Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Meike Schroeder | + 3378 word(s) | 3378 | 2021-09-18 11:33:07 | | | |

| 2 | Lindsay Dong | + 10 word(s) | 3388 | 2021-09-28 08:04:59 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Schroeder, M. Machine Learning Approaches in SCRM. Encyclopedia. Available online: https://encyclopedia.pub/entry/14527 (accessed on 07 February 2026).

Schroeder M. Machine Learning Approaches in SCRM. Encyclopedia. Available at: https://encyclopedia.pub/entry/14527. Accessed February 07, 2026.

Schroeder, Meike. "Machine Learning Approaches in SCRM" Encyclopedia, https://encyclopedia.pub/entry/14527 (accessed February 07, 2026).

Schroeder, M. (2021, September 24). Machine Learning Approaches in SCRM. In Encyclopedia. https://encyclopedia.pub/entry/14527

Schroeder, Meike. "Machine Learning Approaches in SCRM." Encyclopedia. Web. 24 September, 2021.

Copy Citation

Machine learning (ML) has already been implemented within the supply chain risk management (SCRM) field, both in theory and in practice. The applied examples relate primarily to the early identification of production, transport, and supply risks in order to counteract potential supply chain problems quickly. Through the analyzed case studies, we were able to identify the added value that ML integration can bring to the SCRM.

supply chain risk management

machine learning

cases

propositions

supply chain

1. Introduction

Different results in recent years have shown how vulnerable supply chains can be [1][2]. Due to the domino effect, individual actors in the supply chain are often not the only ones affected by an interruption but rather the entire network [3][4][5][6]. The tsunami in Japan in 2004, hurricane Katrina in the US in 2005, the volcanic eruption in Iceland in 2010, and the current COVID-19 pandemic are good examples demonstrating how numerous networks and even entire industries can be impacted by the negative effects of certain events (e.g., [7][8]).

In order to prevent disturbances, companies should apply Supply Chain Risk Management (SCRM) [4][5][9][10]. Supply Chain Risk Management is ‘a part of Supply Chain Management which contains all strategies and measures, all knowledge, all institutions, all processes, and all technologies, which can be used on the technical, personal, and organizational level to reduce supply chain risk’ [11] (p. 157). The aim is to increase the transparency and robustness of value-added processes in order to counteract any supply chain interruptions or even avoid them altogether [12][13][14]. Here, a distinction must be made between reactive and proactive SCRM. Reactive SCRM refers to all activities that are carried out after the occurrence of a supply chain risk in order to keep the extent of damage as low as possible [15]. In contrast, proactive SCRM includes all activities carried out prior to the risk occurring in order to proactively protect the company from supply chain risks [10].

Many companies do not focus on supply chain risks. In addition to a lack of time and personnel resources, the reasons often given are a lack of standards with regards to system compatibility and data consistency, as well as technical difficulties in integrating risk management software into existing information and communication systems [16]. One of the greatest challenges is to receive information about deviations from the planned process at an early stage in order to ensure timeliness of logistics processes within the supply chain [17].

The early identification of different supply chain risks is crucial for the timely introduction of countermeasures in order to avoid supply chain disruptions [4][11]. SCRM must predict potential causes of these process disruptions and analyze interruptions that have occurred in the past in order to minimize financial losses and process failures throughout the supply chain. Here, machine learning (ML) can help to detect risks early on [18][19][20][21][22][23].

Machine Learning can broadly be defined as an algorithm that generates outputs based on available data without first programming the respective learning outcome [24]. Instead, the ML algorithm ‘learns’ and iteratively assimilates its perception to the underlying real-world phenomena represented in the input data.

The current hype regarding ML is based on an amalgamation of several trends, which reinforce each other, making ML a powerful tool in an array of fields and practical use-cases. First, the availability of vast amounts of digital data is a necessary condition for the application of most ML algorithms—particularly for Deep Learning approaches [25], which utilize multi-layered Artificial Neural Networks to enable the most sophisticated, modern use-cases (e.g., the state-of-the-art Natural Language Processing system GPT-3) [26].

In general, the increased availability of data in previous years has been able to empower the application of ML. Supply chain networks generate over 1.6 billion new data points each month, supplying a number of data streams that can be used as inputs in an ML system [27][28]. Second, computational power has proven to be a major driver of progress in AI. Major breakthroughs were enabled through significant improvements in computational performance [29]. Third, algorithmic advances play a relevant role in enabling efficient and scalable applications. Though many of the applied algorithmic foundations (such as backpropagation) were conceived long ago, modern innovations (such as batch normalization [30] and dropout [31]) were crucial in facilitating recent developments [32].

Supplementary factors, such as the increased use of Cloud Computing (and thus easier access to powerful computing), software libraries which make it easier to execute ML projects despite the limited number of available skilled ML engineers, and the Internet of Things which provides more data-generating sensors [33], support the trends outlined above [34].

The increasing digital transformation in companies and supply chains and the associated greater availability of evaluable real-time data open up new potential for a proactive SCRM [21][35][36]. ML approaches can leverage a vast amount of supply chain data and generate solutions that represent improvements over traditional methods [37]. Although the integration of ML into the SCRM can be useful, this topic has rarely been considered scientifically.

2. Machine Learning in Supply Chain Risk Management

2.1. Current Status of ML Application in SCRM in Scientific Literature

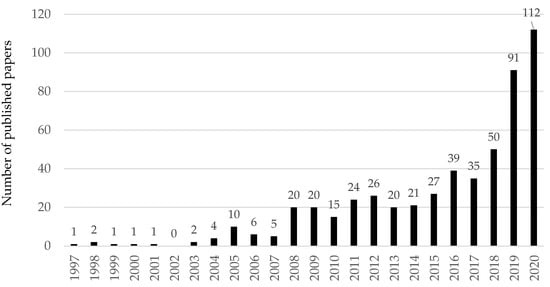

The results of the systematic literature analysis have shown that the link between ML and SCRM has been increasingly investigated over the last ten years. The initial focus has been on individual risks associated with computational intelligence, swarm intelligence, and simulations [38][39]. Only by beginning research on neural networks, such as the developed AlexNet architecture [40], will the number of scientific contributions increase significantly (see Figure 1). In the last two years in particular, there has been an increase in the number of published contributions as ML has become more widely integrated in companies [41][42][43][44].

Figure 1. Historical series of published papers on ML in SCRM.

The results showed that the authors in the articles rarely consciously make a connection to SCRM. For this reason, the link concerning ML and SCRM is often only made indirectly. For example, Alfian et al. [45] use an ML based forecasting model to predict future temperature for perishable food supply chain to minimize food quality and safety risks during transport. To do so, Alfian et al. [41] use ML to detect the direction of passive RFID tags so that products entering or leaving a gate can be correctly identified. The aim is to improve the efficiency of RFID-based product traceability, thereby reducing transport risks. Baryannis et al. [18] are currently developing a framework that uses data-driven artificial intelligence (AI) techniques to predict delivery delays in a multi-level manufacturing supply chain, using the example of a multi-stage supply chain in aerospace. Benjaoran and Dawood [46], on the other hand, present an integrated, comprehensive planning system (Artificial Intelligence Planner), which uses AI techniques to improve data analysis and decision support for production planning, and thus reduce production risks. The case study was conducted in a concrete construction company in the UK.

Blackburn et al. [47] present a time series model (exponential smoothing with covariates) that takes into account both historical data and environmental business information to develop robust demand forecasts to reduce production risks. The model was tested at the chemical company BASF. Bouzembrak and Marvin [48] use climatic, agricultural, and economic data as well as an ML algorithm to construct a Bayesian Network which can be used to optimize specific hazard categories for food safety, thereby avoiding food quality and transport risks. The authors use the Rapid Alert System for Food and Feed for the data. Brintrup et al. [42] use historical data available to an Original Equipment Manufacturer for ML application and prediction, thereby avoiding supply disruptions. Cavalcante et al. [43] combine simulations and ML to explore applications for data-driven decision support in the selection of robust suppliers. The use of ML algorithms supports supplier selection and thus leads to a reduction of supplier risks.

Constante-Nicolalde et al. [49] use ML techniques to predict fraud in an intelligent supply chain. They enable an assessment and classification of whether a transaction can be classified as normal or fraudulent to reduce product quality risks. Fu and Chien [50] present a data-driven analysis framework that integrates ML technologies and temporal aggregation mechanisms to predict the requirements of intermittent electronic components and, thereby, to reduce supply risks. The empirical study was conducted in a distribution company for electronic components. Hassan [19] has designed a conceptual model in which ML is used to identify delivery risks using text documents. Lau et al. [51] present a knowledge-based infrastructure system to collect information on procurement and on the selection of supplier network partners with the help of both ML and neural networks to reduce information risks. The prototype developed by the authors was tested in the Chinese company GPP Limited, which manufactures plastic toys and exports its products to customers in the USA, Europe, and Japan. Layouni et. al. [20] provide an overview of ML techniques and describe how they can be used to reduce transportation risks by assessing the safety of oil and gas pipelines.

Pereira et al. [52] present a conceptual method for a predictive and adaptive omni-channel supply chain management for the retail industry. ML and simulation-based optimization are applied to minimize uncertainty and incompatibility between supply and demand. Rodriguez-Aguilar et al. [22] use ML to model disruptive events and their impact on the supply chain to identify potential risks in a timely manner. Wichmann et al. [44] discuss whether and to what extent supply chain maps can be automatically generated by evaluating unstructured texts in natural language, such as news reports or blog posts, in order to reduce supplier risks. Yong et al. [23] present a vaccine blockchain system as well as ML technologies, which are based on blockchain, to enable vaccine traceability and prevent vaccine record fraud, thereby reducing supply risks.

However, the contributions of Baryannis [53], Sharma et al. [54], and Hamdi et al. [55] which provide a systematic literature analysis do not provide practical examples. Nychas et al. [56] describe the potential of internet technologies for dealing with perishable products, while the Smith publication [57] discusses the potential added value that AI can bring to agriculture in the next decade; both also fail to provide concrete examples of possible applications. Finally, Paul et al. [58] discuss the application of AI adoptions in the field of SCRM. Based on a qualitative study in India they propose a research model on the implementation of AI in SCRM at an organizational level.

2.2. Analysis of Identified Practical Use Cases

The car manufacturer Volkswagen has also developed a so-called bidder list generator, which uses ML to precisely determine possible suppliers. In this way, delays and risks in purchasing can be reduced (www.volkswagen.com, accessed on 21 May 2021; interview with expert from procurement). According to Rao [59] and Qu et al. [60] ML could also be used in procurement in the context of contract management as well as in the determination of optimal prices.

The automotive supplier HELLA, one of the largest trade organizations for vehicle parts and accessories in Europe, develops and manufactures lighting technology and electronic products for the automotive industry (www.hella.com, accessed on 21 May 2021). HELLA transfers material planning to internal and external suppliers within 24 months. Until now, delivery performance has been evaluated retroactively according to predefined criteria in supplier logistics. In order to be able to predict the reliability of deliveries, HELLA has tested the use of ML techniques. Here, call-off history, incoming goods history, advanced shipping notification history, purchasing and supplier data, as well as supplier and material master data were used in ML to forecast the reliability of delivery quantities for a single supplier-material-plant relationship for a defined period of 30 days. The results have shown that the reliability of critical supply quantities can be correctly predicted with an accuracy between 75% and 80%. Therefore, the use of ML in SCRM can reduce supply chain interruptions [61] (interview with expert from SCRM).

In addition to the interface consideration to suppliers, practical examples for the use of ML could be found, which aim at a reduction of transportation risks. For example, the courier—express and parcel (CEP) service providers—such as Fedex, DHL, or UPS, use ML techniques to optimize transport processes. They improve the transparency of their supply chain with the ML-based systems, composed of IoT and scanning devices used to generate a huge data pool. Together with up-to-date information on weather forecasts, traffic scenarios, and other important factors, which can have a direct or indirect influence on transport, the systems provide real-time insight into the supply chain. This allows delivery delays to be predicted and modified routes to be developed if necessary [62]. The ML-based ‘Supply Watch’ system, used by DHL, also monitors more than 140 different risk categories, including financial, environmental, and social factors—e.g., risks due to crime, labour violations, quality defects—and dangers within the supply chain such as general bottlenecks, capacity bottlenecks, and delays [63]. If a disruption is predicted, proactive measures can be taken, and customers can be informed about changes earlier on.

In addition, ML is used especially in the sales area to better predict customer behavior. McDonald’s, which suggests further additional sales to the customer during the purchase transaction, processes information using ML and considers weather data, times of day, local traffic, events in the vicinity, and historical sales data [64].

By addressing supply and demand imbalances and triggering automated responses using ML applications, companies cannot only improve the customer experience, but also limit sales risks. They can also reduce costs through better forecasting of freight and warehouse processes and improve collaboration with logistics service providers [65].

In addition, examples of ML applications in the production area could also be found. Robert Bosch GmbH, a manufacturer of industrial technology and consumer goods, uses ML to test components on the test bench and to recognize error patterns based on collected data, thus distinguishing relevant from non-relevant error messages. As a result, risks regarding product quality and delays in the process flow can be reduced [66].

3. Future Work

Drawing from the above discussion, we propose:

Proposition 1. The integration of ML into SCRM leads to changes in the qualification requirements of supply chain risk managers.

It has been demonstrated that humans have more trust in their own capabilities than in the capabilities of AI [67], and, as such, humans tend to make decisions without the help of AI [67]. Consequently, stronger control mechanisms should be built into ML-based decisions. At the same time, the decision-making process should be systematically and analytically prepared, as shown in the BUFAB example, in order to make the derivations comprehensible and, thus, promote acceptance among employees.

In addition, the automated research and evaluation of real-time information leads to a reduction in the manual activities of the supply chain risk manager. This leaves them more time for analytical and strategic tasks (i.e., their focus shifts from an operations-centered view towards medium to long-term strategies with an SCRM orientation, as shown in the HELLA example) [61].

Furthermore, utilizing ML approaches in SCRM catalyzes a trend towards a more proactive mentality. The potential to include real-time data makes quicker reactions possible [6] and bridges the path towards prescriptive decisions while considering risks in advance [5]. This improvement in flexibility and response time [6] can lead to reduced time demands on data analysis and initiate necessary actions, culminating in the identification of fraud and hazards in real time [68]. The collection of real-time data within the enterprise, and especially within the supply chain, as shown in the FedEx example, means that companies need to pay more attention to risk avoidance strategies as their response time to risk will increase. The perspective of risk assessment as well as the associated risk avoidance measures shift from a reactive SCRM approach to a more proactive approach due to the inclusion of ML. Consequently, the integration of ML also requires the introduction of new assessment standards which include the integration of proactive measures. These measures should consider: to what extent is it economically sensible to avoid risks? For example, when does the effort involved in avoidance exceed the follow-up costs caused by a risk that has occurred?

The traditional assessment criteria, “probability of occurrence” and “extent of damage”, are not sufficient here as a basis for decision-making. Threshold values for deviations from the normal state should be defined, starting from when the intervention of an employee is required (though there are challenges in doing so, see e.g., [69][70]). Drawing from the above discussion, we propose:

Proposition 2. The integration of ML into SCRM requires new evaluation standards.

Additionally, the quality of SCRM decisions can be improved. Using traditional approaches, which involve multiple points of human-supply chain contact, intuition and feelings are often used as decision making tools, increasing the risk of planning fallacies or other biases entering the equation [71]. Relying more on algorithmic decision-making or incorporating data-driven requirements into the judgement process of the SCRM professional reduces this risk, resulting in higher reliability and precision [72]. This precision can be improved further by utilizing algorithms to sort potential risks based on their priority [73].

One should not, however, be blind to the fact that algorithmic bias is an issue and must be considered, particularly in the black-box nature of ML algorithms such as Artificial Neural Nets—despite recent advances in Explainable AI (XAI)-research [74]. Assuming objectivity in decision making because an algorithm was used, falls short of this aim, and as such implementing transparency measures to ensure algorithmic accountability is necessary [75]. Companies must expand their monitoring and data-mining techniques for SCRM in order to ensure high quality data and efficient control measures have been taken [76].

Having implemented these and other necessary prerequisites for data security and privacy concerns, the automatization of decisions and processes is the tantalizing promise of ML in SCRM [68].

These benefits provide tangible value to companies, leading to a more efficient and effective use of resources along the supply chain [36]. However, the results of the literature analysis have clearly highlighted a research gap. Since few application examples are available, companies need more guidance on how to integrate ML into SCRM. What are the first steps they need to take? What approach should they follow? Should existing data be analyzed to determine which risks can be reduced, or should risks be the starting point, and data for problem solving purposes be generated afterwards? What level of maturity should the SCRM have reached before ML can be integrated? Science should provide appropriate recommendations for implementation and action.

In order to sensitize managers to the topic, more publications of use cases from both science and real-world applications are required. As a starting point for further research, existing examples of ML in supply chain management could be analyzed and evaluated against the background of SCRM in order to illustrate the cross-functional added value of ML applications. Another starting point for future research is an empirical review of the improvement of SCRM by ML, which is still pending. Drawing from the above discussion, we propose:

Proposition 3. Companies need more guidance on how to integrate ML into SCRM.

Several supply chain areas can benefit simultaneously from the results of the ML deployment. The use cases of the CEP companies show that the integration of ML not only reduces transport and delivery risks, but also intensifies the customer relationship through an improved information supply. By integrating ML into SCRM, the company can strengthen its position vis-à-vis the customer, since it knows its strengths and weaknesses better. Thus, the cooperation between the individual actors in the supply chain can be improved at the same time. The integration of ML into SCRM can also be an important lever in price negotiations with customers or insurance companies. It can also help to set oneself apart from competitors [4].

ML-based results can help communicating supply risks with organizational decision-makers. Informing decision-makers early on about supply chain risk levels has implications for manager cognition and how they adapt decision-making strategies based on risk knowledge [77]. According to Pournader et al. [78], this is an important component of behavioral SCRM. ML consequently supports decision-making and mitigates problems related to managers’ cognition and potential biases.

Proposition 4. The integration of ML into SCRM can have a positive effect on other supply chain functions and business units.

Finally, it should be noted that the integration of ML into the SCRM also requires a critical examination. For example, it must be considered that ML-based risk management systems require high initial investments [72]. In addition to the IT infrastructure, the storage of data (capacity) and the tracing of failure-causes are expensive [28]. There are also legal concerns about the massive collection or use of data for risk management [79]. Thus, new legal regulations for the use of AI/Big Data could follow in the future, which have to be considered in the process phases of risk management.

References

- Christopher, M.; Peck, H. Building the Resilient Supply Chain. Int. J. Logist. Manag. 2004, 15, 1–13.

- Giunipero, L.C.; Aly Eltantawy, R. Securing the upstream supply chain: A risk management approach. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 698–713.

- Jüttner, U.; Peck, H.; Christopher, M. Supply chain risk management: Outlining an agenda for future research. Int. J. Logist. Res. Appl. 2003, 6, 197–210.

- Manuj, I.; Mentzer, J.T. Global Supply Chain Risk Management. J. Bus. Logist. 2008, 29, 133–155.

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846.

- Schlüter, F.; Henke, M. Smart supply chain risk management—A conceptual framework. In Digitalization in Supply Chain Management and Logistics: Smart and Digital Solutions for an Industry 4.0 Environment; Kersten, W., Blecker, T., Ringle, C.M., Eds.; epubli GmbH: Berlin, Germany, 2017; pp. 361–380.

- Ivanov, D. Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101922.

- Arto, I.; Andreoni, V.; Rueda Cantuche, J.M. Global Impacts of the Automotive Supply Chain Disruption Following the Japanese Earthquake of 2011. Econ. Syst. Res. 2015, 27, 306–323.

- Natarajarathinam, M.; Capar, I.; Narayanan, A. Managing supply chains in times of crisis: A review of literature and insights. Int. J. Phys. Distrib. Logist. Manag. 2009, 39, 535–573.

- Norrman, A.; Jansson, U. Ericsson’s proactive supply chain risk management approach after a serious sub-supplier accident. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 434–456.

- Kersten, W.; Hohrath, P.; Boeger, M.; Singer, C. A Supply Chain Risk Management process. Int. J. Logist. Syst. Manag. 2011, 8, 152–166.

- Tang, C.S. Robust strategies for mitigating supply chain disruptions. Int. J. Logist. Res. Appl. 2006, 9, 33–45.

- Sodhi, M.S.; Son, B.-G.; Tang, C.S. Researchers’ Perspectives on Supply Chain Risk Management. Prod. Oper. Manag. 2012, 21, 1–13.

- Finch, P. Supply chain risk management. Supply Chain Manag. 2004, 9, 183–196.

- Dani, S. Predicting and Managing Supply Chain Risks. In Supply Chain Risk: A Handbook of Assessment, Management, and Performance; Zsidisin, G.A., Ed.; Springer: New York, NY, USA, 2009; pp. 53–66.

- Zimon, D.; Madzík, P. Standardized management systems and risk management in the supply chain. Int. J. Qual. Reliab. Manag. 2020, 37, 305–327.

- Riley, J.M.; Klein, R.; Miller, J.; Sridharan, V. How internal integration, information sharing, and training affect supply chain risk management capabilities. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 953–980.

- Baryannis, G.; Dani, S.; Antoniou, G. Predicting supply chain risks using machine learning: The trade-off between performance and interpretability. Future Gener. Comput. Syst. 2019, 101, 993–1004.

- Hassan, A.P. Enhancing Supply Chain Risk Management by Applying Machine Learning to Identify Risks. Lect. Notes Bus. Inf. Process. 2019, 354, 191–205.

- Layouni, M.; Tahar, S.; Hamdi, M.S. A survey on the application of Neural Networks in the safety assessment of oil and gas pipelines. In Proceedings of the IEEE Symposium on Computational Intelligence for Engineering Solutions, Orlando, FL, USA, 9–12 December 2014.

- Scholz, R.W.; Bartelsman, E.J.; Diefenbach, S.; Franke, L.; Grunwald, A.; Helbing, D.; Hill, R.; Hilty, L.; Höjer, M.; Klauser, S.; et al. Unintended side effects of the digital transition: European scientists’ messages from a proposition-based expert round table. Sustainability 2018, 10, 2001.

- Rodriguez-Aguilar, R.; Marmolejo-Saucedo, J.A. Structural Dynamics and disruption events in supply chains using fat tail distributions. IFAC-Pap. 2019, 52.

- Yong, B.; Shen, J.; Liu, X.; Li, F.; Chen, H.; Zhou, Q. An intelligent blockchain-based system for safe vaccine supply and supervision. Int. J. Inf. Manag. 2020, 52.

- Beam, A.L.; Kohane, I.S. Big data and machine learning in health care. JAMA J. Am. Med Assoc. 2018, 319, 1317–1318.

- Roh, Y.; Heo, G.; Whang, S.E. A survey on data collection for machine learning: A big data-ai integration perspective. IEEE Trans. Knowl. Data Eng. 2019, 33, 1328–1347.

- Brown, T.B.; Mann, B.; Ryder, N.; Subbiah, M.; Kaplan, J.; Dhariwal, P.; Neelakaantan, A.; Shyam, P.; Sastry, G.; Amodei, D.; et al. Language models are few-shot learners. arXiv 2020, arXiv:2005.14165.

- Ilie-Zudor, E.; Ekárt, A.; Kemeny, Z.; Buckingham, C.; Welch, P.; Monostori, L. Advanced predictive-analysis-based decision support for collaborative logistics networks. Supply Chain Manag. Int. J. 2015, 20, 369–388.

- Fan, Y.; Heilig, L.; Voß, S. Supply Chain Risk Management in the Era of Big Data. In Design, User Experience, and Usability: 4th International Conference, Proceedings of the DUXU 2015, Held as a Part of HCI International, 2–7 August 2015; Marcus, A., Ed.; Springer: Cham, Switzerland, 2015; pp. 283–294.

- Amodei, D.; Hernandez, D. AI and Compute. Available online: https://openai.com/blog/ai-and-compute (accessed on 27 May 2021).

- Ioffe, S.; Szegedy, C. Batch normalization: Accelerating deep network training by reducing internal covariate shift. arXiv 2015, arXiv:1502.03167.

- Hinton, G.E.; Srivastava, N.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R.R. Improving neural networks by preventing co-adaptation of feature detectors. arXiv 2012, arXiv:1207.0580.

- Simeone, O. A very brief introduction to machine learning with applications to communication systems. IEEE Trans. Cogn. Commun. Netw. 2018, 4, 648–664.

- Singh, D.; Reddy, C.K. A survey on platforms for big data analytics. J. Big Data 2015, 2, 293–319.

- Li, H.; Ota, K.; Dong, M. Learning IoT in edge: Deep learning for the Internet of Things with edge computing. IEEE Netw. 2018, 32, 96–101.

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2019, 57, 4719–4742.

- Rogetzer, P.; Nowak, T.; Jammernegg, W.; Wakolbinger, T. Impact of Digitalization on Sustainable Supply Chains. In Chancen und Grenzen der Nachhaltigkeitstransformation Ökonomische und Soziologische Perspektiven; Luks, F., Ed.; Springer: Wiesbaden, Germaney, 2019; pp. 131–144.

- Carbonneau, R.; Laframboise, K.; Vahidov, R. Application of machine learning techniques for supply chain demand forecasting. Eur. J. Oper. Res. 2008, 184, 1140–1154.

- Kumar, S.K.; Tiwari, M.K.; Babiceanu, R.F. Minimisation of supply chain cost with embedded risk using computational intelligence approaches. Int. J. Prod. Res. 2010, 48, 3717–3739.

- Umar, A.; Ivanovski, I. Computer aided strategic planning for egovernment agility a global instrument for developing countries. In Artificial Intelligence for Business Agility—Papers from the AAAI Spring Symposium; Technical Report; The AAAI Press: Menlo Park, CA, USA, 2011; pp. 67–70.

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2012, 1097–1105.

- Alfian, G.; Syafrudin, M.; Farooq, U.; Ma’arif, M.R.; Syaekhoni, M.A.; Fitriyani, N.L.; Lee, J.; Rhee, J. Improving efficiency of RFID-based traceability system for perishable food by utilizing IoT sensors and machine learning model. Food Control 2020, 110, 107916.

- Brintrup, A.; Pak, J.; Ratiney, D.; Pearce, T.; Wichmann, P.; Woodall, P.; McFarlane, D. Supply chain data analytics for predicting supplier disruptions: A case study in complex asset manufacturing. Int. J. Prod. Res. 2020, 58, 3330–3341.

- Cavalcante, I.M.; Frazzon, E.M.; Forcellini, F.A.; Ivanov, D. A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing. Int. J. Inf. Manag. 2019, 49, 86–97.

- Wichmann, P.; Brintrup, A.; Baker, S.; Woodall, P.; McFarlane, D. Extracting supply chain maps from news articles using deep neural networks. Int. J. Prod. Res. 2020, 58, 5320–5336.

- Alfian, G.; Syafrudin, M.; Fitriyani, N.L.; Rhee, J.; Ma’arif, M.R.; Riadi, I. Traceability system using IoT and forecasting model for food supply chain. In Proceedings of the 2020 International Conference on Decision Aid Sciences and Application DASA, Sakheer, Bahrain, 8–9 November 2020.

- Benjaoran, V.; Dawood, N. An application of artificial intelligence planner for bespoke precast concrete production planning: A case study. In Proceedings of the 13th Annual Conference of the International Group for Lean Construction, Sydney, Australia, 19–21 July 2005; pp. 493–499.

- Blackburn, R.; Lurz, K.; Priese, B.; Göb, R.; Darkow, I.-L. A predictive analytics approach for demand forecasting in the process industry. Int. Trans. Oper. Res. 2015, 22, 407–428.

- Bouzembrak, Y.; Marvin, H. Impact of drivers of change, including climatic factors, on the occurrence of chemical food safety hazards in fruits and vegetables: A Bayesian Network approach. Food Control 2019, 97, 67–76.

- Constante-Nicolalde, F.-V.; Guerra-Terán, P.; Pérez-Medina, J.-L. Fraud Prediction in Smart Supply Chains Using Machine Learning Techniques. Commun. Comput. Inf. Sci. 2020, 1194, 145–159.

- Fu, W.; Chien, C.-F. UNISON data-driven intermittent demand forecast framework to empower supply chain resilience and an empirical study in electronics distribution. Comput. Ind. Eng. 2019, 135, 940–949.

- Lau, H.; Ning, A.; Pun, K.F.; Chin, K.S.; Ip, W.H. A knowledge-based system to support procurement decision. J. Knowl. Manag. 2005, 9, 87–100.

- Pereira, M.M.; de Oliveira, D.L.; Portela Santos, P.P.; Frazzon, E.M. Predictive and Adaptive Management Approach for Omnichannel Retailing Supply Chains. IFAC-PapersOnLine 2018, 51, 1707–1713.

- Baryannis, G.; Validi, S.; Dani, S.; Antoniou, G. Supply chain risk management and artificial intelligence: State of the art and future research directions. Int. J. Prod. Res. 2019, 57, 2179–2202.

- Sharma, R.; Kamble, S.S.; Gunasekaran, A.; Kumar, V.; Kumar, A. A systematic literature review on machine learning applications for sustainable agriculture supply chain performance. Comput. Oper. Res. 2020, 119.

- Hamdi, F.; Ghorbel, A.; Masmoudi, F.; Dupont, L. Optimization of a supply portfolio in the context of supply chain risk management: Literature review. J. Intell. Manuf. 2018, 29, 763–788.

- Nychas, G.; Panagou, E.Z.; Mohareb, F. Novel approaches for food safety management and communication. Curr. Opin. Food Sci. 2016, 12, 13–20.

- Smith, M.J. Getting value from artificial intelligence in agriculture. Anim. Prod. Sci. 2019, 60, 46–54.

- Paul, S.K.; Riaz, S.; Das, S. Organizational Adoption of Artificial Intelligence in Supply Chain Risk Management. IFIP Adv. Inf. Commun. Technol. 2020, 617, 10–15.

- Rao, S.; Havewala, A.M. Smart Legal Contract Migration using Machine Learning. In First International Conference on Digital Data Processing London, UK, 15–17 November 2019; Robles, R.S., Ed.; IEEE Computer Society, Conference Publishing Services: Los Alamitos, CA, USA, 2019; pp. 65–69.

- Qu, T.; Zhang, J.H.; Chan, F.T.; Srivastava, R.S.; Tiwari, M.K.; Park, W.-Y. Demand prediction and price optimization for semi-luxury supermarket segment. Comput. Ind. Eng. 2017, 113, 91–102.

- Huang, J. How to drive a holistic end-to-end supply chain risk management. J. Supply Chain Manag. Logist. Procure. 2020, 2, 294–306.

- Woyke, E. How UPS Uses AI to Deliver Holiday Gifts in the Worst Storms. Available online: https://www.technologyreview.com/2018/11/21/139000/how-ups-uses-ai-to-outsmart-bad-weather (accessed on 19 May 2021).

- DHL. DHL Supply Watch Uses Machine Learning to Mitigate Supplier Risks: Supply Watch Analyzes Millions of Online Sources in Real-Time to Detect Early Indicators of Potential Supplier Distresses before They Occur. Available online: https://www.sdcexec.com/software-technology/press-release/12337269/dhl-dhl-supply-watch-uses-machine-learning-to-mitigate-supplier-risks (accessed on 27 May 2021).

- Barrett, B. McDonald’s Bites on Big Data with $300 Million Acquisition: The Fast-Food Giant’s Largest Acquisition in 20 Years is Bringing Machine Learning to the Drive-Thru. Available online: https://www.wired.com/story/mcdonalds-big-data-dynamic-yield-acquisition/ (accessed on 21 May 2021).

- Route4Me. How Machine Learning Is Transforming Supply Chain Management. Available online: https://www.globaltrademag.com/how-machine-learning-is-transforming-supply-chain-management/ (accessed on 27 May 2021).

- Titze, F. Industrial Future by ROI: Wie Machine Learning Trennt, was Wichtig und Unwichtig Ist. Available online: https://www.produktion.de/industrial_future_roi/wie-machine-learning-trennt-was-wichtig-und-unwichtig-ist-256.html (accessed on 27 May 2021).

- Fisher, B.; Coops, A.; Klous, S.; op het Veld, M.; Raisbeck, M.; Zahawi, N. Guardians of Trust: Who is Responsible for Trusted Analytics in the Digital Age? Available online: https://assets.kpmg/content/dam/kpmg/xx/pdf/2018/02/guardians-of-trust.pdf (accessed on 27 May 2021).

- Härle, P.; Havas, A.; Samandari, H. The Future of Bank Risk Management. Available online: https://www.mckinsey.com/business-functions/risk/our-insights/the-future-of-bank-risk-management (accessed on 27 May 2021).

- Kuner, C.; Svantesson, D.J.B.; Cate, F.H.; Lynskey, O.; Millard, C. Machine learning with personal data: Is data protection law smart enough to meet the challenge? Int. Data Priv. Law 2017, 7, 1–2.

- Schroeder, M. Changes in Risk Management via Big Data. Research Blog on Supply Chain Risk Management. ISSN 2748-775X. Available online: https://scrm.hypotheses.org/352 (accessed on 29 June 2021).

- Bonabeau, E. Don’t Trust Your Gut: Decision Making. Available online: https://hbr.org/2003/05/dont-trust-your-gut (accessed on 27 May 2021).

- Canizo, M.; Onieva, E.; Conde, A.; Charramendieta, S.; Trujillo, S. Real-time predictive maintenance for wind turbines using Big Data frameworks. In Proceedings of the 2017 IEEE International Conference, Dallas, TX, USA, 19–21 June 2017; pp. 70–77.

- Bates, D.W.; Saria, S.; Ohno-Machado, L.; Shah, A.; Escobar, G. Big Data in Health Care: Using Analytics to Identify and Manage High-Risk and High-Cost Patients. Health Aff. 2014, 33, 1123–1131.

- Rai, A. Explainable AI: From black box to glass box. J. Acad. Mark. Sci. 2020, 48, 137–141.

- Kemper, J.; Kolkman, D. Transparent to whom? No algorithmic accountability without a critical audience. Inf. Commun. Soc. 2019, 22, 2081–2096.

- Xu, Y.; Sun, Y.; Wan, J.; Liu, X.; Song, Z. Industrial Big Data for Fault Diagnosis: Taxonomy, Review, and Applications. IEEE Access 2017, 5, 17368–17380.

- DuHadway, S.; Carnovale, S.; Kannan, V.R. Organizational communication and individual behavior: Implications for supply chain risk management. J. Supply Chain. Manag. 2018, 54, 3–19.

- Pournader, M.; Kach, A.; Talluri, S. A Review of the Existing and Emerging Topics in the Supply Chain Risk Management Literature. Decis. Sci. 2020, 5, 867–919.

- Choi, T.-M.; Chan, H.K.; Yue, X. Recent Development in Big Data Analytics for Business Operations and Risk Management. IEEE Trans. Cybern. 2017, 47, 81–92.

More

Information

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

2 times

(View History)

Update Date:

28 Sep 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No