| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Juan Francisco García Martín | + 8424 word(s) | 8424 | 2021-09-11 15:49:58 | | | |

| 2 | Conner Chen | Meta information modification | 8424 | 2021-09-23 02:57:07 | | |

Video Upload Options

The International Olive Council (IOC) defines virgin olive oils as “the oils obtained from the fruit of the olive tree (Olea europaea L.) solely by mechanical or other physical means under conditions, particularly thermal conditions, that do not lead to alterations in the oil, and which have not undergone any treatment other than washing, decantation, centrifugation and filtration.”. This definition underlines the importance and the strict relation between the fruit on the one side, and the obtained oil on the other. The quality of the latter depends to a large extent on the quality of the former. At the same time, the definition specifies the need to restrict to a minimum the treatments that can be applied before and during the extraction process and explicitly points to the importance of controlling the temperature during the processing.

1. Background

Virgin olive oils are differentiated into Extra virgin olive oil (EVOO), virgin olive oil (VOO), ordinary virgin olive oil (OVOO) and lamp oil (LOO) [1]. EVOO is regarded as the olive oil with the highest quality. It has a free acidity, expressed as oleic acid, of no more than 0.8 g per 100 g (0.8%) besides other characteristics that correspond to those fixed for each category in the IOC standards. In the case of VOO, a maximum level of 2.0% free fatty acids (FFA) is tolerated and 3.5% in the case of OVO. LOO’s have a FFA of more than 3.3%. Moreover, an evaluation by skilled tasters is mandatory and based on the absence (extra virgin) or the weak presence (virgin) of sensory defects and presence of three positive attributes: fruitiness, bitterness and pungency.

The applied harvesting method and the environmental conditions during the pre-processing storage of olive fruit are crucial factors in maintaining the quality of the fruit. For more than 30 years, both aspects have been studied intensively using the official physicochemical parameters and sensory evaluations that determine the quality of the oils and the impact of the applied treatments. The growing economic importance of premium olive oils further triggered fine-tuned studies in which more sophisticated variables and analyses were introduced to differentiate between olive oils that comply with the official EVOO standards and those that aspire to an even higher quality.

2. Explanatory Variables

2.1. Storage Temperature

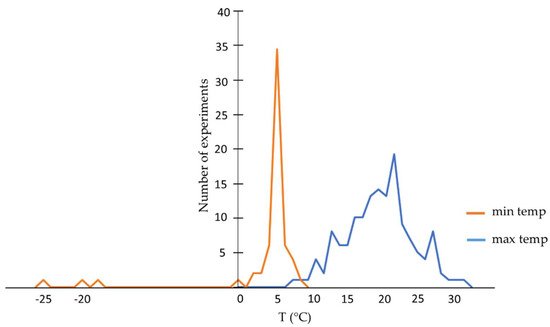

In 80% of the studies, the temperature for the cold storage experiments was kept at 4–6 °C, following the recommendation given in earlier works to respect the 5 °C limit to avoid chilling injuries [2][3][4]. However, the control temperature varied significantly between 15 and 25 °C in 75% of the cases, considered as ambient temperature (Figure 1).

Figure 1. Temperatures use during several experiments of cold storage.

This wider range is partly explained because several studies took the mean maximum day and night temperatures into account or registered the temperatures over longer storages times. A minority of studies used intermediate temperatures of 8 °C [5][6][7] and 10 °C [8][9].

Most of the published studies reported that the quality of the fruit and/or extracted oil were significantly lower when compared to a lower temperature over the same storage time. Yet, it was also suggested that ‘Picual’ and ‘Koroneiki’ cultivar can be stored at 10 °C or even at room temperature for 9 days without much reduction in oil quality [8]. A few studies looked at the possibilities to keep the fruit at lower temperatures. Black ‘Manzanillo’ olives were stored at 0, 2.2 and 5 °C for 6 weeks but, although no chilling injuries were observed, the oil extracted after 4 weeks of storage lost its quality as EVOO [10]. Mechanically and manually harvested olives of the ‘Arbequina’ variety, kept at 3 °C for 21 days neither presented chilling injuries [11]. ‘Manzanilla de Sevilla’ and the ‘Manzanilla Cacereña’ varieties were stored at 2 °C for 11 days in the best conditions without chilling damage [12].

Storage at 0 °C was detrimental due to the destruction of the natural antioxidants present in the olive fruit, leading to a diminishing of the oxidation resistance [13]. Interestingly, oils obtained from ‘Arbequina’, ‘Koroneiki’ and ‘Mission’ cultivars that were kept at −4 °C for up to 3 weeks, maintained the standard indices used for assessing virgin olive oil quality [14]; however, the amounts of FFA in the studied samples were not indicated in that study. After 24 h at −18 °C, a negative effect was found on the oxidative stability of VOO due to olive fruit freezing [15]. It is suggested that without thawing out the fruit before malaxation, the activity of oxidative enzymes is reduced. Olive freezing significantly modified the phenolic and volatile profiles of VOO from ‘Picual’ and ‘Arbequina’ cultivars [16]. Similar results were obtained after storing olive fruit at −25 °C for 6 months [17]. However, they underlined that the extracted oils met the standard commercial parameters for EVOO’s while indicating that the sensorial defects may also be related to microbial activity. It was suggested that an olive sanitization treatment could possibly overcome this problem. The ‘Koroneiki’ cultivar was kept for up to 60 days at −18, 5 and 20 °C, showing no negative effect of storage of olive samples at −18 °C in the extracted oil based on the levels of acidity and peroxide values [18]. After 7 days stored at 4 °C, the two Croatian cultivars, ‘Istarska Bjelica’ and ‘Rosinjola’, preserved the concentration of most phenolic compounds at levels that were comparable with fresh oil [19]. A decrease in sensory quality was observed after storage at room temperature and −20 °C, leading to the conclusion that, under production conditions, refrigeration is the most suitable option when prolonged fruit storage is taken into consideration [19].

2.2. Storage Time

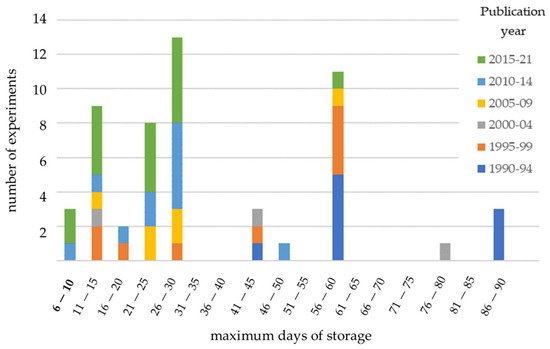

The storage time is a variable of major importance when the effects of cold storage on the physiology of the fruit as well as the quality of the extracted oils therefrom are examined (Figure 2). The effect of the storage time on the quality parameters, and especially on the FFA, is profoundly studied and confirmed for a wide range of varieties.

Figure 2. Maximum days of storage considered in the experiments between 1990 and 2021.

When in the 1990’s the interest in cooling olive fruit took form, timespans up to 3 months were used to follow the official quality parameters of the olive oil [20][5][13][21][22]. Once it became clear that cold storage for more than one month resulted in problematic fruit quality and deficient oils, the maximum storage time was reduced and the observations were made within shorter intervals [23][8][24][25][26][27][28][29][30][31]. Monitoring the amount of polyphenolic and volatile compounds in the stored oils, triggered even more precise observations for only several weeks and between days [32][33][34][35][19]. More recently, the effect of short-term storage of less than one day is acquiring attention as a tool to modulate the aroma profile of the oil [36].

2.3. Use of Controlled Atmosphere

The prospect to control the atmosphere to enlarge the storage time while guaranteeing the quality of the fruit was extensively tested for table olives as well as for mill olives. Increasing the concentration of CO2 and/or the decrease of O2 allows, on the one hand, control of the development of fruit maturation and pathogenic proliferation and can delay the physiological changes due to chilling sensitive crops on the other [37]. On the other hand, these atmospheres can at the same time induce other physiological disorders and even aggravate chilling injuries for specific commodities.

The early experiments at Davis were designed to evaluate the effects of controlled atmosphere (CA) on olive fruit. Olives of the ‘Manzanillo’ and ‘Mission’ cultivars kept at 3.8 °C (39 °F) stored under low O2 and high CO2 concentrations were severely injured fruit due to chilling damage [38]. At the same time and based on color change, there was a clear indication of delaying ripening. ‘Manzanillo’ olives stored under different temperatures and levels of 5% of CO2 caused internal injuries, while storage at 2% O2 retarded fruit softening and color changes [4]. Two Greek varieties for table olives, stored at 5 °C, developed skin injuries after prolonged storage at high CO2 concentrations, with or without low O2. A significant difference was observed between the varieties, with ‘Chondrolia’ being highly sensitive to chilling injury and ‘Conservolea’ having the potential to be stored at 7.5 °C for up to 3 weeks under CA conditions [21][22].

The possibility of applying CA to optimize the cold storage of mill olives was one of the main objectives of the research group of the Instituto de la Grasa of Seville. Their experiments all led to the conclusions that CA induced physiological disorders that facilitated fruit decay [20][39][40][41][42][43]. Oil extracted from these fruits resulted in poor quality levels, characterized by high acidy levels and sensorial defects. The results were confirmed by other authors, reporting the best results after 30 days under air at 5 °C [13]; the lowest panel test scores were obtained for oils extracted from fruit kept during 11 days under low O2 and high CO2 concentrations [44]; several conventional and nonconventional analysis led to the conclusion that CA did not produce any remarkable advantage over storage at 5 °C [24][45]. In the light of this evidence, the results obtained after the storage of Turkish ‘Gemlik’ olives under CO2 are quite surprising, as the treatment protected their physical properties up to 25 days, whilst the quality parameters were not affected, and no significant effect on the phenolic and fatty acid composition of the extracted oil were detected [46].

2.4. Cultivar

Even though the intervarietal comparison among different experiments is often complicated, if not impossible, due to other interfering factors such as different temperature, ripeness or storage conditions, sufficient studies do illustrate the significant effect of the genetic factor on the quality of the fruit and the oils extracted from olives that were cold-stored. ‘Villalonga’ and ‘Blanqueta’ varieties showed significant differences between de levels of FFA of both cultivars when stored for more than 20 days at 5 °C [47]. ‘Manzanillo’ and ‘Ascolano’ could be stored up at 5 °C for 2 and 4 weeks, while ‘Mission’ and ‘Sevillano’ varieties could be kept in good fruit condition up to 6–8 weeks [48]. Comparing the Portuguese cultivars ‘Cobrançosa’, ‘Madural’ and ‘Verdeal Transmontana’, ‘Verdeal Transmontana’ deteriorated the most rapidly, while ‘Cobrançosa’ showed the best results in oil quality after cold storage op 14 days [49]. A significant difference in the bitterness intensity was observed among the ‘Manzanilla’, ‘Picual’ and ‘Verdial’ varieties when stored at 5 °C for 8 weeks [50]. Differences in the levels of decay as well as FFA were reported for three Italian cultivars (‘Coratina’, ‘Olgiarola leccese’ and ‘Leccino’) [45], while the effect of storage temperature and time on the oil quality of mechanically harvested olives from three varieties, ‘Koreneiki’, ‘Picual’ and Barnea’ were compared [8]. Significant differences between the ‘Manzanilla de Sevilla’ and the ‘Manzanilla Cacereña’ were observed in a similar study [12]. Differences on both the fruit as well as oil characteristics of the cultivars studied were confirmed between the Italian varieties ‘Carolea’ and ‘Ottobratica’ [32] and the ‘Arbequina’, ‘Picual’ and ‘Verdial’ cultivars [25][26].

2.5. Loading Unit

The cooling process of fresh fruits and vegetables involves a complex interaction between the thermophysical properties of the commodity (heat generation due to respiration, specific heat and thermal conductivity), the kind of packaging and palletization, flow field parameters (airflow rate and cooling temperature) and the accessibility of the cooling air to the produce [51][52][53][54][55]. The storage of olives implies keeping the fruit in containers that reduces the physical and biological deterioration to a minimum. The capacity of these containers, or the quantity of fruit stored per loading unit, plays a critical role in the storage efficiency of the olives as the incidence of postharvest losses increased together with the container’s capacity [6][56]. After 15 days at 5 °C, the decay incidence approached 40% and at 30 days, and half of the container was rotten. The temperature in the inner zone of a container of 400 kg of ‘Picual’ never went below 25 °C. Olives stored in boxes with a capacity of 64 kg, attained over the same period an incidence below 20% and showed an internal temperature of 6 °C. The incidence of the ones stored in boxes of 2 and 6 kg, stayed below 10% after 45 days of storage. Olives kept in 400 kg containers gave oils with significantly higher acidity values than the ones from containers for 2, 6, 64 kg before 45 days of storage. Similarly, no appreciable differences were reported in the sensorial analysis. Based on these observations, the use of boxes with a capacity of 22 kg of fruit was recommended.

The effect of the layer thickness on the quality and the composition of the minor components was equally studied [33]. For up to 3 weeks, olive batches (ripening index of 4), were stored at 10 and 20 °C in plastic boxes (capacity of 50 kg of olives) filled in different layers, from monolayer, 10 cm, 20 cm to 60 cm thickness. The VOO quality parameters were, besides being affected by the storage temperature and time, also significantly influences by the thickness of the layer. After 5 days of storage, the fruit stored with a 60 cm thickness reached the upper limit for the EVOO (0.8%). The suggestion that olives can be stored for 15 days when placed in one layer at 10 °C, does not offer a workable solution but instead, underline one of the bottlenecks in the cold storage of olive fruit namely the crucial importance of the loading unit.

The handling of many boxes leads to large, if not unsurmountable logistic problems once dealing with several tons. A precooling treatment to the harvested fruit before dumping them in a container for conservation was suggested and investigated [55]. In a first experiment, the evolution of the internal temperature of a container of 400 kg was assessed with and without a precooling treatment at 5 °C. In a second experiment, the effects of a short cooling treatment at −18 °C to attain rapidly the desired 5 °C was tested. In the container with fruit at a field temperature of 18 °C, the mean internal temperature descended towards 10 °C during the first week, followed by a more stabilized period with temperatures between 8.8 and 9 °C. The container with precooled fruit followed an inverse behavior. Starting at 5 °C a slow rise was set in, amounting to 7.6 °C on day 14. The examined parameters of the extracted oils from both treatments showed levels that corresponded to the EVOO category, although the olives that underwent a precooling treatment in small boxes, did not experience a significant increase in the acidity level after 14 days of storage. A comparison with the published data [57] was complicated as neither the intactness nor the state of the ripening of the fruit was provided. Notwithstanding, the observed low acidity levels, suggest that additional factors must have exerted a detrimental effect on the fruit. While fruit at a field temperature of 18 °C is rather low as compared with the day temperatures at the start of the harvesting campaign when fruit temperatures above 25 °C are far from unusual.

Recently, the focus is brought to the short-term cold storage (16–18 h) in containers (perforated plastic bins), either filled with 250 kg, or half-filled with 125 kg, and perforated plastic boxes with 20 kg of fruit [55]. The surface-to-volume ratio (SVR) was 7, 10 and 16, respectively. Unfortunately, the used ambient temperature was only 13.5 ± 1 °C. Thus, the study evaluated the effect of a 5–6 °C fall in temperature. At ambient temperature, the core temperature of the boxes with an SVR of 10 and 16, attained equilibrium in 6 h, while the temperature in bins with 250 kg (SVR 7) showed an increase which reached over 3 °C after 18 h. Regarding the cooled containers, all three reached thermal equilibrium, although the cooling rate depended on the SVR. No significant differences were reported for the oil characteristics (quality parameters, phenolic compounds and VOCs). The concentration of CO2 was significantly higher in the refrigerated storage cell, while the O2 was significantly lower, showing that although the lower temperature reduced cellular respiration, large quantities of CO2 accumulated in olives stored in containers (≅1%) while O2 decreased (≅20%).

2.6. Harvesting System

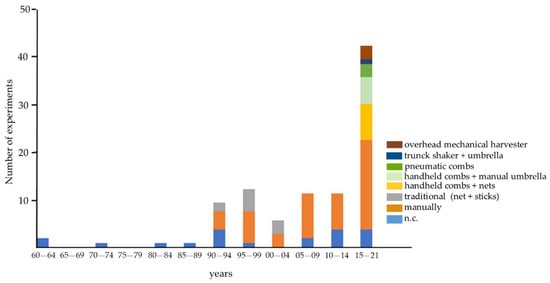

In general, the published articles on the effects of the cold storage conditions on the quality of the olive fruit and the extracted oil used hand-picked olives for their experiments or gave no information on the harvesting method used. It is only with the rise of mechanization and specifically the introduction of straddle machines in super-intensive olive orchards, that the attention was brought to the degree of damage that the used harvesting method could provoke (Figure 3).

Figure 3. Harvesting methods used to harvest olive samples for the cold storage experiments.

The effect of the used harvesting method on the fruit characteristics and the oil quality was brought to the fore [8]. The study reported quality parameters of the oil (FFA, peroxides, polyphenol content) after storage up to 23 days at 4, 10 °C and ambient temperature. It was concluded that, at least for ‘Picual’, the modernization did not reduce the olive’s capacity for storage when the results of [7] were taken as a reference. The potential damage during mechanical harvesting was minimized as well for the ‘Koroneiki’ variety, which kept the values suitable for EVOO up to 24 days when stored at 4 °C. A comparative study to evaluate the effect of the harvesting system and cold storage on ‘Arbequina’ olive fruit and the chemical composition of the extracted oil, revealed that the used adapted wine grape harvester induced internal damage in the fruit that led to more rapid decay, softening and higher weight losses during storage [11][31]. Consequently, the chemical composition of the extracted oils was modified during storage, rendering inferior quality, a decline in oxidative stability and lower phenolic and volatile compounds. A similar study focused on the phenolic and volatile compounds and concluded that the cold storage of mechanically harvested olives was only effective for one of the studied cultivars, ‘Manzanilla Cacereña’ [12]. The damage caused by the grape straddle harvester provoked in the ‘Manzanilla de Sevilla’ cultivar a quick increase in decay and consequently in the acidity levels of the extracted oils, up to the level that the EVOO category was lost. In general, the levels of the phenolic and volatile compounds in the oils obtained from mechanically harvested olives were significantly lower than manually harvested. Few in-depth studies have been performed on the effect of trunk shakers and hand-held machines. One study [58] used five different harvesting systems: (1) gentle manual harvesting; (2) manual harvesting using hand-held combs to detach the olives and nets placed under the tree; (3) using two hand-held pneumatic combs with telescopic handles to detach the olives, while collecting them on nets on the ground; (4) mechanical harvesting with a trunk shaker and a reversed umbrella to collect the olives; (5) a straddle machine. The results left no doubt that gentle hand-harvesting caused the least damage, whereas the trunk shaker and the straddle machine the greatest. Stored at ambient temperature (18 ± 2 °C), the observed fruit damage explained most of the worsening of oil quality across the studied harvesting systems and storage duration.

The effects of a harvesting and conservation method, designed for small producers, on the fruit as well as the oil quality was presented by [25][26]. The studied harvest method consisted of hand-held pneumatic combs (branch shakers) together with a movable structure designed as an inverted umbrella that was placed around the tree, avoiding that the fallen fruit did not fall on the ground, but was recollected in perforated boxes, placed under the lowest part of the canvas [59]. After being harvested, the fruit was stored at the farm in a cold storage room at 5 °C for up to 14 days. Three different varieties (‘Arbequina’, ‘Picual’ and ‘Verdial’) were tested. Fruit evaluation, physicochemical analysis and panel analysis revealed a significant effect of variety, as well as the harvesting and conservation method. Calculation of the magnitude of the strength and panel preference discerned the explanatory weight of each factor and emphasized the need to consider the days of storage when evaluation their importance. When the storage time falls within the range of a few days, the quality is best guaranteed by an optimized harvesting method. When longer storage is expected, high day temperatures are expected or when dealing with sensitive varieties, cold storage turned out to be unavoidable when a high-quality end-product is the goal.

3. Effects on Fruit Physiology and Quality

Harvested olive fruit is a living tissue that respires, consuming oxygen and liberating carbon dioxide [37]. The respiratory process produces the energy required for metabolic activities and fruit maturation. Cooling fruit decreases the effectiveness of the fruit respiration and by doing so the commercial life is extended for the produce stored. By slowing down the metabolic processes, the weight and nutritional value losses are reduced, while pathogenic deterioration of the olive fruit is delayed [56].

3.1. Skin Color and Maturity Index

The progress of the ripening can be registered through changes in skin color, using the CIELAB color space. Alternatively, the maturity index (MI) was calculated following a method that allowed an appreciation of the overall ripening stage of the olive fruit, based on both the skin and flesh color [60].

Each of the studies that used a colorimeter observed a significantly better color for the cold stored olives as compared with the ones kept at room temperature [20][42][7][10][50][11][25][49][9][46][21][22]. This effect became visible from the first week of storage and continued up to 30 days [20]. ‘Picual’ olive fruit kept at 5 °C maintained the same color during the first 14 days of storage independently of the atmosphere [42]. Similar results were obtained when measuring the color variance among ‘Coratina’, ‘Manzanilla’ and ‘Picual’ olives stored at 5 °C [9], and comparing the ‘Arbequina’, ‘Picual’ and ‘Verdial’ cultivars during 14 days at the same storage temperature [25]. A slight change in color after 7 days of storage of the ‘Arbequina’ variety was observed, independent of the harvesting method [11]. It was further reported that storage time and atmospheres had no significant effect on color [10][46]. In olive fruit stored at 5 °C under air, the red skin color was noticed after 45 days, while at 7.5 °C it was observable after 30 days [22]. A significant change in color in the ‘Picual’ cultivar after one week of storage at 5 °C was reported, while this took 3 weeks for the ‘Manzanilla’ and up to 5 weeks for the ‘Verdial’ cultivar [50].

The same tendencies are described when the MI is used to quantify the ripening process and a significant delay of the maturation due to low storage temperatures is observed [5][47][7]. A reddish-brown skin color, corresponding to a number 3, on the scale from 0 to 7, was attained after 15 days when stored at ambient temperature, 30 days when stored at 8 °C and 45 days at 5 °C. The obtained MI values in another study showed only a modest increase in the third and last week of storage at 4 ± 2 °C [23]. The same range of variation was noted with respect to the studied cultivars [50]. Concerning the Croatian varieties, no significant rise in the MI was reported after 1 week of storage at 4 °C [19].

3.2. Firmness

The majority of the published studies define the firmness as the resistance to a deformation of the skin measured either with a shoremeter or densimeter, equipped with a 5- [20][40][42][50][11] or 2-mm probe [46], expressed in Newton/cm2, or with a momentum transfer generator (MTG), that reports the olive firmness as MTG units [10]. From the first studies on, it was demonstrated that the maintenance of flesh firmness depended on storage temperature [20]. At 5 °C, the initial values are maintained, while at ambient temperature they fell to almost 50% after 30 days of storage. At 8 °C, a moderate decrease was observed up to 60 days [5]. The fruit firmness of black-ripe olives declined by 24.4–45.9% in air and 34.2–38.0% in 2 kPa O2 after 4 weeks of storage [10]. These observations were contrary to results on mature green olives which firmness was better when stored under 5 or 2 kPa O2 [42]. However, ‘Gordal’ olives stored under 1 kPa O2 did show a decrease in firmness [20]. The firmness of black-ripe olives at 20 °C decreased by 44% within the first 2 weeks, which was much lower than any of the other examined. Variations among cultivars were observed [48][50]. A clear difference was registered between the ‘Mission’ and ‘Sevillano’ varieties, which maintained their firmness up to 8 weeks, and the ‘Acolano’ and ‘Manzanillo’ cultivars, which, respectively, lost 9 and 29% of their firmness at 4 weeks and 16 and 53% at 8 weeks [48]. Significant differences occurred between ‘Picual’, showing a significant reduction of the firmness after 1 week, and the ‘Manzanilla’ and ‘Verdial’ varieties, only after 4 and 6 weeks, respectively [50]. Hand-harvested olives softened slower as compared to mechanic harvest. However, it was only after 10 days of storage at 5 °C that a significant difference was observed. A difference that was contributed to the internal partial breakage of the cellulose walls of the cells of the mesocarp during mechanical harvesting [11]. A similar observation was made in a recent research [25], in which the use of nets was the damaging factor.

3.3. Humidity

The amount of humidity lost during the storage is measured as the difference between fresh and dry mass and expressed as % [40]. Water loss increased significantly in studies that stored the fruit for more than 60 days [40][42]. Higher temperature and lower relative humidity do provoke higher losses in fruit stored at ambient temperature, while an advanced stage of fungal decomposition induces leakage of cell fluids [40][42]. Kept at 5 °C and up to 60 days, no differences were observed among the fruit stored under different atmospheric concentrations. No significant differences in water content in black-ripe olive were observed after storage of 2 weeks at 20 °C [48] and neither in the ‘Gemlik’ variety after 25 days of storage [46]. However, these results were not confirmed by other studies [9][18]. The former authors registered a significant decline in humidity after 1 week when stored at 20 °C, while at 5 and 10 °C this parameter did not change [9]. Nevertheless, after 2 weeks the fruit stored at the lowest temperature kept significantly higher moisture when compared with the one at 10 °C. The latte authors mentioned a significant decrease of water content after over 20 days for the fruit stored at 20 °C or 5 °C [18].

3.4. Weight Loss

Weight loss is one of the main postharvest changes in fruit and vegetables due to respiration and transpiration. It includes, beside the loss of water, also the loss of other substrates (sugars, organic acids…) that are consumed by the fruit metabolism during the storage. To quantify the weight loss of the olives, the fruit is weighed with a balance before and after each treatment and storage duration. The difference is expressed as percentage loss. Weight losses increase with time over storage [48][13][11][25][9][21][22]. The highest losses were observed at 7.5 °C as compared to at 5 °C under air [13]. At a lower storage temperature and under controlled atmospheres, the weight loss decreased. Slight differences between the two studied varieties, ‘Sevillano’ and ‘Manzanillo’, were reported [48]. While the mass loss after 2 weeks increased in the former by 0.6%, the latter attained 1.5% when stored at 5 °C. At 20 °C the mass loss attained levels between 2.3 and 3%. Varietal variance was also observed among the ‘Coratina’, ‘Manzanillo’ and ‘Picual’ varieties with 16, 12 and 11% weight loss, respectively, when stored at 20 °C. When stored at 10 °C, the weight loss was more than 3 folds those at 5 °C. Prolonging the storage period led to a significant increase in weight loss for all the cultivars [9]. Similar varietal differences between ‘Chondrolia’ and ‘Conservolea’ were reported, although the authors pointed out that this might be due to high chilling injury of the epidermis of ‘Chondrolia’ [22]. Notwithstanding, the study underlined that the olive mass loss increased with storage temperature and duration for both cultivars. This process was accelerated when stored under a controlled atmosphere. The influence of CO2 during the storage at 5 °C is reported as a higher value of average weight at 5 and 15 days with CA, however, the differences became insignificant after 25 days [46]. Significantly higher weight losses were observed in the mechanically harvested ‘Arbequina’ samples [11]. The difference was attributed to the possible internal breakage that led to a lower juice content. The recent experiments of Plasquy et al. showed only an effect of the conservation temperature and the storage time on the weight loss for the three varieties studied (‘Arbequina’, ‘Picual’ and ‘Verdial’) [25].

3.5. Oil Content and Oil Yield

The oil content was determined either by Soxhlet extraction [48][11][33][19] or the method described by Folch et al. [61] (cited in [9]). No significant changes depending on the fruit storage temperature were reported, indicating that accumulation of the oil did not continue during storage [11][33][19]. It was specified that although the oil content remained unchanged in four cultivars studied during storage at 5 °C, when stored at 20 °C, it was lower than the initial values for the ‘Manzanillo’ and ‘Ascolano’ varieties [48]. On the other hand, a significant decrease of the oil content was observed with an increasing storage temperature and the progress of the storage period up to seven weeks [9].

To estimate the oil yield of the olive under different storage treatments, the decanted volume obtained through extraction with an Abencor system was used, considering the value of 0.915 g mL−1 as the value for oil density to obtain the yield as expressed as the percentage of fresh weight [42][50][11][33][18][62][63]. An alternative method [64] takes the mass ratio of the mechanically extracted oil and the centrifuged olive paste and multiplies the result by 100 [19]. One study carried out on a pilot plant scale obtained the data from the producer [23]. The extractability index (EI) was calculated based on the mean value of the percentages of oil physically extracted from the total oil content.

All the published studies reported higher oil yields from olive stored at ambient temperature [39][50][11][33][18][19]. During the first 2 weeks of storage at 5 °C a significant reduction of the yield for the ‘Picual’ and ‘Verdial’ cultivars was observed, followed by a gradual increase up to levels significantly higher than the initial ones [50]. The ‘Manzanilla’ variety, on the other hand, had a low oil yield from day 0 (4.6% against 18.2% and 20.0% for the ‘Picual’ and ‘Verdial’ varieties, respectively) but did not show any significant change. This was related the higher values to the fact that the fruit could continue to ripen at room temperature, facilitating degradation of the walls of oil-bearing cells and consequently an improvement of the extraction process [50][11]. This hypothesis was supported by other authors [19] who also found the highest values of oil yield and EI in olives stored at room temperature. At the same time, it was underlined that the EI is highly dependent on the cultivar and fruit properties. An increase in oil yield in the first 2 weeks of cold storage was observed, followed by a decrease [23]. It is suggested that the increase is a consequence of cell-wall degradation due to low-temperature storage. After two weeks, most of the oil trapped in the cells was easily released. The decrease after 3 weeks was attributed to an advanced stage of hydrolysis.

3.6. Incidence of Decay

Fungal rot was determined visually when fungal mycelium was observed in randomly selected samples of 100 olives and expressed as a percentage of decay [40][42][5][6][47][7][48][11][12]. One study used an ordinal scale for 0 to 5 (0: not rot, 1, few rotting olives without sporulation; 2, 30% rotting but few sporulation; 3, 50% rotting and sporulation; 4, 75% rotting and sporulation; 5, 100% rotting and sporulation) [13].

Low temperatures do reduce fungal growth. Olive fruit from the 4 studied varieties (‘Ascolano’, ‘Manzanillo’, ‘Mission’ and ‘Sevillano’) only showed little or no rot visible on the fruit after 5 weeks of storage at 5 °C [3]. However, after 10 weeks of storage, considerable numbers of decayed fruit were recorded in all varieties. Stored at 12 °C, the decay of ‘Picual’ olives was more than 20% after only 7 days. At 5 °C, 45 days of storage were needed to attain the same level. An intermediate behavior was observed when stored at 8 °C [5][6]. The authors further observed that the entire batch of fruit, stored in air and ambient temperature, was affected at 30 days of storage. Similar results were obtained with the ‘Villalonga’ and ‘Blanqueta’ varieties [47]. Stored at 5 °C, only about 20% were rotten after 60 days, while this level was already attained before 20 days at ambient temperature. Under ambient temperatures, ‘Blanqueta’ was significantly more resistant when compared to ‘Villalonga’, but when refrigerated, no difference was found. A more pronounced intercultivar variance was observed between ‘Manzanillo’ and ‘Ascolano’ with a high decay incidence (12 and 7%, respectively, after 4 weeks, and 90 and 27% after 6 weeks at 5 °C) and the ‘Sevillano’ and ‘Mission’ olives, where the first had 13 and 11% decay after 6 and 8 weeks, respectively, and the second only 8% after 8 weeks. When kept at 20 °C, the ‘Manzanillo’ and ‘Ascolano’ olives showed 40 and 23% decay incidence after 2 weeks, the ‘Sevillano’ 6% and the ‘Mission’ cultivar no decay [48]. The fungal damage on ‘Koroneiki’ was manifest (score of 4) after 30 days of storage at 7.5 °C, independently whether CA was applied or not. At 0 °C in air and 5 °C under 2% of O2 and 5% of CO2, no rot (score 0) was observed after 30 days. At 5 °C in air, few rotting olives were present (score 1). At 60 days of storage the values for each treatment augmented 1 point [13]. The application of CA did not result in significant differences until 60 days of storage after which a higher degree of infection was observed. This shift was attributed to the lowered resistance to the molds, because of the combined effects for high CO2 and/or low O2 and low temperatures [42].

Fruit with physiological disorders or mechanical damage developed infection preferentially [47][7]. Mechanically harvested olives showed a significantly higher incidence of decay when compared to hand-picked olives, regardless of the storage temperature [11]. Independently the method of harvesting, the fruit stored at 3 °C showed a lower percentage of decay. Mechanically harvested ‘Arbequina’ olives attained almost 30% of decay after 4 days of storage at 18 °C, a level that was not attained when stored during 10 days at 3 °C. It was also remarkable that the harvesting system provoked mechanical damages that led to their rapid deterioration, even when the damage was not visually perceptible. A significantly higher decay incidence was reported between the fruit of the ‘Manzanilla de Sevilla’ and ‘Manzanilla Cacereña’ varieties in a hedgerow plantation, and hand-picked olives, although the difference was more pronounced in the first variety [12]. The authors referred to an earlier study in which they compared the damage caused by the used grape straddle harvester in the studied cultivars. The fact that a higher proportion of fruit with cuts was found in green ‘Manzanilla de Sevilla’ (18% versus 2%) may explain the intervarietal difference. Storage during 11 days at 2 °C was highly effective for controlling the fungal rot in the mechanically harvested ‘Manzanilla de Cacereña’, while the ‘Manzanilla de Sevilla’ attained an incidence of 30% under these conditions.

3.7. Microbiological Profile

To study the production of volatile phenols, related to the appearance of VOO sensory defects, the specific microbiological profile on the olive surface of fruit stored in plastic bags and open boxes at 5 ± 3 °C by night and 8 ± 3 °C by day up to 21 days was determined [34][35]. The viable-culturable cell number was determined on different substrates to evaluate the presence of fungi, lactic acid bacteria, enteric bacteria and Pseudomonas. The study revealed that only fungi were present at the initial time. Acetic bacteria attained levels above 104 cfu (colony forming unit) per gram after six days, while the presence of enteric bacteria reached this level at day 5 of storage in a bag and day 15 in an open box. The lactic bacteria became only present after 9 days and the Pseudomonas only after 15 days when stored in a bag. One study [65] focused on the presence of two enzymes, responsible for the oxidation process of the phenolic compounds. The research considered both the phenoloxidase and the peroxidase from the spontaneous microbiota as possible oxidoreductases enzymes involved in the polyphenol decay in the oily fraction of the fruit during storage at 15 °C and registered the total bacteria count, the total molds, and the total yeasts. The microbiological analysis showed a rapid increase of total bacteria and yeasts during the first 4 days of storage. Thereafter, they stabilized at 105 and 106 cfu/g. The molds increased rapidly but never attained a level above 102 cfu/g. The trials further showed that after 3 days of storage, only the total polyphenols presented in the oily fraction decreased rapidly. This was attributed to both the activity of the oxidoreductase’s enzymes from the pulp and the microbiota on the carposphere and in the pulp of damaged fruit.

3.8. Respiration Rate

Low temperature has a direct effect on the respiration rate. Keeping the fruit at 5 °C reduces the metabolism of the fruit cells. When comparing the respiration rate of olive fruit (‘Gordal’ cultivar) over 10 h, a ten-fold higher CO2 production was registered when stored at 18 °C instead of 5 °C [20]. Similar results were observed with 3 Italian cultivars (‘Coratina’, ‘Olgiarola’ and ‘Leccino’) [45]. When kept under 2% O2 and 5 °C, the respiration rate was about three times lower than when stored in ambient air. In the same line, a significant effect on ‘Manzanillo’ olives stored at three temperatures between 5 and 10 °C of both the temperature and atmospheric composition was reported [10]. An increased respiration rate was described when the storage temperature rose, while black olives showed higher values than green at each temperature tested [21]. The values of the CO2 production of ‘Arbequina’ olives that were systematically could be ordered according to the cold storage temperature [31].

The respiratory quotient (RQ), or the ratio of CO2 produced to O2 consumed, is assumed to be equal to 1.0 if the metabolic substrates are carbohydrates. The overall values were calculated to be a little above 1 for the green and black ‘Conservolea’ cultivar when stored at temperatures between 0 and 20 °C during the 24 days [21]. Similar values were obtained at harvest, but a pronounced decline was noticed parallel with the respiration rate for 2 days when stored at temperatures between 10 and 40 °C [62]. This decline was the most pronounced at 40 °C (RQ < 0.4) and the least at 10 °C (±0.6) for both studied cultivars (‘Gordal‘ and ‘Manzanilla’), indicating that above 10 °C sugars were not the only respiratory substrate consumed. The respiration rate increase for a 10 °C rise in temperature, or Q10, were similar in both studies, with values between 1.7 and 2.0 for the green and black ‘Conservolea’ [21] and a range between 1.2 and 2.5 for the ‘Gordal’ and ‘Manzanilla’ varieties [62] in the temperature intervals considered.

Once the fruit is detached, the concentration of substrates for respiration becomes limited. When stored at room temperature these substrates are consumed continuously, while when refrigerated this consumption is reduced. When brought at 20 °C, this fruit still disposes of a higher concentration and therefore, higher CO2 production levels can be expected. This phenomenon is clearly illustrated in the study of Plasquy et al. in which the respiration rate is followed during 14 days of storage for three varieties (‘Arbequina’, ‘Picual’ and ‘Verdial’) at ambient temperature and 5 °C [25]. Meanwhile, higher respiration rates were observed when the fruit was damaged during the harvesting. The fruit of two studied varieties (‘Manzanilla de Sevilla’ y ‘Manzanilla Cacereña’), harvested with a grape straddle harvester, showed a higher respiration rate than the hand-picked ones [12]. Similarly, higher CO2 production was reported in naturally bruised ‘Manzanilla’ olives when compared to healthy [66].

3.9. Ethylene Production

Ethylene production during cold storage was significantly higher for mechanically harvested olives and equally attributed to the damage caused by the harvester [12]. A similar result was obtained by [25], who reported a significant effect of the harvesting method when comparing the traditional harvesting that implied the dragging of nets with olives over the ground, with a gentler picking using a manual inverted umbrella [25]. the ethylene production rate in green olives was almost undetectable for the duration and temperatures tested when manually picked olives were compared [21]. The black ones, on the contrary, showed a 10-fold increase in ethylene production between 0 and 10 °C, indicating that the critical temperature for its synthesis is below 10 °C. This result was in line with earlier published studies that demonstrated the significant effect of ripening on the biosynthesis of ethylene at ambient temperature [4][67][68].

4. Physico-Chemical Analysis of the Extracted Oil

Most of the published studies included a physicochemical analysis of the oil extracted from cold-stored fruits. As a minimum, this includes the official parameters as shared by the European Commission [69], the International Olive Council [1] and the US Department of Agriculture [70] comprising the level of free fatty acids, expressed as the % oleic acid; the peroxide value (PV), expressed in mEq O2/kg oil; and the absorbance at 232 and 270 nm. Additional parameters such as the oxidative stability expressed as the oxidative induction time (h), the chlorophyll and carotenoid pigment profile, and the bitterness index are often included. A specific focus on the minor components of the oil implies the detection and quantification of the kind and amount of polyphenols, tocopherols, volatile compounds (VOC) and alkyl esters.

4.1. Level of Free Acidity

Free fatty acids (FFA) are produced by the hydrolysis of the oil-induced by lipolytic enzymes. These enzymes are normally present in the pulp and seed cells of the olive. When the integrity of the fruit is lost, the enzymes react with the oil that is contained in vacuoles. Unhealthy, damaged or bruised olives, together with detriment storage conditions are the main sources for high values of FFA. The amount of FFA is expressed as the percentage of gram of oleic acid per 100 g of oil. The maximum level for extra virgin olive oil (EVOO) is set at 0.8%. The level of acidity is always present as one of the key parameters to evaluate and compare the different storage conditions. Not only because it is one of the decisive elements in enhancing the quality of the oil, but also because of its sensitivity in detecting changes in the investigated oils. The published reports leave no doubt that the increase in the acidity level is positively related to the storage temperature as well as the period of time [20][39][5][6][47][7][48][13][8][24][32][11][33][34][35][12][71][26][49][27][28][46][18][72].

The combined effect of mechanized harvesting of olives for the mill and the conservation method was the subject of several studies [8][11][12][26]. The acidity of the oil produced from olives harvested with a combine harvester was, after 4 days and regardless of the storage temperature, higher when compared with the values of the oil obtained from fruits harvested by hand [11]. However, it was pointed out that the mechanization of the harvest does not compromise the quality of the oil produced from olives of the ‘Picual’ variety, although it is also not denied that an effect on certain other varieties such as ‘Koroneiki’ and ‘Barnea’ is possible [8]. Gently harvested olives maintained low FFA values over the storage period; however, hand-held combs, increased significantly after 1 week and hand-held machines even evolved above the 0.8% limit after 1 week. Fruit harvested with a straddle machine even attained 1.16% after 48 h [58]. The high incidence of decay is brought forward as the main reason why the acidity levels were significantly higher in oils extracted from mechanically harvested olives, although a varietal difference was noticed between the studied varieties [12].

When the time it takes to exceed the level of 0.80% is compared, the variety ‘Picual’, preserved at 5 °C needed between 23 [8], more than 30 [50] and up to 45 days at 1.00% [5][6]. The ‘Coratina’ variety was maintained for up to 30 days at 5 °C a FFA level below 0.8% [24]. Olives of the ‘Arbequina’ variety, stored at 3 °C and harvested with a harvester, exceed that threshold after 10 days, while when hand-picked, they reach up to 3 weeks [11]. The ‘Verdial’ variety was stored for more than 30 days at 5 °C before it exceeded 0.8% [50].

The intervarietal differences concerning the level of acidity were also noticed among three Portuguese varieties [49], among the ‘Picual’, ‘Barnea’ and ‘Koroneiki’ varieties [8], and between ‘Arbequina’ and ‘Arbosana’ [35]. Regarding the effect of the used harvesting and conservation method for the ‘Arbequina’ variety, conservation became prominent after four days of storage, while the ‘Picual’ cultivar showed to be more resistant to a rise in FFA. The ‘Verdial’ offered a more confusing profile. While in the first year an increased importance of the conservation method was measured, this effect was absent in the second year while the harvesting method was responsible for 30–60% of the variance [26].

Differences between the ripening stage were also observed. Comparing green mature, veraison and black olives of the ‘Picual’ cultivar during a storage period of 4 weeks at 5 °C, the green mature stayed below 0.8% up to 4 weeks, the veraison and black olives attained levels above 0.8% after, respectively, 3 and 2 weeks [71].

4.2. Peroxides

Peroxides are the primary products of the oxidation of olive oil. Peroxide value (PV) is a measure of total peroxides in olive oil expressed as mEq O2 kg−1 oil and hence a major guide of quality. None of the published studies exceeded de maximum value of 20 mEq/kg oil when cold-stored. Notwithstanding, significant differences were observed due to the specific conditions of conservation.

After one week, a sharp rise in the peroxide value was observed up to 30 days at ambient temperature and 8 °C, followed by a decrease until 60 days. At 5 °C, the increase was lower and spread over 45 days [47]. Other authors reported an increase of the PV only for olives stored at 7.5 °C after 30 days [13]. Values higher than 20 mEq were registered in olives stored at 2 weeks after which a decline set in, probably due to the consumption of minor compounds as phenols and tocopherols that make the formation of peroxides difficult [49]. The initial increase followed by a decrease was attributed to the formation of secondary carbonyl compounds [72]. The storage conditions do play a significant role. A doubling of the PV was observed after 11 days when stored in plastic bags, while only after 25 days in plastic containers [28]. The effect of the ripeness of the fruit on the PV values was also reported [71]. A clear difference between on the one hand ‘Arbequina’ and ‘Picual’, and on the other ‘Verdial’ was noticed [26]. The latter attained the PV limit in one week when recollected with nets. The harvesting method stood out as the most influential factor for all varieties.

4.3. K270 and K232

UV-specific extinction determination permits an approximation of the oxidation process in unsaturated oils. At 232 nm, primary oxidation products show absorption (conjugated peroxides) which increase due to inappropriate storage of olive fruits or a defective extraction. At 270 nm secondary oxidation products, such as carbolynic compounds (aldehydes and ketones) are detected which indicates an advanced oxidation process. The maximum permitted values are 2.5 for K232 and 0.20 for K270. The results obtained in relation to the degree of oxidation as measured by these parameters are in line with the one observed with the peroxide values, with only a few studies reporting values that exceeded the set limits even when the fruit was cold-stored for more than a month.

The values of K232 and K270 remained practically constant when stored at 5 °C [20][48][13][24][32][33][34][35][46]. An increase in K232 and K270 at 15 days at ambient temperature was observed, surpassing the limits at 30 days [39]. ‘Picual’ olives, stored in plastic containers of 64 kg of fruit for two months, attained the maximum limit after 14 days when stored at ambient temperature, 33 days at 8 °C. At 5 °C the limit was not yet reached at the end of the experiment. similar values for K232 were obtained at different temperatures up to 30 days [47]. From then on, the samples differed significantly with the lowest values found in oils from olives stored at 5 °C. At 270 nm, and in contrast with the earlier published study [20], the storage temperature showed to significantly affect the presence of carbonylic compounds. [23] on the other hand, observed a significant effect of the K232 but not on the K270. In the same manner, [72] registered an increase of K232 after 7 days, regardless of the storage temperature, and all values surpassing the limit except when stored at 5% and kept a low O2 concentration. The values of K270 showed a significant effect of storage temperature but all values were above maximum.

Mechanical harvesting exerted a significant effect on the K232 and K270 values of the extracted oils. The higher values observed led to an increase in the amount of conjugated fatty acids, meanwhile this process was accelerated at a storage temperature of 18 °C [11]. For the values of K270, no significant differences were found initially. However, in oils from mechanically harvested olives an increase took off after 4 days of storage at 3 °C, while no difference was observed in the oils extracted from manually harvested fruit. This was attributed to the internal rupture of the olive during the crushing in the course of the harvest. Similar changes were not reported in a recent research [26] as no significant effect for K232 was detected. At 270 nm, the effect of the harvesting method was significant in all the varieties. These results indicate that the damages provoked by a harvester are even more severe than those that occur when olives are picked from the ground. However, other authors did not observe the K232 and K270 values to be affected by the variety, type of harvesting and storage time [8][12]. Opposed results were reported, pointing to a varietal difference in the Portuguese cultivars for K232, but obtaining at 270 nm similar values [49]. Olives in open perforated boxes behaved better, as only after 17 days the limit value for K232 was attained [28]. In plastic bags, a drastic increase was observed, without of the limit values after 11 for K232 and 25 days for K270. Significant changes in the K270 due to the time of storage were showed [71]. After one week, green mature fruits exhibited higher values, while no changes were found in riper olives. The values of K232 on the other hand remained constant.

4.4. Oxidative Stability

The oxidative stability, measured with the Rancimat system, although it is not considered as one of the legally established parameters to evaluate the quality of the oils, provides an interesting estimate of the shelf life of the oil. A wide range of studies shows that the levels of oxidative stability are highly influenced by the genetics of the fruit. It is also accepted that not only the values within each variety are reduced during its conservation, but also that this process slows down when the fruits are subjected to low temperatures. Several studies have pointed out that up to at least 21 days, the values obtained with the Rancimat method did not change. Oils stored at 5 °C lost 35% of stability after 60 days of storage, while at 8 °C and ambient temperature, 70 and 93%, respectively [47]. The resistance of ‘Koroneiki’ oil to oxidation did not change at 5 °C in air during 30 days of storage [13]. It was reported that the stability was slightly reduced (<10) after 6 weeks of storage, which was seen as normal because fruit matured, and the stability decreases with olive maturation [50]. A reduction of 7% was also observed after 3 weeks of storage at 5 °C with the Tunisian cultivars ‘Chemlali’ and ‘Chetoui’ [27]. A slightly deviant result was obtained by Pereira et al., reporting a significant decrease during the first week of storage at 5 °C, although a difference between the varieties ‘Cobrançosa’ on the one hand and ‘Madural’ and ‘Verdeal Transmontana’ on the other was also noted [49]. Similar intervarietal differences were observed by Rinaldi et al. and Plasquy et al. [45][26]. In the latter study, the harvesting method showed to be of major importance for up to 4 days. Over 14 days, the strength of the used conservation method increased, although the maximum and rate varied along with the cultivars. In ‘Arbequina’ it attained almost 80% on day 14, in ‘Verdial’ 40% and ‘Picual’ 20%. In the same line, varietal differences with the lowest values for the mechanically harvested olives were reported [11][12].

A bad correlation between PV and stability was observed [39], suggesting the existence of other factors in addition to oxidation state that influence stability. The high concentration of free fatty acid oils extracted from fruit stored at ambient temperature underwent a remarkable decrease after 30 days while at 5 °C the stability was constant. The temperature-dependent loss of stability was attributed to thermocatalyzed hydraulic and oxidative processes, which act on the oil contained in the olives during their ripening, either as a consequence of their own metabolism or as a result of a pathogenic activity [47]. Meanwhile, the detected correlation between the total amount of phenols and the induction times points to the antioxidant activity of hydrophilic phenols [24][15].

References

- IOC [International Olive Council]. Trade Standard Applying to Olive Oils and Olive Pomace Oil; COI/T.15/NC No 3/Rev. 16; IOC: Madrid, Spain, 2021; Available online: https://www.internationaloliveoil.org/wp-content/uploads/2021/07/COI-T15-NC3-REV-16-2021-_ENG.pdf (accessed on 28 June 2021).

- Maxie, E.C. Experiments on cold storage and controlled atmospheres. Calif. Olive Assoc. Annu. Tech. Rep. 1964, 43, 12–15.

- Woskow, M.; Maxie, E.C. Cold storage studies with olives. Calif. Olive Assoc. Annu. Tech. Rep. 1965, 44, 6–11.

- Kader, A.A.; Nanos, G.D.; Kerbel, E.L. Responses of ‘Manzanillo’ olives to controlled atmospheres storage. In Proceedings of the Fifth International Controlled Atmosphere Research Conference, Wenatchee, WA, USA, 14–16 June 1989; Volume 2, pp. 119–125.

- García, J.M.; Castellano, J.M.; Gutiérrez, F.; Castellano, J.M.; Perdiguero, S.; Morilla, A.; Albi, M.A. Cold storage of mill olives. In Contribution du Froid à la Preservation de la Qualité des Fruits, Legumes et Produits Halieutiques: Actes du Sumposium; Bennani, A.L., Messaho, D., Eds.; Actes Éditions Rabat: Rabat, Maroc, 1994; pp. 77–86.

- García, J.M.; Gutiérrez, F.; Castellano, J.M.; Perdiguero, S.; Morilla, A.; Albi, M.A. Storage of olives destined for oil extraction. Acta Hortic. 1994, 368, 673–681.

- García, J.M.; Gutiérrez, F.; Castellano, J.M.; Perdiguero, S.; Morilla, A.; Albi, M.A. Influence of storage temperature on fruit ripening and olive oil quality. J. Agric. Food Chem. 1996, 44, 264–267.

- Dag, A.; Boim, S.; Sobetin, Y.; Zipori, I. Effect of mechanically harvested olive storage temperature and duration on oil quality. Horttechnology 2012, 22, 528–533.

- El-Nagaar, N.I.; El-Saedy, R.M. Storage temperature and storage duration affect fruit and oil quality of Coratina, Manzanillo and Picual olives. Alex. Sci. Exch. J. 2010, 31, 137–154.

- Agar, I.T.; Hess-Pierce, B.; Sourour, M.M.; Kader, A.A. Identification of optimum preprocessing storage conditions to maintain quality of black ripe ‘Manzanillo’ olives. Postharvest Biol. Technol. 1999, 15, 53–64.

- Yousfi, K.; Weiland, C.M.; García, J.M. Effect of harvesting system and fruit cold storage on virgin olive oil chemical composition and quality of superintensive cultivated ‘Arbequina’ olives. J. Agric. Food Chem. 2012, 60, 4743–4750.

- Morales-Sillero, A.; Pérez, A.G.; Casanova, L.; García, J.M. Cold storage of ‘Manzanilla de Sevilla’ and ‘Manzanilla Cacereña’ mil olives from super-high density orchards. Food Chem. 2017, 237, 1216–1225.

- Kiritsakis, A.; Nanos, G.D.; Polymenopoulos, Z.; Thomai, T.; Sfakiotakis, E.M. Effect of fruit storage conditions on olive oil quality. J. Am. Oil Chem. Soc. 1998, 79, 721–724.

- Asheri, M.; Sharifani, M.M.; Kiani, G. An examination into the effects of frozen storage of olive fruit on extracted olive oils. Adv. Hort. Sci. 2017, 31, 191–198.

- Poerio, A.; Bendini, A.; Cerretani, L.; Bonoli-Carbognin, M.; Lercker, G. Effect of olive fruit freezing on oxidative stability of virgin olive oil. Eur. J. Lipid Sci. Technol. 2008, 110, 368–372.

- García-Vico, L.; García-Rodriguez, R.; Sanz, C.; Pérez, A.G. Biochemical aspects of olive freezing-damage: Impact on the phenolic and volatile profiles of virgin olive oil. Food Sci. Technol. 2017, 86, 240–246.

- Masella, P.; Guerrini, L.; Angeloni, G.; Spadi, A.; Baldi, F.; Parenti, A. Freezing/storing olives, consequences for extra virgin olive oil quality. Int. J. Refrig. 2019, 106, 24–32.

- Taluri, S.S.; Jafari, S.M.; Bahrami, A. Evaluation of changes in the quality of extracted oil from olive fruits stored under different tempertures and time intervals. Sci. Rep. 2019, 9, 19688.

- Bubola, K.B.; Lucić, M.; Novoselić, A.; Krapac, M.; Lukić, I. Olive fruit refrigeration during prolonged storage preserves the quality of virgin olive oil extracted therefrom. Foods 2020, 9, 1445.

- García, J.M.; Streif, J. The effect of controlled atmosphere storage on fruit and oil quality of ‘Gordal’ olives. Gartenbauwissenschaft 1991, 56, 233–238.

- Nanos, G.D.; Agtsidou, E.; Sfakiotakis, E.M. Temperature and propylene effects on ripening of green and black ‘Conservolea’ olives. HortScience 2002, 37, 1079–1081.

- Nanos, G.D.; Kiritsakis, A.K.; Sfakiotakis, E.M. Preprocessing storage conditions for green ‘Conservolea’ and ‘Chondrolia’ table olives. Postharvest Biol. Technol. 2002, 25, 109–115.

- Kalua, C.M.; Bedgood, D.R., Jr.; Bishop, A.G.; Prenzler, P.D. Changes in Virgin Olive Oil Quality during Low-Temperature Fruit Storage. J. Agric. Food Chem. 2008, 56, 2415–2422.

- Clodoveo, M.L.; Delcuratolo, D.; Gomes, T.; Colelli, G. Effect of different temperatures and storage atmospheres on Coratina olive oil quality. Food Chem. 2007, 102, 571–576.

- Plasquy, E.; Blanco-Roldán, G.; Florido, M.C.; García, J.M. Effects of an integrated harvest system for small producers on the quality of the recollected olive fruit. Grasas Aceites 2021, 72, e436.

- Plasquy, E.; Florido, M.C.; Sola-Guirado, R.R.; García, J.M. Effect of a harvesting and conservation method for small producers on the quality of the produced olive oil. Agriculture 2021, 11, 417.

- Ouni, Y.; Nabil, B.Y.; Zarrouk, M.; Flamini, G. Influence of olive storage period on volatile compounds and oil quality of two Tunisian cultivars of Olea europea, Chemlali and Chetoui. Int. J. Food Sci. Technol. 2011, 46, 1245–1252.

- Jabeur, H.; Zribi, A.; Abdelhedi, R.; Bouaziz, M. Effect of olive storage conditions on Chemlali olive oil and the effective role of fatty acids alkyl esters in checking olive oil authenticity. Food Chem. 2015, 169, 289–296.

- Hbaieb, R.H.; Kotti, F.; Gargouri, M.; Msallem, M.; Vichi, S. Ripening and storage conditions of Chétoui and Arbequina olives: Part I. Effect on olive oils volatiles profile. Food Chem. 2016, 203, 548–558.

- Hbaieb, R.H.; Kotti, F.; Cortes-Francisco, N.; Caixach, J.; Gargouri, M.; Msallem, M.; Vichi, S. Ripening and storage conditions of Chétoui and Arbequina olives: Part II. Effect on olive endogenous enzymes and virgin olive oil secoiridoid profile determined by high resolution mass spectrometry. Food Chem. 2016, 210, 631–639.

- Yousfi, K.; Weiland, C.M.; García, J.M. Responses of fruit physiology and virgin oil quality to cold storage of mechanically harvested ‘Arbequina’ olives cultivated in hedgerow. Grasas Aceites 2013, 64, 572–582.

- Piscopo, A.; De Bruno, A.; Zappia, A.; Gioffrè, G.; Grillone, N.; Mafrica, R.; Poiana, M. Effect of olive storage temperature on the quality of Carolea and Ottobratica oils. Emir. J. Food Agric. 2018, 30, 563–572.

- Inarejos-García, A.M.; Gómez-Rico, A.; Salvador, M.D.; Fregapane, G. Effect of Preprocessing olive storage conditions on virgin olive oil quality and composition. J. Agric. Food Chem. 2010, 58, 4858–4865.

- Vichi, S.; Romero, A.; Gallardo-Chacón, J.; Tous, J.; López-Tamames, E.; Buxaderas, S. Influence of olives’ storage conditions on the formation of volatile phenols and their role in off-odor formation in the oil. J. Agric. Food Chem. 2009, 57, 1449–1455.

- Vichi, S.; Romero, A.; Gallardo-Chacón, J.; Tous, J.; López-Tamames, E.; Buxaderas, S. Volatile phenols in virgin olive oil: Influence of olive variety on their formation during fruit storage. Food Chem. 2009, 116, 651–656.

- Guerrini, L.; Corti, F.; Cecchi, L.; Mulinacci, N.; Calamai, L.; Masella, P.; Angeloni, G.; Spadi, A.; Parenti, A. Use of refrigerated cells for olive cooling and short-term storage: Qualitative effects on extra virgin olive oil. Int. J. Refrig. 2021, 127, 59–68.

- Ramaswamy, H.S. Post-Harvest Technologies of Fruit & Vegetables; DEStech Publilcations: Lancaster, PA, USA, 2015; ISBN 978-1-932078-27-5.

- Maxie, E.C. Storing olives under controlled temperature and atmospheres. Calif. Olive Assoc. Annu. Tech. Rep. 1993, 42, 34–40.

- Gutiérrez, F.; Perdiguero, S.; García, J.M.; Castellano, J.M. Quality of oils from olives stored under controlled atmosphere. J. Am. Oil Chem. Soc. 1992, 69, 1215–1218.

- García, J.M. Efecto del CO2 en la atmósfera de almacenamiento sobre la fisiología de la aceituna de molino. Grasas Aceites 1993, 44, 81–84.

- García, J.M. Efecto del CO2 en la atmósfera de almacenamiento sobre la calidad del aceite de oliva. Grasas Aceites 1993, 44, 169–174.

- Castellano, J.M.; García, J.M.; Morilla, A.; Perdiguero, S.; Gutierrez, F. Quality of Picual olive fruit stored under controlled atmospheres. J. Agric. Food Chem. 1993, 41, 537–539.

- Pérez-Camino, M.C.; García, J.M.; Castellano, J.M. Polar compound concentrations in virgin olive oils from stored cultivar Picual olive fruits. J. Agric. Food Chem. 1992, 40, 2260–2262.

- Yousfi, K.; Cayuela, J.A.; García, J.M. Effect of temperature, modified atmosphere and Ethylene during olive storage on quality and bitterness level of the oil. J. Am. Oil Chem. Soc. 2009, 86, 291–296.

- Rinaldi, R.; Amodio, M.L.; Colelli, G.; Clodoveo, M.L. Controlled atmosphere storage of 3 Italian cultivars of olives for oil production. Acta Hort. 2010, 857, 97–105.

- Bozdogan, A.; Eker, T.; Konuskan, D.; Oz, A.T.; Kafkas, E. Effects of the storage of Turkish Gemlik olives under CO2 and N2 on the phenolic compounds and fatty acid compositions of olive oils. J. Food Meas. Charact. 2019, 13, 187–195.

- García, J.M.; Gutiérrez, F.; Barrera, M.J.; Albi, M.A. Storage of Mill Olives on an Industrial Scale. J. Agric. Food Chem. 1996, 44, 590–593.

- Agar, I.T.; Hess-Pierce, B.; Sourour, M.M.; Kader, A.A. Quality of fruit and oil of black-ripe olives is influenced by cultivar and storage period. J. Agric. Food Chem. 1998, 46, 3415–3421.

- Pereira, J.A.; Casal, S.; Bento, A.; Oliveira, M.B.P.P. Influence of olive storage period on oil quality of three Portuguese cultivars of Olea Europea, Cobrançosa, Madural and Verdial Transmontana. J. Agric. Food Chem. 2002, 50, 6335–6340.

- Yousfi, K.; Cayuela, J.A.; García, J.M. Reduction of virgen olive oil bitterness by fruit cold storage. J. Agric. Food Chem. 2008, 56, 10085–10091.

- Becker, B.R.; Misra, A.; Fricke, B.A. Bulk refrigeration of fruits and vegetables. Part 1: Theoretical considerations of heat and mass transfer. HVACR Res. 1996, 2, 122–134.

- Brosnan, T.; Sun, D.W. Precooling techniques and applications for horticultural products. A review. Int. J. Refrig. 2001, 24, 154–170.

- Redding, G.P.; Yang, A.; Shim, Y.M.; Olatunji, J.; East, A. A review of the use and design of produce simulators for horticultural forced-air cooling studies. J. Food Eng. 2016, 190, 80–93.

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time-Temperature Management Along the Food Cold Chain: A review of Recent Developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667.

- Plasquy, E.; Florido, M.C.; Sola-Guirado, R.B.; García-Martos, J.M. Precooling and cold storage of olives (cv Picual) in containers with a capacity of 400 kg. Grasas Aceites 2022, 73, e467.

- García, J.M.; Yousfi, K. The postharvest of mill olives. Grasas Aceites 2006, 57, 16–24.

- Nabil, Y.; Ouni, Y.; Dabbech, N.; Baccouri, B.; Abdelly, C.; Zarrouk, M. Effect of olive storage period at two different temperatures on oil quality of two Tunisian cultivars of Olea europea, Chemlali and Chétoui. Afr. J. Biotechnol. 2012, 11, 888–895.

- Famiani, F.; Farinelli, D.; Urbani, S.; Al Hariri, R.; Paoletti, A.; Rosati, A.; Esposto, S.; Selvaggini, R.; Taticchi, A.; Servili, M. Harvesting system and fruit storage affect basic quality parameters and phenolic and volatile compounds of oils from intensive and super-intensive olive orchards. Sci. Hortic. 2020, 263, 109045.

- Plasquy, E.; Sola-Guirado, R.R.; Florido, M.C.; García, J.M.; Blanco Roldán, G. Evaluation of a manual olive fruit harvester for small producers. Res. Agric. Eng. 2019, 65, 105–111.

- Uceda, M.; Frías, L. Épocas de recolección. Evolución del contenido graso del fruto y de la composición y calidad del aceite. In Proceedings of II Seminario Oleícola; IOOC, Ed.; International: Córdoba, Spain, 1975.

- Folch, J.; Lees, M.; Stanley, G.H.S. A simple method for the isolation and purification of total lipides from animal tissues. J. Biol. Chem. 1957, 226, 497–509.

- García, P.; Brenes, M.; Romero, C.; Garrido, A. Respiration and psysicochemical changes in harvested olive fruits. J. Hortic. Sci. 1995, 70, 925–933.

- Gutiérrez Rosales, F.; Perdiguero, S.; Gutiérrez, R.; Olias, J.M. Evaluation of the bitter taste in virgin olive oil. J. Am. Oil Chem. Soc. 1992, 69, 394–395.

- Koprivnjak, O.; Brkić Bubola, K.; Kosić, U. Sodium chloride compared to talc as processing aid has similar impact on volatile compounds but more favorable on ortho-diphenols in virgin olive oil. Eur. J. Lipid Sci. Technol. 2016, 118, 318–324.

- Zullo, B.A.; Di Stefano, M.G.; Cioccia, G.; Ciafardini, G. Evaluation of polyphenols decay in the oily fraction of olive fruit during storage using a mild sample handling method. Eur. J. Lipid Sci. Technol. 2014, 116, 160–168.

- Segovia-Bravo, K.; García-García, P.; Lopéz-Lopéz, A.; Garrido-Fernández, A. Effect of bruising on respiration, superficial colour and phenolic changes in fresh Manzanilla olives (Olea europea pomiformis): Development of treatments to mitigate browning. J. Agric. Food Chem. 2011, 59, 5456–5465.

- Maxie, E.C.; Catlin, P.B.; Hartman, H.T. Respiration and ripening of olive fruits. Proc. Am. Soc. Hort. Sci. 1960, 75, 275–291.

- Fernández-Bolaños, J.; Heredia, A.; Vioque, B.; Castellano, J.M.; Guillén, R. Changes in cell-wall-degrading enzyme activities in stored olives in relation to respiration and ethylene production. Z. Lebensm. Unters. Forsch. A 1997, 204, 293–299.

- EC 2568/91. Characteristics of olive and olive pomance oils and their analytical methods. Off. J. 1991, L248, 1–82.

- USDA [United States Dept of Agriculture]. United States Standards for Grades of Olive Oil and Olive-Pomace Oil; United States Department of Agriculture: Washington, DC, USA, 2010. Available online: https://www.ams.usda.gov/sites/default/files/media/Olive_Oil_and_Olive-Pomace_Oil_Standard%5B1%5D.pdf (accessed on 25 June 2021).

- Petrón, M.J.; Timón, M.L.; Carrapiso, A.I.; Andrés, A.I. Effect of ripening and olive cold storage on oil yield and some olive oil characteristics. Riv. Ital. Sostanze Grasse 2018, 95, 255–259.

- Ben-Yahia, L.; Baccouri, B.; Ouni, Y.; Hamdi, S. Quality, stability and radical scavenging activity of olive oils after Chétoui olives (Olea europaea L.) storage under modified atmospheres. Food Sci. Technol. Int. 2012, 18, 353–365.