Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Rohan Dassanayake | + 2510 word(s) | 2510 | 2021-11-23 09:27:08 | | | |

| 2 | Catherine Yang | Meta information modification | 2510 | 2021-11-23 10:23:46 | | | | |

| 3 | Lindsay Dong | Meta information modification | 2510 | 2022-03-28 05:47:52 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Dassanayake, R. Compatibilization in Starch/Synthetic Biodegradable Polymer Blends. Encyclopedia. Available online: https://encyclopedia.pub/entry/16291 (accessed on 08 February 2026).

Dassanayake R. Compatibilization in Starch/Synthetic Biodegradable Polymer Blends. Encyclopedia. Available at: https://encyclopedia.pub/entry/16291. Accessed February 08, 2026.

Dassanayake, Rohan. "Compatibilization in Starch/Synthetic Biodegradable Polymer Blends" Encyclopedia, https://encyclopedia.pub/entry/16291 (accessed February 08, 2026).

Dassanayake, R. (2021, November 23). Compatibilization in Starch/Synthetic Biodegradable Polymer Blends. In Encyclopedia. https://encyclopedia.pub/entry/16291

Dassanayake, Rohan. "Compatibilization in Starch/Synthetic Biodegradable Polymer Blends." Encyclopedia. Web. 23 November, 2021.

Copy Citation

The immiscibility issue between starch and synthetic polymers impacts the water absorption, thermo-mechanical properties, and chemical stability demanded by various engineering applications. Incorporating compatibilizers into the blend mixtures has significantly reduced the particle sizes of the dispersed phase while improving the interfacial adhesion between the starch and synthetic biodegradable polymer, leading to fine and homogeneous structures.

thermoplastic starch

synthetic biodegradable polymers

food packaging

Polysaccharides

1. Starch/PCL Blends

Singh et al. [1] explored the effect of PCL grafted dextran copolymer (PGD) as a compatibilizer for cornstarch/PCL blends and surface modification of granular starch via a hydrophobic coating. This study displayed an increased degradation rate compared to pure PCL since the incorporation of starch accelerates the biodegradation rate of the blend compounds. However, when surface-modified starch was replaced by high amylose corn starch or waxy maize starch, a significant reduction in the degradation rate was observed. The authors also reported an improvement in the degradation rate of compatibilized starch/PCL blend compatibilized with PGD compared to pure PCL/starch blend. From a mechanical point of view, the grafting of PCL chains at the surface of starch enhanced both rigidity and toughness with a significant increase in both Young’s modulus and tensile strength from 295 to 365 MPa and 9.6 to 13.0 MPa, respectively. Moreover, it was evidenced that, whatever the compatibilizing agent, the biodegradation of starch/PCL blends starts with starch consumption and continuously increases with the content in natural filler [1].

The thermo-mechanical properties of this study are enumerated in Table 1. The starch particles in compatibilized blends displayed a smoother interface with the PCL matrix than a non-compatibilized blend. The authors also displayed a higher modulus compared to that of a non-compatibilized blend incorporating 1 wt% of PCL-g-DEM. However, at higher DEM intakes, a significant reduction in modulus was observed, see Table 1. During the experiment, PCL-g-GMA (2 wt%) was incorporated with varying starch/PCL blends. Herein, for all the starch intakes, the tensile strength and strain at break decreased while the modulus was constant at low starch contents and significantly increased for the compatibilized blends with 30% starch. Therefore, based on the above results, it is suggested that the efficacy of PCL-g-GMA as a compatibilizer increased considerably at higher starch contents. Interestingly, PCL-g-DEM seems to provide a better compatibilization effect at a fixed starch content than PCL-g-GMA, as depicted in Table 1. Moreover, from a practical point of view, PCL-g-DEM can replace PCL-g-GMA at low starch contents [2].

Table 1. Comparison of thermo-mechanical properties of Starch/PCL blends [2].

| Sample | Maximum Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) | Melting Temperature (°C) |

|---|---|---|---|---|

| Neat PCL | 16.3 | 640.5 | 270.2 | 57 |

| Starch/PCL: 10/90 | 15.3 | 489.5 | 321.2 | 57 |

| Starch/PCL: 20/80 | 10.5 | 425.4 | 337.0 | 57 |

| Starch/PCL: 30/70 | 7.1 | 230.0 | 341.8 | 57 |

| Starch/PCL/PCL-g-DEM: 20/80/1 | 11.1 | 401.8 | 371.2 | 57 |

| Starch/PCL/PCL-g-DEM: 20/80/2 | 10.9 | 384.9 | 342.8 | 57 |

| Starch/PCL/PCL-g-DEM: 20/80/5 | 11.0 | 379.5 | 329.9 | 57 |

| Starch/PCL/PCL-g-GMA: 20/80/1 | 9.2 | 357.2 | 368.3 | 57 |

| Starch/PCL/PCL-g-GMA: 20/80/2 | 9.6 | 343.4 | 380.8 | 58 |

| Starch/PCL/PCL-g-GMA: 20/80/5 | 11.7 | 431.6 | 372.6 | 57 |

| Starch/PCL/PCL-g-GMA: 20/80/10 | 10.1 | 305.9 | 386.0 | 57 |

| Starch/PCL/PCL-g-GMA: 10/90/2 | 13.6 | 424.6 | 332.0 | 58 |

| Starch/PCL/PCL-g-GMA: 30/70/2 | 5.5 | 168.9 | 430.3 | 5 |

2. Starch/PVA Blends

TPS and polyvinyl alcohol (PVA) blends have captured greater attention since starch lowers the cost [3], improves gas barrier properties, and enhances biodegradation. In addition, PVA can also improve the excellent mechanical, thermal, and water resistance properties of the film material [4][5][6][7][8].

Even though the combined properties of starch-PVA make them popular biodegradable blends, mechanical and water barrier properties are still lower than those of some synthetic petroleum-based polymeric materials [4][9]. However, the properties of the blends deteriorated as the starch content in the blend films increased due to poor compatibility between starch and PVA, leading to phase separation during blend preparation [6]. Moreover, the modification of starch, blend ratio, and molecular weight of PVA control the properties of these starch/PVA blends [10][11][12].

3. Starch/PBS Blends

Currently, it has become a common practice to incorporate starch in the PBS matrix to achieve a cost reduction, improved rate of biodegradation, and sustainable film materials with numerous properties, while expanding its applications in packaging and flushable hygiene products remains possible [13][14]. However, the blending mechanism of thermoplastic starch and PBS is quite difficult due to their immiscibility caused by differences in their viscosity and interfacial tension [14].

The observations related to water absorption experiments revealed that incorporating hydrophobic PBS lowered the water absorption of TPS and reduced the water sensitivity of TPS/PBS blends. However, the amount of compatibilizer did not affect the water resistance of TPS/PBS blends. The authors suggested that the compatibilized TPS/PBS blends with rPBS, combined with biodegradability, high strength, and water resistance, could represent a strong candidate as packaging materials [15].

To evaluate the performance of compatibility of starch/PBS blends, the phase separation in terms of the gap between starch and PBS was examined. The results indicated that the compatibilized blends had few gaps between the starch granules and PBS. Moreover, the starch-g-PBS could provide better compatibility in the blends containing 20% and 40% starch. Suchao-M et al. [16] also reported an improvement in the modulus and higher yield strengths in compatibilized blends, and this behavior might be due to the fact that the compatibilizer provides the interfacial adhesion between starch and PBS, resulting in an improvement of the stress transfer between the two-component phases. Apart from the above-described properties, melt viscosity plays a significant role as a guideline for processing. According to the results obtained related to melt viscosity index, the melt viscosity index of the compatibilized blends containing 20% and 40% starch was ~5–7 g/10 min, which is suitable for the production of foam products [16].

Besides, Fahrngruber et al. [14] prepared TPS/PBS blends in the presence of two different types of compatibilizer systems based on native starch and pre-plasticized/destructurized starch. The study demonstrated an improvement in elongation at break, maximum tensile strength, and tear resistance in the compatibilized blends with increased starch and pre-plasticized/destructurized starch contents in the compatibilizers. However, with the addition of a native starch-based compatibilizer, only limited stability was provided. In contrast, the destructurized starch-based compatibilizng agent could provide a larger interaction surface (amylose/amylopectin-PBS, and probably also glycerol-PBS) and give a more homogenized sample. Apart from the above observations, the water vapor permeability increased in all the compatibilized samples compared to that of the pure TPS/PBS blend, and such behavior might be due to the improved incorporation of native starch and TPS within the polyester matrix, due to which the hydrophilic characteristics of the starch component became more dominant. Furthermore, the disintegration results imply that, after 10 days, visible cracks developed on the surfaces of both compatibilized and non-compatibilized samples, transforming into holes after 20 days. However, the disintegration of the pure TPS/PBS blend sample processed slightly faster compared to that of the compatibilized samples [14].

4. Starch/PLA Blends

Although PLA has suitable properties related to packaging applications, the usage has been reduced due to high cost, brittleness, poor processability window, high moisture permeability, and low toughness [17][18][19]. Therefore, the low price and completely biodegradable nature of starch make it possible to be used as filler in PLA, improving the properties suitable for various applications [18][20].

Akrami et al. [21] explored the effect of maleic anhydride grafted poly-ethylene glycol grafted starch (mPEG-g-St) as a compatibilizer for biodegradable TPS/PLA blend composites. This study demonstrated that, in compatibilized blends, spherical particles were formed, and a better dispersion was obtained. This is probably due to improved interfacial adhesion between the two polymer phases in the blends compared to that of control blends.

Wang et al. examined the effect of low toxicity maleic anhydride as a compatibilizer in dried thermoplastic corn starch (DTPS)/PLA blends. Here, dicumyl peroxide (DCP) was used as the initiator along with MA. The authors reported a better dispersion between TPS and PLA while the granule size of starch decreased dramatically in the presence of MA and DCP compared to that of control blends. Moreover, it was observed that, with the increment of the starch contents in the blends, the mechanical properties worsened notably, and such behavior could be attributed to the poor interfacial adhesion between the two phases. However, in all the compatibilized blends, the mechanical properties improved dramatically while exhibiting the highest values for maximum tensile strength (40.5 MPa) and elongation at break (3.5%) by the blend possessing the highest amount of compatibilizer and the lowest amount of dried starch. Interestingly, even at increased starch contents in the blends, the mechanical properties did not worsen considerably in the presence of MA along with DCP [22].

Liu and his coworkers synthesized PLA grafted glycidyl methacrylate (GPLA-x) as the compatibilizing agent to improve the compatibility in PLA/TPS blended sheets. The authors reported an enhanced dispersion of the starch granules in the PLA matrix while reinforcing interface bonding between PLA and starch with the addition of GPLA-x. The expected reaction mechanism of GPLA-x compatibilizer might be that GPLA consists of the glycidyl functional group of the epoxide, which may react with OH groups of glucose units in starch. The study also provided a remarkable increase in maximum tensile strength from 18.6 to 29.3 MPa, tensile modulus from 510 to 901 MPa, and elongation at break from 1.8% to 3.4% for the non-compatibilized blend and PLA/TPS/GPLA-11 blend, respectively.

Wootthikanokkhan and coworkers investigated the effect of polylactic acid grafted maleated thermoplastic starch (PLA-g-MTPS) as a compatibilizer in PLA/TPS blends. This study revealed that the tensile properties of the blends were highly dependent on the type of copolymer used. As the PLA grafted maleic anhydride (PLA-g-MA) was added into the blends, a slight decrease in the tensile properties compared to that of control blends was observed. However, with the incorporation of PLA-g-MTPS into PLA/TPS 80/20, the blend could display a notable increase in tensile strength compared to that of the control blends, while the compatibilizing efficacy of the PLA-g-MTPS copolymer became more pronounced when the starch content was further increased to 30% and 40%. A similar behavior could be observed for both elongation at break and toughness [23].

The effectiveness of PCL after grafting with maleic anhydride and glycidyl methacrylate in corn starch/PLA blends was also investigated [24]. Here two modification reactions were carried out to prepare two different types of PCL-based compatibilizers: (i) Modification of MA and glycidyl methacrylate to obtain PCLMG; (ii) Modification with only using glycidyl methacrylate to obtain PCLG. The authors discovered that the blend containing 20% of PLA compatibilized with 5% PCLG exhibited the most homogeneous structure with the highest dispersion level of PLA in the starch matrix. According to thermo-gravimetry analysis (TGA) results, all the compatibilized and non-compatibilized blends exhibited three degradation phases at different intensities depending on the composition of the mixture. However, both the initial degradation temperature and the temperature at the maximum degradation rate of polymers were closer to the corresponding temperature of starch due to its higher ratios in the blended sheets. Moreover, in compatibilized blends containing 20% PLA, there was a significant increase in elastic modulus (a nearly two-fold increase with PCL2.5MG) and tensile strength (a nearly 1.5-fold increase with the incorporation of PCL2.5G) when compared to the control blend. Even though the partial substitution of PLA into starch reduced the water vapor permeability of the blends, there was no significant reduction in oxygen gas permeability. Interestingly, the reduction in water vapor permeability in the compatibilized blend with 40% PLA and 5% PCLG was more remarkable. Furthermore, it was reported that, from a mechanical point of view, the blend containing 20% PLA and 5% PCL showed comparatively better tensile strength and extensibility. Besides, dry or partially dehydrated products and fatty or oxidation-sensitive foods could be adequately packaged with these films, thus improving their preservation [24].

5. Starch/PHBV Blends

To overcome the drawbacks of PHBV, efforts have been made towards PHBV/thermoplastic starch (TPS) blends to reduce the cost and improve the biodegradation rate of PHBV [25][26]. However, only a limited number of research has been conducted to explore the effect of compatibilization of starch/PHBV blends.

Moreover, the biodegradation rate drastically increased from 76% to 90% with organically modified montmorillonite. Moreover, all PHBV/TPS blends degraded faster than PHBV alone. Therefore, it was evidenced that organically modified montmorillonite acted as a compatibilizing agent for the two immiscible polymer pairs, namely PHBV and thermoplastic starch [25].

6. Starch/PBAT Blends

Although the tensile strength at break decreased in the presence of both MA and CA to around 8 MPa, the best mechanical properties were achieved when the blend was compatibilized with 2% PBAT-g-MA with a maximum tensile strength of 12 MPa, elongation at break of 380%, and a modulus of 58 MPa. Moreover, the minimum amount of water was absorbed in the presence of PBAT-g-MA. The authors also reported an enhanced interfacial adhesion in the presence of PBAT-g-MA occurred via ester-linkage between the grafted MA onto starch and PBAT. Based on the above facts, the authors reported PBAT-g-MA as the best compatibilizer for TPS/PBAT 60/40 blends over MA and CA compatibilizers alone [27].

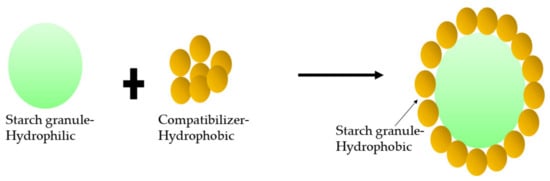

Ren and coworkers explored the effect of maleic anhydride as a compatibilizer for TPS/PLA/PBAT blends prepared via one-step melt processing. The results of the study indicated an increase in both tensile strength and elongation at break for the whole composition range after incorporating a small amount of compatibilizer into the blends. However, as PBAT content was increased, the elongation at break increased. This behavior could be observed for both compatibilized and non-compatibilized blends. Moreover, it was deduced from SEM images that, in non-compatibilized blends, large starch phase domains could be found, while after compatibilized, the starch granules were mostly melted and formed a continuous phase with synthetic polymer matrix. Therefore, the non-compatibilized blends showed lower mechanical properties compared to those of compatibilized blends. The above results imply that the anhydride functionalized polymer acted as a hydrophobic coating around hydrophilic TPS, thus improving the interfacial adhesion between the blend components (see Figure 1), thereby producing finer and uniform morphology with improved mechanical properties. In addition, the authors demonstrated an increase in melt flow index of the compatibilized blends, suggesting the suitability of the prepared blends for injection moulding. Furthermore, it was also reported that the equilibrium water content increased from 16% to 20% as the PBAT content was increased from 0% to 50%. However, the equilibrium water uptake of the compatibilized blends was comparatively lower than the non-compatibilized blends [28].

Figure 1. The formation of hydrophobic starch granule.

7. Starch/PHB Blends

Blending PHB with thermoplastic starch (TPS) has become one of the widely used methods to address the previously mentioned drawbacks of PHB alone while reducing the cost and maintaining biocompatibility and renewability. However, the necessity of improving the compatibility between PHB and TPS has drawn particular attention due to the immiscibility between these two separate components [29][30].

An investigation has been carried out by Ma et al. [29] to explore the effect of in situ compatibilization via maleic anhydride (MA) and benzoyl peroxide (BPO) in PHB/polyethylene-co-vinyl acetate (EVA)/starch blends. According to the results obtained through SEM images, in a non-compatibilized PHB/EVA/starch blend, large starch particles were observed in the PHB matrix while EVA existed as fine domains. However, with the incorporation of MA into the blends, the size of starch particles reduced, suggesting a better adhesion between the phases, while starch migrated from the PHB matrix into the EVA phase when the MA content was increased to 0.18 and 0.36 wt%. The authors also reported a significant variation in the mechanical properties of the blends. Although the maximum tensile strength at break first increased with the addition of MA content and then gradually decreased, the elongation at break increased monotonically with the increment of MA content in the blends.

References

- Singh, R.P.; Pandey, J.K.; Rutot, D.; Degee, P.; Dubois, P. Biodegradability of poly(ξ-caprolactone)/starch blends and composites in composting and culturing environments: The effect of compatibilization on the inherent biodegradability of the host polymer. J. Carbohydr. Res. 2003, 338, 1759–1769.

- Sugih, A.K.; Driijfhout, J.P.; Picchioni, F.; Janssen, L.P.B.M.; Heeres, H.J. Synthesis and properties of reactive interfacial agents for polycaprolactone-starch blend. J. Appl. Polym. Sci. 2009, 114, 2315–2326.

- Chen, Y.; Cao, X.; Chang, P.R.; Hunealut, M.A. Comparative study on the films of poly (vinyl alcohol)/pea starch nanocrystals and poly (vinyl alcohol)/native pea starch. Carbohydr. Polym. 2008, 73, 8–17.

- Poescu, M.; Dogavu, B.; Goanta, M.; Timpu, D. Structural and morphological evaluation of CNC reinforced PVA/Starch biodegradable films. Int. J. Biol. Macromol. 2018, 116, 385–393.

- Ismail, H.; Zaaba, N.F. Effect of additives on properties of polyvinyl alcohol (PVA)/tapioca starch biodegradable films. J. Polym. Plast. Technol. Eng. 2011, 49, 37–41.

- Gupta, V.K.; Priya, B.; Pathania, D.; Singh, A.S. Synthesis, characterization and antibacterial activity of biodegradable Starch/PVA composite films reinforced with cellulose fiber. J. Carbohydr. Polym. 2014, 109, 171–179.

- Luo, X.; Li, J.; Lin, X. Effect of gelatinization and additives on morphology and thermal behavior of corn starch/PVA blend films. Carbohydr. Polym. 2012, 90, 1595–1600.

- Jian, X.; Jiang, T.; Gan, L.; Zhang, X.; Dai, H.; Zhang, X. The plasticizing mechanism and effect of calcium chloride on starch/poly (vinyl alcohol) films. Carbohydr. Polym. 2012, 90, 1677–1684.

- Ismail, H.; Zaaba, N.F. The mechanical properties, water resistance and degradation behavior of silica-filled sago starch/PVA plastic films. J. Elastometer Plast. 2014, 46, 96–109.

- Jose, J.; De, S.K.; Almadeed, M.A.; Dakua, J.B.; Sreekumar, P.A.; Sougrat, R.; Al-Harthi, M.A. Compatibilizing role of carbon nanotubes in poly (vinyl alchohol)/Starch blend. Starch Starke 2014, 67, 147–153.

- Waterschoot, J.; Gomand, S.V.; Fierens, E.; Delcour, J.A. Production, structure, physiochemical and functional properties of maize, cassava, wheat, potato and rice starches. J. Starch Strake 2014, 66, 1–16.

- Wang, W.; Diao, E.; Zhang, H.; Dai, Y.; Huo, H.; Dong, H. Effect of co-plasticization of acetyl tributyl citrate and glycerol on the properties of starch/PVA films. J. Appl. Polym. Sci. 2015, 42544, 1–9.

- Ayadi, F.; Mamzad, S.; Portella, C.; Dole, P. Synthesis of bis (pyrrolidone-4-carboxylic acid)-based polyamides derived from renewable itaconic acid—Application as a compatibilizer in biopolymer blends. Soc. Polym. Sci. 2013, 45, 766–774.

- Fahrngruber, B.; Fortea-Verdejo, M.; Wimmer, R.; Mundigler, N. Starch/poly(butylene succinate) compatibilizers: Effect of different reaction-approaches on the properties of thermoplastic starch-based compostable films. J. Polym. Environ. 2020, 28, 257–270.

- Yin, Q.; Chen, F.; Zhang, H.; Liu, C. Fabrication and characterization of thermoplastic starch/poly (butylene succinate) blends with maleated poly (butylene succinate) as the compatibilizer. Plast. Rubber Compos. 2015, 44, 362–367.

- Suchao-in, K.; Koombhongse, P.; Chirachanchai, S. Starch grafted poly(butylene succinate) via conjugating reaction and its role of enhancing the compatibility. J. Carbohydr. Polym. 2014, 102, 95–102.

- Palai, B.; Biswal, M.; Mohanty, S.; Nayak, S.K. In situ reactive compatibilization of polylactic acid (PLA) and thermoplastic starch (TPS) blend: Synthesis and evaluation of extrusion blown films thereof. J. Ind. Crop. Prod. 2019, 141, 111748.

- Karagoz, S.; Ozkoz, G. Effects of a Diisocyanate compatibilization on the properties of Citric acid modified thermoplastic starch/poly (lactic acid) blend. J. Polym. Eng. Sci. 2013, 53, 2183–2193.

- Orozco, V.H.; Bristow, W.; Chankaew, W.; Lopez, B.L. Preparation and characterization of poly (lactic acid)-g-maleic anhydride + starch blends. J. Macromol. Sym. 2009, 277, 69–80.

- Hwang, S.W.; Shim, J.K.; Selke, S.; Soto-Valdez, H.; Rubino, M.; Aaras, R. Effect of maleic-anhydride grafting on the physical and mechanical properties of poly (l-lactic acid)/ starch blends. J. Mol. Mater. Eng. 2013, 298, 624–633.

- Akrami, M.; Ghasemi, I.; Azizi, H.; Karrabi, M.; Segedabadi, M. A new approach in compatibilization of the poly (lactic acid)/thermoplastic starch (PLA/TPS) blends. J. Carbohydr. Polym. 2016, 144, 254–262.

- Wang, N.; Yu, J.; Ma, X. Preparation and characterization of thermoplastic starch/PLA blends by one-step reactive extrusion. J. Polym. Int. 2007, 56, 1440–1447.

- Wootthikanokkhan, J.; Kasemawananimit, P.; Sombatsompop, N.; Kositchaiyong, A.; Ayuththaya, S.I.; Kaabbuathons, N. Preparation of modified starch-grafted-poly (lactic acid) and a study on compatibilizing efficacy of the copolymers in poly (lactic acid)/thermoplastic starch blends. J. Appl. Sci. 2012, 126, E389–E396.

- Collazo-Bigliardi, S.; Ortego-Toro, R.; Chiralt, A. Using grafted poly(ξ-caprolactone) for the compatibilization of thermoplastic starch-polylactic acid blends. J. React. Funct. Polym. 2019, 142, 25–35.

- Magalhaes, N.F.; Dahmouche, K.; Lopes, G.K.; Andrade, C.T. Using an organically-modified montmorillonite to compatibilize a biodegradable blend. J. Appl. Clay Sci. 2013, 72, 1–8.

- Lu, D.R.; Xiao, C.M.; Xu, S.J. Starch-based completely biodegradable polymer materials. Polym. Lett. 2009, 3, 366–375.

- Fourati, Y.; Taries, Q.; Mutje, P.; Boufi, S. PBAT/thermoplastic starch blends: Effect of compatibilizers on the rheological, mechanical and morphological properties. J. Carbohydr. Polym. 2018, 199, 51–57.

- Ren, J.; Fu, H.; Ren, T.; Yuan, W. Preparation and characterization of binary and ternary blends with thermoplastic starch, poly (lactic acid) and poly(butylene adipate-co-terephthelate). J. Carbohydr. Polym. 2009, 77, 576–582.

- Ma, P.; Xu, P.; Chen, M.; Dong, W.; Cai, X.; Schmit, P.; Spolstra, A.B.; Lemistic, P.J. Structure-properties relationship of reactively compatibilized PHB/EVA/Starch blends. J. Carbohydr. Polym. 2014, 108, 299–306.

- Florez, J.P.; Fazeli, M.; Simao, R.A. Preparation and characterization of thermoplastic starch composite reinforced by plasma-treated poly(hydroxybutyrate) PHB. Biomac 2018, 123, 609–621.

More

Information

Subjects:

Materials Science, Composites

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.0K

Revisions:

3 times

(View History)

Update Date:

28 Mar 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No