Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Nishata Royan Rajendran Royan | + 4703 word(s) | 4703 | 2021-07-21 07:48:45 | | | |

| 2 | Bruce Ren | -21 word(s) | 4682 | 2021-07-23 02:55:44 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Rajendran Royan, N.R. Natural Fibre-Reinforced Polymer Composites. Encyclopedia. Available online: https://encyclopedia.pub/entry/12315 (accessed on 07 February 2026).

Rajendran Royan NR. Natural Fibre-Reinforced Polymer Composites. Encyclopedia. Available at: https://encyclopedia.pub/entry/12315. Accessed February 07, 2026.

Rajendran Royan, Nishata Royan. "Natural Fibre-Reinforced Polymer Composites" Encyclopedia, https://encyclopedia.pub/entry/12315 (accessed February 07, 2026).

Rajendran Royan, N.R. (2021, July 22). Natural Fibre-Reinforced Polymer Composites. In Encyclopedia. https://encyclopedia.pub/entry/12315

Rajendran Royan, Nishata Royan. "Natural Fibre-Reinforced Polymer Composites." Encyclopedia. Web. 22 July, 2021.

Copy Citation

As one of the fastest-growing additive manufacturing (AM) technologies, fused deposition modelling (FDM) shows great potential in printing natural fibre-reinforced composites (NFRC). However, several challenges, such as low mechanical properties and difficulty in printing, need to be overcome. Therefore, the effort to improve the NFRC for use in AM has been accelerating in recent years.

natural fibre

additive manufacturing

filament

surface treatments

optimisation

printing parameters

mechanical properties

1. Introduction

In recent years, the scientific and industrial communities have begun to acknowledge the need for environmentally friendly processes, materials and waste management. As environmental awareness is on the rise, product designers and engineers recognise the impacts of their decisions to use non-renewable resources or non-biodegradable resources. The trend in the industry has begun to shift from using conventional plastics, which are mostly non-biodegradable, to using bio-composites which depend on the polymer matrix that can be biodegradable or carbon neutral. This is primarily due to the great impact of synthetic polymers towards the environment. As part of the efforts to increase the recycling of plastics and reduce its production, researchers have developed natural fibre-reinforced composites (NFRC). These composites are polymers mixed with natural fibres, such as hemp, jute, rice stalk, kenaf and rice husk. The result is a material that has far superior mechanical properties and reduced cost, depending on the type of polymer matrix or even biodegradable [1]. NFRCs are gaining popularity mainly due to their high strength to weight ratio, and thus they can be 25% to 30% stronger than glass fibre composites of the same weight [2]. Because of its various benefits, the global use of NFRCs is starting to grow rapidly. In recent reports, the NFRC market value in 2016 was 4.46 billion USD and is forecasted to grow with a compound annual growth rate of 11.8% from 2016 to 2024 [2]. The use of NFRCs is mainly to produce housing decks and railings but has recently gained popularity in the automotive sectors with manufacturers producing car interiors from NFRCs. Current processing techniques for NFRCs do not differ much from the processing of conventional plastics. Techniques, such as extrusion, compression moulding and injection moulding are used to process and form NFRCs just as they would be used for conventional plastics [3]. As mankind steps into the fourth industrial revolution, the focus has shifted to interconnectivity, automation, machine learning and real-time data. The digitalisation of the manufacturing industries is rising rapidly [4]. There has been a rise in the need for rapid prototyping and ability to produce customised parts quickly and at a low cost. Conventional methods of manufacturing remove material from a large piece of stock, which is known as subtractive manufacturing. These processes are sometimes complicated and time-consuming for complex parts as many parameters need to be considered, such as tool speed, draft angles and tooling types. Even with computer numerical control (CNC) technology, the cost of producing a one-off part with CNC is much higher than using additive manufacturing (AM) techniques. Therefore, researchers have identified AM as one of the more essential components in the rise of the fourth industrial revolution [5]. Almost all of the AM technologies operate based on the same principle, whereby a part is produced through the deposition of material layer by layer. The part starts as a computer-aided design (CAD) model, which is then loaded into the special software known as a slicer. The slicer slices the CAD model into the desired layer height and produces the code to control the printer for each layer. Currently, AM technology is more widely used for polymers. However, although rare, there are commercially available machines that can perform additive manufacturing on metal [6]. As AM technology gains popularity amongst researchers and the industrial sector, there have been efforts to utilise NFRCs in AM. One of the most predominant and popular techniques for AM is fused deposition modelling or sometimes known as fused filament fabrication [7], whereby a polymer filament is extruded through a heated nozzle while the printer traces out the cross-section of each layer.

The use of NFRCs in AM is still a relatively unexplored field as literature on this topic is limited. However, the ability to use NFRCs in AM proves to be beneficial as it can greatly speed up the prototyping process when working with NFRCs. As compared to conventional processes like the injection moulding, a mould needs to be produced before the prototype can be tested. These processes are costly and limit the number of prototypes that can be produced. If NFRCs can be used in AM reliably, the prototyping process can be significantly hasten and at a much lower cost. Furthermore, because there is no need for a mould, more iterations of a product can be tested.

Therefore, the target of this review is to provide a background of the current state of using NFRCs in AM. The review aims to provide an insight into how NFRCs are currently used for AM. The parameters of all stages, involving from raw materials to the final printing process are discussed to provide readers with an insight into what is involved and what affects the properties of a NFRC for use in AM. First, an overview of the currently available AM technologies and works which utilise NFRCs in AM is provided. Next, preparation methods and parameters involved in producing the NFRCs are discussed, followed by the process of producing the filament for use in AM. Printing parameters involved and how they affect the mechanical performance of the composite are discussed in the following sections. Finally, the mechanical properties reported by various researchers who use NFRCs in AM are discussed, followed by an overview of how optimisation methods are employed to optimise the mechanical properties of these composites.

2. Additive Manufacturing Technologies

Additive manufacturing, commonly referred to as 3D printing is the process of fabricating three-dimensional solid objects from a digital machine. The object is typically created by depositing materials layer by layer until the overall object is fabricated successfully. 3D printing is getting more popular as compared to conventional machining techniques, such as milling, drilling, cutting, etc. AM technology is superior to conventional techniques when the object complexity increases. A few technologies that are generally used in 3D printing include fused deposition modelling (FDM), whereby a polymer material is extruded layer by layer to form a 3D object. In stereolithography (SLA), a photosensitive resin is hardened by a UV projector layer by layer. Meanwhile, in selective laser sintering (SLS), a laser sinters polymer or metal powder on a powder bed and forms each layer. Direct write (DW), which is very similar to FDM but does not involve material heating, is directly extruded. This technique is usually used for clay or concrete. Lastly, binder jetting (BJ) is very similar to SLS but instead of laser sintering a binder is injected onto a powder bed to form each layer [8]. FDM-based 3D printing is a popular additive manufacturing technology that is widely used, with thermoplastic materials which have a melting point of lower than 300 °C. For the printing process, the feeder, which is commonly known as a filament, is fed into the 3D printer, whereby the polymer filament is melted and extruded from a temperature-controlled nozzle, also known as the extrusion head, onto a build platform. Depending on the type of polymer, the build platform can be heated or left as it is. The object is created by the layering of thermoplastic at a certain degree of accuracy, whereby either the nozzle or build platform moves in the x-axis, y-axis and z-axis. Type of thermoplastics material that works in the process of FDM includes acrylonitrile butadiene styrene (ABS), polylactide acid (PLA) and high-density polyethylene (HDPE).

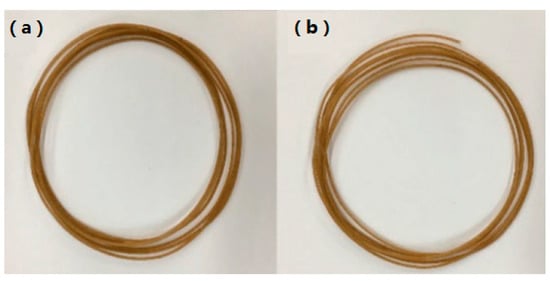

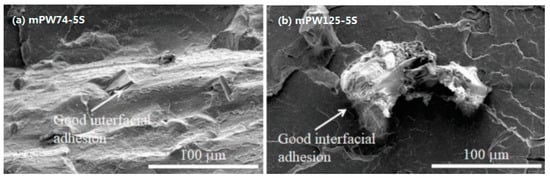

However, there are few significant drawbacks of FDM as compared to stereolithography (SLA) and selective laser sintering (SLS), as well as similar standard processing methods (e.g., injection moulding). The quality and mechanical properties of the printed product are not as good, mainly due to the layering technique in printing which adds more points of contact/failure, and the inevitable presence of voids. Furthermore, the mechanical properties of 3D-printed objects are anisotropic and highly dependent on the processing parameters [8]. On the other hand, the small nozzle size of this technology could have a drawback on printing composites like NFRCs because the fibres exist as small particles in a polymer matrix. Moreover, it is not always possible to produce a homogenous mix of polymer and natural fibre matrices, whereby agglomeration might occur in the filament which will clog the nozzle. This phenomenon is shown in Petchwattana [9] studies, in which a modified PLA/Teak wood flour composite filament was produced and the specimen with 125-µm particles clogged the printer nozzle. Figure 1 shows the composite filament for both 74 µm and 125 µm teak wood flour filler. The SEM micrograph of the modified PLA/Teak wood flour composite filament is shown in Figure 2, whereby good interfacial adhesion can be seen. Nevertheless, due to the large particle size the specimen with 125-µm particles still clogged the printer nozzle.

Figure 1. PLA/teak wood flour (TWF) composite filament of (a) 74-µm TWF (b) 125-µm TWF [9] Licensed under Creative Commons Attribution 4.0 International License.

Figure 2. SEM micrograph of modified PLA/TWF composite filament of (a) 74-µm TWF (b) 125-µm TWF [9] Licensed under Creative Commons Attribution 4.0 International License.

2.1. Thermoplastics for Additive Manufacturing

Thermoplastics polymers are plastics that return to the solid state upon cooling after being moulded above the threshold temperature [10]. In terms of choosing a suitable polymeric matrix material, thermoplastics are the most compelling choice. This is due to its various advantages, such as low moisture absorption, mechanical properties and infinite shelf life [11], low cost [12], better design flexibility and simple processing technique [13]. Moreover, thermoplastics tend to stay attached during the 3D-printing process [14]. Polymeric matrices can be categorised into non-biodegradable and biodegradable polymers. A variety of standard thermoplastics that are suitable and generally referred to as ‘plastics’ include acrylonitrile butadiene styrene (ABS), polylactide acid (PLA), polypropylene (PP) and polyethylene (PE) [15]. However, in terms of additive manufacturing, only polymers with working temperatures of below 300 °C are suitable, as FDM printing temperature is around 300 °C [16]. The comparison of melting temperatures of some common thermoplastics is shown in Table 1. As seen in Table 1, all common thermoplastics have a melting temperatures below 300 °C, which indicate the suitability of these thermoplastics to be utilised in FDM 3D printing.

Table 1. Melting temperature of different thermoplastic.

| Thermoplastic | Melting Temperature (°C) | Ref. |

|---|---|---|

| Polypropylene (PP) | 150–160 | [17][18][19] |

| Low density polyethylene (LDPE) | 105–115 | [20] |

| High-density polyethylene (HDPE) | 120–190 | [15][20] |

| Polyethylene terephthalate (PET) | 235–260 | [19] |

| Acrylonitrile butadiene styrene (ABS) | 190–250 | [15][21] |

| Polylactic Acid (PLA) | 120–170 | [15] |

ABS polymer is considered as one of the most common materials that are widely used as the filament in AM [8]. Nowadays, ABS-made applications in various industries can be found easily, with their wide range of manufacturing methods, including injection moulding and filament for 3D printing [22]. It comprises the combination of acrylonite, butadiene and styrene monomers to form a single polymer with great mechanical performance [15], durability as well as ease to print [8]. With stresses above their tensile strength, ABS has strong durability, but elasticity modulus and hardness are higher. Meanwhile, PLA is one of the most popular thermoplastic polymers because it is inexpensive with high modulus and strength [23]. Its low melting point requires lesser energy in 3D printing [24]. Its renewability and biodegradability have made it popularly used in a wide range of applications in the industry, especially in additive manufacturing. Besides, PLA does not emit any unwanted gases or unpleasant smells during the process [25]. Melnikova et al. [26] had successfully produced a flexible cloth with PLA by using FDM technology. PLA had also been added with various compatibilizers or reinforcing agents to mainly enhance its properties [27].

In another case, high-density polyethylene (HDPE) poses excellent mechanical properties, such as high stiffness and melting point, as well as high compressive tensile strength that outperforms other polyethylenes (e.g., low density polyethylene) [15][28][29]. It has a high strength-to-density ratio as compared to another thermoplastic. With its advantages, such as watertight, lightweight yet strong, recyclable and FDA approved, it has become one of the ubiquitous plastics used in different applications and commercial products. Schirmeister et al. [30] reported the success of printing HDPE by FDM technology with similar mechanical properties as compared to the injection-moulded HDPE, without significant warpage and void formation. HDPE is also a reusable thermoplastic polymer, unlike thermoset polymers [31]. Moreover, HDPE is easy to transform into new material through recycling. Recycling plastics could cause a significant impact on the environment, leading to more sustainability. Regardless, a recycled high-density polyethylene (rHDPE) still possess its unique characteristics even as a recycled material, such as chemical resistance, moderate tensile and impact strength, as well as excellent abrasion-resistant properties [32]. Even though research on rHDPE for additive manufacturing is scarce, the availability of HDPE waste had encouraged efforts to use recycled materials for more beneficial use, such that recycled HDPE from milk jugs were adapted to 3D printing in various recycling projects [31]. Baechler et al. [33] also reported the success of using the extruded recycled HDPE polymer to produce increasing successful parts with the 3D printer. Moreover, Angatkina [31] reported that rHDPE is suitable for 3D printing without any significant differences in mechanical properties as compared to the pure HDPE polymer.

2.2. Natural Fibre-Reinforced Composites in Additive Manufacturing

Natural fibres (NF) are known as hair-like raw material that is obtained from animals, plants or mineral sources. The main difference between animal and plant fibre is that animal fibre is mainly made out of protein, whereas plant fibres are composed of cellulose. Examples of natural fibre that is derived from plants include rice husk, wheat, hemp, bamboo and cotton. Thiranan Kunanopparat et al. [34] reported that the mechanical properties of wheat composites were less sensitive to thermal treatment when the fibre content was increased. The processing temperature was reported to be an important parameter that affected the physical adhesion, whereby this physical adhesion played a big role in the mechanical properties of the composites. Chen et al. [35] reported that bamboo fibres have much lower volumes of fracture behaviours, high proportions of fibre dissociations and matrix failure due to its hierarchical fibrous woven structure. On the other hand, Sueli Aparecida de Oliveira et al. [36] reported that composites that have natural cotton fibres as fillers exhibited a reduced environmental impact as compared exclusively to PLA or PLA/thermoplastic starch (TPS)-based thermoplastics. Moreover, the natural cotton fibre composites had a better overall performance, under the eco-efficiency perspective. V. Mazzanti et al. [37] reported that the presence of even small amounts of hemp fibres accelerates PLA degradation to an extent similar to that of residual water in non-dried pure PLA. A natural fibre that can be found abundantly and replenished in a predictable period is known as renewable natural fibre. This NF is commonly used as a low-cost alternative to synthetic fibres (e.g., nylon) mainly due to its biodegradability, cost-effectiveness, satisfactory mechanical properties and low density [38]. Natural fibre generally has low densities, ranging between 1.1 g/cm3 and 1.6 g/cm3, and thus result in low weight [8]. Plant fibre generally contains 60–80% cellulose, 5–20% hemicellulose, while the rest constitutes lignin, waxes, moisture (up to 20%) [39]. Besides, the cellulose content or cellulose crystallinity is also a factor to be considered when choosing a reinforcement for polymer. For example, bast fibre with 50–90% cellulose crystallinity is utilised in various automotive components to achieve better mechanical properties of products in terms of modulus, strength and stiffness [40]. Moreover, rice husk natural fibre was introduced recently as reinforcement in polymer to form NFRCs. Their high cellulose content would result in higher lignocelluloses fibre strength, which could potentially improve the mechanical properties of composites [8]. According to Rosa [11], rice husk can be processed at a higher temperature as compared to wood due to its cellulose and lignin contents. Besides, with its lignocelluloses properties, it represents a potentially valuable source of fibre which could be introduced as a filler or direct substitute for wood [41]. Since rice husk usually ends up in a landfill and has no other important commercial interest, it is highly recommended to be used as reinforced fibres in composites. With the success of incorporating rice husk with reinforced composites or substitute wood in various applications, it could eventually be beneficial in terms of environmental impact, such as minimising deforestation.

Recently, natural fibres have been widely introduced as additives in additive manufacturing filaments [42]. It is also gaining popularity in various industrial sectors, such as construction, automotive, thermally insulating and sound-absorbing materials [43][44]. Engineers are always searching for new materials as well as improving processes to manufacture better products to achieve maximum efficiency, sustainability and simultaneously reduce waste. Reinforcing thermoplastic polymer with natural fibres can cause certain peculiar issues. First, the lignocellulose in natural fibre undergoes degradation during the process of constant high temperature of above 200 °C [45][46]. Therefore, the melting temperature had to be considered when choosing a suitable thermoplastic. Furthermore, natural fibre drying is important before any processing to prevent the development of water vapour during mixing, and avoid the hydrolysis of polymeric matrices [47][48]. NFRC is commonly produced through the process of continuous extrusion and used in additive manufacturing. However, this had led to several challenges such as an inhomogeneous mix between filler and polymer matrix [8], temperature control [49], as well as the creation of voids during processing [50][51]. Eventually, these result issue, including nozzle clogging in a 3D printer [49], and inconsistent mechanical performance. To improve the homogenous mixing between matrices and filler, additives such as coupling agents [8], chemical treatment [52][53] and compatibilizer [54] are added to improve the interfacial bonding between the polymer matrices and filler. Besides, the effect of processing parameters and printing parameters has not been explored deeply until recently. Table 2 shows the summarised literature investigated by various researchers in NFRC filament and their respective treatments based on some common types of thermoplastics. Each polymer, types of fibre, content percentage and presence of compatibilizer are detailed, together with their respective references. In addition, additives, such as chemical treatments [52][53][55], compatibilizer [49], plasticiser [51][56] and toughening agent [57] performed on the composites are shown. For instance, Nguyen [57] reported that toughening agent of nitrile rubber contributed considerably in terms of increased mechanical performance. Stoof [52] suggested that layer adhesion, reduce in pore size, surface finish and the mechanical performance of the composite can be improved with the addition of a plasticiser. Besides, it can be seen that the fibre amount rarely exceeded 30 wt.%. Higher fibre amount eventually results in more complex printing in the 3D printer such as a non-homogenous mixture of NFRC that could cause blockage at the nozzle [49], as well as increase the melt viscosity, which requires higher power for extrusion. Moreover, lower polymeric matrices could result in a more brittle filament as the polymer matrix that can wet the fibres decreases [57].

Table 2. Natural fibre-reinforced composites filaments.

| Fibres | Polymer Matrix | Fibre Content (wt.%) | Chemical Treatment | Toughening Agent | Plasticiser | Compatibilizer | References |

|---|---|---|---|---|---|---|---|

| Hardwood lignin + carbon fibres | ABS | 20–40 | / | Nitrile rubber | / | / | [57] |

| Rice straw | ABS | 0–15 | / | / | / | / | [50] |

| Bamboo | PLA | 20 | / | / | PEG 600 Ester | / | [56] |

| Hemp | PLA | 0–30 | Alkaline | / | / | / | [52] |

| Sugarcane | PLA | 3–15 | Alkaline | / | / | / | [53] |

| Bamboo | PLA | 15 | / | / | cPLA1–cPLA2 | / | [51] |

| Flax | PLA | 15 | / | / | cPLA1–cPLA2 | / | [51] |

| Hemp | PP | 10–30 | Alkaline | / | / | MAHg-PP 2 wt.% | [55] |

3. Processing of Natural Fibres and Fabrication of Filament

3.1. Pre-Processing of Fibres

Most plant-based natural fibres used for NFRCs are lignocellulosic, in which the major components of the fibres are cellulose and lignin with small amounts of other constituents, such as pectin, wax and moisture, in which the composition vary depending on the source of fibre. The main issue with these fibres is the incompatibility with the polymer matrix when compounded together [58]. The natural fibre surface has a high concentration of hydroxyl (-OH) groups which result in hydrophilicity, whereby the fibre surface attracts water. This coupled with the fact that most polymer matrices used in compounding are hydrophobic or repels water, raise an issue of compatibility between fibres and polymer matrix. The impacts of this incompatibility are significant. First, weak bonding at the fibre/polymer interface can negatively impact the mechanical properties of the composite. Fibre composites which exhibit debonding have been reported in the absence of any fibre treatment or coupling agent by Panthapulakkal et al. [58]. The debonding behaviour, which significantly reduced the mechanical properties of composite and load transfer between the matrix and fibres, is poor. Furthermore, with poor compatibility of the fibres and polymer matrix, it is harder to produce a homogenous mix. The fibres would often agglomerate and form lumps in the polymer matrix [59]. The issue of agglomeration not only affects the mechanical properties of composite, but also causes issues during the fabrication of feedstock for AM because clogging occurs very frequently. Therefore, there has been extensive research on fibre/polymer compatibility. Various methods of pre-processing to fibre were tested and proven to be effective [60][61]. Most methods were under two categories (i) modification of the fibre surface and (ii) modification of polymer matrix.

Surface treatment of fibre aims to cut down on the hydrophilicity of the fibre; hence, improve interfacial bonding between fibre and polymer matrix. This process can also make the fibre surface rougher to improve adhesion. Many methods are employed to achieve surface modification of the fibres and the methods can be further categorised as physical, chemical and mechanical surface modifications. Of the three categories, the simplest method is mechanical surface treatment [62]. The fibres are rolled or swaged to create a coarse surface to improve adhesion. These methods are usually not as popular due to the cost-effectiveness and their effect on the fibres. Therefore, most fibres pre-processing involves chemical processes.

The main purpose of a chemical process to treat the fibre is to reduce the number of hydroxyl groups on the surface, and consequently the hydrophilicity. Other processes can reduce the hydrophilicity of the fibre at one end and form chemical bonds with the polymer matrix at the other end. There are a host of chemical processes currently used to treat fibres for compounding such as silanisation, dewaxing, treatment with isocyanates and alkalisation [63]. Depending on the types of fibre and the polymers used, the chemical treatments can vary. Out of all methods listed above, the most popular surface treatment would be alkaline treatments [62]. This is primarily due to its cost-effectiveness. The main mechanism behind alkaline treatments is the removal of fibre constituents that prevents bonding with the polymer matrix, which include pectin, oils, lignin, wax and hemicellulose which is weaker than cellulose. After the removal of these constituents, it is observed that the surface of fibres is rougher and with some improvements to the mechanical properties of the composite as reported by Rajendran Royan et al. [64]. However, the success and effectiveness of this treatment, depend on the concentration of the alkaline, treatment time, type of alkaline and temperature. Researchers reported different values and performances for the composite due to a change in the alkaline treatment parameters [65]. As for the physical treatment of the fibres, these involve processes such as heat treatment, gamma-ray irradiation, corona discharge, electron beam treatment and UV ozone treatment [59][66][67]. These processes can also reduce the hydroxyl groups and increase adhesion. In the case of UV/O3 treatments, there might also be an increase in active groups on the surface of the treated fibre, further promoting chemical bonding to the matrix [64].

Despite the effectiveness of surface treatment to the fibres, these methods are usually coupled with compatibilizing agents to further improve adhesion to the fibre [64]. This is the second type of pre-processing which involves the modification of polymer matrix. This process works by modifying the chemical composition of polymer matrix to promote better adhesion. One of the most popular compatibilizing agents that is widely used by many researchers is maleic anhydride (MA). MA is often grated with a specific type of polymers, such as PP or HDPE and mixed with the composite. The result of this addition is an interaction between the MAPP/MAPE and the hydroxyl groups on the fibre, which in turn improves adhesion. This method is widely used due to the improvements in the performance composite. Researchers have reported significant increases in mechanical properties when using compatibilizing agents such as (MAPP/MAPE) [68].

3.2. Fabrication of Filament

The current method of producing NFRC filaments for the AM process is similar to that of conventional filaments. However, the composite preparation plays an important role in the mechanical properties of composite. Processes such as sieving the fibres, drying and mixing methods have a direct impact on properties and usability of the final filament. The preparation of the composites affects how RH interacts with the polymer matrix and ultimately affects how the composite handles loads. These processes such as drying and surface treatment ensure that there is good bonding between the fibre and polymer matrix. Furthermore, pre-mixing ensures a homogeneous mix, resulting in a stronger material. Therefore, this section first discusses the current approaches in producing the composites before methods of producing the filament are discussed. The first step in preparing the NFRC is to sieve the fibre powder [9]. For NFRCs to be used in AM, especially in the FDM process, the particle size of fibres has to be as small as possible to avoid clogging at the printer nozzle. Therefore, depending on the source of fibres, the powder is sometimes sieved to ensure no large particles are mixed in with the composite. This is an essential step as later it directly affects the quality of filament. Petchwattana et al. [9] reported that in a teak wood flour/PLA composite, the composites produced with 125-µm particle size were not able to print successfully due to clogging and only those composites produced with 75 µm particle size were printed without issue. The next step is to dry the materials. This is a very common step that is reported in almost all papers for preparing NFRC. The raw materials are oven dried for a set period or until the moisture content falls below a certain level [69][70][71][72]. The main reason for this is to eliminate any form of moisture in the fibres or polymer granules. The presence of moisture in the materials could negatively impact the downstream processes such as extrusion. If the mixture has high moisture content during extrusion or hot mixing, the evaporation of water might create gas bubbles in the polymer matrix and thus voids. This will not only affect the mechanical properties of composite but also its porosity. It is a well-known fact that NFRCs are susceptible to moisture and can swell or even break if the amount of moisture uptake is sufficient. Chen et al. [70] reported a significant increase in porosity of composites as the fibre loading increased. Therefore, it is important to ensure that moisture is minimum during the preparation of filament to decrease porosity.

After the polymer and fibres are well prepared, the polymer matrix and fibre are mixed. Various methods of mixing were reported amongst researchers from first dry mixing and then melt mixing to directly extruding the filament [9][73][74]. However, from the literature reviewed, most mixing procedures follow a similar pattern. The polymer granules, fibre powder and compatibilizing agent are first to dry, and then mixed either by a dry mixer or by hand before being mixed in a dual screw extruder [73][75]. When compared to single-screw extruders, twin-screw extruders perform significantly better when compounding is required. Many industrial applications of extrusion which involve mixing and compounding plastics to either pigments or fillers utilise twin-screw extruders due to their much better compounding ability [76]. Because of this, many researchers utilise a twin-screw extruder for melt mixing the composite. The extrudate is then granulated and put through the extrusion machine again to ensure a homogeneous mix. After a homogenous mix is produced, the filament is simply produced by running the composite granules through an extrusion machine and forcing the melted composite through a die of desired diameter. For FDM processes the feeder is usually a 1.75-mm or 2.85-mm diameter filament. The diameter of this filament must stay constant or without large variations as FDM printers rely on software that assumes a constant diameter of filament. Filaments that are too small or large cause under/over extrusion, respectively, thus affecting the quality of the printed specimen [31]. Despite this, there is currently limited literature on how researchers ensure dimensional consistency when extruding the filament. There has been a limited amount of current research into the area of utilising NFRC for AM processes, more specifically the FDM process. This proves that there is still much room for research exploration in this area.

References

- Ashori, A. Wood–plastic composites as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667.

- Grand View Research. Natural Fiber Composites (NFC) Market Size, Share & Trends Analysis Report by Raw Material, by Matrix, by Technology (Injection Molding, Compression Molding, Pultrusion), by Application, and Segment Forecasts. 2018–2024; Report ID: 978-1-68038-890-9; Grand View Research: San Francisco, CA, USA, 2018.

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons: Hoboken, NJ, USA, 2007.

- Zhou, J. Digitalization and intelligentization of manufacturing industry. Adv. Manuf. 2013, 1, 1–7.

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The role of additive manufacturing in the era of industry 4.0. Procedia Manuf. 2017, 11, 545–554.

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928.

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2014; Volume 17.

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094.

- Petchwattana, N.; Channuan, W.; Naknaen, P.; Narupai, B. 3D printing filaments prepared from modified poly(lactic acid)/teak wood flour composites: An investigation on the particle size effects and silane coupling agent compatibilisation. J. Phys. Sci. 2019, 30, 169–188.

- Pucci, A. Smart and modern thermoplastic polymer materials. Polymers 2018, 10, 1211.

- Rosa, S.M.L.; Santos, E.F.; Ferreira, C.A.; Nachtigall, S.M.B. Studies on the properties of rice-husk-filled-PP composites: Effect of maleated PP. Mater. Res. 2009, 12, 333–338.

- Avinc, O.; Khoddami, A. Overview of poly (lactic acid) (PLA) fibre. Fibre Chem. 2010, 42, 68–78.

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956.

- Kochesfahani, S.H. Improving PLA-based material for FDM 3D-printers using minerals (principles and method development). In Proceedings of the Society of Plastics Engineers Annual Technical Conference, Indianapolis, IN, USA, 23–25 May 2016; pp. 1614–1958.

- Hamod, H. Suitability of Recycled HDPE for 3D Printing Filament. Ph.D. Thesis, Arcada University of Applied Science, Helsinki, Finland, 2014.

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys. Prototyp. 2017, 12, 47–59.

- Tabatabaei, S.H.; Carreau, P.J.; Ajji, A. Rheological and thermal properties of blends of a long-chain branched polypropylene and different linear polypropylenes. Chem. Eng. Sci. 2009, 64, 4719–4731.

- Ye, Z.B.; AlObaidi, F.; Zhu, S.P. Synthesis and rheological properties of long-chain-branched isotactic polypropylenes prepared by copolymerization of propylene and nonconjugated dienes. Ind. Eng. Chem. Res. 2004, 43, 2860–2870.

- Asgari, M.; Masoomi, M. Tensile and flexural properties of polypropylene/short poly (ethylene terephthalate) fibre composites compatibilized with glycidyl methacrylate and maleic anhydride. J. Thermoplast. Compos. Mater. 2015, 28, 357–371.

- Fernández, C.; Puig, C.C. Changes in melting behavior and morphology on annealing of linear and branched polyethylene. J. Macromol. Sci. Part B 2002, 41, 991–1005.

- Wojtyła, S.; Klama, P.; Baran, T. Is 3D printing safe? Analysis of the thermal treatment of thermoplastics: ABS, PLA, PET, and nylon. J. Occup. Environ. Hyg. 2017, 14, D80–D85.

- Niessner, N. Practical Guide to Structures, Properties and Applications of Styrenic Polymers; Smithers Rapra: Shrewsbury, UK, 2013.

- Zhang, K.; Mohanty, A.K.; Misra, M. Fully biodegradable and biorenewable ternary blends from polylactide, poly (3-hydroxybutyrate-co-hydroxyvalerate) and poly (butylene succinate) with balanced properties. ACS Appl. Mater. Interfaces 2012, 4, 3091–3101.

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. Recycled poly (lactic acid)–based 3D printed sustainable biocomposites: A comparative study with injection molding. Mater. Today Sustain. 2020, 7, 100027.

- Gkartzou, E.; Koumoulos, E.P.; Charitidis, C.A. Production and 3D printing processing of bio-based thermoplastic filament. Manuf. Rev. 2017, 4, 1.

- Melnikova, R.; Ehrmann, A.; Finsterbusch, K. 3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials. IOP Conf. Ser. Mater. Sci. Eng. 2014, 62, 012018.

- Nyambo, C.; Mohanty, A.K.; Misra, M. Effect of maleated compatibilizer on performance of PLA/wheat Straw-Based green composites. Macromol. Mater. Eng. 2011, 296, 710–718.

- Subramanian, M.N. Basics of Troubleshooting in Plastics Processing: An Introductory Practical Guide; John Wiley & Sons: Hoboken, NJ, USA, 2011; Volume 51.

- Goodship, V. (Ed.) Troubleshooting Injection Moulding; iSmithers Rapra Publishing: Shrewsbury, UK, 2004; Volume 15.

- Schirmeister, C.G.; Hees, T.; Licht, E.H.; Muelhaupt, R. 3D printing of high density polyethylene by fused filament fabrication. Addit. Manuf. 2019, 28, 152–159.

- Angatkina, K. Recycling of HDPE from MSW Waste to 3D Printing Filaments. Ph.D. Thesis, Arcada University of Applied Science, Helsinki, Finland, 2018.

- Vasile, C.; Pascu, M. Practical Guide to Polyethylene; iSmithers Rapra Publishing: Shrewsbury, UK, 2005.

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125.

- Kunanopparat, T.; Menut, P.; Morel, M.-H.; Guilbert, S. Plasticized wheat gluten reinforcement with natural fibers: Effect of thermal treatment on the fiber/matrix adhesion. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1787–1792.

- Chen, G.; Luo, H. Effects of node with discontinuous hierarchical fibers on the tensile fracture behaviors of natural bamboo. Sustain. Mater. Technol. 2020, 26, e00228.

- de Oliveira, A.S.; de Macedo, N.J.R.; Rosa, D.S. Eco-efficiency of Poly (lactic acid)-Starch-Cotton composite with high natural cotton fiber content: Environmental and functional value. J. Clean. Prod. 2019, 217, 32–41.

- Mazzanti, V.; de Luna, S.M.; Pariante, R.; Mollica, F.; Filippone, G. Natural fiber-induced degradation in PLA-hemp biocomposites in the molten state. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105990.

- Stoof, D. Development of Recycled Polypropylene Composite Materials for Applications in 3D Printing. Ph.D. Thesis, University of Waikato, Hamilton, New Zealand, 2016.

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Sustainable green composites: Value addition to agricultural residues and perennial grasses. ACS Sustain. Chem. Eng. 2013, 1, 325–333.

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274.

- Kim, S.; Kim, H.J.; Park, J.C. Application of recycled paper sludge and biomass materials in manufacture of green composite pallet. Resour. Conserv. Recycl. 2009, 53, 674–679.

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458.

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127.

- Santoni, A.; Bonfiglio, P.; Fausti, P.; Marescotti, C.; Mazzanti, V.; Mollica, F.; Pompoli, F. Improving the sound absorption performance of sustainable thermal insulation materials: Natural hemp fibres. Appl. Acoust. 2019, 150, 279–289.

- Moran, J.; Alvarez, V.; Petrucci, R.; Kenny, J.; Vazquez, A. Mechanical properties of polypropylene composites based on natural fibers subjected to multiple extrusion cycles. J. Appl. Polym. Sci. 2007, 103, 228–237.

- Mazzanti, V.; Mollica, F. In-process measurements of flow characteristics of wood plastic composites. J. Polym. Environ. 2017, 25, 1044–1050.

- Elsawy, M.A.; Kim, K.H.; Park, J.W.; Deep, A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew. Sustain. Energy Rev. 2017, 79, 1346–1352.

- Van den Oever, M.J.A.; Beck, B.; Müssig, J. Agrofibre reinforced poly (lactic acid) composites: Effect of moisture on degradation and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1628–1635.

- Filgueira, D.; Holmen, S.; Melbø, J.K.; Moldes, D.; Echtermeyer, A.T.; Chinga-Carrasco, G. Enzymatic-assisted modification of thermomechanical pulp fibers to improve the interfacial adhesion with poly (lactic acid) for 3D printing. ACS Sustain. Chem. Eng. 2017, 5, 9338–9346.

- Osman, M.A.; Atia, M.R. Investigation of ABS-rice straw composite feedstock filament for FDM. Rapid Prototyp. J. 2018, 24, 1067–1075.

- Depuydt, D.; Balthazar, M.; Hendrickx, K.; Six, W.; Ferraris, E.; Desplentere, F.; Ivens, J.; Van Vuure, A.W. Production and characterization of bamboo and flax fiber reinforced polylactic acid filaments for fused deposition modeling (FDM). Polym. Compos. 2019, 40, 1951–1963.

- Stoof, D.; Pickering, K.; Zhang, Y. Fused deposition modelling of natural fibre/polylactic acid composites. J. Compos. Sci. 2017, 1, 8.

- Liu, H.; He, H.; Peng, X.; Huang, B.; Li, J. Three dimensional printing of poly (lactic acid) bio based composites with sugarcane bagasse fiber: Effect of printing orientation on tensile performance. Polym. Adv. Technol. 2019, 30, 910–922.

- Guo, R.; Ren, Z.; Bi, H.; Song, Y.; Xu, M. Effect of toughening agents on the properties of poplar wood flour/poly (lactic acid) composites fabricated with Fused Deposition Modeling. Eur. Polym. J. 2018, 107, 34–45.

- Milosevic, M.; Stoof, D.; Pickering, K.L. Characterizing the mechanical properties of fused deposition modelling natural fiber recycled polypropylene composites. J. Compos. Sci. 2017, 1, 7.

- Zhao, D.X.; Cai, X.; Shou, G.Z.; Gu, Y.Q.; Wang, P.X. Study on the preparation of bamboo plastic composite intend for additive manufacturing. In Key Engineering Materials; Trans. Tech. Publications Ltd.: Bäch, Switzerland, 2016; Volume 667, pp. 250–258.

- Nguyen, N.A.; Bowland, C.C.; Naskar, A.K. A general method to improve 3D-printability and inter-layer adhesion in lignin-based composites. Appl. Mater. Today 2018, 12, 138–152.

- Panthapulakkal, S.; Law, S.; Sain, M. Enhancement of processability of rice husk filled high-density polyethylene composite profiles. J. Thermoplast. Compos. Mater. 2005, 18, 445–458.

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485.

- Herrera-Franco, P.J.; Drzal, L.T. Comparison of methods for the measurement of fibre/matrix adhesion in composites. Composites 1992, 23, 2–27.

- Qaiss, A.E.K.; Bouhfi, D.R.; Essabir, H. Natural fibers reinforced polymeric matrix: Thermal, mechanical and interfacial properties. In Biomass and Bioenergy; Hakeem, K.R., Jawaid, M., Rashid, U., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 225–245.

- Fuqua, M.A.; Huo, S.; Ulven, C.A. Natural fiber reinforced composites. Polym. Rev. 2012, 52, 259–320.

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Olayo, R.J.I.P.; Herrera-Franco, P.J. Effect of fiber surface treatment on the fiber–matrix bond strength of natural fiber reinforced composites. Compos. Part B Eng. 1999, 30, 309–320.

- Rajendran Royan, N.R.; Sulong, A.B.; Yuhana, N.Y.; Chen, R.S.; Ab Ghani, M.H.; Ahmad, S. UV/O3 treatment as a surface modification of rice husk towards preparation of novel biocomposites. PLoS ONE 2018, 13, e0197345.

- Mahjoub, R.; Yatim, J.M.; Sam, A.R.M.; Hashemi, S.H. Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 2014, 55, 103–113.

- Trindade, W.G.; de Paiva, J.M.F.; Leao, A.L.; Frollini, E. Ionized-Air-Treated Curaua Fibers as Reinforcement for Phenolic Matrices. Macromol. Mater. Eng. 2008, 293, 521–528.

- Faulstich de Paiva, J.M.; Frollini, E. Unmodified and modified surface sisal fibers as reinforcement of phenolic and lignophenolic matrices composites: Thermal analyses of fibers and composites. Macromol. Mater. Eng. 2006, 291, 405–417.

- Duy, T.T.; Dang, N.M.; Thuc, C.; Thuc, H.; Dang, T.T. Study of Mechanical Properties of Composite Material Based on Polypropylene and Vietnamese Rice Husk Filler. J. Chem. 2013, 161, 1–6.

- Chen, R.S.; Salleh, M.N.; Ab Ghani, M.H.; Ahmad, S.; Gan, S. Biocomposites Based on Rice Husk Flour and Recycled Polymer Blend: Effects of Interfacial Modification and High Fibre Loading. BioResources 2015, 10, 6872–6885.

- Chen, R.S.; Ahmad, S.; Gan, S. Characterization of Rice Husk-Incorporated Recycled Thermoplastic Blend Composites. BioResources 2016, 11, 8470–8482.

- Chen, R.S.; Ab Ghani, M.H.; Salleh, M.N.; Ahmad, S.; Tarawneh, M.A. Mechanical, water absorption, and morphology of recycled polymer blend rice husk flour biocomposites. J. Appl. Polym. Sci. 2014, 132, 41494.

- Chen, R.S.; Ahmad, S.; Gan, S. Rice husk bio-filler reinforced polymer blends of recycled HDPE/PET: Three-dimensional stability under water immersion and mechanical performance. Polym. Compos. 2016, 39, 2695–2704.

- Zhang, Q.; Cai, H.; Zhang, A.; Lin, X.; Yi, W.; Zhang, J. Effects of lubricant and toughening agent on the fluidity and toughness of poplar powder-reinforced polylactic acid 3D printing materials. Polymers 2018, 10, 932.

- Le Guen, M.; Hill, S.; Smith, D.; Theobald, B.; Gaugler, E.; Barakat, A.; Mayer-Laigle, C. Influence of Rice Husk and Wood Biomass Properties on the Manufacture of Filaments for Fused Deposition Modeling. Front. Chem. 2019, 7, 735.

- Badouard, C.; Traon, F.; Denoual, C.; Mayer-Laigle, C.; Paës, G.; Bourmaud, A. Exploring mechanical properties of fully compostable flax reinforced composite filaments for 3D printing applications. Ind. Crops Prod. 2019, 135, 246–250.

- Giles, H.F., Jr.; Mount, E.M., III; Wagner, J.R., Jr. Extrusion: The Definitive Processing Guide and Handbook; William Andrew: Norwich, NY, USA, 2004.

More

Information

Subjects:

Polymer Science

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.7K

Revisions:

2 times

(View History)

Update Date:

23 Jul 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No