| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Monica Gallo | + 2310 word(s) | 2310 | 2021-06-30 05:07:12 | | | |

| 2 | Peter Tang | Meta information modification | 2310 | 2021-07-07 03:11:39 | | |

Video Upload Options

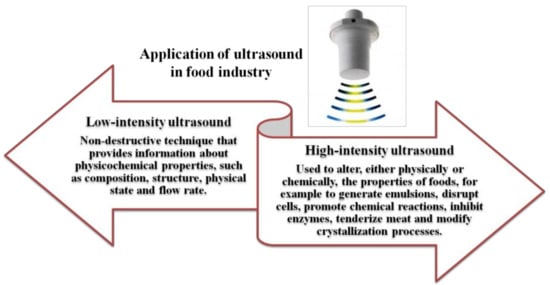

Ultrasound is composed of mechanical sound waves that originate from molecular movements that oscillate in a propagation medium. The waves have a very high frequency, approximately 20 kHz, are divided into two categories (i.e. low intensity waves and high intensity waves) and cannot be perceived by the human ear. Ultrasound is commonly associated with the biomedical field.

1. Introduction

Sound is an oscillation of particles (i.e., atoms and molecules) in an elastic medium. The oscillations displace the particles around the resting position and along the direction of propagation of the wave caused by vibratory movements. These vibrations are produced by a given object, which is called the source of sound, which transmits its movement to the adjacent particles by virtue of the mechanical properties of the medium. When oscillation begins, the particles transmit their movements to neighbouring particles, and these particles in turn transmit their movements to others, causing a local variation in pressure; therefore, a simple vibratory movement propagates mechanically to produce a sound wave (or acoustic wave) [1]. Ultrasound (US) is defined as waves of a mechanical nature that require an elastic medium to propagate [2][3]. Sounds and ultrasounds differ in frequency: sound waves propagate at frequencies audible to the human ear (from 16 Hz to 16–20 kHz), while US waves propagate at frequencies greater than 20 kHz (upper limit of audibility for the human ear) up to frequencies of 10 MHz, which then proceeds to the so-called hypersonic region. Ultrasound, which is composed of mechanical waves, propagate in a medium through the transfer of energy and not of particles; the latter, in fact, simply oscillate around their equilibrium position, with the transfer of energy from one particle to another. The oscillation propagates in the medium in various directions, and therefore, distinguish as longitudinal waves and transverse waves. In longitudinal waves, the oscillatory movement of the particles in the transmission medium is parallel to the propagation direction, while in the transverse waves the movement is perpendicular. The longitudinal (or compression) waves propagate in any medium, while the transverse waves only propagate in solid media. The US wave is a longitudinal wave characterized by the alternation of compression and rarefaction cycles of the medium in which it propagates, which entails variations in the pressure of the medium; energy is transferred from the motion of particles. This process of compression and rarefaction of the particles in the medium and their subsequent collapse is known as the phenomenon of cavitation, the most important effect of high-energy US waves [4][5]. In particular, cavitation is a physical phenomenon that leads to the formation and activity of bubbles (or cavities) inside a liquid when it is subjected to the action of high-speed pressure and depression waves generated by ultrasound waves in an intense ultrasonic field. During the depression phase, numerous bubbles are created inside the liquid. During the second phase of ultrasound compression, the enormous pressure exerted on the bubble decompresses until it implodes, i.e., collapse on itself. The bubbles have a diameter of a few micrometres, while the lifetime of the bubbles is on the order of microseconds. Two types of cavitation have been distinguished: in the first type, known as stable cavitation, the bubble remains stable around an equilibrium size for many compression-decompression cycles; in the second type, known as transitory or unstable cavitation, the bubble grows in a single cycle, doubles its size, and then collapses.

The chemical effects of US vary, and three distinct phases have been identified in the reaction environment: the gaseous environment inside the bubble cavity, the liquid-bubble interface, and the liquid. In the gas phase, pyrolysis reactions occur, such as the pyrolysis of water. In the bubble-liquid zone and the liquid mass, various radicals can form, and the most frequently encountered radical in the aqueous environment is the hydroxide radical OH·, which is highly reactive and readily attacks organic substrates present in the reaction environment or recombines with another OH· radical to form H2O2. In the interface area, where the temperatures are very high, solute reactions with OH· radicals or thermal degradation reactions may occur. The diffusion of these radicals is mainly due to the disruption of the cavitation bubble and subsequent formation of smaller bubbles. Non-volatile solutes react in the interface zone or in the liquid, and volatile solids enter the bubble and degrade during bubble collapse. The effects of radicals are important because they induce molecular sonolysis and degradation of the solvent and solute structure. In contrast, mechanical effects alter electrochemical processes, modify the properties of certain solids and alter the liquid-liquid and gas-liquid systems by facilitating the formation of solid-state emulsions and solute dispersion in the solvent [6][7]. Historically, US has developed similar to a branch of acoustics. In parallel to the progress in understanding the propagation of acoustic waves, we have witnessed the development of technologies capable of generating US. As described above, US waves are sound waves with a frequency range ranging from 20 kHz to 10 MHz. Further subdivisions within this range have been identified [8]; these subdivisions may in fact have substantially different characteristics, depending on the frequency at which they are generated and the amount of energy generated by the acoustic field. In particular, US power influences chemical reactivity and is grouped into two subfamilies: A) high-energy US characterized by low frequencies (20 kHz–100 kHz), which are used in some food technologies, and intermediate power US processes characterized by medium frequencies (100 kHz–1 MHz); and B) low-energy diagnostic US that is used in physical measurements, mainly for medical and diagnostic uses, and is characterized by high frequencies (5 MHz–10 MHz). Although cavitation is considered an event to be avoided in many fields, other fields exploit cavitation produced in a controlled manner, such as the military, which uses torpedoes that travel at very high speeds, or ultrasonic cleaning systems used to clean small objects, where the implosions of the bubbles clean even the most delicate and unreachable surfaces. In the medical field, controlled cavitation is used to remove kidney stones (lithotripsy), which are precisely crushed through the formation of microbubbles that implode the solid formations inside the kidneys, as well as for diagnosis and antalgic thermal effects [9]. Cavitation is also used in aesthetic medicine to eliminate or reduce adiposity, a technique known as non-surgical non-bloody liposuction (Ultrasound Lipoclasia). In addition, acoustic cavitation has been used to facilitate the delivery of small molecules and macromolecules, including proteins and DNA. Controlled generation of cavitation has also been used for the targeted delivery of drugs to diseased tissues, including the skin, brain, eyes and endothelium [10]. Moreover, US has been employed as a treatment for several diseases, including thromboembolism, arteriosclerosis, and cancer [11][12][13][14]. On the other hand, the study of the propagation of US waves in humans has allowed the construction of stable medical diagnostic instruments used in gynaecology, gastroenterology, angiology, and cardiology, which exploit the return echo resulting from an US wave that propagates inside the human body and is slowed in a different way by the different anatomical structures it crosses [15]. Moreover, precisely because of the different acoustic impedance of the various tissues, US has been used to determine various biological effects, among which the thermal effect was the original use of US in orthopaedics, physiatrics, and sports medicine to inhibit pain and particularly in the aesthetic field to treat localized adiposity and cellulite [16].

|

Mechanical Effects |

References |

|

Crystallization of fats, sugars, etc. |

Luque de Castro et al., 2007 [19]; Cook and Hartel, 2010 [20] |

|

Degassing and destruction of foams |

Dedhia et al., 2004 [21] |

|

Extraction of aromas |

Chemat et al., 2017a [22] |

|

Filtration and drying |

Tao and Sun, 2015 [23] |

|

Freezing |

Kiani et al., 2011 [24] |

|

Mixing and homogenization |

Mason et al., 2005 [25] |

|

Precipitation of airborne powders |

Riera et al., 2006 [26] |

|

Meat tenderization |

Jayasooriya et al., 2004 [27]; Alarcon-Rojo et al., 2015 [28] |

|

Chemical and Biochemical Effects |

References |

|

Bactericidal action |

Yu et al., 2012 [29] |

|

Wastewater treatment |

Oturan et al., 2014 [30] |

|

Modification of the growth of living cells |

Guo et al., 2015 [31] |

|

Alteration of enzymatic activity |

Huang et al., 2017 [32] |

|

Sterilization of equipment |

2. US in Food Science and Technology

3. US Technology in Different Processes

References

- Cheeke, J.; David, N. Fundamental and Applications of Ultrasonics, 2nd ed.; CRC Press: Boca Raton, Florida, USA, 2002.

- Mason, T.J.; Peters, D. Practical Sonochemistry: Power Ultrasound Uses and Applications; Woodhead Publishing: Sawston, Cambridge, UK, 2002.

- Lempriere, B.M. Ultrasound and Elastic Waves: Frequently Asked Questions; Elsevier: San Diego, CA, USA, 2013.

- Krautkrämer, J.; Krautkrämer, H. Ultrasonic Testing of Materials; Springer Science & Business Media: Heidelberg, Germany, 2013.

- Rose, J.L. Ultrasonic Guided Waves in Solid Media; Cambridge University Press: Cambridge, UK, 2014.

- Yasui, K. Influence of ultrasonic frequence on multibubble sonoluminescence. J. Acoust. Soc Am. 2002, 112, 1405–1413.

- Yasui, K.; Towata, A.; Tuziuti, T.; Kozuka, T.; Kato, K. Effect of static pressure on acoustic Energy radiated by cavitation bubbles in viscous liquid under ultrasound. J. Acoust. Soc. Am. 2011, 130, 3233–3242.

- Feng, H.; Lee, H. Effect of Power Ultrasound on Food Quality. In Ultrasound Technologies for Food and Bioprocessing; Springer: New York, NY, USA, 2011.

- Ikeda, T.; Yoshizawa, S.; Koizumi, N.; Mitsuishi, M.; Matsumoto, Y. Focused ultrasound and Lithotripsy. In Therapeutic Ultrasound; Springer: Cham, Switzerland, 2016; pp. 113–129.

- Paliwal, S.; Mitragotri, S. Ultrasound-induced cavitation: Applications in drug and gene delivery. Expert Opin. Drug Deliv. 2006, 3, 713–726.

- Barnett, S.B.; Ter Haar, G.R.; Ziskin, M.C.; Rott, H.D.; Duck, F.A.; Maeda, K. International recommendations and guidelines for the safe use of diagnostic ultrasound in medicine. Ultrasound Med. Biol. 2000, 26, 355–366.

- Miller, D.L.; Smith, N.B.; Bailey, M.R.; Czarnota, G.J.; Hynynen, K.; Makin, I.R.S. Bioeffects Committee of the American Institute of Ultrasound in Medicine. Overview of therapeutic ultrasound applications and safety considerations. J. Ultrasound Med. 2012, 31, 623–634.

- Wang, X.; Gkanatsas, Y.; Palasubramaniam, J.; Hohmann, J.D.; Chen, Y.C.; Lim, B.; Hagemeyer, C.E.; Peter, K. Thrombus-targeted theranostic microbubbles: A new technology towards concurrent rapid ultrasound diagnosis and bleeding-free fibrinolytic treatment of thrombosis. Theranostics 2016, 6, 726–738.

- Wood, A.K.; Sehgal, C.M. A review of low-intensity ultrasound for cancer therapy. Ultrasound Med. Biol. 2015, 41, 905–928.

- Rumack, C.M.; Levine, D. Diagnostic Ultrasound E-Book; Elsevier Health Sciences: Philadelphia, PA, USA, 2017.

- Kapoor, R.; Shome, D.; Ranjan, A. Use of a novel combined radiofrequency and ultrasound device for lipolysis, skin tightening and cellulite treatment. J. Cosmet. Laser Ther. 2017, 19, 266–274.

- Shirsath, S.R.; Sonawane, S.H.; Gogate, P.R. Intensification of extraction of natural products using ultrasonic irradiations—A review of current status. Chem. Eng. Process. Process. Intensif. 2012, 53, 10–23.

- Laborde, J.-L.; Bouyer, C.; Caltagirone, J.-P.; Gerard, A. Acoustic bubble cavitation at low frequencies. Ultrasonics 1998, 36, 589–594.

- Luque de Castro, M.D.; Priego-Capote, F. Ultrasound-assisted crystallization (sonocrystallization). Ultrason. Sonochem. 2007, 14, 717–724.

- Cook, K.L.K.; Hartel, R.W. Mechanisms of ice crystallization in ice cream production. Compr. Rev. Food Sci. Food Saf. 2010, 9, 213–222.

- Dedhia, A.C.; Ambulgekar, P.V.; Pandit, A.B. Static foam destruction: Role of ultrasound. Ultrason. Sonochem. 2004, 11, 67–75.

- Chemat, F.; Rombaut, N.; Sicaire, A.G.; Meullemiestre, A.; Fabiano-Tixier, A.S.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560.

- Tao, Y.; Sun, D.W. Enhancement of food processes by ultrasound: A review. Crit. Rev. Food Sci. Nutr. 2015, 55, 570–594.

- Kiani, H.; Zhang, Z.; Delgado, A.; Sun, D.W. Ultrasound assisted nucleation of some liquid and solid model foods during freezing. Food Res. Int. 2011, 44, 2915–2921.

- Mason, T.J.; Riera, E.; Vercet, A.; Lopez-Buesa, P. Application of ultrasound. Emerg. Technol. Food Process. 2005, 323–351.

- Riera, E.; Gallego-Juárez, J.A.; Mason, T.J. Airborne ultrasound for the precipitation of smokes and powders and the destruction of foams. Ultrason. Sonochem. 2006, 13, 107–116.

- Jayasooriya, S.D.; Bhandari, B.R.; Torley, P.; D’arcy, B.R. Effect of high power ultrasound waves on properties of meat: A review. Int. J. Food Prop. 2004, 7, 301–319.

- Alarcon-Rojo, A.D.; Janacua, H.; Rodriguez, J.C.; Paniwnyk, L.; Mason, T.J. Power ultrasound in meat processing. Meat Sci. 2015, 107, 86–93.

- Yu, H.; Chen, S.; Cao, P. Synergistic bactericidal effects and mechanisms of low intensity ultrasound and antibiotics against bacteria: A review. Ultrason. Sonochem. 2012, 19, 377–382.

- Oturan, M.A.; Aaron, J.J. Advanced oxidation processes in water/wastewater treatment: Principles and applications. A review. Crit. Rev. Environ. Sci. Technol. 2014, 44, 2577–2641.

- Guo, F.; Li, P.; French, J.B.; Mao, Z.; Zhao, H.; Li, S.; Nama, N.; Fick, J.R.; Benkovic, S.J.; Huang, T.J. Controlling cell–cell interactions using surface acoustic waves. Proc. Natl. Acad. Sci. USA 2015, 112, 43–48.

- Huang, G.; Chen, S.; Dai, C.; Sun, L.; Sun, W.; Tang, Y.; Xiong, F.; He, R.; Ma, H. Effects of ultrasound on microbial growth and enzyme activity. Ultrason. Sonochem. 2017, 37, 144–149.

- Chemat, F.; Rombaut, N.; Meullemiestre, A.; Turk, M.; Perino, S.; Fabiano-Tixier, A.S.; Abert-Vian, M. Review of green food processing techniques. Preservation, transformation, and extraction. Innov. Food Sci. Emerg. Technol. 2017, 41, 357–377.

- Koubaa, M.; Mhemdi, H.; Fages, J. Recovery of valuable components and inactivating microorganisms in the agro-food industry with ultrasound-assisted supercritical fluid technology. J. Supercrit. Fluids 2018, 134, 71–79.

- Bates, D.; Patist, A. Industrial applications of high power ultrasonics in the food, beverage and wine industry. In Case Studies in Novel Food Processing Technologies; Woodhead Publishing Series in Food Science; Technology and Nutrition: San Diego, CA, USA, 2010; pp. 119–138.

- Arvanitoyannis, I.S.; Kotsanopoulos, K.V.; Savva, A.G. Use of ultrasounds in the food industry–Methods and effects on quality, safety, and organoleptic characteristics of foods: A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 109–128.

- Patist, A.; Bates, D. Ultrasonic innovations in the food industry: From the laboratory to commercial production. Innov. Food Sci. Emerg. Technol. 2008, 9, 147–154.

- Knorr, D.; Zenker, M.; Heinz, V.; Lee, D.U. Applications and potential of ultrasonics in food processing. Trends Food Sci. Technol. 2004, 15, 261–266.

- Paniwnyk, L. Applications of ultrasound in processing of liquid foods: A review. Ultrason. Sonochem. 2017, 38, 794–806.

- Kentish, S.; Feng, H. Applications of power ultrasound in food processing. Annu. Rev. Food Sci. Technol. 2014, 5, 263–284.