Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Orhan Gülcan | + 1169 word(s) | 1169 | 2021-08-31 13:26:29 | | | |

| 2 | Orhan Gülcan | + 2 word(s) | 1171 | 2021-09-02 10:52:24 | | | | |

| 3 | Camila Xu | + 2 word(s) | 1171 | 2021-09-02 11:38:32 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Gülcan, O. Art of Material Jetting. Encyclopedia. Available online: https://encyclopedia.pub/entry/13830 (accessed on 08 March 2026).

Gülcan O. Art of Material Jetting. Encyclopedia. Available at: https://encyclopedia.pub/entry/13830. Accessed March 08, 2026.

Gülcan, Orhan. "Art of Material Jetting" Encyclopedia, https://encyclopedia.pub/entry/13830 (accessed March 08, 2026).

Gülcan, O. (2021, September 02). Art of Material Jetting. In Encyclopedia. https://encyclopedia.pub/entry/13830

Gülcan, Orhan. "Art of Material Jetting." Encyclopedia. Web. 02 September, 2021.

Copy Citation

Material jetting (MJ) technology is an additive manufacturing method that selectively cures liquid photopolymer to build functional parts.

tray location

build direction

surface finish

matte

glossy

PolyJet

MultiJet

1. Introduction

The demand for complex parts is steadily increasing in different industries (especially in aerospace, automotive and biomedical industries) to manufacture lighter parts with higher stiffness, higher strength and lower cost. Thanks to the recent advances in additive manufacturing (AM) technologies, engineers have more freedom to design and produce complex parts which were more difficult if not impossible to manufacture with conventional means [1]. The main difference in AM from conventional, subtractive manufacturing methods is that it is based on a layer-by-layer manufacturing which results in a reduced low buy to fly ratio (the ratio of weight of raw material to weight of the final part) [2][3].

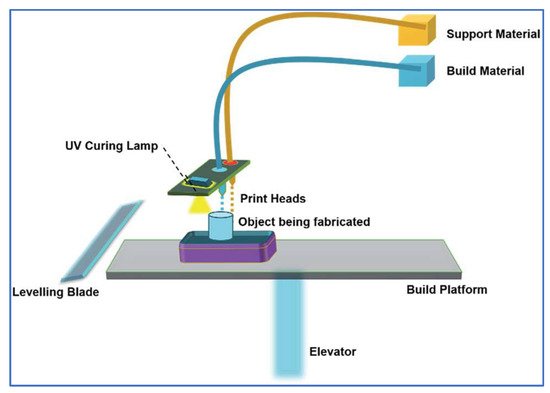

According to “The American Society for Testing and Materials (ASTM) Committee F42 on Additive Manufacturing Technologies” AM technologies can be classified as: powder bed fusion, material jetting, vat photopolymerization, directed energy deposition, material extrusion, binder jetting and sheet lamination [4]. The two different terms are utilized to refer to material jetting processes synonymously. These names are used due to secured naming rights of the material jetting printer manufacturers Stratasys (PolyJet) and 3DSystems (MultiJet). The technology was first developed by Objet Geometries Ltd. in 2000 and was acquired later by Stratasys in 2012 [5]. According to ISO/ASTM 52900: 2015 standard, “droplets of feedstock material are selectively deposited” in MJ technology [6]. Although the MJ printer design varies slightly from manufacturer to manufacturer, a general schematic representation of MJ can be seen in Figure 1. In MJ, air-excluding tanks are used to store photopolymer materials and these are deposited as droplets forming a very thin layer on the build platform after heating photopolymer in the transmission line in which photopolymer is transmitted from tank to nozzle [7]. Ultraviolet (UV) light is emitted onto the molten material on the build platform for curing. In this photopolymerization/photo-curing process, a light source of a specific wavelength is used to cure monomers/oligomers in the liquid state [8]. Unlike the wavelength of lamps used by SLA (355 nm) and DLP (405 nm), the wavelength of the light source in MJ can theoretically be unrestricted [9], but, practically, a light source of a wavelength between 190 and 400 nm is used [10][11]. After curing a layer, the build platform is lowered at a level of certain layer thickness amount and new liquid material is jetted onto the previous layer. After curing each successive layer, a full-scale part is completely built [12]. Since liquid or molten material is used in MJ, a gel-like support structure is needed, especially in overhang regions. These support structures are removed from the part using different methods: sonication in a bath of sodium hydroxide solution, heating or using a high-pressure water jet [13].

Figure 1. A schematic representation of MJ [14].

The MJ technology is a prominent additive manufacturing method in the polymer printing field due its advantages in comparison with other polymer printing techniques. Technology allows us to adapt thin layer thicknesses which allows for printing high-quality parts and less evident staircase effects and thin wall features [8]. The layer thicknesses can be as low as 16 µm [14]. The low surface roughness texture is another advantage which is one of the major problems for additive manufacturing technologies. There are two surface finish options in MJ technology: matte and glossy. In matte the setting, the whole part is covered with support material. In the glossy setting, only structurally needed areas are supported and the model is exposed to air during curing. After printing, supported areas will be matte and unsupported areas will be glossy. Furthermore, no post-processes are required for MJ technology, and parts are usable in the as-built condition after separating them from build platform and support removal processes. Rather than printing parts directly on substrate, a photopolymer resin can be printed onto substrate as a printing bed [15]. Due to easy detachment of photopolymer, separating printed parts from the built plate is possible with a hand tool by applying less amount of force. In addition, different materials such as PLA, ABS, polyamide and their combinations can be combined in a single in MJ technology, called the multi-material approach [14]. The multi-material approach can be utilized to produce composite parts for specific purposes. Lastly, MJ printers have a closed ambient chamber for production which prevents undesirable effects of draught or dirt and can be used in offices and homes.

2. Polymeric Composites via MJ

The improvement in AM enables new ideas to produce innovative parts to fulfill mechanical needs. One of these ideas is the production of composite materials, which was inspired by natural composites, with a mixture of soft–hard materials to create new materials with better mechanical properties [16]. The combination of two different materials exhibiting different hardness specifications creates unique properties such as improved flexibility and hardness [17][18]. The benefit of AM methods for the production of these complex structures is relatively less time needed and cost in comparison to conventional techniques. These composite materials are generally utilized in applications of specially designed structures such as hierarchical structures, including honeycombs, lattice structures and foams for the purpose of energy absorption [19][20][21]. MJ is one of the most convenient methods for composite material production. Sugawaneswaran et al. suggested a novel methodology for fabrication of a randomly oriented plastic reinforced composite structure with elastomer matrix phase. The random distribution of reinforcing materials was determined in a CAD model. As a result, the composite exhibited 22% more stiffness and 10% more elongation in comparison with constituent materials, while the orientation of reinforcements did not inflences the stress–strain curves considerably [22][23]. One of the composite structures that can be fabricated with MJ is interpenetrating phase composites (IPCs). An IPC is made of lattice-based solid sheets embedded in a soft matrix. Dalag et al. investigated the compression behavior of triply periodic minimal surface (TPMS) reinforced IPCs. It was concluded that an increase in reinforcement structure volume fraction of 5% to 20% affects the mechanical behavior of the IPC. Moreover, with the increase in the reinforcement structure volume fraction, ultimate compression strength and yield strength rise considerably. During the deformation of the IPCs, local bucklings and debonding failure mechanisms were experienced [24]. As for the dimensional accuracy of 3D printed microcomposites via MJ, Tee et al. [25] suggested that geometric resolution is convenient whenever it is greater than 500 µm. Additionally, in this study, the mechanical behaviors of 3D printed polymeric microcomposites with different compositions and arrangements of reinforced particles are investigated. As a result, it is shown that orientations and reinforced particle geometries dominate the stiffness of the composites under compressive loads. However, the composite specimen tensile test results showed that build orientation is insignificant for strength whenever the reinforced particle volume fraction is kept at a level of 5%. In addition, it was stated that the composition and reinforced particle arrangement considerably influences the mechanical behavior. In particular, the hardness of the reinforced particles has an effect on the failure mechanism of the polymeric composite structures. Even though the use of hard particles is able to increase the strength, soft particles serve as crack initiators.

References

- Flores, I.; Kretzschmar, N.; Azman, A.H.; Chekurov, S.; Pedersen, D.B.; Chaudhuri, A. Implications of lattice structures on economics and productivity of metal powder bed fusion. Addit. Manuf. 2020, 31, 100947.

- Avila, J.D.; Bose, S.; Bandyopadhyay, A. Additive manufacturing of titanium and titanium alloys for biomedical applications. In Titanium in Medical and Dental Applications; Froes, F.H., Qian, M., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 325–343.

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392.

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Froes, F., Boyer, R., Eds.; Elsevier Publishing: Amsterdam, The Netherlands, 2019; pp. 7–31.

- Udroiu, R.; Braga, I.C. PolyJet technology applications for rapid tooling. MATEC Web Conf. 2017, 112, 03011.

- ISO/ASTM 52900: 2015. Additive Manufacturing—General Principles—Terminology. Available online: https://www.iso.org/standard/69669.html (accessed on 25 June 2021).

- Leary, M. Design for Additive Manufacturing; Elsevier Publishing: Amsterdam, The Netherlands, 2020; p. 270.

- Pilipović, A.; Baršić, G.; Katić, M.; Havstad, M.R. Repeatability and reproducibility assessment of a PolyJet technology using x-ray computed tomography. Appl. Sci. 2020, 10, 7040.

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115.

- Bagheri, A.; Jin, J. Photopolymerization in 3D printing. ACS Appl. Polym. Mater. 2019, 1, 593–611.

- Bennett, J. Measuring UV curing parameters of commercial photopolymers used in additive manufacturing. Addit. Manuf. 2017, 18, 203–212.

- Gardan, J. Additive manufacturing technologies: State of the art and trends. Int. J. Prod. Res. 2016, 54, 3118–3132.

- O’Neill, P.; Jolivet, L.; Kent, N.J.; Brabazon, D. Physical integrity of 3D printed parts for use as embossing tools. Adv. Mater. Process. Technol. 2017, 3, 308–317.

- Sireesha, M.; Lee, J.; Kiran, A.S.K.; Babu, V.J.; Kee, B.B.T.; Ramakrishna, S. A review on additive manufacturing and its way into the oil and gas industry. RSC Adv. 2018, 8, 22460–22468.

- Dilag, J.; Chen, T.; Li, S.; Bateman, S.A. Design and direct additive manufacturing of three-dimensional surface micro-structures using material jetting technologies. Addit. Manuf. 2019, 27, 167–174.

- Mirzaali, M.J.; Edens, M.E.; de la Nava, A.H.; Janbaz, S.; Vena, P.; Doubrovski, E.L.; Zadpoor, A.A. Length-scale dependency of biomimetic hard-soft composites. Sci. Rep. 2018, 8, 1–8.

- Ganesan, S.; Ranganathan, R. Design and development of customised split insole using additive manufacturing technique. Int. J. Rapid Manuf. 2018, 7, 295–309.

- Gu, G.X.; Takaffoli, M.; Hsieh, A.J.; Buehler, M.J. Biomimetic additive manufactured polymer composites for improved impact resistance. Extrem. Mech. Lett. 2016, 9, 317–323.

- Yap, Y.L.; Yeong, W.Y. Shape recovery effect of 3D printed polymeric honeycomb: This paper studies the elastic behaviour of different honeycomb structures produced by PolyJet technology. Virtual Phys. Prototyp. 2015, 10, 91–99.

- Li, W.; Xu, K.; Li, H.; Jia, H.; Liu, X.; Xie, J. Energy absorption and deformation mechanism of lotus-type porous coppers in perpendicular direction. J. Mater. Sci. Technol. 2017, 33, 1353–1361.

- Gu, G.X.; Takaffoli, M.; Buehler, M.J. Hierarchically enhanced impact resistance of bioinspired composites. Adv. Mater. 2017, 29, 1700060.

- Sugavaneswaran, M.; Arumaikkannu, G. Modelling for randomly oriented multi material additive manufacturing component and its fabrication. Mater. Des. 2014, 54, 779–785.

- Sugavaneswaran, M.; Arumaikkannu, G. Analytical and experimental investigation on elastic modulus of reinforced additive manufactured structure. Mater. Des. 2015, 66, 29–36.

- Dalaq, A.S.; Abueidda, D.W.; Al-Rub, R.K.A. Mechanical properties of 3D printed interpenetrating phase composites with novel architectured 3D solid-sheet reinforcements. Compos. Part A Appl. Sci. Manuf. 2016, 84, 266–280.

- Tee, Y.L.; Tran, P.; Leary, M.; Pille, P.; Brandt, M. 3D Printing of polymer composites with material jetting: Mechanical and fractographic analysis. Addit. Manuf. 2020, 36, 101558.

More

Information

Subjects:

Engineering, Electrical & Electronic

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.4K

Revisions:

3 times

(View History)

Update Date:

02 Sep 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No