| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mansoor Soomro | + 1527 word(s) | 1527 | 2020-07-16 05:21:08 | | | |

| 2 | Nora Tang | Meta information modification | 1527 | 2020-07-17 05:37:22 | | |

Video Upload Options

It is critical for organizations to self-assess their Industry 4.0 readiness to survive and thrive in the age of the Fourth Industrial Revolution. Thereon, conceptualization or development of an Industry 4.0 readiness model with the fundamental model dimensions is needed. This paper used a systematic literature review (SLR) methodology with the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines and content analysis strategy to review 97 papers in peer-reviewed academic journals and industry reports published from 2000 to 2019. The review identifies 30 Industry 4.0 readiness models with 158 unique model dimensions. Based on this review, there are two theoretical contributions. First, this paper proposes six dimensions (Technology, People, Strategy, Leadership, Process and Innovation) that can be considered as the most important dimensions for organizations. Second, this review reveals that 70 (44%) out of total 158 total unique dimensions on Industry 4.0 pertain to the assessment of technology alone. This establishes that organizations need to largely improve on their technology readiness, to strengthen their Industry 4.0 readiness. In summary, these six most common dimensions, and in particular, the dominance of the technology dimension provides a research agenda for future research on Industry 4.0 readiness.

1. Definition

Industry 4.0 readiness is described as the degree to which organizations are able to take advantage of Industry 4.0 technologies [1]. In other words, it is about companies being digitally prepared for Industry 4.0 technologies [2][3]. Digital transformation has changed the software and hardware side of organizations [4][5]. For instance, in engineering, three-dimensional simulations and printing are already in full scale practice, involving raw materials, finished product, and the production cycle [6]. Software-as-a-service applications are another window of opportunity. These opportunities can be best addressed under Industry 4.0 technologies, which can then contribute towards Industry 4.0 readiness. Moreover, Industry 4.0 readiness can also be studied from competitive, technological and organizational perspectives. Most of the studies classify Industry 4.0 as disruptive for the same reason.

2. Development

Therefore, to successfully master Industry 4.0 readiness, academic and industry researchers have developed a variety of Industry 4.0 readiness models in the recent years.

3. Methodology

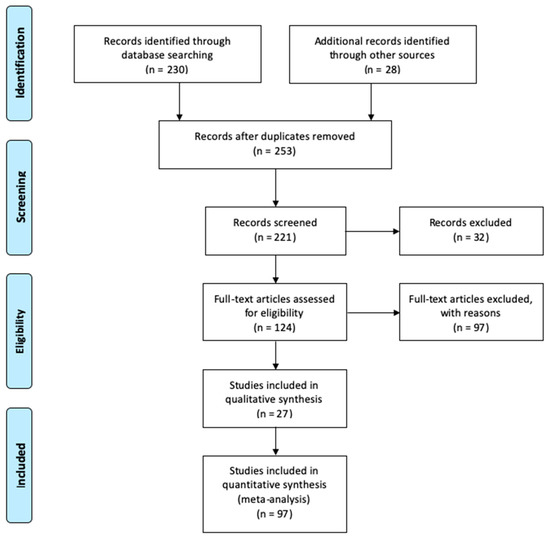

As this paper aims at specific results through three independent research questions, systematic literature review is more appropriate than the broad traditional literature review. Thereon, to contribute to the existing body of knowledge on Industry 4.0 readiness, systematic literature review (SLR) methodology of Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) by Moher and Liberati was deployed [11]. PRISMA is an evidence-based reporting standard that is effective for critical appraisal. The technique of SLR methodology is particularly helpful as it meticulously summarizes the available research in response to research questions [12]. Furthermore, the inclusion and exclusion criteria, with two attempts on the reduction of articles as per this technique leads to a targeted list of articles. In this paper, this review technique has helped considerably in exploring the various readiness models available, and then narrowing down the choices to merely Industry 4.0 readiness models and Industry 4.0 readiness dimensions. Overall, the steps of systematic methodology adapted for this review article are shown in Figure 1. By definition, a systematic review is an examination of a clearly formulated question that uses explicit methods to critically appraise research. This can be done with or without statistical procedures [13]. This literature review has been designed in a structured and rigorous manner. It is replicable, hence can be updated in the future with the state of art findings on Industry 4.0 readiness.

Figure 1. PRISMA flowchart, adapted [27].

For data analysis, the methodology was further supported by content analysis, as it is often preferred in the social sciences. Content analysis can be described as a systematic technique in which certain words (codes) in a text are summarized within categories [14]. Likewise, for this review paper, themes were constructed based on similar contexts and meaning, which led to the findings that are depicted in the next section in this paper [15].

The scanning of existing literature on the topics related to Industry 4.0 Readiness was done, which led to 97 articles, with timeline spanning from 2000 to 2019. There were four search keywords used, spanning over 15 publishers and databases, as shown in Table 1. The systematic review considers both inclusion and exclusion criteria as shown in Table 2. There were three criteria used for inclusion and exclusion: literature type, language and timeline. Since the majority of the literature exists in English, this review tends to be comprehensive in terms of available literature. Secondly, magazine articles are considered to be less formal with missing academic rigor, hence those are excluded from this review. However, industry reports and whitepapers from credible and reputable consultancy houses have been considered. From this review of 124 screened full text articles, 27 (22%) were qualitative and 97 (78%) were quantitative. There were two elimination rounds conducted following PRISMA approach, which led to the targeted 97 articles which constitute this review results and discussion. These 97 articles range from 2000 to 2019. The first elimination round was based on sorting conceptual, theoretical and empirical studies. The second elimination round was extensive which was based on reading the full text, keeping only the literature based on the research objectives of the systematic review. Here, the papers which did not provide Industry 4.0 readiness model questionnaires and model dimensions were excluded. The findings or results obtained follow in the next section.

Table 1. Search boundaries and keywords.

| Search Boundaries | Google Scholar, Literary Databases, Emerald, JSTOR, MDPI, Sage, Research Gate, Science Direct, Wiley, Springer Link, EBSCO Host, Journal Citation Reports (JCR), Taylor & Francis, Wiley, Industry Reports |

| Keywords Search | Industry 4.0 Readiness Model, Industry 4.0 Readiness Framework, Industry 4.0 Readiness Assessment, Industry 4.0 Readiness Transformation |

Table 2. Inclusion and exclusion criteria.

| Inclusion | Exclusion | |

|---|---|---|

| Literature type | Indexed journals, book chapters, conference proceeding, industry reports | Non-indexed journals, magazine articles |

| Language | English | Non-English |

| Timeline | Between years 2000 and 2019 | Before year 2000 |

4. Conclusions and Influences

Industry 4.0 readiness is a contemporary topic in management studies. This systematic literature review unearths 30 existing Industry 4.0 readiness models from both academia and industry in line with the first research question of this study. The review further explores the available 158 model dimensions used by different authors and firms to evaluate Industry 4.0 readiness, which subsequently answers the second and third research question of this study. In terms of contributions from a theoretical point of view, this study has two original contributions. First, this systematic literature review on Industry 4.0 readiness models provides an original contribution in the form of six most common dimensions pooling from 158 individual dimensions, deriving from 30 existing Industry 4.0 readiness models. These six dimensions (Technology, People, Strategy, Leadership, Process and Innovation) can be considered as the most important dimensions for most of the organizations, irrespective of their size and industry. Secondly, most of the Industry 4.0 readiness models have technology related dimensions for assessment. This study reveals that 70 (44%) out of total 158 total unique dimensions on Industry 4.0 pertain to the assessment of technology alone. This implies that organizations need to largely improve on their technology readiness, to strengthen their Industry 4.0 readiness. Furthermore, there is an increasing level of interest among academics and industry professionals about Industry 4.0 readiness [16][17][18].

In terms of study limitations, the review performed in this study was based on historical data, which is a snapshot of a given situation at a specific point in time. Secondly, this study used specific databases with certain keywords, as listed in the methodology section of this paper. As the number of research repositories and databases are increasing, and those are updated continuously, the body of knowledge is continuously expanding which contributes towards limitations and future research both. Overall, the systematic review of existing Industry 4.0 readiness models and dimensions highlighted in this paper are potent enough to set a research agenda for future. The proposed six pooled dimensions as the main dimensions in this review paper can be followed by semi-structured interviews and case studies that can yield new and valuable insights. Further, empirical studies through quantitative research can further establish the inter-relationships between these dimensions. In terms of implications, this review paper has significance for government policy, industry and SMEs. For policy-making, the findings of this study can help government to improve their economy through gap assessment on their Industry 4.0 readiness. For industry, organizations can improve their competitive advantage in domestic and international market by improving their readiness towards Industry 4.0 technologies. For SMEs, this review paper provides six main dimensions that all SMEs in common can benefit from in evaluating their Industry 4.0 readiness.

References

- Stentoft, J.; Jensen, K.W.; Philipsen, K.; Haug, A. Drivers and Barriers for Industry 4.0 Readiness and Practice: A SME Perspective with Empirical Evidence. In Proceedings of the 52nd Hawaii International Conference on System Sciences; HICSS Press: Hawaii, HI, USA, 2019; Volume 6, pp. 5155–5164.

- Schwab, K. The Fourth Industrial Revolution; Encyclopædia Britannica, Inc.: Chicago, IL, USA, 2017.

- Vazire, S. Implications of the Credibility Revolution for Productivity, Creativity, and Progress. Perspect. Psychol. Sci. 2018, 13, 411–417.

- Haber, R.E.; Juanes, C.; Del Toro, R.; Beruvides, G. Artificial cognitive control with self-x capabilities: A case study of a micro-manufacturing process. Comput. Ind. 2015, 74, 135–150.

- Wank, A.; Adolph, S.; Anokhin, O.; Arndt, A.; Anderl, R.; Metternich, J. Using a Learning Factory Approach to Transfer Industrie 4.0 Approaches to Small- and Medium-Sized Enterprises. Procedia CIRP 2016, 54, 89–94.

- Williams, C.; Chen, P.L.; Agarwal, R. Rookies and Seasoned Recruits: How experience in different levels, firms and industries shapes strategic renewal in top management. Strateg. Manag. J. 2017, 38, 1391–1415.

- Henning, K.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0; National Academy of Science and Engineering: Washington, DC, USA, 2013.

- Schaupp, E.; Abele, E.; Metternich, J. Potentials of Digitalization in Tool Management. Procedia CIRP 2017, 63, 144–149.

- Canetta, L.; Barni, A.; Montini, E. Development of a Digitalization Maturity Model for the Manufacturing Sector. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–7.

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846.

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement: The PRISMA statement. PLoS Med. 2009, 6, e1000097.

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222.

- Higgins, J.; Green, S. Cochrane Handbook for Systematic Reviews of Interventions; John Wiley & Sons: Hoboken, NJ, USA, 2011.

- Elo, S.; Kyngäs, H. The qualitative content analysis process. J. Adv. Nurs. 2008, 62, 107–115.

- Roberts, C.W. Content Analysis. In International Encyclopedia of the Social & Behavioral Sciences, 2nd ed.; Elsevier: Oxford, UK, 2015; Volume 4, pp. 769–773.

- Hamidi, S.R.; Aziz, A.A.; Shuhidan, S.M.; Aziz, A.A.; Mokhsin, M. SMEs maturity model assessment of IR4.0 digital transformation. Adv. Intell. Syst. Comput. 2018, 739, 721–732.

- Ertan, J. Digital Readiness of Swedish Organizations. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2018.

- Lokuge, S.; Sedera, D.; Grover, V.; Xu, D. Organizational readiness for digital innovation: Development and empirical calibration of a construct. Inf. Manag. 2018, 56, 445–461.