontsev, V. The European Conference on Lasers and Electro-Optics; 415 W Single-Mode CW Thulium Fiber Laser in All-Fiber Format; Optical Society of America: Washington, DC, USA, 2007.

- Lin, H.; Feng, Y.; Barua, P.; Sahu, J.K.; Nilsson, J. Advanced Solid State Lasers; 405 W Erbium-Doped Large-Core Fiber Laser; Optical Society of America: Washington, DC, USA, 2017.

- Zhang, J.; Schulze, F.; Mak, K.F.; Pervak, V.; Bauer, D.; Sutter, D.; Pronin, O. High-power, high-efficiency Tm: YAG and Ho: YAG thin-disk lasers. Laser Photonics Rev. 2018, 12, 1700273.

- Ye, Y.; Yang, B.; Wang, P.; Zeng, L.; Xi, X.; Shi, C.; Zhang, H.; Wang, X.; Zhou, P.; Xu, X. Industrial 6 kW high-stability single-stage all-fiber laser oscillator based on conventional large mode area ytterbium-doped fiber. Laser Phys. 2021, 31, 035104.

- IPG Photonics Corporation. Available online: https://www.ipgphotonics.com/en/products/lasers/high-power-cw-fiber-lasers# (accessed on 24 October 2021).

- Hoffman, A.; Gmachl, C. Extending opportunities. Nat. Photonics 2012, 6, 407.

- Wang, F.; Slivken, S.; Wu, D.H.; Lu, Q.Y.; Razeghi, M. Continuous wave quantum cascade lasers with 5.6 W output power at room temperature and 41% wall-plug efficiency in cryogenic operation. AIP Adv. 2020, 10, 055120.

- Tabata, N.; Nagai, H.; Yoshida, H.; Hishii, M.; Tanaka, M.; Myoi, Y.; Akiba, T. Conference on Lasers and Electro-Optics; Industrial 20-kW cw CO2 SAGE Laser; Optical Society of America: Washington, DC, USA, 1984.

- Mid-Infrared Laser Sources. Available online: https://www.rp-photonics.com/mid_infrared_laser_sources.html (accessed on 12 September 2021).

- Hudson, D.D. Short pulse generation in mid-IR fiber lasers. Opt. Fiber Technol. 2014, 20, 631–641.

- Yang, X.; Kitzler, O.; Spence, D.J.; Bai, Z.; Feng, Y.; Mildren, R.P. Diamond sodium guide star laser. Opt. Lett. 2020, 45, 1898–1901.

- de Lima Ribeiro, A.; Pask, H. Remote Sensing of Natural Waters Using a Multichannel, Lidar-Compatible Raman Spectrometer and Blue Excitation. Front. Mar. Sci. 2020, 7, 43.

- Yellow and Orange Lasers. Available online: https://www.rp-photonics.com/yellow_and_orange_lasers.html (accessed on 12 March 2021).

- Lux, O.; Sarang, S.; Kitzler, O.; Spence, D.J.; Mildren, R.P. Intrinsically stable high-power single longitudinal mode laser using spatial hole burning free gain. Optica 2016, 3, 876–881.

- Ahmed, S.A.; Mohsin, M.; Ali, S.M.Z. Survey and technological analysis of laser and its defense applications. Def. Technol. 2020, 17, 583–592.

- Paschotta, R. Laser Applications in the Encyclopedia of Laser Physics and Technology. Available online: https://www.rp-photonics.com/encyclopedia_cite.html?article=laser%20applications (accessed on 24 October 2021).

- Cousins, A.K. Temperature and thermal stress scaling in finite-length end-pumped laser rods. IEEE J. Quantum Electron. 1992, 28, 1057–1069.

- Tidwell, S.C.; Seamans, J.F.; Bowers, M.S.; Cousins, A.K. Scaling CW diode-end-pumped Nd: YAG lasers to high average powers. IEEE J. Quantum Electron. 1992, 28, 997–1009.

- Shukla, P.; Lawrence, J.; Zhang, Y. Understanding laser beam brightness: A review and new prospective in material processing. Opt. Laser Technol. 2015, 75, 40–51.

- Franken, E.P.; Hill, A.E.; Peters, C.W.; Weinreich, G. Generation of optical harmonics. Phys. Rev. Lett. 1961, 7, 118.

- Bass, M.; Franken, P.A.; Hill, A.E.; Peters, C.W.; Weinreich, G. Optical mixing. Phys. Rev. Lett. 1962, 8, 18.

- Guha, S.; Falk, J. The effects of focusing in the three-frequency parametric upconverter. J. Appl. Phys. 1980, 51, 50–60.

- Giordmaine, J.A.; Miller, R.C. Tunable coherent parametric oscillation in LiNbO3 at optical frequencies. Phys. Rev. Lett. 1965, 14, 973.

- Ammann, E.; Decker, C. 0.9-W Raman oscillator. J. Appl. Phys. 1977, 48, 1973–1975.

- Liao, Z.M.; Payne, S.A.; Dawson, W.J.; Drobshoff, A.D.; Ebbers, C.A.; Pennington, D.M.; Jovanovic, I.; Taylor, L.R. Nonlinear Optics: Materials, Fundamentals and Applications; Thermally Induced Dephasing in Periodically Poled KTiOPO4 Nonlinear Crystals; Optical Society of America: Washington, DC, USA, 2004.

- Tovstonog, S.V.; Kurimura, S.; Suzuki, I.; Takeno, K.; Moriwaki, S.; Ohmae, N.; Mio, N.; Katagai, T. Thermal effects in high-power CW second harmonic generation in Mg-doped stoichiometric lithium tantalate. Opt. Express 2008, 16, 11294–11299.

- Kumar, S.C.; Samanta, G.K.; Ebrahim-Zadeh, M. High-power, single-frequency, continuous-wave second-harmonic-generation of ytterbium fiber laser in PPKTP and MgO: sPPLT. Opt. Express 2009, 17, 13711–13726.

- Černý, P.; Jelínková, H.; Zverev, P.G.; Basiev, T.T. Solid state lasers with Raman frequency conversion. Prog. Quantum Electron. 2004, 28, 113–143.

- Strößner, U.; Meyn, J.P.; Wallenstein, R.; Urenski, P.; Arie, A.; Rosenman, G.; Mlynek, J.; Schiller, S.; Peters, A. Single-frequency continuous-wave optical parametric oscillator system with an ultrawide tuning range of 550 to 2830 nm. JOSA B 2002, 19, 1419–1424.

- Colville, F.G.; Henderson, A.J.; Padgett, M.J.; Zhang, J.; Dunn, M.H. Continuous-wave parametric oscillation in lithium triborate. Opt. Lett. 1993, 18, 205–207.

- Batchko, R.G.; Weise, D.; Plettner, T.; Miller, G.D.; Fejer, M.M.; Byer, R.L. CLEO’97. Summaries of Papers Presented at the Conference on Lasers and Electro-Optics; Continuous-Wave 532-nm-Pumped Singly Resonant Optical Parametric Oscillation in Periodically Poled Lithium Niobate; IEEE: Piscataway, NJ, USA, 1997.

- Martinelli, M.; Zhang, K.S.; Coudreau, T.; Maître, A.; Fabre, C. Ultra-low threshold CW triply resonant OPO in the near infrared using periodically poled lithium niobate. J. Opt. A Pure Appl. Opt. 2001, 3, 300.

- Zeil, P.; Thilmann, N.; Pasiskevicius, V.; Laurell, F. High-power, single-frequency, continuous-wave optical parametric oscillator employing a variable reflectivity volume Bragg grating. Opt. Express 2014, 22, 29907–29913.

- Boyd, R.W. Nonlinear Optics; Academic Press: Cambridge, MA, USA, 2019.

- Williams, R.J.; Kitzler, O.; Bai, Z.; Sarang, S.; Jasbeer, H.; McKay, A.; Antipov, S.; Sabella, A.; Lux, O.; Spence, D.J.; et al. High power diamond Raman lasers. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 1–14.

- Yang, X.; Kitzler, O.; Spence, D.J.; Williams, R.J.; Bai, Z.; Sarang, S.; Zhang, L.; Feng, Y.; Mildren, R.P. Single-frequency 620 nm diamond laser at high power, stabilized via harmonic self-suppression and spatial-hole-burning-free gain. Opt. Lett. 2019, 44, 839–842.

- Casula, R.; Penttinen, J.P.; Guina, M.; Kemp, A.J.; Hastie, J.E. Cascaded crystalline Raman lasers for extended wavelength coverage: Continuous-wave, third-Stokes operation. Optica 2018, 5, 1406–1413.

- Antipov, S.; Sabella, A.; Williams, R.J.; Kitzler, O.; Spence, D.J.; Mildren, R.P. 1.2 kW quasi-steady-state diamond Raman laser pumped by an M2 = 15 beam. Opt. Lett. 2019, 44, 2506–2509.

- Myers, L.E.; Bosenberg, W.R. Periodically poled lithium niobate and quasi-phase-matched optical parametric oscillators. IEEE J. Quantum Electron. 1997, 33, 1663–1672.

- Zhao, H.; Lima, I.; Major, A. Near-infrared properties of periodically poled KTiOPO4 and stoichiometric MgO-doped LiTaO3 crystals for high power optical parametric oscillation with femtosecond pulses. Laser Phys. 2010, 20, 1404–1409.

- Robertson, G. Optical Parametric Oscillators: A Comparison of New Materials. Ph.D. Thesis, University of St. Andrews, St. Andrews, Scotland, 1993.

- Akbari, R.; Major, A. Optical, spectral and phase-matching properties of BIBO, BBO and LBO crystals for Opticalparametric oscillation in the visible and near-infrared wavelength ranges. Laser Phys. 2013, 23, 035401.

- Bierlein, J.D.; Vanherzeele, H. Potassium titanyl phosphate: Properties and new applications. JOSA B 1989, 6, 622–633.

- Hellström, J. Nanosecond Optical Parametric Oscillators and Amplifiers Based on Periodically Poled KTiOPO4. Ph.D. Thesis, Fysiska Institutionen, Lund, Sweden, 2001.

- Karlsson, H. Fabrication of Periodically Poled Crystals from the KTP Family and Their Applications in Nonlinear Optics. Ph.D. Thesis, Fysiska Institutionen, Lund, Sweden, 1999.

- Lithium Niobate Properties. Available online: http://www.azurephotonicsus.com/material/crystals/Lithium%20Niobate%20crystal.html (accessed on 21 February 2021).

- Grabtchikov, A.S.; Lisinetskii, V.A.; Orlovich, V.A.; Schmitt, M.; Maksimenka, R.; Kiefer, W. Multimode pumped continuous-wave solid-state Raman laser. Opt. Lett. 2004, 29, 2524–2526.

- Piper, J.A.; Pask, H.M. Crystalline Raman lasers. IEEE J. Sel. Top. Quantum Electron. 2007, 13, 692–704.

- Sarang, S.; Williams, R.J.; Lux, O.; Kitzler, O.; McKay, A.; Jasbeer, H.; Mildren, R.P. High-gain 87 cm−1 Raman line of KYW and its impact on continuous-wave Raman laser operation. Opt. Express 2016, 24, 21463–21473.

- Mildren, R.; Rabeau, J. Optical Engineering of Diamond; Diamond Raman Laser Design and Performance; John Wiley & Sons: Hoboken, NJ, USA, 2013.

- Lubeigt, W.; Bonner, G.M.; Hastie, J.E.; Dawson, M.D.; Burns, D.; Kemp, A.J. Continuous-wave diamond Raman laser. Opt. Lett. 2010, 35, 2994–2996.

- Linares, R.; Doering, P. Properties of large single crystal diamond. Diam. Relat. Mater. 1999, 8, 909–915.

- Friel, I.; Geoghegan, S.L.; Twitchen, D.J.; Scarsbrook, G.A. Optics and Photonics for Counterterrorism and Crime Fighting VI and Optical Materials in Defence Systems Technology VII; Development of High Quality Single Crystal Diamond for Novel Laser Applications; International Society for Optics and Photonics: Bellingham, WA, USA, 2010.

- Martineau, P.M.; Gaukroger, M.P.; Guy, K.B.; Lawson, S.C.; Twitchen, D.J.; Friel, I.; Hansen, J.O.; Summerton, G.C.; Addison, T.P.G.; Burns, R. High crystalline quality single crystal chemical vapour deposition diamond. J. Condens. Matter Phys. 2009, 21, 364205.

- Romanyuk, Y. Liquid-Phase Epitaxy of Doped KY(WO4)2 Layers for Waveguide Lasers. Ph.D. Thesis, EPFL, Lausanne, Switzerland, 2005.

- Kaminskii, A.A.; Konstantinova, A.F.; Orekhova, V.P.; Butashin, A.V.; Klevtsova, R.F.; Pavlyuk, A.A. Optical and nonlinear laser properties of the χ (3)-active monoclinic α-KY(WO4)2 crystals. Crystallogr. Rep. 2001, 46, 665–672.

- Sabella, A.; Spence, D.J.; Mildren, R.P. Pump–probe measurements of the Raman gain coefficient in crystals using multi-longitudinal-mode beams. IEEE J. Quantum Electron. 2015, 51, 1–8.

- Basiev, T.T.; Osiko, V.V.; Prokhorov, A.M.; Dianov, E.M. Topics in Applied Physics; Crystalline and Fiber Raman Lasers. Solid-State Mid-Infrared Laser Sources; Springer: Berlin, Germany, 2003; Volume 89.

- Denker, B.; Shklovsky, E. Handbook of Solid-State Lasers: Materials, Systems and Applications; Elsevier: Amsterdam, The Netherlands, 2013.

More

Information

Subjects:

Optics

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

3 times

(View History)

Update Date:

30 Jan 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No