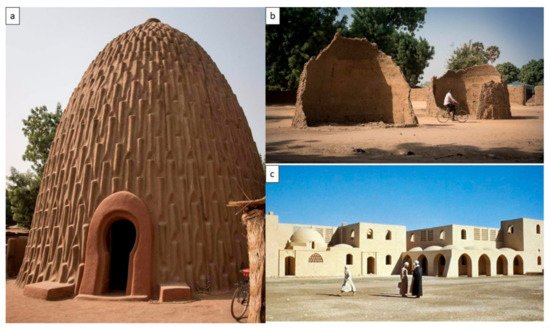

From a biolearning point of view, physiology is the scientific study of functions and mechanisms in a living system. Physiology focuses on how organisms, organ systems, individual organs, cells, and biomolecules carry out their chemical and physical functions in a living system

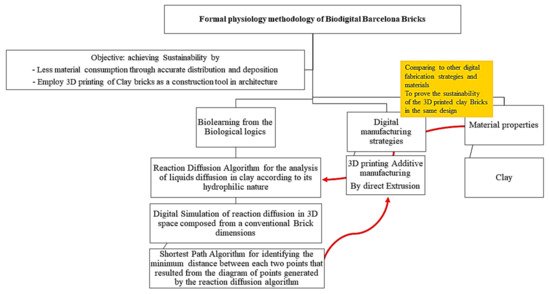

[13], whereas histology is the microscopic anatomy or microanatomy of biological tissues. Looking deeply into these two concepts, a strong bond always exists to relate the shape or form to its function. Human beings have always been subconsciously aware of this interdependent form–physiology relation, and they have applied it in designing their lives, from the simplest utilities to the largest shelters. Of course, the maturity, scale, and level of processing and integrating this concept in the design process has always been dependent on the level of invasion and magnification of visualization and analysis of the natural source of inspiration. This multi-scale biolearning started by the mere imitation of successful bio examples that applied the concept of formal physiology on a “macro” scale, for example, Gaudi’s Casa Batllo Bony Facade. Moving forward in time and in technological advancement, the level of invasion and magnification of these sources of inspiration has matured the biolearning process and enabled deep understanding and integration of the concept of formal physiology, from design to production. Complying with this concept, the Biodigital Barcelona Bricks presented in this work applied formal physiology in their formal design to achieve sustainability through minimum material usage and form-function adequacy. In the current study, a digital simulation was applied to perform a two-step simulation of the reaction–diffusion behavior based on clay’s hydrophilic properties and water content diffusion through its particles, as well as tuning the structural coherency of the resulting forms by applying the shortest path algorithm to minimize the distance between every two bearing points in the brick’s design, resulting in a distributed load effect. As implied from the structural function of the bricks, the function can be broken down into its physical and mechanical requirements

[14]. The first of these requirements is the load distribution avoiding stress being concentrated over specific points. The second is achieving maximum coherency and strength with the minimum amount of material.

Figure 2. Exhibits the followed methods to design and fabricate the proposed biodigital bricks.

2.1. Form Physiology: Biodigital Form-Finding, Simulation, and Optimization

Recently, achieving sustainability in the built environment takes the track of material customization and control. This is focused on developing the formal design of clay-based materials that open both the possibilities of integrating biodigital generative forms of digital DNA that is the algorithms or digital codes that are responsible for specific formal phenotypes that are extracted from the shape grammars of the original biological reference, or via hosting natural organisms or parts of them (as bacteria, fungi, algae, cells, genes, etc.) in an autonomous way to attain generative behavioral materials. These materials also facilitate the shape-changing of architectural elements, enabling the design process to include real-time morphogenesis by integrating an organism that grows and interacts with a consortium of materials, that compos its microenvironment. This aspect opens infinite applications of self-healing, clay-based materials and morphogenetic architecture in real performance, which are still a novel multidisciplinary field that requires further contributions.

Clay bricks in our biodigital age and by biodigital means, aims to achieve formal physiological sufficiency using a biolearning method while maintaining ease of implementation, mass production, and standardization. These were applied in the design and fabrication of the Biodigital Barcelona Bricks that were generatively designed using a form-finding process utilizing branching and reaction–diffusion algorithms to simulate the physical reaction of aqueous diffusion in clay. Reaction–diffusion systems are mathematical models which correspond to several physical phenomena. The most common of these is the change in space and time of the concentration of one or more chemical substances due to local chemical reactions and diffusion, which causes the substances to spread out over a surface in space. Reaction–diffusion systems are naturally applied in chemistry, biology, geology, and physics. Physically, the reaction–diffusion model describes the emergence of periodic patterns such as spots, stripes, and mazes through chemical interaction among cells

[15]. In the current work, this was applied as a first step of form finding a simulation. Through this simulation, the latest regions to absorb water (in clay) in the diffusion reaction were then connected through a branching algorithm of the shortest path, which, at the same time, describes a behavioral growth pattern found in nature. The shortest path, or Dijkstra’s algorithm, is an algorithm for finding the shortest paths between nodes in a graph, which may represent, for example, road networks.

[16], and as the name of the algorithm suggests, the “Shortest Path” was developed congruently with the structural function of these bricks, shortening the span between each bearing’s solid point in order to create a distributed load effect. In structural mechanics, the distributed load is a load that is distributed continuously over a given area or along a given line. A continuous load may be uniformly distributed, having a constant intensity, or vary according to some specific patterns

[17]. Thus, this shortest path algorithm applied in the current brick’s form finding is congruent with achieving the distributed load by minimizing the distance between each two points in the population of points composing the 3D space of this brick. These form-finding simulations were performed in Rhinoceros 3D

[18][19] (Anemone, and Kangaroo and fabricated by 3D printing by Noumena in Barcelona from November 2020 to March 2021, with the measurements of the traditional Catalan manual ceramic brick (4.5 × 14.5 × 29.5 cm).

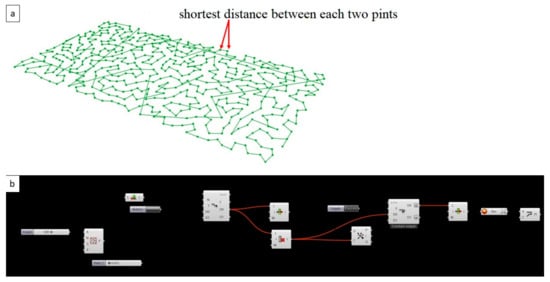

As an initial step, the reaction–diffusion algorithm was employed to generate a diagram of the latest points to absorb water or liquids based on the clay hydrophilic nature. Given these maps that specify where the latest points to absorb liquids are, a shortest path algorithm in Anemone was used to connect these points. Figure 3 shows the diagram of the shortest path algorithm connecting the reaction–diffusion’s latest points to absorb water.

Figure 3. The shortest path algorithm in Grasshopper Anemone that was employed to connect the resultant latest points in the reaction–diffusion system based on the hydrophilic nature of clay. This proves the structural coherence of the bricks’ design by minimizing the span between every two points while also minimizing the material consumption due to the accurate distributed material deposition where needed. (a) the resultant shortest path diagram of the connected points that were the last to absorb water in the volume of a conventional Catalan brick, and were resulting from the first step simulation of reaction diffusion, (b) the grasshopper algorithm of the shortest path logic that was applied to connect the result points from the first step simulation, in order to find the shortest distance between these points to minimize the span between them to achieve distributed load and minimum material deposition as well. Images by the author.

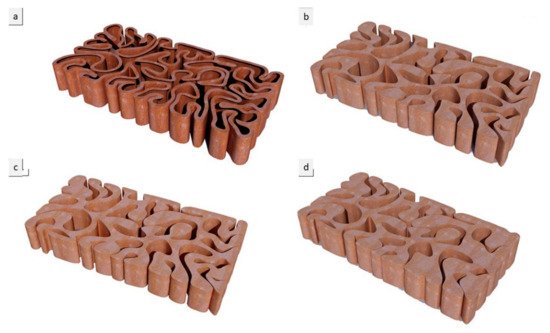

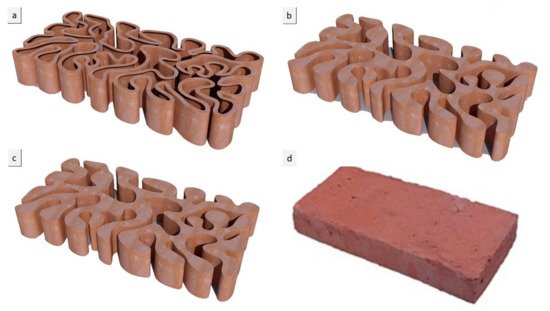

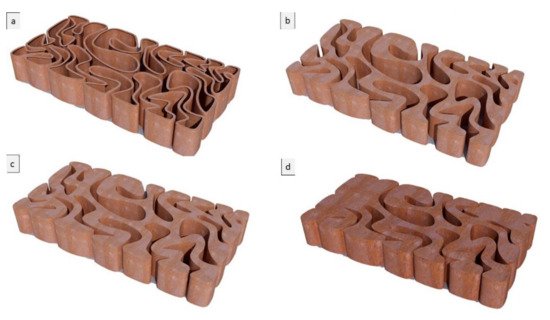

The third step was to examine these resulting shortest paths forms for the final brick resistance to cracking by applying a standard load simulation in Kangaroo, resulting in different design iterations: V1, V2, and V3. The optimum design iterations for structural behavior were selected to be further tested for various material densities, varying the density of each brick in a bulk brick model from 25%, to 55%, 75%, and 95%, and a linear or hollow brick model starting from the thickness of 0.25 cm, 0.55 cm, 0.75 cm, and 0.95 cm for each iteration (V1, V2, and V3), as shown in Figure 4, Figure 5 and Figure6.

Figure 4. Alberto T. Estévez (Yomna K. Abdallah, computational designer), Biodigital Barcelona Bricks (3D-printed clay), GENARQ/iBAG, UIC Barcelona. V1 design iteration of the Biodigital Barcelona Bricks showing the bricks’ varied material density from a linear model of 0.5 cm thickness to a bulk model (a–d), with the densities of the brick varying from 25% to 55% and 75%, to experiment structurally different densities of the 3D-printed bricks. Images by the author.

Figure 5. Alberto T. Estévez (Yomna K. Abdallah, computational designer), Biodigital Barcelona Bricks (3D-printed clay), GENARQ/iBAG, UIC Barcelona. V2 design iteration of the Biodigital Barcelona Bricks showing the bricks’ varied material density from a linear model of 0.5 cm thickness in (a) to a bulk model, with densities of the brick varying from (b) 25% material deposition density to (c) 55% material deposition density, (d) exhibits the original Catalan brick form and unified density in comparison to the optimized proposed Biodigital Barcelona Bricks. Images by the author.

Figure 6. Alberto T. Estévez (Yomna K. Abdallah, computational designer), Biodigital Barcelona Bricks (3D-printed clay), GENARQ/iBAG, UIC Barcelona. V3 design iteration of the Biodigital Barcelona Bricks showing the bricks’ varied material density from a linear model of 0.5 cm thickness to a bulk model (a–d), with the density of the bricks varying from 25% to 55% and 75%. Images by the author.

This density variation in the biodigital bricks’ iterations enabled the actual study of the used material amount in these physical models, as well as their resistance to cracking. A following research paper will exhibit in detail further mechanical tests to prove the structural efficiency of the proposed forms of the biodigital bricks. This 3D printed material examination customization was also reinforced by comparing to other digital fabrication strategies that will be exhibited in the following section, to prove the competence of 3D printing to achieve sustainability in material usage and production processes