Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Nino Adamashvili | + 3440 word(s) | 3440 | 2021-11-29 02:25:06 | | | |

| 2 | Bruce Ren | Meta information modification | 3440 | 2021-12-01 01:51:06 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Adamashvili, N.; Fiore, M. Blockchain-Based Wine Supply Chain for the Industry Advancement. Encyclopedia. Available online: https://encyclopedia.pub/entry/16564 (accessed on 12 January 2026).

Adamashvili N, Fiore M. Blockchain-Based Wine Supply Chain for the Industry Advancement. Encyclopedia. Available at: https://encyclopedia.pub/entry/16564. Accessed January 12, 2026.

Adamashvili, Nino, Mariantonietta Fiore. "Blockchain-Based Wine Supply Chain for the Industry Advancement" Encyclopedia, https://encyclopedia.pub/entry/16564 (accessed January 12, 2026).

Adamashvili, N., & Fiore, M. (2021, November 30). Blockchain-Based Wine Supply Chain for the Industry Advancement. In Encyclopedia. https://encyclopedia.pub/entry/16564

Adamashvili, Nino and Mariantonietta Fiore. "Blockchain-Based Wine Supply Chain for the Industry Advancement." Encyclopedia. Web. 30 November, 2021.

Copy Citation

Wine production counts more than 8000 years and it is still one of the most significant agri-food sectors worldwide considering the generated revenues in the countries' economies and employment level in the sector as well as the health aspects of wine consumption.

blockchain technology

wine

supply chain

traceability

time-to-recall

1. Introduction

Today’s society continues to place growing importance on health and wellness and address issues surrounding them, taking responsibility for a healthy lifestyle. The attitudes and demand for higher quality have changed considerably [1][2]. Consequently, an important issue is the process of food and beverage production and its perfection [3]. Therefore, in the recent times, agricultural policies have aimed to produce higher quality products.

Still, as reported by WHO [4], an estimated 600 million people in the world become ill and 420 thousand die yearly because of eating contaminated products. In turn, it causes lower productivity of the people and higher healthcare costs [5][6]. These numbers are motivated by the fact that certain bacteria not only damage the product, but they can also be transmitted to humans [7].

On the other hand, globalization has caused the complication of supply chains as they have gotten longer. They contain more participants from suppliers to final consumers. This caused the complexity of finding a bottleneck through the supply chain and provoked the simplicity of falsification of products [8][9]. Difficulties in tracing the product timely may result in spreading the contaminated goods on the market and problems of identifying affected items. As a result, the producer may become forced to recall a greater amount of products and may be under the risk of losing the reputation as well [10]. Therefore, the information about each stage of supply chain acquires greater importance.

According to Martins-Lopes and Gomes [11], special attention is focused on the products with PDO (Protected Designation of Origin), PGI (Protected Geographical Indication) or TSG (Traditional specialty guaranteed). In these cases, the information about geographical and climate conditions, production techniques, and alike matters, is extremely valuable as they guarantee the characteristics, safety, and quality of products. One of the most sensitive products in this regard, is wine [12][13]. The quality of wine depends on the grape sort; the zone where the grape is grown; its treatment; when the grape is picked up and crushed; the production process and environment including the variation of temperature and utensils in which the liquid is prepared; if there is any mistake in bottling and packaging; storage; and transportation conditions. A little error in any stage can result in the failure of the product [14][15][16][17][18][19]. Subsequently, the transparency of all processes through the wine supply chain is becoming crucial for each participant of the supply chain and especially for final consumers [20].

In order to be able to achieve this mission, modern software innovations need to play a crucial part in the overall process [21]. Meaning, a corresponding software and hardware can be complemented towards determining challenges, avoiding those obstacles in short time periods, and making overall process of bringing the products to the customer as efficiently as possible.

The main obstacles that arise usually are the lack of information, its falsification, or unreliability [22][23]. Ultimately, the absence of necessary information or its inaccessibility may cause a negative impact on product quality and reliability, and subsequently, on the health of consumers [24]. At such times, the emerging technologies play a crucial role. They allow the information to be accessible and controlled in a short period of time. This is happening through the digitization of data and the acceleration of industry and society [25][26].

Despite the fact that the emerging technologies can digitalize the data and make it accessible, the reliability of the information still remains as a challenge [27]. So, it should not remain out of consideration. It is necessary to be sure that the information provided by governments, suppliers, producers, as well as other external entities such as IoT companies, is reliable, complete, immaculate, and not falsified [28][29]. In order to achieve this condition, having a centralized system can be an impediment. There is a high potential for central authority to forge the information according to their own illegitimate interests. [30] Additionally, the usage of invalid, misinterpreted, or unrelated data while performing the data analysis can result in less accurate outputs, expectations, or system behavior, which will affect the total productivity of the agricultural system under analysis [31].

2. Blockchain Technology—General Description

“Blockchain is a distributed ledger maintaining a continuously growing list of data records that are confirmed by all of the participating nodes” [32]. Blockchain technology is a digital ledger of records, called “transactions”, secured with a hash function, authenticated, and maintained through a distributed network of nodes using a consensus protocol [33]. Nodes are all participants involved in the blockchain, each one has a copy of the blockchain and equal authority to accept or not the new blocks [34]. The new blocks are added on the blockchain if all nodes achieve consensus on the transaction. An indestructible chain is formed, since once the new line (block) is added on the blockchain and proved from all nodes applying the hash function, it is not possible to change even a little detail in the older data by any single participant [35][36]. Therefore, as any distributed ledger technology (DLT), blockchain enables parties who do not trust or even not know each other, to interact on a peer-to-peer basis without any need of third-party authorities, and to exchange the data in a secure way. In the blockchain, parties trust each other on the basis of a consensus mechanism—a set of the rules that should be followed by each of the nodes to verify and validate the transaction and to add the block on a chain [37].

One way to provide reliable information is through a decentralized system that is trusted by all participants in the production and delivery process [38]. Also, this system should ensure data immutability. The reliability can be considered achieved, if the data is available to all participants and if they have the opportunity to verify that the data has not been falsified since its inception [39]. Besides, if there is a system that can ensure the reliability of the data, it will also be able to deliver the information securely to the recipient [40].

From this point of view, blockchain technology (BCT), the first decentralized technology originally developed for mining of cryptocurrency, has a potential to solve the problem of data reliability, transparency, and traceability, thus guaranteeing the trustworthiness of information. It represents a protocol providing the infrastructure that ensures the immutability of the information over time [27]. Because of this property, BCT has been applied in various different areas. The benefit for the food and beverage supply chain is noteworthy.

A very early beginning of blockchain technology can be found in the 90s when Haber & Stornetta [41] introduced the work “How to time-stamp a digital document”. The authors proposed two solutions in order to certify when a document was created or last modified: the hash function and the digital signature. Since these solutions time-stamp the actual bits of the document, changing even one character in this document causes the difference in hash value. So it is easy to show that the signed documents are modified.

Later, in 2008, on the basis of Haber & Stornetta’s [41] work, the blockchain technology (BCT) itself was invented by Satoshi Nakamoto as the technological basis for the Bitcoin cryptocurrency [42]. It is a decentralized digital database that allows the secure recording and sharing of all information regarding transactions, registered by different actors involved in the production and distribution processes. The main characteristics of blockchain technology are the immutability, transparency, and traceability of transactions, as well as security based on cryptographic techniques [27][43][44][45][46]. Regardless of these features, BCT remained under shadow for several years; in 2014 it began to emerge and it has continued to gain massive attention globally. This attention is shifting to different areas of uses other than money as well. Indeed, at present, BCT is among the popular topics for academic research and application in practice. Only in the first three quarters of 2016, 1.4 billion dollars were invested by startups [47].

Hence, recently, BCT has attracted increasing attention in the context of new applications. Using the BCT in various areas has made it necessary to diversify its types [48]. Each field has different requirements and restrictions. For instance, several studies [49][50][51][52] have shown that the transparent nature of BCT could be a problem in some areas. For this reason, the necessity of protecting the information from accessibility for everyone has risen. Additionally, in some cases, it is impossible to run the system in a totally decentralized and uncontrolled way. Some fields have legal requirements to know each party in the network [53]; the business sector mostly has the necessity to have the system more strictly controlled, with a restriction to modify or even read the blockchain state for several users [54][55]. Therefore, it becomes important to identify each node in the network. As a consequence, there are Public or Private/Permissionless and Permissioned Blockchain Technologies, described in the next section.

On the other hand, in some cases, the main requirement for the system is to minimize the latency or reduce operational cost. In this case, the consensus protocol plays a crucial role [56]. It determines the scalability of BCT, since the computational power and consequently the time for confirming the transaction depend on the quantity of transactions in each block and the interval between blocks [57]. Individual businesses independently determine the type of BCT that is comfortable for their work. According to the necessities of various industries, the different features of BCT have been evolved and diverse types of BCT have been developed. Consequently, the architecture of different blockchain technologies differ from one other. The public and private blockchains are described in the following section.

3. Public and Private Blockchains

Blockchain Technology, with its classical definition, provides complete decentralization and uncontrollability of the system [58]. However, over time, the necessity of permissioned BCTs has been raised. These kinds of BCTs make a possibility to predefine the nodes involved in the system [59]. It does not mean full centralization of a system. In this case, nodes need the acceptance for joining the network. After that, the system continues to work in a decentralized manner. This function supports a better authorization and authentication processes. It eliminates the problem of privacy in transaction processes [56].

Now blockchains can be categorized into three types: public (permissionless), consortium (permissioned), and private (permissioned) blockchains. Canadian programmer Buterin Vitalik [60] describes them in his article “On Public and Private Blockchains”, their characteristics (Table 1), and advantages and disadvantages (Table 2).

Table 1. Characteristics of public, consortium and private blockchains (Source: Buterin [60]; Zheng et al. [61]).

| To Read | To Send Transaction |

To Participate in Consensus Process | The Mechanism | Other Characteristics | |

|---|---|---|---|---|---|

| Public “fully decentralized” |

anyone | anyone | anyone | PoW (Proof of Work), PoS (Proof of Stake) | Secured by crypto economics; the degree of influence is proportional to the quantity of economic resources |

| Consortium “partially decentralized” |

Anyone/pre-defined nodes | pre-defined nodes | pre-defined nodes | The majority have to sign every block | |

| Private “fully private” |

Anyone/restricted | centralized | centralized | Likely applications include database management, auditing, etc. internal to a single company |

Table 2. Advantages and disadvantages of public, consortium, and private blockchains (Source: Buterin [60]; Zheng et al. [61]).

| Advantages | Disadvantages | |

|---|---|---|

| Public “fully decentralized” |

Protects users from developers’ influence; Trust of the system (blockchain) Censorship resistance Network effect; Immutability nearly impossible to tamper |

Can reduce the block time till 15 s (Ethereum) instead of 2 h (Bitcoin), but still it is more than in the cases of private or consortium blockchains |

| Consortium “partially decentralized” |

Easy changes, revert transaction, modify balances; The validators are known; Cheap transactions; Nodes can be trusted to be very well-connected; |

Immutability could be tampered |

| Private “fully private” |

Easy changes, revert transaction, modify balances; The validators are known; Cheap transactions; Nodes can be trusted to be very well-connected; Greater level of privacy if read permissions are restricted. |

Immutability could be tampered In some cases, in order to efficiently work the BC, some heterogeneous assets from different industries need to be on the same database, which is difficult to happen in private BCs. |

Seemingly, public blockchain is “fully decentralized”, anyone can read and send transactions; consortium blockchain is “partially decentralized”, anyone or pre-defined nodes can read, and only pre-defined nodes can send transactions; while private blockchain is “fully private” meaning that read permissions can be both restricted or public while the writing is centralized [60][61].

All three types of blockchain technology have their advantages and disadvantages. The users should choose the one that fits better to the requirements of a specific field of application.

3. Blockchain Application in Supply Chain

Agriculture is experiencing several environmental, economic, and social issues that push and motivate a transition towards sustainable paths within the global economic system [62][63][64]. Therefore, over the last decade, there was an exponential increase in promoting smart systems and in identifying ingenious solutions for all the sectors [65][66]. On the other hand, BCT has been found to be a revolutionizing technology for a number of different fields of the economy. One of the industries where BCT is very promising is agriculture.

The adoption of ICT in agriculture sector can certainly strengthen the large-scale transformation, decrease production costs, and increase investments growth [67]. Especially the adoption of blockchain technology promotes sustainable e-agriculture [68][69]. Therefore, BCT can play a fundamental role and could have a wide scope of application, taking into account the importance of knowing the origin of an agri-food product for consumers and of the usefulness of this technology to fight against counterfeiting and falsification of products.

Besides, BCT in the agricultural sector is being adopted for optimizing the processes in the supply chain; improving the traceability; enhancing food safety, and reducing times and cost of transaction, food fraud, and inefficient processes. In addition, blockchain can improve the profits of farmers and promote ethical businesses, like fair-trade, animal welfare, and reduce environmental impacts [63][70][71][72][73]. Therefore, the implementation of the BCT improves the traceability—the ability to trace and track the food through all the steps [74]. It can avoid a diffuse use of pesticides and fertilizers, which can cause the presence of residues dangerous for human health [75]. Additionally, BCT gives the ability to suppliers, farmers, producers, retailers, and governments to identify and confine contaminated elements and to follow its road along the supply chain.

It is noteworthy that thanks to abovementioned characteristics, BCT significantly reduces the time of re-call if the hazardous product appears in the retail shops. Therefore, it reduces the inefficiencies along the supply chain that may cause disastrous results [5][6]. Precisely detecting maleficent goods in time promotes recalling back the products before it spreads to the consumers, it does so only with the ones that are affected, so it reduces health risk, financial loss, and reputation damage [10][76].

Blockchain technology influences several factors in the agricultural sector (climate-environment related data, payments, soil-moisture, demand and sale price, seed quality, products’ convenience to the farmers, equipment, finance, loans etc.) and focuses on four key aspects [77][78][79]:

-

Consensus and distributed trust among farmers regarding crucial rights;

-

Security in terms of safety of the data;

-

Provenance that ensures safe sure transactions and avoids fraudulent data;

-

Trust among actors that are part of a ledger within buyer–seller relationships.

Consequently, BCT collects several advantages and generates an exclusive level of credibility but some limits persist and have to be dealt with: regulations, relationships among actors, data ownership, scalability, etc. [68]. Every business of the agri-food supply chain manages its own data-recording systems; so, a unique tracking system for info appears tricky due to the mismatch among software or data structures [80]. In addition, it is necessary to highlight that the costs of skilled human resources and of developing, adopting, and maintaining blockchain technology can be considered higher than other systems [81].

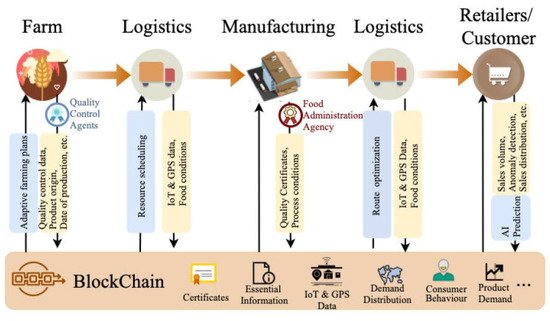

A recent work [63] investigated BCT in the light of the COVID-19 pandemic and of weaknesses and needs that emerged in the agri-food chain: The necessity of both real-time accurate information reflecting the purchase choices and of effective coordination between actors to reply with fast and adequate responses, and the urgency of efficient processes for reducing times in bureaucracy-based procedures. The figure below (Figure 1) illustrates an improved BCT-based supply chain system that can be arranged in COVID-19 era to improve the allocation of resources when dealing with unforeseen events.

Figure 1. BCT in the COVID-19 pandemic economy (Source: Lin et al. [63]).

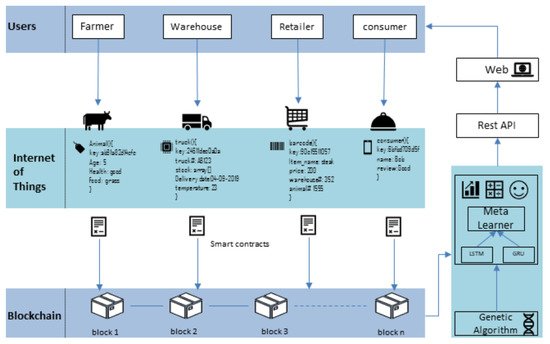

Another recent research [82] proposes to implement a consortium BCT-based machinery scheduling system to join the advantages of the BCT to the intelligent distributed scheduling of agricultural machinery: In this way, it is possible to overcome a single point crash, high costs, and waste of resources. On the other hand, Khan et al. [80] suggested to combine IoT (Internet of Thinks) with BCT, implementing an IoT–blockchain-enabled intelligent system taking farmers as participants and allowing them to create personnel files and duly record files for each section (see Figure 2).

Figure 2. The IoT–blockchain-enabled intelligent system (Source: Khan et al. [80]).

In order to combine BCT to risk issues, FAO proposes an interesting scheme, FARMS (Financial and Agricultural Risk Management for Smallholders), which provides, through the BCT, easy access to formal financial risk management, while increasing farmers’ financial literacy.

To underline the fundamental role that this technology could have in the future, Italian Ministry of Economic Development launched on 18 June 2020 a public consultation to collect proposals collected in the report “Proposals for the Italian Strategy on technologies based on distributed registers and blockchain”. The report reaffirms the importance of implementing a digital infrastructure based on blockchain technologies to promote the development of an ecosystem for the exchange of product information in order to increase its transparency and strengthen guarantees of origin and food safety, involving all the actors in the supply chain and the final consumer. The BCT is proposed as a transparent traceability and communication system aimed at fighting counterfeiting in the various production sectors and the spread of so-called Italian sounding, together representing valid tools for the promotion of Made in Italy above all in the agri-food sector.

In line with the above-mentioned framework, the European Green Deal by European Commission and the “Farm to Fork” strategy for a fair, healthy, and environmentally-friendly food system aim to address in a systemic way the challenges related to the sustainability of food systems, recognizing the connections that link the health of individuals, companies, and environment. This strategy is developed around six macro-objectives, which concern the sustainability of food production phases, food security, promotion of sustainable food consumption, reduction of food losses and waste, and the fight against fraud in food supply chains.

One of the most sensitive products with features such as provenience and quality is wine. Indeed, the world of wine has always been associated with traditions related to territory and production methods, but also to sales and distribution systems. In recent years, there has been an increasing awareness on the side of wine producers. They, in order to face the increasing global international competition, have favored more and more the inclusion of production criteria aimed in particular at obtaining high quality products and the sustainability of processes, which are factors appreciated by end consumers [83]. In particular, in terms of marketing strategies, companies must adopt effective communication strategies to inform end-customers about the uniqueness of each bottle and its added value, in order to create an unconditional relationship of trust with the customer, both intermediate or final. In fact, there is an increasing tendency for consumers to seek information on the products they want to buy, and almost all of them are also prepared to incur higher costs, if this means achieving transparency in the production processes and guaranteed quality [84][85][86].

The blockchain solutions can ensure the traceability, transaction history, provenience, and quality standards of each bottle in a safe and immutable way. In addition, the importance of introducing BCT into the wine supply chain derives from the wine classification system on EU and national level. In fact, there are two main categories of wines: with designation of origin (PGI and PDO) and wines without this denomination (varietal wines). The difference is between wine products that maintain a close correlation with the cultivation territory and that have to follow a regulated winemaking procedures, and wines not linked to determinate areas and production processes.

In addition, adopting BCT can affect not only the traceability of the entire production process, but in particular can result in [87]:

-

Consumer’s feedback by means of the use of simple apps;

-

Customizing a reading system for customers and launching a strong commercial message;

-

Reliability of information that, not being centralized, is globally available, thus allowing to protect the image of each winery that can, therefore, protect its product from fakes on the market (fight against counterfeiting);

-

Automated mechanisms that allow to eliminate intermediaries, reduce waste, and increase production efficiency.

*For the examined model, results and discussion please see the full paper.

References

- Mollet, B.; Rowland, I. Functional foods: At the frontier between food and pharma. Curr. Opin. Biotechnol. 2002, 13, 483–485.

- Young, Y. Functional foods and the European consumer. In Functional Foods. II. Claims and Evidence; Buttriss, J., Saltmarsh, M., Eds.; The Royal Society of Chemistry: London, UK, 2000.

- D’Alessandro, A.; Zolla, L. We are what we eat: Food safety and proteomics. J. Proteome Res. 2012, 11, 26–36.

- WHO. Food Safety: Key Facts 2020. Available online: https://www.who.int/news-room/fact-sheets/detail/food-safety#:~:text=An%20estimated%20600%20million%20%E2%80%93%20almost,healthy%20life%20years%20(DALYs) (accessed on 23 September 2021).

- Kadariya, J.; Smith, T.C.; Thapaliya, D. Staphylococcus aureus and staphylococcal food-borne disease: An ongoing challenge in public health. BioMed Res. Int. 2014, 2014, 827965.

- Scharff, R.L. Economic burden from health losses due to foodborne illness in the united states. J. Food Prot. 2012, 75, 123–131.

- Astill, J.; Fraser, E.; Dara, R.; Sharif, S. Detecting and Predicting Emerging Disease in Poultry with the Implementation of New Technologies and Big Data: A Focus on Avian Influenza Virus. Front. Vet. Sci. 2018, 5, 263.

- Esteki, M.; Regueiro, J.; Simal-Gándara, J. Tackling fraudsters with global strategies to expose fraud in the food chain. Compr. Rev. Food Sci. Food Saf. 2019, 18, 425–440.

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135.

- Kshetri, N.; Loukoianova, E. Blockchain adoption in supply chain networks in asia. IT Prof. 2019, 21, 11–15.

- Martins-Lopes, P.; Gomes, S. Olive oil traceability through DNA markers. Olive Consum. Health 2012, 211–224. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-84895403310&origin=inward&txGid=eec05861da4577b2b9a6f86bcf458732 (accessed on 23 September 2021).

- Camin, F.; Boner, M.; Bontempo, L.; Fauhl-Hassek, C.; Kelly, S.D.; Riedl, J.; Rossmann, A. Stable isotope techniques for verifying the declared geographical origin of food in legal cases. Trends Food Sci. Technol. 2017, 61, 176–187.

- Durante, C.; Bertacchini, L.; Cocchi, M.; Manzini, D.; Marchetti, A.; Rossi, M.C.; Sighinolfi, S.; Tassi, L. Development of 87Sr/86Sr maps as targeted strategy to support wine quality. Food Chem. 2018, 255, 139–146.

- Hill, G.N.; Beresford, R.M.; Evans, K.J. Tools for accurate assessment of botrytis bunch rot (Botrytis cinerea) on wine grapes. N. Z. Plant Prot. 2010, 63, 174–181.

- Moreno-Arribas, M.V.; Polo, M.C. Wine Chemistry and Biochemistry; Springer: New York, NY, USA, 2009.

- Yin, S.; Liu, L.; Hou, J. A multivariate statistical combination forecasting method for product quality evaluation. Inf. Sci. 2016, 355–356, 229–236.

- Fotakis, C.; Kokkotou, K.; Zoumpoulakis, P.; Zervou, M. NMR metabolite fingerprinting in grape derived products: An overview. Food Res. Int. 2013, 54, 1184–1194.

- Fernández-Novales, J.; Sánchez, M.; López, M.; Garcúa-Mesa, J.; Ramúrez, P. Feasibility of using a miniature fiber optic UV-VIS-NIR spectrometer to assess total polyphenol index, color intensity and volumic mass in red wine fermentations. J. Food Process. Eng. 2011, 34, 1028–1045.

- Zhang, Q.; Chen, B. Research progress of four sulfur compounds related to red wine flavor. Sci. Agric. Sin. 2020, 53, 1029–1045.

- Exposito, I.; Cuinas, I.; Gay-Fernandez, J.A. Efficient traceability solutions in the wine production by RFID and WSN. In Proceedings of the 2013 7th European Conference on Antennas and Propagation (EuCAP), Gothenburg, Sweden, 8–12 April 2013; pp. 3539–3542.

- Galvez, J.F.; Mejuto, J.C.; Simal-Gandara, J. Future challenges on the use of blockchain for food traceability analysis. TrAC Trends Anal. Chem. 2018, 107, 222–232.

- Shahid, A.; Almogren, A.S.; Javaid, N.; Al-Zahrani, F.A.; Zuair, M.; Alam, M. Blockchain-Based Agri-Food Supply Chain: A Complete Solution. IEEE Access 2020, 8, 69230–69243.

- Tian, F. A supply chain traceability system for food safety based on HACCP, blockchain & internet of things. In Proceedings of the 14th International Conference on Services Systems and Services Management (ICSSSM 2017), Dalian, China, 16–18 June 2017.

- Aiello, G.; Enea, M.; Muriana, C. The expected value of the traceability information. Eur. J. Oper. Res. 2015, 244, 176–186.

- Beaman, R.; Cellinese, N. Mass digitization of scientific collections: New opportunities to transform the use of biological specimens and underwrite biodiversity science. ZooKeys 2012, 209, 7–17.

- Adamashvili, N.; Fiore, M.; Contò, F.; La Sala, P. Ecosystem for Successful Agriculture. Collaborative Approach as a Driver for Agricultural Development. Eur. Countrys. 2020, 12, 242–256.

- Caro, M.P.; Ali, M.S.; Vecchio, M.; Giaffreda, R. Blockchain-based traceability in agri-food supply chain management: A practical implementation. In Proceedings of the 2018 IoT Vertical and Topical Summit on Agriculture-Tuscany (IOT Tuscany), Tuscany, Italy, 8–9 May 2018; pp. 1–4.

- Huck, C.W.; Pezzei, C.K.; Huck-Pezzei, V.A. An industry perspective of food fraud. Curr. Opin. Food Sci. 2016, 10, 32–37.

- Alketbi, A.; Nasir, Q.; Talib, M.A. Blockchain for government services-use cases, security benefits and challenges. In Proceedings of the 2018 15th Learning and Technology Conference (L and T), Jeddah, Saudi Arabia, 25–26 February 2018; pp. 112–119.

- Meroni, G.; Plebani, P. Combining artifact-driven monitoring with blockchain: Analysis and solutions. In Advanced Information Systems Engineering Workshops; CAiSE 2018; Lecture Notes in Business Information Processing; Matulevičius, R., Dijkman, R., Eds.; Springer: Cham, Switzerland, 2018; p. 316.

- Stubbs, M. Big Data in U.S. Agriculture, Congressional Research Service. 2016. Available online: https://sgp.fas.org/crs/misc/R44331.pdf (accessed on 23 September 2021).

- Raikwar, M.; Gligoroski, D.; Kralevska, K. SoK of Used Cryptography in Blockchain. IEEE Access 2019, 7, 148550–148575.

- Condos, J.; Sorrell, W.H.; Donegan, S.L. Blockchain Technology: Opportunities and Risks. 2016. Available online: https://legislature.vermont.gov/assets/Legislative-Reports/blockchain-technology-report-final.pdf (accessed on 23 September 2021).

- Smith, J.; Tennison, J.; Wells, P.; Fawcett, J.; Harrison, S. Applying blockchain technology in global data infrastructure. Open Data Inst. 2016. Available online: https://theodi.org/article/applying-blockchain-technology-in-global-data-infrastructure-2/ (accessed on 23 September 2021).

- Caseau, Y.; Soudoplatoff, S. The Blockchain, or Distributed Trust. Fond. Pour L’innovation Polit. 2016. Available online: https://oiipdf.com/yves-caseau-and-serge-soudoplatoff-the-blockchain-or-distributed-trust (accessed on 23 September 2021).

- Hon, W.K.; Palfreyman, J.; Tegart, M. Distributed Ledger Technology and Cybersecurity: Improving Information Security in the Financial Sector; Technical Report; European Union Agency For Network and Information Security: Heraklion, Greece, 2016.

- Anderberg, A.; Andonova, E.; Bellia, M.; Calès, L.; Inamorato dos Santos, A.; Kounelis, I.; Nai Fovino, I.; Petracco Giudici, M.; Papanagiotou, E.; Sobolewski, M.; et al. Blockchain Now and Tomorrow: Assessing Multidimensional Impacts of Distributed Ledger Technologies; Report EUR 29813 EN; Nascimento, S., Pólvora, A., Eds.; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-76-08977-3.

- Zhang, Z.; Zhao, L. A design of digital rights management mechanism based on blockchain technology. In Blockchain–ICBC 2018; Chen, S., Wang, H., Zhang, L.J., Eds.; ICBC 2018; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2018; Volume 10974.

- Zhang, K.; Jacobsen, H. Towards dependable, scalable, and pervasive distributed ledgers with blockchains. In Proceedings of the International Conference on Distributed Computing Systems, Vienna, Austria, 2–5 July 2018; pp. 1337–1346.

- Reyna, A.; Martín, C.; Chen, J.; Soler, E.; Díaz, M. On blockchain and its integration with IoT. challenges and opportunities. Future Gener. Comput. Syst. 2018, 88, 173–190.

- Haber, S.; Stornetta, W.S. How to time-stamp a digital document. J. Cryptol. 1991, 3, 99–111.

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. 2008. Available online: https://bitcoin.org/bitcoin.pdf. (accessed on 23 September 2021).

- Zhao, G.; Liu, S.; Lopez, C.; Lu, H.; Elgueta, S.; Chen, H.; Boshkoska, B.M. Blockchain technology in agri-food value chain management: A synthesis of applications, challenges and future research directions. Comput. Ind. 2019, 109, 83–99.

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the blockchain enabled traceability in agriculture supply chain. Int. J. Inf. Manag. 2020, 52, 101967.

- Malik, S.; Kanhere, S.S.; Jurdak, R. ProductChain: Scalable blockchain framework to support provenance in supply chains. In Proceedings of the 2018 IEEE 17th International Symposium on Network Computing and Applications (NCA), Cambridge, MA, USA, 1–3 November 2018.

- Gourisetti, S.N.G.; Mylrea, M.; Patangia, H. Evaluation and demonstration of blockchain applicability framework. IEEE Trans. Eng. Manag. 2020, 67, 1142–1156.

- Kennedy, J. $1.4bn Investment in Blockchain Start-Ups in Last 9 Months, Says PwC Expert. 2016. Available online: https://www.siliconrepublic.com/start-ups/blockchain-pwc-investment (accessed on 23 September 2021).

- Okada, H.; Yamasaki, S.; Bracamonte, V. Proposed classification of blockchains based on authority and incentive dimensions. In Proceedings of the International Conference on Advanced Communication Technology (ICACT), Pyeongchang, Korea, 19–22 February 2017; pp. 593–597.

- Fabiano, N. Internet of things and blockchain: Legal issues and privacy. the challenge for a privacy standard. In Proceedings of the 2017 IEEE International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Exeter, UK, 21–23 June 2017; pp. 727–734.

- Hebert, C.; Di Cerbo, F. Secure blockchain in the enterprise: A methodology. Pervasive Mob. Comput. 2019, 59, 101038.

- Chaudhry, N.; Yousaf, M.M. Consensus algorithms in blockchain: Comparative analysis, challenges and opportunities. In Proceedings of the 2018 International Conference on Open Source Systems and Technologies (ICOSST), Lahore, Pakistan, 19–21 December 2018; pp. 54–63.

- Desai, H.; Kantarcioglu, M.; Kagal, L. A hybrid blockchain architecture for privacy-enabled and accountable auctions. In Proceedings of the 2019 2nd IEEE International Conference on Blockchain (Blockchain), Atlanta, GA, USA, 14–17 July 2019; pp. 34–43.

- Regulation (EU). 2018/1807 of the European Parliament and of the Council of 14 November 2018 on a Framework for the Free Flow of Non-Personal Data in the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32018R1807 (accessed on 23 September 2021).

- Sheldon, M.D. A primer for information technology general control considerations on a private and permissioned blockchain audit. Curr. Issues Audit. 2019, 13, A15–A29.

- Terzi, S.; Zacharaki, A.; Nizamis, A.; Votis, K.; Ioannidis, D.; Tzovaras, D.; Stamelos, I. Transforming the supply-chain management and industry logistics with blockchain smart contracts. In Proceedings of the 23rd Pan-Hellenic Conference on Informatics (PCI’19); Association for Computing Machinery: New York, NY, USA, 2019; pp. 9–14.

- Malik, S.; Dedeoglu, V.; Kanhere, S.S.; Jurdak, R. TrustChain: Trust management in blockchain and iot supported supply chains. In Proceedings of the 2019 2nd IEEE International Conference on Blockchain (Blockchain), Atlanta, GA, USA, 14–17 July 2019; pp. 184–193.

- Gemeliarana, I.G.A.K.; Sari, R.F. Evaluation of proof of work (POW) blockchains security network on selfish mining. In Proceedings of the 2018 International Seminar on Research of Information Technology and Intelligent Systems (ISRITI), Yogyakarta, Indonesia, 21–22 November 2018; pp. 126–130.

- Yao, Z.; Pan, H.; Si, X.; Zhu, W. Decentralized access control encryption in public blockchain. In Blockchain and Trustworthy Systems; Zheng, Z., Dai, H.N., Tang, M., Chen, X., Eds.; BlockSys 2019; Communications in Computer and Information Science; Springer: Singapore, 2019; Volume 1156.

- Falazi, G.; Khinchi, V.; Breitenbücher, U.; Leymann, F. Transactional properties of permissioned blockchains. SICS Softw. Intensive Cyber-Phys. Syst. 2020, 35, 49–61.

- Buterin, V. On Public and Private Blockchains. 2015. Available online: https://blog.ethereum.org/2015/08/07/on-public-and-private-blockchains/ (accessed on 1 December 2020).

- Zheng, Z.; Xie, S.; Hongning, D.; Xiangping, C.; Huaimin, W. An overview of blockchain technology: Architecture, consensus, and future trands. In Proceedings of the IEEE 6th international congress on Big Data, Honolulu, HI, USA, 25–30 June 2017; pp. 557–564.

- El Bilali, H.; Bottalico, F.; Ottomano Palmisano, G.; Capone, R. Information and Communication Technologies for Smart and Sustainable Agriculture. In 30th Scientific-Experts Conference of Agriculture and Food Industry; Brka, M., Omanović-Mikličanin, E., Karić, L., Falan, V., Toroman, A., Eds.; AgriConf 2019; IFMBE Proceedings; Springer: Cham, Switzerland, 2020; Volume 78.

- Lin, W.; Huang, X.; Fang, X.; Wang, V.; Hua, Y.; Wang, J.; Yin, H.; Yi, D.; Yau, L. Blockchain Technology in Current Agricultural Systems: From Techniques to Applications. IEEE Access 2020, 8, 143920–143937.

- Jabir, B.; Falih, N. Digital agriculture in morocco, opportunities and challenges. In Proceedings of the 6th International Conference on Optimization and Applications (ICOA 2020), Beni Mellal, Morocco, 20–21 April 2020; pp. 1–5.

- Ciruela-Lorenzo, A.M.; Del-Aguila-Obra, A.R.; Padilla-Meléndez, A.; Plaza-Angulo, J.J. Digitalization of Agri-Cooperatives in the Smart Agriculture Context. Proposal of a Digital Diagnosis Tool. Sustainability 2020, 12, 1325.

- Jennath, H.S.; Adarsh, S.; Anoop, V.S. Distributed IoT and Applications: A Survey. In Integrated Intelligent Computing, Communication and Security; Krishna, A., Srikantaiah, K., Naveena, C., Eds.; Studies in Computational Intelligence; Springer: Singapore, 2019; Volume 771.

- Gorshkova, N.V.; Kusmartseva, J.V. Financial Aspects of the Digital Economy Development in the Agricultural Sector. In Competitive Russia: Foresight Model of Economic and Legal Development in the Digital Age; Inshakova, A., Inshakova, E., Eds.; CRFMELD 2019; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2019; Volume 110.

- Demestichas, K.; Peppes, N.; Alexakis, T.; Adamopoulou, E. Blockchain in Agriculture Traceability Systems: A Review. Appl. Sci. 2020, 10, 4113.

- Song, L.; Wang, X.; Merveille, N. Research on Blockchain for Sustainable E-Agriculture. In Proceedings of the IEEE Technology & Engineering Management Conference (TEMSCON), Novi, MI, USA, 3–6 June 2020; pp. 1–5.

- Fernandez, A.; Waghmare, A.; Tripathi, S. Agricultural Supply Chain using Blockchain. In Proceedings of International Conference on Intelligent Manufacturing and Automation; Lecture Notes in Mechanical Engineering; Vasudevan, H., Kottur, V., Raina, A., Eds.; Springer: Singapore, 2020.

- Katsikouli, P.; Wilde, A.S.; Dragoni, N.; Høgh-Jensen, H. On the Benefits and Challenges of Blockchains for Managing Food Supply Chains. J. Sci. Food Agric. 2020, 101, 2175–2181.

- Caballero, R.; Rivera, B. Blockchain: An Alternative to Enable Traceability in the Agricultural Supply Chain in Panama. In Proceedings of the 7th International Engineering, Sciences and Technology Conference (IESTEC), Panama, Panama, 9–11 October 2019; pp. 46–51.

- Bermeo-Almeida, O.; Cardenas-Rodriguez, M.; Samaniego-Cobo, T.; Ferruzola-Gómez, E.; Cabezas-Cabezas, R.; Bazán-Vera, W. Blockchain in Agriculture: A Systematic Literature Review. In Technologies and Innovation. CITI 2018. Communications in Computer and Information Science; Valencia-García, R., Alcaraz-Mármol, G., Del Cioppo-Morstadt, J., Vera-Lucio, N., Bucaram-Leverone, M., Eds.; Springer: Cham, Switzerland, 2018; Volume 883.

- European Parliament and of the Council. European Parliament Regulation (EC) No 178/2002; Official Journal of the European Union: Brussels, Belgium, 2002; pp. 1–24.

- Mirabelli, G.; Solina, V. Blockchain and Agricultural Supply Chains Traceability: Research Trends and Future Challenges. Procedia Manuf. 2020, 42, 414–421.

- Pouliot, S.; Sumner, D.A. Traceability, recalls, industry reputation and product safety. Eur. Rev. Agric. Econ. 2013, 40, 121–142.

- Dave, D.; Parikh, S.; Patel, R.; Doshi, N. A Survey on Blockchain Technology and its Proposed Solutions. Procedia Comput. Sci. 2019, 160, 740–745.

- Umamaheswari, S.; Sreeram, S.; Kritika, N.; Jyothi Prasanth, D.R. BIoT: Blockchain Based IoT for Agriculture. In Proceedings of the 1th International Conference on Advanced Computing (ICoAC), Chennai, India, 2019; pp. 324–327.

- Tian, F. An agri-food supply chain traceability system for China based on RFID & Blockchain technology. In Proceedings of the 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016; pp. 1–6.

- Khan, P.W.; Byun, Y.; Park, N. IoT-Blockchain Enabled Optimized Provenance System for Food Industry 4.0 using Advanced Deep Learning. Sensors 2020, 20, 2990.

- FAO; International Telecommunication Union. E-agriculture in Action: Blockchain for Agriculture, Opportunity and Challenges; FAO: Bangok, Thailand, 2019.

- Yang, H.; Xiong, S.; Frimpong, S.A.; Zhang, M. A Consortium Blockchain-Based Agricultural Machinery Scheduling System. Sensors 2020, 20, 2643.

- Fiore, M.; Silvestri, R.; Contò, F.; Pellegrini, G. Understanding the relationship between green approach and marketing innovations tools in the wine sector. J. Clean. Prod. 2017, 142, 4085–4091.

- Fiore, M.; Alaimo, L.S.; Chkhartishvili, N. The Amazing Bond among Wine Consumption, Health and Hedonistic Well-being. Br. Food J. 2019, 122, 2707–2723.

- Contò, F.; Santini, C.; La Sala, P.; Fiore, M. Reducing Information Gap and Increasing Market Orientation in the Agribusiness Sector: Some Evidences from Apulia Region. Recent Pat. Food Nutr. Agric. 2016, 8, 48–54.

- Fiore, M. Direct Selling in the Wine Sector: Lessons from Cellars in Italy’s Apulia Region. Br. Food J. 2016, 118, 1946–1959.

- Valmori, I. Enology: La Blockchain Pubblica e Gratuita a Garanzia Del Vino. AgroNotizie–Le Novità Per L’agricoltura 2018. Available online: https://agronotizie.imagelinenetwork.com/agricoltura-economia-politica/2018/04/19/enology-la-blockchain-pubblica-e-gratuita-a-garanzia-del-vino/58387 (accessed on 23 September 2021).

More

Information

Subjects:

Agricultural Economics & Policy

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.7K

Revisions:

2 times

(View History)

Update Date:

01 Dec 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No