Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Igor Razumovskii | + 1183 word(s) | 1183 | 2022-01-04 08:45:50 |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Razumovskii, I. The Design of Ni-Based Single Crystal Superalloys. Encyclopedia. Available online: https://encyclopedia.pub/entry/18344 (accessed on 07 February 2026).

Razumovskii I. The Design of Ni-Based Single Crystal Superalloys. Encyclopedia. Available at: https://encyclopedia.pub/entry/18344. Accessed February 07, 2026.

Razumovskii, Igor. "The Design of Ni-Based Single Crystal Superalloys" Encyclopedia, https://encyclopedia.pub/entry/18344 (accessed February 07, 2026).

Razumovskii, I. (2022, January 17). The Design of Ni-Based Single Crystal Superalloys. In Encyclopedia. https://encyclopedia.pub/entry/18344

Razumovskii, Igor. "The Design of Ni-Based Single Crystal Superalloys." Encyclopedia. Web. 17 January, 2022.

Copy Citation

The most important performance characteristics of heat-resistant alloys (HRAs) are creep and fatigue resistance, which are very complex functions of chemical composition and microstructure. The microstructure of metal HRAs, among which the first place is occupied by Ni-based alloys, usually consists of two main phases: a solid solution based on the main element containing alloying elements (matrix), and a strengthening phase, which is usually used as intermetallides, carbides and silicides.

Ni-based superalloys

cohesive strength

1. Introduction

The metal matrix of the heat-resistant alloys (HRAs) can have both a monocrystalline and polycrystalline structure. The single-crystal structure is usually obtained by directional solidification methods. The most typical example of such monocrystalline objects are the blades of gas turbine engines of aircraft made of nickel HRAs. Single crystals are characterized by higher creep resistance compared to polycrystals. As a result, one of the main last decades successes of HRAs manufacturing technology is the development of the casting process for single-crystal blades of gas turbine engines [1]. The transition from polycrystalline parts to single crystals made it possible to eliminate the weakest element of the structure of polycrystals—high-angle grain boundaries (GBs). Compared to the bulk, GBs have excessive energy, increased diffusion permeability [2][3], and other characteristics which contributes to the acceleration of creep of alloys at elevated temperatures under load.

The main gas turbines blades and disks heat resistance characteristics are fatigue resistance and creep resistance. For gas turbine blades, the most important characteristic is creep resistance, since they operate under alternating loads and, as a rule, they are made of monocrystalline alloys. The disks operate under conditions of simultaneous action of thermocyclic, cyclic loads and tensile loads. For discs, the most important characteristic of heat resistance is fatigue resistance. Ni-based alloys obtained using powder metallurgy technology have a higher fatigue properties due to the dispersed structure provided by this technology. Such alloys are used in aircraft and rocket engines [4][5].

An important factor of high heat resistance of HRAs is the strength of interatomic bonds in the crystal lattices of the phases that make up the structure of the alloys and first—the alloy matrix [6]. The characteristic of the binding forces of atoms in the crystal lattice of solids is the cohesive energy [7] this is the energy necessary for the decomposition of a crystal into free atoms, and it can be obtained as the difference between the total energies of an atom in the free state Eat, and a crystal, Ecrist. To increase the interatomic interaction forces, the alloying elements introduced into the alloy should improve the cohesion properties of the alloy. For improvement the performance characteristics of polycrystalline alloys, it is necessary to develop approaches to enhance not only the cohesive energy of the matrix, but also to increase the cohesive strength of the GBs.

2. The Design of Ni-Based Single Crystal Superalloys

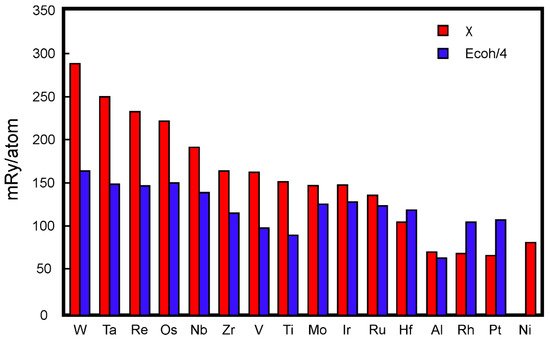

The results of the calculation of the parameter χ for several alloying elements (Ti, Al, Zr, hafnium (Hf), vanadium (V), niobium (Nb), tantalum (Ta), Mo, tungsten (W), rhenium (Re), ruthenium (Ru), osmium (Os), rhodium (Rh), iridium (Ir), and platinum (Pt) in Ni-based alloys are shown in Figure 1 [8]. Figure 1 first shows that the most efficient alloying additions to the Ni-based superalloys are W, Ta and Re, and secondly indicates the primary role of W in ensuring high cohesive strength of the nickel HRAs.

It is interesting to note in this regard that such well-known Ni-based HRAs as MAR-M200 and GS6U developed many years ago did not contain Ta and Re as alloying additives at all but included a relatively large amount of W (concentrations are indicated weight percentages (wt. %) in further): 12.5 in the alloy MAR-M200 and 10.5 in the alloy GS6U. Later, when first Ta and then Re were included in the HRAs alloying system, W was partially replaced by Ta and Re. As a result, W amount in the HRAs gradually decreased with an increase in Ta and Re concentration. For instance, the tendency can be easily seen in several CMSX superalloys (CMSX is a trademark of the Cannon-Muskegon Corporation) chemical compositions evolution. W concentration in the CMSX-2 (the first Ni-base generation superalloys for single crystal blades) was 8 and Ta concentration—6. In CMSX-4 superalloy (the second generation) W concentration was 6, also it consisted of 6.5 Ta and 3 Re. Finally, Ta and Re concentration was 8 and 6, respectively, and W concentration was reduced to 5 in the CMSX-10M superalloy (the third generation).

Although Ta and Re have large and approximately equal values of the parameter χ, and therefore can equally strongly increase the creep resistance of the alloy, it is interesting to introduce Ta and Re into the HRAs not only at the expense of W, but at the expense of Ni while maintaining a high concentration of W. If we consider the high solubility of W in Ni, this approach seems quite reasonable.

Several similar alloys KS-(1-3) with an increased W content were proposed in [8][9]; the chemical compositions of KS alloys are shown in Table 1.

Table 1. Chemical compositions of single-crystal superalloys KS-(1-3) (wt. %).

| Ni-Based Alloy | W | Ta | Re | Cr + Co + Ti + Nb + Al | Others, Nominal |

|---|---|---|---|---|---|

| KS-1 | 16.0 | 6.3 | 0 | 12.3 | 0.02La + 02Y + 0.02Ce |

| KS-2 | 15.0 | 6.3 | 2.0 | 13.3 | 0.02La + 02Y + 0.02Ce |

| KS-3 | 9.9 | 7.6 | 5.5 | 9.7 | 0.02La + 02Y + 0.02Ce |

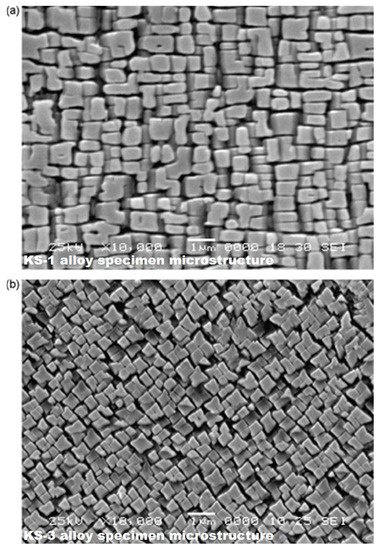

KS alloys with a single-crystal structure after complete heat treatment had a coherent γ-γ′ microstructure typical for nickel HRAs, Figure 2. In the microstructure of cylindrical castings with a growth axis of [100], a typical casting porosity was observed, which was minimized by hot isostatic pressing according to a special regime [10].

Figure 2. Coherent γ-γ′ microstructures of the KS-1 (a) and KS-3 (b) alloys specimens were producing via complete heat treatment included hot isostatic pressing (HIP), homogenization and two-step aging. Reproduced with permission from Razumovskii IM [8]. Copyright 2008 Elsevier.

The results of long-term tests of the mechanical properties of samples of KS-(1-3) alloys at a temperature of 1000 °C after complete heat treatment are shown in Table 2. Similar characteristics of Ni-based superalloys CMSX for single crystal blades and Ru-bearing superalloy EPM-102 are also presented there for comparison.

Table 2. The long-term strength of the fully treated KS-(1-3) alloys at the temperature 1000 °C.

| Ni-Base Alloy | Chemical Alloy Composition (wt.%) | σ1001000 (MPa) | σ5001000 (MPa) |

|---|---|---|---|

| KS-1 | 16 W, 5Ta | 255 | 194 |

| KS-2 | (12–15) W, 8Ta, 2Re | 270 | - |

| KS-3 | 10 W, 8Ta, 6Re | 330 | 263 |

| CMSX-2 | 8 W, 6Ta | 226 | 180 |

| CMSX-4 | 6 W, 7Ta, 3Re | 270 | 190 |

| CMSX-10M | 5 W, 8Ta, 6Re | 300 | 215 |

| EPM-102 | 6 W, 8.25Ta, 6Re, 3Ru | 330 | 240 |

Table 2 shows that creep rupture characteristics of KS-1 alloy (5 of Ta) has improved compared with the CMSX-2 (6 of Ta) for σ1001000 as well as for σ5001000. Although σ1001000 value is the same in KS-2 and CMSX-4 alloys, and KS-2 alloy contains less expensive Re amount. According to the table one can see that KS-3 alloy has been improved creep-rupture characteristics compared with CMSX-10M. Comparing the KS-3 alloy with Ru-bearing EPM-102 alloy, which has the highest creep-rupture properties. In addition, one can see that these alloys have the same σ1001000 (330 MPA) value, but KS-3 again has improved σ5001000 characteristic.

Using this approach together with other methods of design of Ni-based HRAs, it was developed a series of experimental HRAs with high heat resistance [11].

References

- Petrov, D.A.; Tumanov, A.T. Device for making single-crystal products. U.S. Patent No. 4,015,657, 5 April 1977.

- Bokshtein, S.; Ginsburg, S.; Razumovskii, I.; Kishkin, S.; Stroganov, G. Autoradiography of Interfaces and Structural Stability of Alloys; Metallurgiya: Moscow, Russia, 1987. (In Russian)

- Bokstein, B.; Mendelev, M.; Srolovitz, D. Thermodynamics and Kinetics in Materials Science; Oxford University Press: Oxford, UK, 2005.

- Koptev, Y.N. (Ed.) 50 Years Ahead of the Century; Rossiiskoe Kosmicheskoe Agentstvo: Moscow, Russia, 1998. (In Russian)

- Beresnev, A.; Logunov, A.; Logacheva, A.; Razumovskii, I. Powder and granular materials. Tekhnol. Metallov 2009, 12, 24–37. (In Russian)

- Kornilov, I. Physico-Chemical Bases of Heat Resistance of Alloys; Academy of Sciences of the USSR: Moscow, Russia, 1961. (In Russian)

- Kittel, C. Introduction to Solid State Physics, 7th ed.; Wiley: New York, NY, USA, 1996.

- Razumovskii, I.; Ruban, A.; Razumovskiy, V.; Logunov, A.; Larionov, V.; Ospennikova, O.; Poklad, V.; Johansson, B. New generation of Ni-based superalloys designed on the basis of first-principles calculations. Mater. Sci. Eng. A 2008, 497, 18–24.

- Logunov, A.; Razumovskii, I.; Stroganov, G.; Ruban, A.; Razumovskii, V.; Larionov, V.; Ospennikova, O.; Poklad, V. Theoretical Analysis of the Alloying System and Design of New Nickel-Base Superalloys. Dokl. Akad. Nauk. 2008, 421, 621–624.

- Logunov, A.; Marinin, S.; Poklad, V.; Razumovskii, I. Hot Isostatic Pressing of single crystals of heat-resistant nickel alloys. Technol. Light Alloys 2005, 1, 71–77.

- Eliseev, Y.; Poklad, V.; Ospennikova, O.; Larionov, V.; Logunov, A.; Razumovskii, I. Composition of Heat-Resistant Nickel Alloy for Single-Crystal Casting (Options). Russian Patent No. 2,348,724, 3 October 2009.

More

Information

Subjects:

Chemistry, Physical

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.8K

Entry Collection:

Chemical Bond

Revision:

1 time

(View History)

Update Date:

17 Jan 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No