| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Alina-Cristina Bunea | + 3395 word(s) | 3395 | 2021-10-15 04:35:14 | | | |

| 2 | Jessie Wu | Meta information modification | 3395 | 2021-10-18 03:39:57 | | |

Video Upload Options

Mimicking skin sensorial properties, the development of “electronic skin” (e-skin) holds the promise of developing medical monitoring and highly sensitive prosthetic devices, biocompatible compliant medical implants, enhanced robotics, and more. The e-skin-related research field is a robust interdisciplinary approach, which combines micro-/nanoelectronics, material science, biotechnology, data transmission, and data processing technologies. The potential of epidermal electronics as biomimetic sensors, soft neural probes, prosthetics, implantable biomedical electronics, robotics, and a whole range of other skin-inspired devices show great potential to change the world. Its feasibility, however, relies on the desired e-skin characteristics such as flexibility, stretchability, self-healing ability, self-powering, biocompatibility, biodegradability and last, but not least, the reliability of large-scale manufacturing processes.

1. Introduction

The skin, the largest human organ, weighs about 16% of the total body weight and completes numerous and various functions. First and foremost, it is a powerful physical and immunological barrier between the body and the external environment while providing efficient housing for the muscles, bones, internal organs and fluids. The skin also acts as a highly efficient temperature and, to some extent, humidity sensor and regulator. As the primary interface between the external environment and the central nervous system, skin provides tactile, thermal, humidity and pain-related information [1]. The remarkable multi-functional organ possesses excellent elasticity and healing abilities. Suppose we were to translate its biological functions into electronics terminology. In that case, the skin is a massive array of highly sensitive sensors with negative feedback control loops, able to process a considerable amount of data in real-time and further control the balance of the human functions (homeostasis).

Mimicking skin sensorial properties, the development of the “electronic skin” (e-Skin) holds the promise for medical monitoring applications, highly sensitive prosthetic devices, biocompatible compliant medical implants, enhanced robotics and even more. The e-Skin-related research field is a robust interdisciplinary approach, which combines micro-/nanoelectronics, material science, biotechnology, data transmission and data processing technologies. The potential of epidermal electronics as biomimetic sensors [2], soft neural probes [3], prosthetics [4], implantable biomedical electronics [5], robotics [6], and a whole range of other skin-inspired devices [7] show great potential to change the world [8]. The feasibility, however, relies on the desired e-skin characteristics such as flexibility, stretchability, self-healing ability, self-powering, biocompatibility, biodegradability and last, but not least, reliability of processes and large-scale manufacturability [9].

The present work revises e-skin development and provides a historical overview, describes the recent trends in material development and fabrication techniques, analyzes some of the most promising health-oriented e-skin sensors and finally addresses e-skin power-related management. Thoughts on future research trends and current limitations conclude the paper.

2. The concept of e-skin: A short history and schemata

2.1. e-skin: from fiction to science

In the early 1950s, researchers explored the possibility of human/machine interfaces for prosthetics control, with first attempts to exploit the phantom-limb pain of amputees for motion control of motorized prostheses [10]. The 1960s saw the advent of the “artificial touch-sense” when researchers used pressure transducers fitted on hand prostheses to generate stimuli. These developed sensors, applied to the skin with the help of electrodes [11], and implants provided direct neural stimulation [12]. The feedback-based sensory systems, demonstrated in the 1970s, allowed proportional nerve stimulation and prosthesis control [13][14]. Essentially, the research on artificial touch with the development of robotic skins and mainstreaming of the touchscreen flourished in the 1980s [15]. In the 1990s, the advances in flexible materials, particularly polymers, such as polyimide (PI) [16] and polydimethylsiloxane (PDMS) [17], allowed the design of large surface flexible circuits [18][19].

Furthermore, the early 2000s introduced the concept of electronic skin referred to as “sensitive skin” and defined as “a large-area, flexible array of sensors with data processing capabilities, which can be used to cover the entire surface of a machine or even a part of a human body” [20]. Lumelsky et al [21]presented an extensive overview of the first workshop dedicated to the electronic skin and organized in 2000 by the NSA and DARPA. Consequently, the world of the e-skin expanded rapidly with some of the first stretchable metal electrodes presented in [22]. One step further, taken in 2014, demonstrated how the graphene-based transparent neural microelectrode arrays allowed simultaneous imaging and optogenetic neural stimulation [23]. A few years later, in 2018, Tybrandt et al [3] used a composite material of gold-coated titanium dioxide nanowires in a silicone matrix to develop stretchable electrode grids for chronic neural recording. A recent paper described a silk-based transparent e-skin for thermoregulation with potential application in arthritis treatment [24]. Moreover, Gao et al proposed a bifunctional temperature and pressure imaging e-skin with self-healing capabilities [25]. The device integrated polyurethane and multi-walled carbon nanotubes on the same flexible cellulose nanocrystals carboxylated nitrile rubber polyethyleneimine (CNC XNBR) substrate.

2.2 The concept of e-skin systems

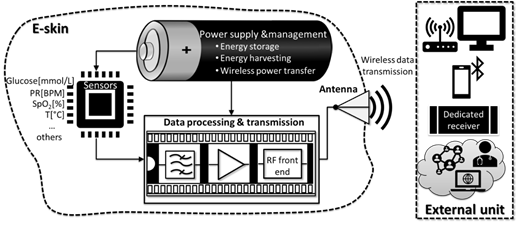

The currently accepted concept of e-skin implemented into research can be described in Fig. 1 (which provides the overview of the main building blocks of an e-skin system). First, there is the sensing block, which picks up the relevant biological stimuli, such as blood glucose levels, pulse rate (PR), peripheral capillary oxygen saturation (SpO2), temperature, etc. and translates their magnitude in a measurable electrical signal. Next, a data processing and transmission unit, which can include filters, amplifiers, and a radiofrequency (RF) front end can be included directly into e-skin. This unit collects the analog signals from the sensor block and performs initial processing of the signal. The RF front end generates and modulates an RF signal, with the output usually connected to an antenna for wireless data transmission. The data is then relayed to an external unit (dedicated receiver, mobile phone, cloud or other means) using WiFi, Bluetooth, or near field communication (NFC). All blocks are supplied with energy by the power supply and management block, which can use an exchangeable/rechargeable battery, wireless power transfer (WPT) or perform energy harvesting in a self-powered scenario.

Figure 1. Working principle of an e-skin system.

3. MATERIALS & FABRICATION METHODS

3.1 General considerations

Developing mechanically flexible and stretchable materials similar to the human epidermis is challenging when the fabrication of high-performance e-skin sensors is attempted. These materials must allow and maintain intimate contact between devices and dynamically structured human skin or complex machine surfaces (for robotics applications)[26]. Moreover, developing patterning and assembling technologies of these materials to fabricate of classical electronic components is a crucial element for building stretchable electronic systems. In this direction, the microfabrication technologies developed for rigid materials need to be modified to obtain electronic devices capable of withstanding torsions, elongations, compressions with preserved electrical functions. If the monitoring of biological parameters is the targeted application of the designed e-skin sensors, the wearability and biocompatibility will be other elements to be considered. Therefore, the sensors must not cause discomfort, irritation, or local sweating over that targeted attachment period to the skin. Wang et al reported that thinner and softer sensors with smaller contact pressure between substrate and epidermis are more comfortable to wear[26].

Meanwhile, studies explore the potential use of biodegradable advanced 2D materials for health monitoring devices. Recently, ultra-thin, soft elastomeric materials have demonstrated conformal contact with the skin surface. The performance of this class of integrated electronic e-skin sensors, mounted onto epidermis based only on van der Waals interactions, is improved through increased contact area and fewer motion artefacts[27][28]. It also has been observed that the materials used for the fabrication of the e-skin sensors must present elastic moduli between 0.5 and 1.95 MPa and stretchability of more than 140%[29].

In conclusion, the main “building blocks” of the e-skin electronic components such as substrate, conductors, semiconductors, and dielectrics must meet specific requirements: they should bend, twist or being stretch without modification of functional properties and electronic performance during operation.

3.2 Trends in e-skin’s materials

The use of self-healing materials could increase the lifetime of electronic devices that come into intimate contact with the skin surface and move in tandem with the skin[30]. During long-term wearing, due to fatigue or accidental damage, the composite surfaces may develop micro-cracks that can spread throughout the substrate, conductors, or dielectric. In extrinsic self-healing composites, these microcracks cand be healed, their propagation can be prevented, thus the major structural damage is avoided. To date, different methods of obtaining self-healing electronic materials have been tested. One of them is to use microcapsules, which release the healing agent in the form of liquid monomer. This monomer polymerizes in the presence of a catalyst, a process initiated by the contact between the microcracks and the microcapsules[31]. A fundamental condition for an efficient self-healing is the homogeneous distribution of these microcapsules within the entire mass of the composite. Another method is the incorporation of conductive fillers into a self-healing network, a common approach to obtain self-healable electronic conductors. In intrinsic self-healing materials, the repair of the cracks in composites occurs through reversible covalent, non-covalent, and hydrogen bonds. For example, Song et al reported a dynamic Ag–S bonds (between Ag from an AgNW aerogel and S from sulfur-containing molecule in a ternary network hydrogel to obtain 93% healing under near-infrared (NIR) laser irradiation[32]. Markvicka et al used liquid metal droplets (GaIn eutectic) evenly distributed in a soft, silicone elastomer[33]. By controlled pressure, the microcapsules break and gather to form pathways with high electrical conductivity. In general, some progress has been made in the recent years towards the solutions to increase the potential of self-healing materials, despite the decrease in material’s stretchability[34].

Since these sensors are in close contact with the skin and could be worn for a long time, they should be biocompatible and comfortable. To comply with these requirements, air permeability was considered as an essential property for wearable skin-like electronics, materials with interconnected pores have been proposed as substrates. For example, Yang et al [35] developed a poly(vinylidene fluoride) nanofiber membrane with hydrophobicity and breathability. These nanofiber membranes (NM) obtained by electrospinning have high porosity, flexibility, and smoothness and could be incorporated in light, breathable, and printable electronic.

3.3 Deposition methods

In almost all e-skin applications, the substrate must comply with two main requirements: flexibility and stretchability. Usually, the selected substrate for the application is the one that defines the right technology to be used for sensors, transistors, resistors, or any other necessary types of electronic components. E-skin devices fabrication techniques can be grouped into two major groups: (1) classical techniques based on conventional microfabrication processes such as photolithography, vacuum based-deposition technology, etching, and (2) printing techniques.

Conventional vacuum deposition (sputtering and e-beam) could be mentioned as the most used technological process in the fabrication of thin-films (TF) for e-skin applications such as sensors, thin film transistors (TFT) and flexible printed circuit boards (PCB). Nevertheless, the fabrication cost is relatively high (considering the required area of the e-skin device). However, this issue is compensated by significant advantages such as low temperature, which controls material growth and the possibility of reactive deposition for unique materials such as AIN or PZT (Pb(Zr, Ti)O3) for piezoelectric sensors on flexible materials[36]. Metal-organic chemical vapour deposition (MOCVD) and Metal-organic molecular beam deposition (MOMBD) have great technological importance in the fabrication of an extensive range of electronic devices; however, the temperatures used in both cases are pretty high [37] once the substrates are considered for e-skin devices. Still, this process is used to fabricate sensors or rigid substrates for e-skin devices. An alternative to the method mentioned above is the low-temperature pulsed laser deposition (LT PLD). It is a physical vapour deposition (PVD) technique, which comprises a high-power ultrashort pulsed laser beam focused inside a vacuum chamber and used to strike a target of the material to be deposited. The material is heated, vaporized from the target and then deposited as a thin film on a substrate facing the target. Some recent developments in this area [38] demonstrated that this method could succeed in PZT thin-film pressure sensors fabrication. Spray pyrolysis is often used for the deposition of doped ZnO thin film layers for TFT on flexible substrates[39][40]. Ultrasonic spray was used to deposit graphene materials on textile [41] and air spray to deposit conductive films (Ag NWs)[42].

Most of the e-skin sensors do not require the resolution and performances of conventional microsensors. Once disposable e-skin sensors become the fabrication target, printing can be a solution for low-cost and mass production of such devices. The printing techniques are also suitable for exploring new avenues for materials processing and for developing sensors and systems on even non-planar surfaces. It is acknowledged that such outcomes are reached with difficulty via the conventional wafer-based fabrication techniques[43].The most frequently used methods for printing on flexible substrates are screen printing [44], inkjet printing [45], gravure printing[46] ,and air-jet printing[47] .Certain applications use e‐skin with a specific appropriate curvature to be further attached to the corresponding 3D structure, or e‐skin fabricated onto a 3D surface. 3D printing of sensors, antennas and conductive traces are promising. For instance, Huang et al [48] mentioned a 3D printed tactile sensor of an elastomer made of graphene and PDMS, Adams et al [49] presented a 3D printed antenna made of silver nanoparticle, and Valentine et al [50] presented PCB conductive flexible traces made of highly-stretchable thermoplastic polyurethane (TPU) and silver flakes.

A recent trend in e-skin fabrication is based on mask-free and chemical-free methods, which employ a laser to prepare graphene and fabricate graphene-based electronic skins. Furthermore, Xiong et al [51] presented the technique of chemically derived graphene oxide (GO) preparation using laser, while Ye et al [52] reported further significant advances in mask-free created micro-patterns.

4. APPLICATIONS

The e-skin sensors designed and developed nowadays measure variables like heart rate, blood oxygen saturation, glucose, or moisture and display them, sense capabilities of transparent [53] or semitransparent [54] layer-based devices extended for most of the sensing organs of the human body[55], to detect colorless and odorless gasses[56], vibration-, respiration-, sound- and pulse-changes[57] .The analysis of biomarkers and stimuli signals occurs in a network of e-skin sensors. For instance, flexible sensor tag kits can monitor the surface temperature long-term and non-invasively for a precise diagnostics and feedback treatment[58]. Various requirements in terms of performance and multiple functions for dedicated sensing features are met by the array structures of biomaterials systems and conventional or hybrid polymers grown on top of flexible and stretchable substrates[59]. Active matrix temperature sensor arrays [60], or passive sensors for temporary implants [61], are characterized by excellent sensitivity and stretchable reversibility. Thin-film materials deposition [62], and additive material deposition [63], can be done onto different substrates to enable sensing functions for precise physical quantities measurements as skin surface temperature changes. For such e-skin-mimic sensors alike, it is necessary to increase the sensitivity and the resolution, reduce the detection limit, and expand the monitoring range, (i.e. to recognize temperature changes as small as 0.02° C [64]).

5 POWER MANAGEMENT APPROACHES

In order for e-skin technology to be practically implemented the whole system needs to be considered. This includes the means to power the e-skin, including the various types of sensors and/or actuators, and the means of signal extraction and processing.

Wearable devices need to have enhanced portability and should not rely on interchangeable batteries. The main approaches considered for e-skin devices are based either on self-powering schemes for long term continuous use sensors or wireless power transfer (WPT) systems for on-demand data acquisition. A good example are electronic tattoos such as the one presented in [65] where a flexible Ag-In-Ga coil is used receive up to 300 mW when placed directly on the skin and up to 100 mW if implanted.

Self-powering or autonomous e-skin devices need to employ energy harvesting schemes. They take advantage of naturally available energy sources such as light, heat, movement or bio-chemical elements which are harvested using dedicated transducers[66]. By storing the excess energy in a battery or supercapacitor, continuous operation can be achieved. Out of these, flexible photovoltaic cells have the highest reported power conversion efficiency (PCE) with a maximum of 30.8% for a InGaP-GaAs tandem solar cell reported in [67].

As far as flexible batteries are concerned the main research directions have focused on lithium (Li) based batteries with flexible electrodes [68], supercapacitors [69][70] and combinations of traditional and carbon-based materials.

Data transfer from e-skin systems mainly relies on standard communication protocols such as RFID and near field communications (NFC)[71][72], Bluetooth Low Energy (BLE) [65][73], and Wi-Fi [74], for short range, medium range and long range transmission, respectively.

The choice of using an on-demand wireless power transfer and data acquisition configuration, energy harvesting for continuous sensing and data transmission configuration, battery powered configuration or an energy harvesting/battery storage/on demand data transfer combination is highly application and technology dependent.

6. Conclusions and Perspectives

Since active monitoring of health conditions is a pressing and continuous priority, efforts focused on developing methods and devices to support the diagnostic, therapeutic and preventive approaches. Recent development of technology opened new avenues for effective and patient friendly measurement of physical and biochemical physiological parameters and even for ongoing analysis for rapid and personalized interventions. Either minute collection of biofluids for biomarkers detection or collecting large data on physical and chemical homeostatic parameters could capture meaningful and timely health status variations to enable prompt interventions and allow appropriate prevention. Therefore, the past few years efforts consolidated the progress in designing and manufacturing of flexible electronic skin systems known as e-skin to contribute with cost-efficient products. Few aspects consolidated the profile of e-skin: the quality materials used with adequate flexibility[75][76], stretchability [77], transparency[78],), light weightiness[28][79], high precision sensorial functions [4] as well as the sensitive techniques for complex molecules detection.

Originally, organic transistors have been used for the active-matrix backplane of e-skin, and established the feasibility of the concept However, their low carrier mobility imposed the inorganic crystalline semiconductors, with miniaturized dimensions and superior mechanical flexibility [75][80] .The newly employed materials contributed to various kinds of flexible and stretchable devices based on an ultrathin [81] and stretchable design [28][82] have been developed for monitoring individual health status and delivering the corresponding feedback therapy [83][84]. However, the new designs require improved scalability, and multifunctionality to comply with the desired forms of the physical and chemical sensing e-skin and for future medical applications. One more aspect to be considered when developing e-skin is the previous biosensors’ limitations, as they can only monitor a single analyte and do not have on-site signal processing circuitry and sensor calibration mechanisms)[85]. Therefore, further development of flexible platforms that can house several sensors simultaneously is a priority. The fully integrated platforms for continuous and simultaneous detection of several physiological parameters build inside passively activated microfluidic systems and from biocompatible protective compartment-sealing membranes may also be coupled with capabilities for wireless data collection. Such extended capability will contribute to the e-skin potential as real-time, multi-parameter concurrent analysis with little or no discomfort to the subjects being tested. This type of solution overcomes the problems associated with blood sample collection, and provide higher compliance among various users (e.g., athletes, patients).

The improved features will further develop the diagnostic application of e-skin based on the recent increase in collection of body biomarkers to detect presence of different biomarkers in the body and to include their measurement for physiological parameters, biomolecules, and bodily fluids monitoring. Furthermore, the progress of personalized medicine- and IoT-related fields is the motor for improved and consistent manufacturing of reliable and stable systems that integrate more sensing modalities[86]. Therefore, the next steps taken will employ artificial intelligence to address the motion artifacts, the interaction of e-skin with the human skin for higher level of comfort and accurate feedback. Moreover, expanding the wearable platform towards new more complex analytes such as sweat hormones and proteins requires more work to develop sensitive and selective techniques for measuring them. To date, developing such sensors have been difficult due to the intrinsic complexities of using antibodies or aptamers as biorecognition elements. However, achieving technological standards for these sensors could contribute tremendously towards a better molecular diagnostic and personalised therapy. The complexity of the multidisciplinary work involved in perfecting the e-skin will also strengthen the collaboration between the academia and industry to achieve long-term stability of the integrated e-skin platforms capable to facilitate ongoing monitoring, timely diagnostic for efficient therapy and prevention. The evolving technology will not only consolidate the transition from conventional electronics but will open new avenues for multifunctional, smart, user-friendly, and cost-efficient products. The variety of considerations presented established not only challenges but opportunities for new era of sensor technology to enable non-invasive investigation at molecular levels for personalized and predictive healthcare. The crucial goal of flexible and wearable health-monitoring devices for periodic health monitoring is to allow data to be collected and integrated for medical purposes and even to predict illness prior to the onset of symptoms.

References

- Filingeri, D. and G. Havenith, Human skin wetness perception: psychophysical and neurophysiological bases. Temperature (Austin, Tex.), 2015. 2(1): p. 86-104.

- Li, T., Y. Li, and T. Zhang, Materials, Structures, and Functions for Flexible and Stretchable Biomimetic Sensors. Accounts of Chemical Research, 2019. 52(2): p. 288-296.

- Tybrandt, K., et al., High-Density Stretchable Electrode Grids for Chronic Neural Recording. Advanced Materials, 2018. 30(15): p. 1706520.

- Chortos, A., J. Liu, and Z. Bao, Pursuing prosthetic electronic skin. Nature materials, 2016. 15(9): p. 937-950.

- Guan, H., et al., Self-powered, wireless-control, neural-stimulating electronic skin for in vivo characterization of synaptic plasticity. Nano Energy, 2020. 67: p. 104182.

- Hsiao, L.-Y., et al., Carbon nanotube-integrated conductive hydrogels as multifunctional robotic skin. Carbon, 2020. 161: p. 784-793.

- Ma, Z., et al., Skin-inspired electronics: emerging semiconductor devices and systems. Journal of Semiconductors, 2020. 41(4): p. 041601.

- Ge, G., et al., Stretchable, Transparent, and Self‐Patterned Hydrogel‐Based Pressure Sensor for Human Motions Detection. Advanced Functional Materials, 2018. 28(32): p. 1802576.

- Zhang, S., et al., A review of electronic skin: soft electronics and sensors for human health. Journal of Materials Chemistry B, 2020. 8(5): p. 852-862.

- Siehlow, K., Phantom Controlled Electro Prosthesis for BE and AE Amputees. Orthopädie Technik, 1951. 3.

- Beeker, T.W., J. During, and A. Den Hertog, Artificial touch in a hand-prosthesis. Medical and biological engineering, 1967. 5(1): p. 47-49.

- Kawamura, Z. and O. Sueda, Sensory Feedback Device for the Artificial Arm. Fourth Pan-Pacific Rehabilitation Conference, 1969.

- Clippinger, F.W., R. Avery, and B.R. Titus, A sensory feedback system for an upper-limb amputation prosthesis. Bull Prosthet Res, 1974: p. 247-58.

- Brittain, R.H., W.F. Sauter, and D.A. Gibson, Sensory feedback in a myoelectric upper limb prosthesis: a preliminary report. Can J Surg, 1979. 22(5): p. 481-2.

- Walker, G., A review of technologies for sensing contact location on the surface of a display. Journal of the Society for Information Display, 2012. 20(8): p. 413-440.

- Fukang, J., et al. A flexible MEMS technology and its first application to shear stress sensor skin. in Proceedings IEEE The Tenth Annual International Workshop on Micro Electro Mechanical Systems. An Investigation of Micro Structures, Sensors, Actuators, Machines and Robots. 1997.

- Lötters, J.C., et al., The mechanical properties of the rubber elastic polymer polydimethylsiloxane for sensor applications. Journal of Micromechanics and Microengineering, 1997. 7(3): p. 145-147.

- Drury, C.J., et al., Low-cost all-polymer integrated circuits. Applied Physics Letters, 1998. 73(1): p. 108-110.

- Crone, B., et al., Large-scale complementary integrated circuits based on organic transistors. Nature, 2000. 403(6769): p. 521-523.

- Lumelsky, V.J., M.S. Shur, and S. Wagner, Sensitive skin. IEEE Sensors Journal, 2001. 1(1): p. 41-51.

- Bowden, N., et al., Spontaneous formation of ordered structures in thin films of metals supported on an elastomeric polymer. Nature, 1998. 393(6681): p. 146-149.

- Lacour, S.P., et al., Stretchable gold conductors on elastomeric substrates. Applied Physics Letters, 2003. 82(15): p. 2404-2406.

- Park, D.-W., et al., Graphene-based carbon-layered electrode array technology for neural imaging and optogenetic applications. Nature Communications, 2014. 5(1): p. 5258.

- Huang, J., et al., Stretchable and Heat-Resistant Protein-Based Electronic Skin for Human Thermoregulation. Advanced Functional Materials, 2020. 30(13): p. 1910547.

- Gao, Z., et al., A self-healable bifunctional electronic skin. ACS Applied Materials & Interfaces, 2020.

- Wang, S., et al., Mechanics of epidermal electronics. Journal of Applied Mechanics, 2012. 79(3).

- Chung, H.U., et al., Binodal, wireless epidermal electronic systems with in-sensor analytics for neonatal intensive care. Science, 2019. 363(6430): p. eaau0780.

- Kim, D.-H., et al., Epidermal electronics. science, 2011. 333(6044): p. 838-843.

- Yu, B., et al., An elastic second skin. Nature materials, 2016. 15(8): p. 911-918.

- Wang, T., et al., A self‐healable, highly stretchable, and solution processable conductive polymer composite for ultrasensitive strain and pressure sensing. Advanced Functional Materials, 2018. 28(7): p. 1705551.

- White, S.R., et al., Autonomic healing of polymer composites. Nature, 2001. 409(6822): p. 794-797.

- Song, P., et al., Self-healing and superstretchable conductors from hierarchical nanowire assemblies. Nature communications, 2018. 9(1): p. 1-9.

- Markvicka, E.J., et al., An autonomously electrically self-healing liquid metal–elastomer composite for robust soft-matter robotics and electronics. Nature materials, 2018. 17(7): p. 618-624.

- Zhang, L., et al., A highly efficient self‐healing elastomer with unprecedented mechanical properties. Advanced Materials, 2019. 31(23): p. 1901402.

- Yang, W., et al., A breathable and screen‐printed pressure sensor based on nanofiber membranes for electronic skins. Advanced Materials Technologies, 2018. 3(2): p. 1700241.

- Khan, S., L. Lorenzelli, and R.S. Dahiya, Technologies for printing sensors and electronics over large flexible substrates: a review. IEEE Sensors Journal, 2014. 15(6): p. 3164-3185.

- Pan, M., et al., Metal-organic chemical vapor deposition of ZnO. Journal of crystal growth, 2006. 287(2): p. 688-693.

- Zhang, S., et al., A Flexible e-skin based on micro-structured PZT thin films prepared via a low-temperature PLD method. Journal of Materials Chemistry C, 2019. 7(16): p. 4760-4769.

- Bukke, R.N., et al., Lanthanum doping in zinc oxide for highly reliable thin-film transistors on flexible substrates by spray pyrolysis. ACS Applied Materials & Interfaces, 2020. 12(31): p. 35164-35174.

- Ameur, S.B., et al., Physical investigations and photocatalytic activities on ZnO and SnO2 thin films deposited on flexible polymer substrate. Vacuum, 2018. 155: p. 546-552.

- Sadanandan, K.S., et al., Graphene coated fabrics by ultrasonic spray coating for wearable electronics and smart textiles. Journal of Physics: Materials, 2020.

- Ko, Y.-H., et al., Ultrasonic-sprayed graphene oxide and air-sprayed silver nanowire for the preparation of flexible transparent conductive films. Chemistry Letters, 2014. 43(8): p. 1242-1244.

- Kelly, B.E., et al., Volumetric additive manufacturing via tomographic reconstruction. Science, 2019. 363(6431): p. 1075-1079.

- Cao, X., et al., Screen printing as a scalable and low-cost approach for rigid and flexible thin-film transistors using separated carbon nanotubes. ACS nano, 2014. 8(12): p. 12769-12776.

- Chen, P., et al., Fully printed separated carbon nanotube thin film transistor circuits and its application in organic light emitting diode control. Nano letters, 2011. 11(12): p. 5301-5308.

- Noh, J., et al., Fully gravure-printed D flip-flop on plastic foils using single-walled carbon-nanotube-based TFTs. IEEE electron device letters, 2011. 32(5): p. 638-640.

- Ha, M., et al., Aerosol jet printed, low voltage, electrolyte gated carbon nanotube ring oscillators with sub-5 μs stage delays. Nano letters, 2013. 13(3): p. 954-960.

- Huang, K., et al., Three-dimensional printing of a tunable graphene-based elastomer for strain sensors with ultrahigh sensitivity. Carbon, 2019. 143: p. 63-72.

- Adams, J.J., et al., Conformal printing of electrically small antennas on three‐dimensional surfaces. Advanced Materials, 2011. 23(11): p. 1335-1340.

- Valentine, A.D., et al., Hybrid 3D printing of soft electronics. advanced Materials, 2017. 29(40): p. 1703817.

- Xiong, W., et al., Laser-based micro/nanofabrication in one, two and three dimensions. Frontiers of Optoelectronics, 2015. 8(4): p. 351-378.

- Ye, R., D.K. James, and J.M. Tour, Laser‐induced graphene: from discovery to translation. Advanced Materials, 2019. 31(1): p. 1803621.

- Guo, H., et al., Transparent, flexible, and stretchable WS 2 based humidity sensors for electronic skin. Nanoscale, 2017. 9(19): p. 6246-6253.

- Kwon, D.-K. and J.-M. Myoung, Wearable and Semitransparent Pressure-Sensitive Light-Emitting Sensor Based on Electrochemiluminescence. ACS nano, 2020. 14(7): p. 8716-8723.

- Dahiya, R., E-skin: from humanoids to humans [point of view]. Proceedings of the IEEE, 2019. 107(2): p. 247-252.

- Cai, G., et al., A semitransparent snake-like tactile and olfactory bionic sensor with reversibly stretchable properties. NPG Asia Materials, 2017. 9(10): p. e437-e437.

- Chen, X., et al., A dual‐functional graphene‐based self‐alarm health‐monitoring E‐skin. Advanced Functional Materials, 2019. 29(51): p. 1904706.

- Niu, S., et al., A wireless body area sensor network based on stretchable passive tags. Nature Electronics, 2019. 2(8): p. 361-368.

- Ren, X., et al., A low‐operating‐power and flexible active‐matrix organic‐transistor temperature‐sensor array. Advanced Materials, 2016. 28(24): p. 4832-4838.

- Hong, S.Y., et al., Stretchable active matrix temperature sensor array of polyaniline nanofibers for electronic skin. Advanced materials, 2016. 28(5): p. 930-935.

- Lu, D., et al., Bioresorbable, wireless, passive sensors as temporary implants for monitoring regional body temperature. Advanced Healthcare Materials, 2020. 9(16): p. 2000942.

- Chen, Y., et al., Breathable and stretchable temperature sensors inspired by skin. Scientific reports, 2015. 5(1): p. 1-11.

- Barmpakos, D. and G. Kaltsas, A Review on Humidity, Temperature and Strain Printed Sensors—Current Trends and Future Perspectives. Sensors, 2021. 21(3): p. 739.

- Li, S., et al., Physical sensors for skin‐inspired electronics. InfoMat, 2020. 2(1): p. 184-211.

- Alberto, J., et al., Fully Untethered Battery-free Biomonitoring Electronic Tattoo with Wireless Energy Harvesting. Scientific Reports, 2020. 10(1): p. 5539.

- García Núñez, C., L. Manjakkal, and R. Dahiya, Energy autonomous electronic skin. npj Flexible Electronics, 2019. 3(1): p. 1.

- Kayes, B.M., et al., Flexible Thin-Film Tandem Solar Cells With >30% Efficiency. IEEE Journal of Photovoltaics, 2014. 4(2): p. 729-733.

- Zhao, Y. and J. Guo, Development of flexible Li-ion batteries for flexible electronics. InfoMat, 2020. 2(5): p. 866-878.

- Wang, J., et al., Stretchable energy storage E-skin supercapacitors and body movement sensors. Sensors and Actuators B: Chemical, 2020. 305: p. 127529.

- Yun, Y., et al., Extremely flexible and mechanically durable planar supercapacitors: High energy density and low-cost power source for E-skin electronics. Nano Energy, 2020. 78: p. 105356.

- Cheng, C., et al., Battery-free, wireless, and flexible electrochemical patch for in situ analysis of sweat cortisol via near field communication. Biosensors and Bioelectronics, 2021. 172: p. 112782.

- Bandodkar, A.J., et al., Sweat-activated biocompatible batteries for epidermal electronic and microfluidic systems. Nature Electronics, 2020. 3(9): p. 554-562.

- Mohammadifar, M., et al., Biopower-on-Skin: Electricity generation from sweat-eating bacteria for self-powered E-Skins. Nano Energy, 2020. 75: p. 104994.

- Dong, W., et al., Soft wrist-worn multi-functional sensor array for real-time hand gesture recognition. IEEE Sensors Journal, 2021: p. 1-1.

- Someya, T., et al., Conformable, flexible, large-area networks of pressure and thermal sensors with organic transistor active matrixes. Proceedings of the National Academy of Sciences, 2005. 102(35): p. 12321-12325.

- Takei, K., et al., Nanowire active-matrix circuitry for low-voltage macroscale artificial skin. Nature materials, 2010. 9(10): p. 821-826.

- Sekitani, T. and T. Someya, Stretchable, large‐area organic electronics. Advanced Materials, 2010. 22(20): p. 2228-2246.

- Ju, S., et al., Transparent active matrix organic light-emitting diode displays driven by nanowire transistor circuitry. Nano letters, 2008. 8(4): p. 997-1004.

- Kaltenbrunner, M., et al., An ultra-lightweight design for imperceptible plastic electronics. Nature, 2013. 499(7459): p. 458-463.

- Sekitani, T., et al., Organic nonvolatile memory transistors for flexible sensor arrays. Science, 2009. 326(5959): p. 1516-1519.

- Kim, J., et al., A wearable multiplexed silicon nonvolatile memory array using nanocrystal charge confinement. Science advances, 2016. 2(1): p. e1501101.

- Jang, K.-I., et al., Soft network composite materials with deterministic and bio-inspired designs. Nature communications, 2015. 6(1): p. 1-11.

- Son, D., et al., Multifunctional wearable devices for diagnosis and therapy of movement disorders. Nature Nanotechnology, 2014. 9(5): p. 397-404.

- Kim, J., et al., Stretchable silicon nanoribbon electronics for skin prosthesis. Nature Communications, 2014. 5.

- Bandodkar, A.J. and J. Wang, Non-invasive wearable electrochemical sensors: A review. Trends in Biotechnology, 2014. 32(7): p. 363-371.

- Zhu, H., et al., IoT PCR for pandemic disease detection and its spread monitoring. Sensors and Actuators B: Chemical, 2020. 303: p. 127098.