| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Justyna Żulewska | + 1175 word(s) | 1175 | 2021-08-09 09:33:34 |

Video Upload Options

Ultraviolet (UV) light is a dry and biologically inert process that decreases the microorganism count by around 99.9% with minimum heating of the packing material. Between the UV lamp and the area to be disinfected, there should be no obstruction. Since dirt absorbs radiation and thereby protects bacteria, the effectiveness of this application is therefore dependent on the sanitation of the material surfaces.

1. Introduction

Non-thermal technologies, i.e., microfiltration, UV light processing, pulsed light, high hydrostatic pressure, high-pressure homogenization, pulsed electric fields, ohmic and microwave heating, and carbon dioxide processing, have recently been implemented as an alternative to thermal treatment and have piqued public interest as a means of avoiding nutrient damage that would otherwise occur during food heat processing [1].

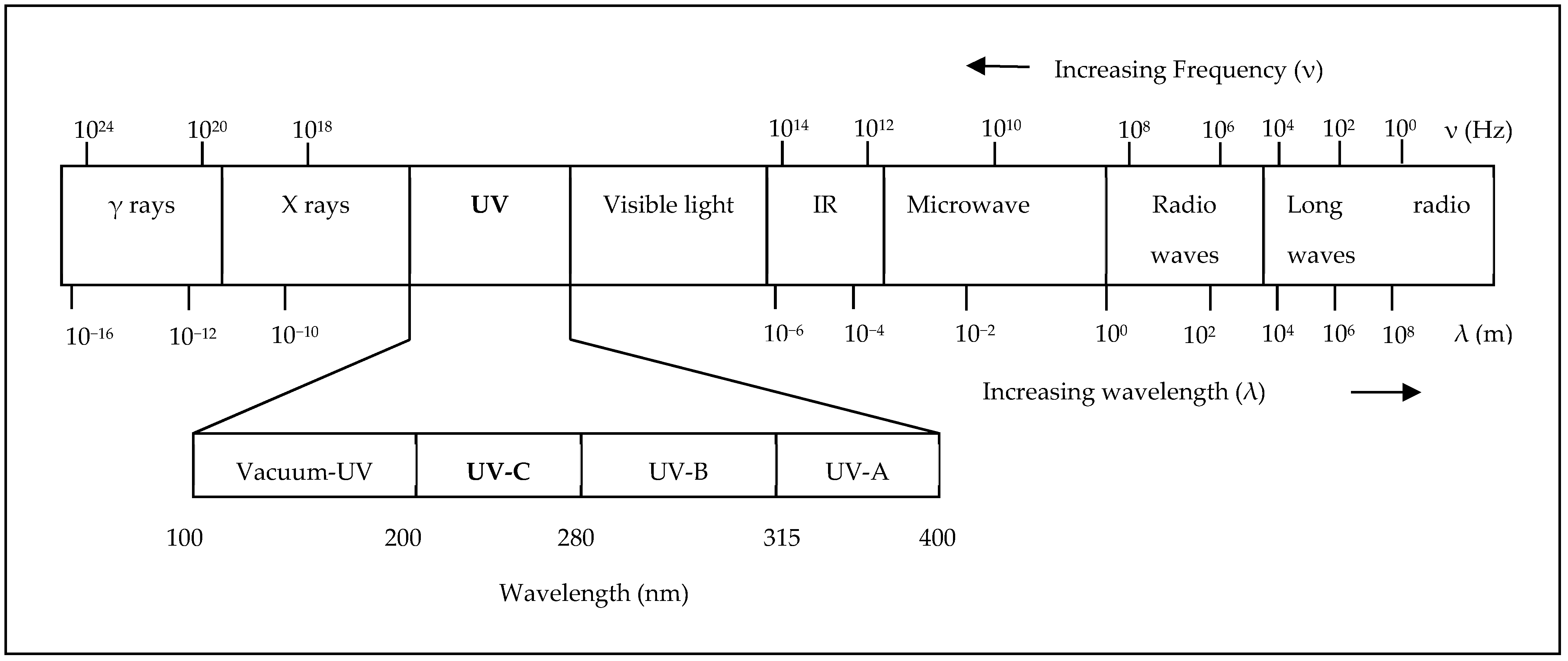

The Sun is the primary source of Ultraviolet light, which radiates light at several different wavelengths [2]. The alternative UV radiations can be emitted from tanning beds, mercury vapor lamps, selected halogens, fluorescents, incandescent lights, and some types of lasers [3]. Ultraviolet radiation is a non-ionizing source of invisible light that exists between visible light and X-rays in the electromagnetic spectrum (EM). UVA (315–400 nm), UVB (280–315 nm), UVC (200–280 nm), and vacuum-UV (100–200 nm) are the four major forms of UV rays produced by ultraviolet light with wavelengths between 100 and 400 nm as shown in Figure 1 [4][5]. UV has the best germicidal effect when the wavelength is about 254 nm, which mercury vapor lamps emit [6]. The microbial deactivation can become more efficient through greater penetration of UV light which is possible with the correct UV source [2].

2. Future Technology: UV-LEDs

3. Conclusions

References

- Datta, N.; Tomasula, P.M. Emerging Dairy Processing Technologies: Opportunities for the Dairy Industry; Wiley-Blackwell: Hoboken, NJ, USA, 2015.

- Koca, N.; Urgu, M.; Saatli, T.E. Ultraviolet light applications in dairy processing. In Technological Approaches for Novel Applications in Dairy Processing; InTechOpen: London, UK, 2018.

- CDC. UV Radiation. 2020. Available online: https://www.cdc.gov/nceh/features/uv-radiation-safety/index.html (accessed on 15 June 2021).

- Delorme, M.M.; Guimarães, J.T.; Coutinho, N.M.; Balthazar, C.F.; Rocha, R.S.; Silva, R.; Margalho, L.P.; Pimentel, T.C.; Silva, M.C.; Freitas, M.Q.; et al. Ultraviolet radiation: An interesting technology to preserve quality and safety of milk and dairy foods. Trends Food Sci. Technol. 2020, 102, 146–154.

- Ansari, J.A.; Ismail, M.; Farida, M. Investigate the efficacy of UV pretreatment on thermal inactivation of Bacillus subtilis spores in different types of milk. Innov. Food Sci. Emerg. Technol. 2019, 52, 387–393.

- Clark, J.P. Shedding new light on UV radiation and pulsed light processing. Food Technology Magazine. 2013. Available online: https://www.ift.org/news-and-publications/food-technology-magazine/issues/2013/october/columns/processing-1 (accessed on 10 June 2021).

- Quantometrix, J.-C. Quanto-Geometry-Vol II-Chapter 8: A Quantum Optics Deconstruction of Maxwell’s Theory of Electromagnetism and the Kinetic Theory. Available online: https://www.researchgate.net/publication/332098527 (accessed on 15 May 2021).

- Marktech Optoelectronics. Understanding Ultraviolet LED Applications and Precautions. Marktech Optoelectronics. 2021. Available online: https://marktechopto.com/technical-articles/understanding-ultraviolet-led-applications-and-precautions (accessed on 1 June 2021).

- Doctoruv.com. UV Curing Wavelength. UV Curing. UV Processing Equipment. 2021. Available online: https://www.doctoruv.com/difference-between-uva-uvb-uvc-uvv (accessed on 14 May 2021).

- Coohill, T.P.; Sagripanti, J. L Invited review: Overview of the inactivation by 254 nm ultraviolet radiation of bacteria with particular relevance to biodefense. J. Photochem. Photobiol. 2008, 84, 1084–1090.

- Gayán, E.; Álvarez, I.; Condón, S. Inactivation of bacterial spores by UV-C light. Innov. Food Sci. Emerg. Technol. 2013, 19, 140–145.

- Choudhary, R.; Bandla, S.; Watson, D.G.; Haddock, J.; Abughazaleh, A.; Bhattacharya, B. Performance of coiled tube ultraviolet reactors to inactivate Escherichia coli W1485 and Bacillus cereus endospores in raw cow milk and commercially processed skimmed cow milk. J. Food Eng. 2011, 107, 14–20.

- Bandla, S.; Choudhary, R.; Watson, D.G.; Haddock, J. UV-C treatment of soymilk in coiled tube UV reactors for inactivation of Escherichia coli W1485 and Bacillus cereus endospores. LWT 2012, 46, 71–76.

- LightSources (NaN): The Various Uses for UV Light—LightSources. Available online: https://www.light-sources.com/blog/the-various-uses-for-uv-light/ (accessed on 10 June 2021).

- Jermann, C.; Koutchma, T.; Margas, C.; Ros-Polski, V. Mapping trends in novel and emerging food processing technologies around the world. Innov. Food Sci. Emerg. Technol. 2015, 31, 14–27.

- EFSA. Safety of UV-treated milk as a novel food pursuant to Regulation (EC) No 258/97. EFSA J. 2016, 14, 4370. Available online: http://www.efsa.europa.eu/en/efsajournal/pub/4370 (accessed on 25 July 2021).

- Kim, S.J.; Kim, D.K.; Kang, D.H. Using UVC light-emitting diodes at wavelengths of 266 to 279 nanometers to inactivate foodborne pathogens and pasteurize sliced cheese. Appl. Environ. Microbiol. 2016, 82, 1–17.

- Bowker, C.; Sain, A.; Shatalov, M.; Ducoste, J. Microbial UV fluence-response assessment using a novel UV-LED collimated beam system. Water Res. 2011, 45, 2011–2019.

- Li, G.Q.; Wang, W.; Huo, Z.; Lu, Y.; Hu, H. Comparison of UV-LED and low pressure UV for water disinfection: Photoreactivation and dark repair of Escherichia coli. Water Res. 2017, 126, 134–143.

- Kebbi, Y.; Muhammad, A.I.; Sant’Ana, A.S.; do Prado-Silva, L.; Liu, D.; Ding, T. Recent advances on the application of UV-LED technology for microbial inactivation: Progress and mechanism. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3501–3527.

- Green, A.; Popovi, V.; Pierscianowski, J.; Biancaniello, M.; Warriner, K.; Koutchma, T. Inactivation of Escherichia coli, Listeria and Salmonella by single and multiple wavelength ultravioletlight emitting diodes. Innov. Food Sci. Emerg. Technol. 2018, 47, 353–361.

- Shin, J.-Y.; Kim, S.-J.; Kim, D.-K.; Kang, D.-H. Fundamental characteristics of deep-UV light-emitting diodes and their application to control foodborne pathogens. Appl. Environ. Microbiol. 2016, 82, 2–10.