Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Professor Kharisheh | + 2981 word(s) | 2981 | 2022-01-05 04:48:43 | | | |

| 2 | Catherine Yang | -3 word(s) | 2978 | 2022-01-12 07:08:04 | | | | |

| 3 | Catherine Yang | Meta information modification | 2978 | 2022-01-14 08:58:39 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kharisheh, P. Humidification and Dehumidification Desalination. Encyclopedia. Available online: https://encyclopedia.pub/entry/18111 (accessed on 08 February 2026).

Kharisheh P. Humidification and Dehumidification Desalination. Encyclopedia. Available at: https://encyclopedia.pub/entry/18111. Accessed February 08, 2026.

Kharisheh, Professor. "Humidification and Dehumidification Desalination" Encyclopedia, https://encyclopedia.pub/entry/18111 (accessed February 08, 2026).

Kharisheh, P. (2022, January 12). Humidification and Dehumidification Desalination. In Encyclopedia. https://encyclopedia.pub/entry/18111

Kharisheh, Professor. "Humidification and Dehumidification Desalination." Encyclopedia. Web. 12 January, 2022.

Copy Citation

Humidification–dehumidification desalination (HDH) is described as a novel volume reduction method that employs a carrier gas for the thermal desalination of water. Currently used for small scale desalination, the advantages provided by the HDH method are too great to be ignored. The benefits of the process include the use of low-grade energy and simple design and construction.

water management

humidification and dehumidification

1. HDH Design Optimization

Further attempts to optimize the HDH process involved investigation on the types of humidifiers and dehumidifiers available. The knowlegde that the humidity of the air entering the humidifier contributes to the performance of the unit prompted reseachers to optimize the parameter through a variation in design. Kassim [1] performed a numerical analysis of parallel plate channel humidifiers. They claimed the optimal performance was recorded at a low inlet air humidity. Packed bed, spray towers, and bubble towers could also be used as humidifiers; however, it was found that packed bed humidifiers enhanced the effectiveness of the system while direct contact dehumidifiers out-performed conventional dehumidifers [2]. The use of solar film humidifiers presented by Saidi et al. [3] provided mass and thermal yields of above 80%.

It was reported that dehumidifiers played a more crucial role in the production of freshwater as compared to humidifiers [4]. This prompted reseachers to investigate various types of heat exchangers to be used as a dehumidifer with an emphasis on the materials and heat transfer surface to be used. Muller-Holst [5] investigated the use of flat plate heat exchangers while El-Agouz [6] proposed the use of a finned tube heat exchanger. The flat plate and the finned tube heat exchangers are also the most commonly used in dehumidification processes; however, a copper coiled tube condenser tower has been in consistent use as a condenser. The theoretical and experimanetal working of this condenser can be found in the works reported by Amer [7]. Research on the effectiveness of a bubble column dehumidifier was carried out by Tow [8]. Among the various observations reported by them, it was claimed that the effectiveness of the process decreased as the air flowrate and moist air temperature increased. Moreover, the use of smaller coils was associated with an increased parallel flow effectiveness. The use of a packed bed column and spray towers as dehumidifiers was suggested as it promoted direct contact between humid air and the cooling medium. This allowed for a greater thermal energy transfer with minimized resistance. In addition, direct contact dehumidifiers offer a higher specific area of interface between the two mediums, thus minimizing the loss of humid air pressure. Eslamimanesh [9] theoretically modelled a HDH system to investigate the influence of operating parameters on the performance of the system. It was reported that an increase in the inlet airflowrate and recycled water flowrate led to an increase in freshwater yield. Increasing the temperature of the inlet air to the humidifier or decreasing the water inlet temperature of the dehumidifier helped achieve increased water productivity. On the contrary, raising the flowrate ratio of water to air in the humidifier was not suggested as it led to a drop in the system’s productivity.

2. Humidification–Dehumidification (HDH) Desalination Hybridization

2.1. HDH and Refrigeration Cycles

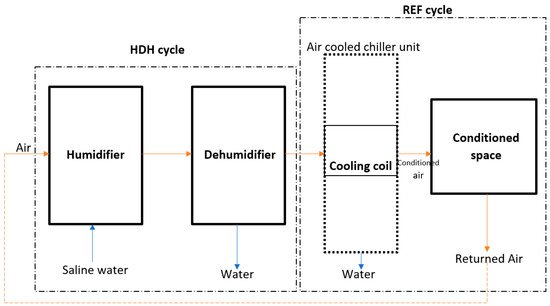

Despite the undeniable advantages of the HDH system, evidently the process can be greatly optimized through a combination of the system with different technologies. Nada [10] proposed the hybridization of the HDH desalination system with air conditioning to simultaneously produce freshwater and attain thermal comfort within the conditioned space. The working prinicple behind this proposal was employing vapor compression refrigeration cycles (VCR). In their studies, Nada [10] coupled the HDH system with the VCR cycles to investigate the efficiency of using the VCR evaporator as a HDH system dehumidifier. Traditionally in the HDH–VCR process, freshwater is first produced through a conventional dehumidifier using an external cooling medium, after which additional freshwater was produced using the VCR evaporator as an auxiliary dehumidifier. The cooled air exiting the dehumidifiers was further used for air conditioning purposes. Although the HDH–VCR process is known to have higher electrical power consumption, it compensates for the drawback through increased freshwater production and cooling capacity [2]. Elattar [11] claimed that the proposed HDH–VCR system would provide an efficient application in regions of hot and humid climates. Figure 1 depicts the simple HDH–REF combined cycle for graphical comprehension.

Figure 1. Simple HDH–REF cycle.

In a similar fashion, vapor absorption refrigeration (VAR) cycles could be used with the HDH process in place of the VCR cycles. Chiranjeevi and Srinivas [12][13] in their studies provided holistic analysis and results for the HDH–VAR cycles. In such a system, freshwater is first attained through the air-cooling dehumidifiers, after which chilled water from the VAR unit is used to increase freshwater production while simultaneously providing conditioned air. The use of solar flat plate collectors (FPCs) and concentrating collectors have been recommended to satisfy the heating demand of the HDH–VAR cylces. It was further demonstrated that the HDH–VAR system displayed improved performance at higher evaporator exit temperatures and higher humidifier effetiveness.

Despite the numerous studies conducted on the HDH–Refrigeration (HDH–REF) cycles, no verifible results were obtained in terms of water productivity, air condition quality, energy utilization factor (EUF) and total operating cost (TOC) savings. The varying results were attributed to the different types of refrigeration cycles used and the configuration of the system. Generally, VCR cycles were recommended for application in hot and humid regions as it boosted the performance of the HDH–VCR system. Strong emphasis was made on the proper selection of location of the evaporator of the cycle for maximized productivity. Similarly, optimization of the feedwater concentration, humidifier effectiveness, and evaporator temperatures were recommended for improved HDH–VAR performances.

Further optimization of the HDH–REF cycle was explored by utilizing the heating load of the refrigeration cycle in the HDH process. Lawal [14] studied the efficiency of using the VCR condenser to heat the feedwater to the humidifier or to increase the temperature of the inlet for humid air entering the dehumidfier. It was further reported that AH cycles yielded more favorable energy and exergetic results. He et al. [15][16] studied the thermodynamic performanc of the HDH–VCR system wherein the VCR was used to transfer heat from the discharged brine to raise the VCR condenser feedwater temperature. It was reported that the GOR of this system increased from 4.91 to 5.14. An increase in freshwater productivity was observed at a lower pinch temperature difference of the VCR condenser. Furthermore, although elevated pressure was favorable in the VCR cycle to increase water production, it was essential to operate the cycle at optimal pressure as elevated pressures translates to higher power consumption. In their studies Rostamzadeh [17] mathematically modeled a HDH–VAR cycle using ammonia and water. In this system, the waste heat from the discharged brine was recovered by the cooling effect of the VAR desorber while the heating effect of the VAR was used to heat the HDH cycle.

Dehghani [18] investigated the use of a direct contact humidifier in a HDH–REF cycle. They noted that a fully coupled HDH–REF could eliminate the need for additional coolers by adjusting the mass flowrate ratio of seawater to dry air or seawater to freshwater. A set up similar to that investiagted by Dehghani [18] was studied by Zhang [19]. In their set-up, however, the heating and cooling load of the VCR cycle was recovered through separate heat exchangers. They claimed that a maximized GOR is attained at an optimium air flowrate value. Furthermore, the results indicated that the system’s productivity was influenced by the seawater inlet temperature at the dehumidifier while the air inlet temperature had negligible affect on the performance. Further studies conducted indicated that an increase in seawater flowrate is linked with increase yield while maximum productivity is attained through an optimized air flowrate. Shafii [20] attempted to reduce the number of heat exchangers used in the HDH–REF process by replacing the conventional HDH dehumidifier with the evaporator of the VCR cycle. An increase in freshwater yield and GOR was observed at a higher relative humidity and VCR evaporator air flowrate. An increase in the ambient temperature of the system aided in attaining a higher freshwater yield, although the GOR value decreased due to the increased energy consumption of the compressor.

Table 1 summarizes the notable observation from various HDH–REF studies conducted while Table 2 is used to provide a comparison of the heating and cooling cycles used in the HDH–REF cycles.

Table 1. Observations from various HDH–REF processes.

| REF Type | Type of Study | Observations | Reference |

|---|---|---|---|

| VCR | Theoretical | Increased specific humidity and mass flowrate increased yield of freshwater and refrigeration capacity. Water productivity increased upon decreasing temperature of inlet air to the evaporator. |

[10] |

| VCR | Theoretical | Electrical consumption of auxiliary heaters could be decreased upon increasing the air temperature and decreasing the flowrate of air. Raising the air temperature resulted in increased yield, recovery rate and power consumption. |

[11] |

| VCR | Theoretical | Increase in air temperature and humidity along with an increase in area of the solar collector helped achieve higher freshwater yield. It also increased water recovery, power consumption and COP of the system. Temperature and humidity ratio were claimed to significantly influence the performance of the system. For improved economic efficiency, the proposed system is suggested to be applied in hot and humid regions. |

[12] |

| VAR | Theoretical | EUF of the system increased with higher humidifier effectiveness and hot water temperature. | [13] |

| VAR | Experimental and Numerical | Chilled water temperature and humid air temperature significantly influenced performance of the third dehumidifier. Average condition air supply was reported to be 21 °C and relative humidity was at 67%. |

[21] |

Table 2. Summary of performance of various HDH–REF cycles.

| REF Type | HP Heating | HP Cooling | GOR | Hourly Yield | Reference |

|---|---|---|---|---|---|

| VCR | Seawater/Air Heater | Seawater | 8.88 | - | [14] |

| VCR | Seawater heater | Brine Cooler | 5.14 | 82.12 kg/h | [15] |

| VCR | Seawater heater | Brine Cooler | 5.28 | 71.56 kg/h | [16] |

| VCR | Seawater heater | Brine Cooler | 9.02 | 0.647 kg/s | [17] |

| VCR | Seawater heater | 2nd stage dehumidifier | 2.05 | 22.26 kg/h | [19] |

To recapitulate, numerous studies have been dedicated to the study of the optimization of the HDH desalination system through its hybridization with refrigeration cycles, and in particular the VCR system. The VCR unit was primarily used to increase the temperature of the feedwater or air. The cooling effect of the VCR was also utilized to decrease the inlet saline water temperature for improved dehumidification and subsequently increased freshwater production. The studies were developed further to determine the best dehumidication unit for increased efficiency and performance.

3. HDH and Power Cycles

Growing population and industrialization has placed stress on water and energy demands. It has been projected that by 2050, the demand for freshwater may increase by 50% while energy demands will increase by 100% [22][23]. Scarce water resources and rapidly depleting fossil fuels have created an urgent need for the development of promising technologies that are capable of satisfying both water and energy needs globally. Humidification–dehumidification desalination paired with power cycles have been suggested for the cogeneration of freshwater and electricity.

The humidification–dehumidification power cycles (HDH–PWR) are generally driven by renewable heat sources or waste heat sources and therefore not only produce freshwater and energy but also generate low levels of pollution. Ariyanfar [24] reported that the HDH–PWR sytem provided better advantages over reverse osmosis–power hybrid systems. While limited experimental studies have been conducted on HDH–PWR systems, the theoretical works available primarily consist of the organic Rankine cycles (ORCs) as the power cycle. This is mainly because ORCs are simple and flexible in design while also providing reliable results. Furthermore, ORCs are able to utilize low-grade heat sources.

He et al. (2016) [25] studied an HDH–ORC system wherein the hot brine of the HDH cycle was used as a heat source for the ORC. It was reported that controlling parameters such as the inlet water temperature to the humidifier can optimize the performance of the system. Ariyanfar [24] conducted a thermoeconomic study of an HDH–ORC cycle. Their study analyzed the impact of various system configurations and different organic fluids on the performance of the process. It was concluded that coupling the HDH with the condenser of the ORC yielded more economical results and that n-heptane increased freshwater yield at a lower unit cost. In a similar study, He et al. [25] conducted a thermodynamic analysis of pairing the ORC condenser as the heater for the HDH cycle. They observed that freshwater yield could be increased by decreasing the pinch temperature of the ORC condesner. He et al. [25] further reported that for an HDH–ORC system, in order to boost the performance of the ORC, the brine entering the evaporator was reheated using a boiler. Moreover, the maximum efficiency and GOR was achieved as an optimal saline water to air mass flowrate ratio. Thermoeconomic results of a regenerative HDH–ORC system powered by geothermal water concluded that the ORC vapor generator displayed maximum irreversibility [15]. Besides, rasising the ORC evaporator temperature yielded beneficial thermodynamic and economical results. Studies were also conducted on a HDH–PWR system that employed a flashing Rankine system instead of an ORC and geothermal water as a heat source.

The results showed that lower temperatures of seawater and a lower temperature difference of saline water in the heat exchanger improved the performance of the process [15]. Employing a single extraction ORC with a WH–HDH process displayed an increase in freshwater productivity while net power decreased when the extracton pressure of the system was raised [16]. The advantage of this system was in the various amounts of power and water generated by controlling the extraction parameters, a benefit unseen in other HDH–PWR systems.

Sayyaadi [26] proposed coupling the HDH process with a Stirling engine (SE) [27] for the cogeneration of water and power. In this HDH–SE system, waste thermal energy from the SE was supplied to the HDH unit. The objective to optimize the HDH–SE process for maximized water productivity and power generation with minimal cost was achievd through a multi-extraction HDH–SE cycle. Furthermore, the mentioned system exhibited a reliable performance at varying salinity levels of seawater.

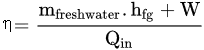

Among the several studies conducted on the HDH–PWR systems, varying values of freshwater productivity and power generation have been reported. An important parameter often not emphasized in these systems is the thermal efficiency, which is defined using Equation (1):

where mfreshwater is the freshwater production rate, hfg is the latent heat of evaporation of desalinated water, and W and Qin are the power generated and input power, respectively.

The diverse results reported in the studies conducted on the HDH–PWR system is mainly attributed to the difference in configuration, power cycles, heat sources, and operating conditions employed in the study. Furthermore, while the HDH–PWR system has been studied from a thermo-economic standpoint, the cost of freshwater has been neglected by many [28].

Table 3 summarizes the innovations employed in the HDH–PWR cycles with the results obtained.

4. HDH and Other Systems

Research to enhance the performance of the HDH combined cycles have led to the inclusion of multi-generation systems (MGR) that are capable of not only generating freshwater and power but also provide heating or cooling loads, and in some cases the production of hydrogen. Ghaebi [29] conducted a thermo-economic analysis of an MGR system consisting of a Kalina cycle, VAR refrigeration cycle and WH–HDH process. They aimed to maximize the energy efficiency of the system while lowering the cost. They reported a maximum thermal efficiency of 94.8% and exergy efficiency of 47.8%. Sadeghi [30] investigated the thermodynamic behavior of an HDH–ORC cycle integrated with an ejector refrigeration cycle. They reported a maximum exergy efficiency of 17.1%. Although various PWR and REF cycles have been investigated for integration in HDH–MGR systems, the ORC, Kalina, and Rankine cycles were most studied. Similarly, VAR cycles were the preferred option to provide cooling in the refrigeration cycles. Furthermore, it should be highlighted that the MGR cycles are compatible with different sources of heat such as air, water, geothermal energy, and biogas.

Investigation to improve the efficiencies of the desalination process showed that combining HDH cycles with other desalination (DES) processes improved the overall productivity and efficiency of the process compared to the standalone systems. Mistry [31] conducted a theoretical analysis of an HDH–RO system with the aim of optimizing the hybrid system. They observed that coupling the HDH–thermal vapor compressor (TVC) with an RO unit provided results that outperformed the multi-stage flash (MSF) evaporator and multi-effect distillation (MED) in terms of GOR and energy consumption. Mahmoud [32] investigated the performance of the HDH system integrated with solar stills. They reported that the productivity declined with an increasing basin height and recommended modification to the hybrid system for improved performance. Integrating a flashing evaporator (FE) with the HDH system was suggested by Kabeel [33]. They claimed that the HDH–FE process paired with a solar air heater provided the most economical layout.

5. Innovations in HDH Design

Among the several innovations suggested to the HDH process, mechanical compression of vapor is perhaps the most debated of them. HDH desalination integrated with vapor compression entails humidified air to be compressed to high pressures in order to elevate its pressure and temperature. Condensation of the water vapor present in the humidified air then occurs when the compressed air is cooled by the saline feedwater. The prime disadvantage associated with the mechanical vapor compression (MVC) method is its high-power consumption. El-Dessouky and Ettouney [34] claim that the power consumption of MVC may exceed that of single-effect MVC and RO processes without proper control and management. Limited research has been conducted on the potential of the HDH–MVC integrated system; however, the unexplored potential of an HDH–MVC system is highlighted through the advantages provided by a MVC unit integrated with a multi-effect desalination (MED) unit. Therefore, the following sections are dedicated to detailing the MED process and to presenting the benefits of an MED–MVC integrated system.

References

- Kassim, M.A.; Benhamou, B.; Harmand, S. Effect of air humidity at the entrance on heat and mass transfers in a humidifier intended for a desalination system. Appl. Therm. Eng. 2011, 31, 1906–1914.

- Faegh, M.; Behnam, P.; Shafii, M.B. A review on recent advances in humidification-dehumidification (HDH) desalination systems integrated with refrigeration, power and desalination technologies. Energy Convers. Manag. 2019, 196, 1002–1036.

- Saidi, S.; Ben Radhia, R.; Dhifaoui, B.; Ben Jabrallah, S. Experimental study of the inclined solar film evaporator. Desalination Water Treat. 2014, 56, 2576–2583.

- Klausner, J.F.; Li, Y.; Mei, R. Evaporative heat and mass transfer for the diffusion driven desalination process. Heat Mass Transf. 2005, 42, 528–536.

- Müller-Holst, H.; Engelhardt, M.; Herve, M.; Schölkopf, W. Solarthermal seawater desalination systems for decentralised use. Renew. Energy 1998, 14, 311–318.

- El-Agouz, S.; Abugderah, M. Experimental analysis of humidification process by air passing through seawater. Energy Convers. Manag. 2008, 49, 3698–3703.

- Amer, E.; Kotb, H.; Mostafa, G.; El-Ghalban, A. Theoretical and experimental investigation of humidification–dehumidification desalination unit. Desalination 2009, 249, 949–959.

- Tow, E.W.; Lienhard, J.H. Experiments and modeling of bubble column dehumidifier performance. Int. J. Therm. Sci. 2014, 80, 65–75.

- Eslamimanesh, A.; Hatamipour, M. Mathematical modeling of a direct contact humidification–dehumidification desalination process. Desalination 2009, 237, 296–304.

- Nada, S.; Elattar, H.; Fouda, A. Experimental study for hybrid humidification-dehumidification water desalination and air conditioning system. Desalination 2015, 363, 112–125.

- Elattar, H.; Fouda, A.; Nada, S. Performance investigation of a novel solar hybrid air conditioning and humidification-dehumidification water desalination system. Desalination 2016, 382, 28–42.

- Chiranjeevi, C.; Srinivas, T. Influence of vapor absorption cooling on humidification-dehumidification (HDH) desalination. Alex. Eng. J. 2016, 55, 1961–1967.

- Chiranjeevi, C.; Srinivas, T. Combined two stage desalination and cooling plant. Desalination 2014, 345, 56–63.

- Lawal, D.U.; Antar, M.; Khalifa, A.; Zubair, S.; Al-Sulaiman, F. Humidification-dehumidification desalination system operated by a heat pump. Energy Convers. Manag. 2018, 161, 128–140.

- He, W.; Han, D.; Ji, C. Investigation on humidification dehumidification desalination system coupled with heat pump. Desalination 2018, 436, 152–160.

- He, W.; Yang, H.; Han, D. Thermodynamic Analysis of A Novel Humidification Dehumidification Desalination System Driven by Heat Pump. Energy Procedia 2019, 158, 6030–6037.

- Rostamzadeh, H.; Namin, A.S.; Ghaebi, H.; Amidpour, M. Performance assessment and optimization of a humidification dehumidification (HDH) system driven by absorption-compression heat pump cycle. Desalination 2018, 447, 84–101.

- Dehghani, S.; Date, A.; Akbarzadeh, A. Performance analysis of a heat pump driven humidification-dehumidification desalination system. Desalination 2018, 445, 95–104.

- Zhang, Y.; Zhu, C.; Zhang, H.; Zheng, W.; You, S.; Zhen, Y. Experimental study of a humidification-dehumidification desalination system with heat pump unit. Desalination 2018, 442, 108–117.

- Shafii, M.B.; Jafargholi, H.; Faegh, M. Experimental investigation of heat recovery in a humidification-dehumidification desalination system via a heat pump. Desalination 2018, 437, 81–88.

- Fouda, A.; Nada, S.; Elattar, H. An integrated A/C and HDH water desalination system assisted by solar energy: Transient analysis and economical study. Appl. Therm. Eng. 2016, 108, 1320–1335.

- Marale, S.; Chiranjeevi, C.; Srinivas, T.; Raj, R.T. Experimental and Computational Fluid Dynamics Studies on Dehumidifier in a Combined Cooling and Desalination Plant. J. Therm. Sci. Eng. Appl. 2016, 9, 011007.

- Sadeghi, S.H.; Moghadam, E.S. Renewable Energy in the Water, Energy & Food Nexus; IRENA: Abu Dhabi, United Arab Emirates, 2015; pp. 1–125.

- Ariyanfar, L.; Yari, M.; Aghdam, E.A. Proposal and performance assessment of novel combined ORC and HDD cogeneration systems. Appl. Therm. Eng. 2016, 108, 296–311.

- He, W.; Han, D.; Xu, L.; Yue, C.; Pu, W. Performance investigation of a novel water–power cogeneration plant (WPCP) based on humidification dehumidification (HDH) method. Energy Convers. Manag. 2016, 110, 184–191.

- Sayyaadi, H.; Ghorbani, G. Conceptual design and optimization of a small-scale dual power-desalination system based on the Stirling prime-mover. Appl. Energy 2018, 223, 457–471.

- Oh, S.-Y.; Binns, M.; Cho, H.; Kim, J.-K. Energy minimization of MEA-based CO2 capture process. Appl. Energy 2016, 169, 353–362.

- Rostamzadeh, H.; Ghiasirad, H.; Amidpour, M.; Amidpour, Y. Performance enhancement of a conventional multi-effect desalination (MED) system by heat pump cycles. Desalination 2019, 477, 114261. Available online: http://www.sciencedirect.com/science/article/pii/S0011916419307556 (accessed on 9 July 2021).

- Ghaebi, H.; Namin, A.S.; Rostamzadeh, H. Performance assessment and optimization of a novel multi-generation system from thermodynamic and thermoeconomic viewpoints. Energy Convers. Manag. 2018, 165, 419–439.

- Sadeghi, M.; Yari, M.; Mahmoudi, S.; Jafari, M. Thermodynamic analysis and optimization of a novel combined power and ejector refrigeration cycle—Desalination system. Appl. Energy 2017, 208, 239–251.

- Mistry, K.H.; Mitsos, A.; Lienhard, J.H. Optimal operating conditions and configurations for humidification–dehumidification desalination cycles. Int. J. Therm. Sci. 2011, 50, 779–789.

- Mahmoud, A.; Fath, H.; Ahmed, M. Enhancing the performance of a solar driven hybrid solar still/humidification-dehumidification desalination system integrated with solar concentrator and photovoltaic panels. Desalination 2018, 430, 165–179.

- Kabeel, A.; El-Said, E.M. A hybrid solar desalination system of air humidification dehumidification and water flashing evaporation: A comparison among different configurations. Desalination 2013, 330, 79–89.

- El-Dessouky, H.T.; Ettouney, H.M. Fundamentals of Salt Water Desalination; Elsevier: Amsterdam, The Netherlands, 2002; ISBN 0080532128.

More

Information

Subjects:

Water Resources

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.6K

Revisions:

3 times

(View History)

Update Date:

14 Jan 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No