Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Rajesh Kumar | + 1325 word(s) | 1325 | 2022-01-05 07:16:47 | | | |

| 2 | Jason Zhu | Meta information modification | 1325 | 2022-01-10 02:35:16 | | | | |

| 3 | Lindsay Dong | Meta information modification | 1325 | 2022-03-28 06:14:49 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kumar, R. Lightweight Aggregate Concrete. Encyclopedia. Available online: https://encyclopedia.pub/entry/17866 (accessed on 07 February 2026).

Kumar R. Lightweight Aggregate Concrete. Encyclopedia. Available at: https://encyclopedia.pub/entry/17866. Accessed February 07, 2026.

Kumar, Rajesh. "Lightweight Aggregate Concrete" Encyclopedia, https://encyclopedia.pub/entry/17866 (accessed February 07, 2026).

Kumar, R. (2022, January 07). Lightweight Aggregate Concrete. In Encyclopedia. https://encyclopedia.pub/entry/17866

Kumar, Rajesh. "Lightweight Aggregate Concrete." Encyclopedia. Web. 07 January, 2022.

Copy Citation

Lightweight aggregate concrete (LWAC) exhibits the advantages of thermal insulation, reduces energy consumption building costs, improves building efficiency and easy construction. Furthermore, the utilization of industrial wastes in concrete is advantageous in terms of environmental sustainability.

lightweight aggregate concrete

industrial waste

thermal insulation

1. Introduction

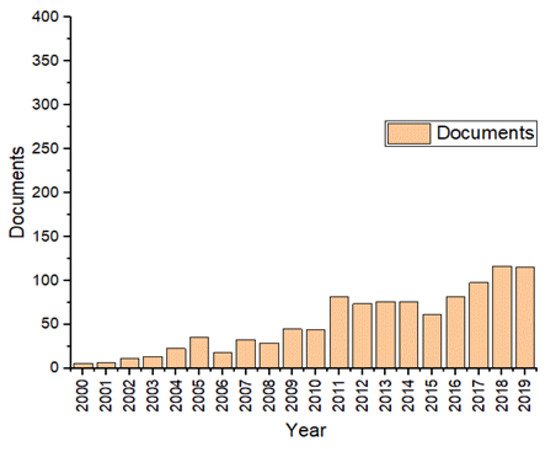

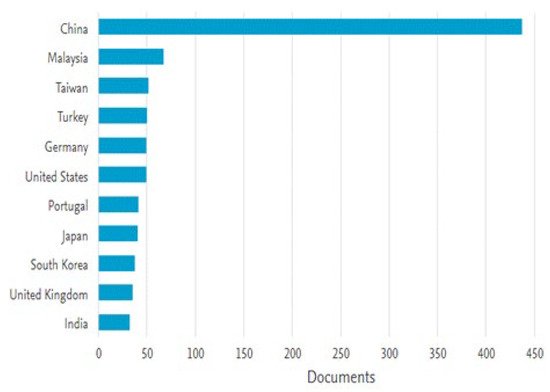

In the 21st century, energy-efficient buildings are one of the important issues, which include both techno-economic and sustainable environmental factors [1]. Energy-efficient buildings are designed to use energy as little as possible. Many developing countries are leading towards the construction of green buildings using cost-effective, durable concrete. The huge demand for concrete in the infrastructural development using normal-weight aggregates (NWAs) has reduced the natural stone deposits, which causes irreplaceable damage to the environment. As a result, the priority of searching for sustainable materials has been enhanced worldwide. LWAC is one such alternative to normal weight aggregate concrete (NWC) with various physical, mechanical, social and economic advantages [2]. Figure 1 and Figure 2 show the current trend of research (year-wise and location-wise) in the area of lightweight aggregate concrete (Source: https://www.scopus.com/; accessed on 12 September 2021). The trend shows that day by day, the practical use of LWACs is increasing and thus requires the current status of the research conducted to date.

Figure 1. Year-wise research trend.

Figure 2. Location-wise research trend.

The use of lightweight aggregates (LWA) in concrete has the following advantages:

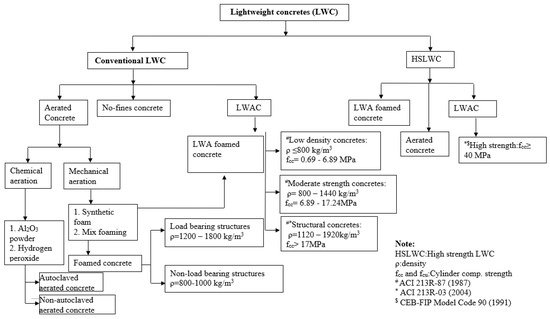

However, lower absolute mechanical strength, higher water absorption, porosity, etc., are some of the negative impacts. LWAC is an alternative solution to NWC, especially when lightweight energy-efficient solutions are needed. Thus, to overcome the problem of natural stone deterioration and for making energy-efficient buildings, different lightweight concretes are used. Chart 1 shows the classification of LWAC. It can be ascertained from the flow chart that LWAC can be used for load-bearing and non-load-bearing purposes. Different LWAs commonly used in making LWAC are vermiculite, OPS, perlite, LECA, pumice, scoria, tuff, cinder, lytag, etc. (Koksal et al. [1]). LWAs are a type of coarse/fine aggregates used for the manufacturing of LWC products, and these products are used in different structural work (Alengaram et al. [2]). LWAs have a cellular type structure and were used for producing different types of masonry blocks, wall panels, cladding and LWC. When they are used as fine aggregates, they function similar to active pozzolanic materials. It can be produced from the naturally available raw materials such as expanded clay, shale, slate, etc., as well as from SCMs such as FA and slags, etc.

Chart 1. Classification of lightweight concretes.

2. Types of LWAs

In general, LWAs can be divided into two categories.

2.1. Natural Aggregate

Natural LWAs are the materials that are available as natural resources. These are naturally ready to use with mechanical treatment, i.e., crushing and sieving. Mostly, natural LWAs are of volcanic origin, e.g., pumice and scoria [10][11]. Thus, they are only found in a few areas of the world. Pumice is formed when the molten lava from the explosive eruption of a volcano cools [12]. Quick cooling freezes the material existing at the molten state, which does not have zero probability of a crystallization process. Scoria is darker in color than pumice but has all the properties same as that of pumice. Volcanic tuffs are a kind of volcanic rock, which develops pores through rapid cooling and hardening of lava. The pore may vary from 10% to 60%. These tuffs are classified as rhyolite, dacite, andesite, etc. Similarly, volcanic slag is also derived from lava, which is less vitreous and more crystalline slag-like materials. These all-natural LWAs are used to produce LWC with a density range from 1860 to 1988 kg/m3 [13][14][15].

2.2. Manufactured/Artificial Aggregate

These LWAs are classified as brick rubble, cinder, sintered cinder, blast-furnace slag, LECA, etc. These types of aggregates are produced by thermal treatment of either naturally occurring materials such as clay, shale, vermiculite, perlite and slate, etc., or industrial byproducts/waste materials such as FA, municipal solid waste (MSW), waste of dredging, blast furnace slag, etc. Cinder LWAs are produced as coal burnt residues in the industrial boilers. The residue is melted and sintered to form cinders. Sintered fly ash is developed at a temperature of 1100–1300 °C [16]. They have a hard, coarse red shell and fine pore structures, which are commercially available in a size range of 7 to 30 mm. Similarly, foamed blast-furnace slag aggregates are produced by sintering slag at a temperature of 1400–1600 °C. The size range lies between less than 3 mm and 20 mm, with a varying bulk density of 300 to 700 kg/m3. LECA is produced using clay or shale after heating at the point of incipient vitrification (at a temperature of about 1200 °C) [17]. After exposure, clay/shale expands or bloats to seven times their original volume and forms a cellular structure that remains stable even after cooling. In the market, different kind of LECA is available by different names such as hydite, rocklite, lytag, aglite, keramzit, etc. In a similar manner, expanded perlite is developed after exposing perlite at a temperature of 900–1100 °C, which leads to an increase in volume by 15–20 times [18]. Vermiculite is a type of mica with high magnesium content, which is formed at a temperature of 900 °C [19].

3. The Comparisons among Different LWAs/LWACs on the Basis of Various Parameters

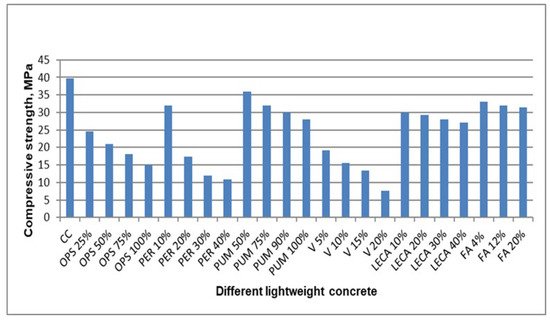

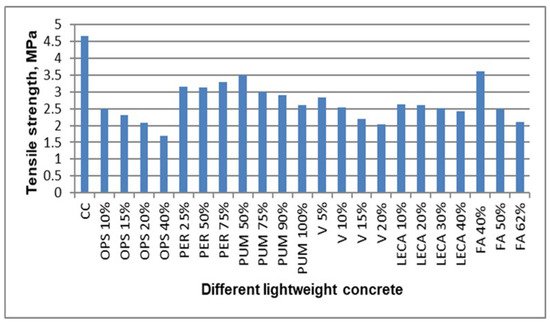

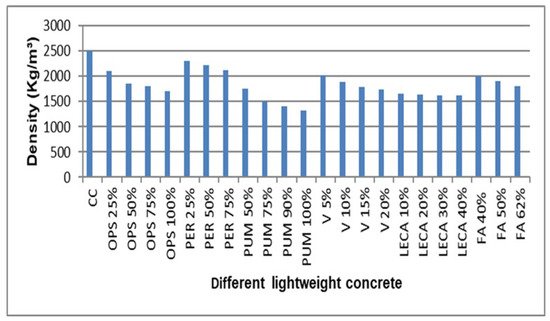

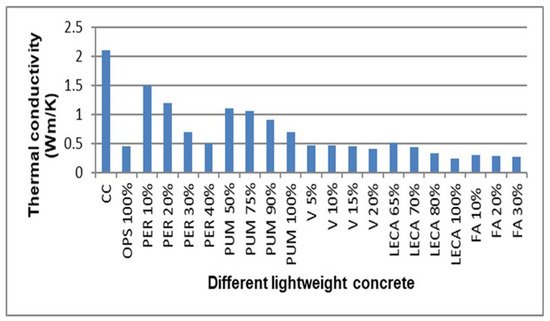

Researchers reported different properties of LWC, which are shown in Table 1. Majorly, the investigated properties were uniaxial compressive strength, split tensile strength, modulus of rupture or flexural strength, thermal conductivity, elastic modulus, water absorption, etc. For comparison purposes of compressive strength, splitting tensile strength, density and thermal conductivity, graphs containing six major LWAs are depicted in Figure 3, Figure 4, Figure 5 and Figure 6. The control concrete (CC) showed the maximum compressive strength among all LWC, i.e., 38 MPa, as presented in Figure 3. As the content of LWA in concrete increased, the compressive strength decreased. Here, 50% pumice used in concrete gave maximum compressive strength up to 36 MPa, while vermiculite LWC showed minimum compressive strength. The tensile strength of conventional concrete was varied in the range from 4 to 4.7 MPa, as depicted in Figure 4. Adding LWA in the mix proportion showed a gradual decrement in tensile strength. Forty percent FA sintered aggregate replacement showed maximum tensile strength, while 40% OPS replacement provided minimum strength. Figure 5 shows that perlite used as an aggregate showed a maximum density around 2300 kg/m3, while pumice concrete showed a minimum density of 1300 kg/m3. The thermal conductivity of LWC was lower than the NWCs. As shown in Figure 6, LECA concrete showed minimum thermal conductivity when used as a whole in place of coarse aggregate while control concrete showed maximum k value, i.e., 2.3 W/mK.

Figure 3. Compressive strength of different LWACs.

Figure 4. Tensile strength of different LWACs.

Figure 5. Density of different LWACs.

Figure 6. Thermal conductivity of different LWACs.

Table 1. Fresh, hardened and durability properties of LWAs, as per the literature.

| Aggregate Type | References | Compressive Strength | Splitting Tensile Strength |

Flexural Strength | Thermal Conductivity |

Modulus of Elasticity | Water Absorption |

|---|---|---|---|---|---|---|---|

| OPS | Mannan and Ganapathy [20] | ✓ | ✓ | ✓ | ✓ | ||

| Sobuz et al. [21] | ✓ | ✓ | ✓ | ✓ | |||

| Mo et al. [22] | ✓ | ✓ | ✓ | ||||

| Mo et al. [23] | ✓ | ✓ | |||||

| LECA | Maghsoudi et al. [24] | ✓ | ✓ | ||||

| Zohrabi et al. [25] | ✓ | ✓ | |||||

| Kumar and Prakash [26] | ✓ | ✓ | |||||

| Heiza et al. [27] | ✓ | ✓ | |||||

| Reddy et al. [28] | ✓ | ||||||

| Al-Jabri et al. [29] | ✓ | ✓ | |||||

| Vermiculite | Schackow et al. [30] | ✓ | |||||

| Koksal et al. [1] | ✓ | ✓ | ✓ | ✓ | |||

| Divya et al. [31] | ✓ | ✓ | ✓ | ||||

| Mo et al. [19] | ✓ | ✓ | |||||

| Arun et al. [32] | ✓ | ✓ | ✓ | ||||

| Karakoc and Demirboga [18] | ✓ | ✓ | |||||

| Perlite | Sengul et al. [33] | ✓ | ✓ | ✓ | ✓ | ||

| Gandage et al. [34] | ✓ | ✓ | ✓ | ||||

| Polat et al. [35] | ✓ | ||||||

| Wan et al. [36] | ✓ | ✓ | |||||

| Gunduz and Ugur [37] | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Pumice | Gunduz [38] | ✓ | ✓ | ✓ | ✓ | ||

| Parhizkar et al. [12] | ✓ | ✓ | ✓ | ||||

| Tasdemir et al. [39] | ✓ | ✓ | ✓ | ||||

| Kilincarslan et al. [40] | ✓ | ✓ | |||||

| Sintered fly ash | Kockal and Ozturan [41] | ✓ | ✓ | ✓ | |||

| Kockal and Ozturan [14] | ✓ | ✓ | ✓ | ✓ | |||

| Nadesan and Dinakar [42] | ✓ | ✓ | ✓ |

Figure 5 shows that perlite used as an aggregate showed a maximum density around 2300 kg/m3, while pumice concrete showed a minimum density of 1300 kg/m3. The thermal conductivity of LWC was lower than the NWCs. As shown in Figure 6, LECA concrete showed minimum thermal conductivity when used as a whole in place of coarse aggregate while control concrete showed maximum k value, i.e., 2.3 W/mK.

References

- Koksal, F.; Gencel, O.; Kaya, M. Combined effect of silica fume and expanded vermiculite on properties of lightweight mortars at ambient and elevated temperatures. Constr. Build. Mater. 2015, 88, 175–187.

- Alengaram, U.J.; Al Muhit, B.A.; Jumaat, M.Z. Utilization of oil palm kernel shell as lightweight aggregate in concrete–A review. Constr. Build. Mater. 2013, 38, 161–172.

- Olanipekun, E.; Olusola, K.; Ata, O. A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Build. Environ. 2006, 41, 297–301.

- Teo, D.C.L.; Mannan, M.A.; Kurian, V.J.; Ganapathy, C. Lightweight concrete made from oil palm shell (OPS): Structural bond and durability properties. Build. Environ. 2007, 42, 2614–2621.

- Zach, J.; Hubertova, M.; Hroudova, J. Possibilities of determination of thermal conductivity of lightweight concrete with utilization of nonstationary hot-wire method. In The 10th International Conference of the Slovenian Society for Non-Destructive Testing; Application of Contemporary Non-Destructive Testing in Engineering: Ljubljana, Slovenia, 2009; pp. 207–213.

- Grabois, T.M.; Cordeiro, G.C.; Filho, R.D.T. Fresh and hardened-state properties of self-compacting lightweight concrete reinforced with steel fibers. Constr. Build. Mater. 2016, 104, 284–292.

- Nirmal, C.; Jaiswal, D.S. Dynamic Analysis of High Rise Building Structure with Lightweight concrete. Int. Res. J. Eng. Technol. 2018, 05, 368–372.

- Omar, W.; Mohamed, R.N. The performance of pretensioned prestressed concrete beams made with lightweight concrete. Malays. J. Civ. Eng. 2002, 14.

- Lo, T.; Cui, H.; Li, Z. Influence of aggregate pre-wetting and fly ash on mechanical properties of lightweight concrete. Waste Manag. 2004, 24, 333–338.

- Bogas, J.A.; Cunha, D. Non-structural lightweight concrete with volcanic scoria aggregates for lightweight fill in building’s floors. Constr. Build. Mater. 2017, 135, 151–163.

- Karatas, M.; Balun, B.; Benli, A. High temperature resistance of self-compacting lightweight mortar incorporating expanded perlite and pumice. Comput. Concr. 2017, 19, 121–126.

- Parhizkar, T.; Najimi, M.; Pourkhorshidi, A.R. Application of Pumice Aggregate in Structural Lightweight Concrete. Asian J. Civ. Eng. 2012, 13, 43–54.

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H. Oil palm shell as a lightweight aggregate for production high strength lightweight concrete. Constr. Build. Mater. 2011, 25, 1848–1853.

- Kockal, N.U.; Ozturan, T. Effects of lightweight fly ash aggregate properties on the behavior of lightweight concretes. J. Hazard. Mater. 2010, 179, 954–965.

- Dinakar, P. Properties of fly-ash lightweight aggregate concretes. Proc. Inst. Civ. Eng.-Constr. Mater. 2013, 166, 133–140.

- Sahoo, S.; Selvaraju, A.K.; Prakash, S.S. Mechanical characterization of structural lightweight aggregate concrete made with sintered fly ash aggregates and synthetic fibres. Cem. Concr. Compos. 2020, 113, 103712.

- Youssf, O.; Hassanli, R.; Mills, J.; Elrahman, M.A. An experimental investigation of the mechanical performance and structural application of LECA-Rubcrete. Constr. Build. Mater. 2018, 175, 239–253.

- Karakoç, M.B.; Demirboga, R. HSC with Expanded Perlite Aggregate at Wet and Dry Curing Conditions. J. Mater. Civ. Eng. 2010, 22, 1252–1259.

- Mo, K.H.; Lee, H.J.; Liu, M.Y.J.; Ling, T.-C. Incorporation of expanded vermiculite lightweight aggregate in cement mortar. Constr. Build. Mater. 2018, 179, 302–306.

- Mannan, M.; Ganapathy, C. Engineering properties of concrete with oil palm shell as coarse aggregate. Constr. Build. Mater. 2002, 16, 29–34.

- Sobuz, H.R.; Hasan, N.M.S.; Tamanna, N.; Islam, S. Structural Lightweight Concrete Production by Using Oil Palm Shell. J. Mater. 2014, 2014, 1–6.

- Mo, K.H.; Alengaram, U.J.; Visintin, P.; Goh, S.H.; Jumaat, M.Z. Influence of lightweight aggregate on the bond properties of concrete with various strength grades. Constr. Build. Mater. 2015, 84, 377–386.

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Liu, M.Y.J.; Lim, J. Assessing some durability properties of sustainable lightweight oil palm shell concrete incorporating slag and manufactured sand. J. Clean. Prod. 2016, 112, 763–770.

- Maghsoudi, A.A.; Mohamadpour, S.; Maghsoudi, M. Mix design and mechanical properties of self-compacting lightweight concrete. Int. J. Civ. Eng. 2011, 9, 230–236.

- Zohrabi, M.; Zohrabi, A.; Chermahini, A.G. Investigation of the Mechanical Properties of Lightweight Concrete Containing LECA with Metakaoline Pozzolan Using Polypropylene and Steel Fibers. J. Appl. Environ. Biol. Sci. 2015, 5, 11–15.

- Kumar, A.; Prakash, P. Studies on Structural Light Weight Concrete by Blending Light Weight Aggregates. Int. J. Innov. Res. Eng. Manag. 2015, 2, 48–52.

- Heiza, K.M.; Eid, F.M.; Masoud, T. Lightweight self-compacting concrete with light expanded clay aggregate (LECA). ERJ Eng. Res. J. 2017, 40, 65–71.

- Reddy, S.R.; Swetha, N.; Desai, V.B. Flexural Study on Slab Specimens with Partial to Fully Replacement of Natural Coarse Aggregate by Light Weight Expandable Clay Aggregate (LECA). Int. J. Tech. Innov. Mod. Eng. Sci. 2018, 4, 2935–2942.

- Al-Jabri, K.S.; Hago, A.W.; Taha, R.; Alnuaimi, A.; Al-Saidy, A.H. Strength and Insulating Properties of Building Blocks Made from Waste Materials. J. Mater. Civ. Eng. 2009, 21, 191–197.

- Schackow, A.; Effting, C.; Folgueras, M.V.; Güths, S.; Mendes, G.A. Mechanical and thermal properties of lightweight concretes with vermiculite and EPS using air-entraining agent. Constr. Build. Mater. 2014, 57, 190–197.

- Divya, M.R.; Rajalingam, M.; George, S. Study on Concrete with Replacement of Fine Aggregates by Vermiculite. Int. J. New Tech. Res. 2016, 2, 87–89.

- Arun, L.; Kowsalya, K.; Madhumathi, S.; Preethi, K.; Pradheepa, R. An experimental study on concrete with partial replacement of fine aggregate by vermiculite and silica fume as a mineral admixture. Int. J. Intell. Adv. Res. Eng. Comput. 2018, 06, 224–227.

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011, 43, 671–676.

- Gandage, A.S.; Rao, V.V.; Sivakumar, M.; Vasan, A.; Venu, M.; Yaswanth, A. Effect of Perlite on Thermal Conductivity of Self Compacting Concrete. Procedia-Soc. Behav. Sci. 2013, 104, 188–197.

- Polat, R.; Demirboğa, R.; Karagöl, F. The influence of expanded perlite aggregate on compressive strength, linear autogenous shrinkage, restrained shrinkage, heat of hydration of cement-based materials. Struct. Concr. 2018, 19, 1771–1781.

- Law Yim Wan, D.S.; Aslani, F.; Ma, G. Lightweight Self-Compacting Concrete Incorporating Perlite, Scoria, and Polystyrene Aggregates. J. Mater. Civ. Eng. 2018, 30, 04018178.

- Gündüz, L.; Uğur, I. The effects of different fine and coarse pumice aggregate/cement ratios on the structural concrete properties without using any admixtures. Cem. Concr. Res. 2005, 35, 1859–1864.

- Gündüz, L. The effects of pumice aggregate/cement ratios on the low-strength concrete properties. Constr. Build. Mater. 2008, 22, 721–728.

- Tasdemir, C.; Sengul, O.; Tasdemir, M.A. A comparative study on the thermal conductivities and mechanical properties of lightweight concretes. Energy Build. 2017, 151, 469–475.

- Kilincarslan, Ş.; Davraz, M.; Akça, M. The effect of pumice as aggregate on the mechanical and thermal properties of foam concrete. Arab. J. Geosci. 2018, 11, 1–6.

- Kockal, N.U.; Ozturan, T. Durability of lightweight concretes with lightweight fly ash aggregates. Constr. Build. Mater. 2011, 25, 1430–1438.

- Nadesan, M.S.; Dinakar, P. Structural concrete using sintered flyash lightweight aggregate: A review. Constr. Build. Mater. 2017, 154, 928–944.

More

Information

Subjects:

Engineering, Civil

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.3K

Revisions:

3 times

(View History)

Update Date:

28 Mar 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No