Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Dimitrios Bikiaris | + 1979 word(s) | 1979 | 2021-06-13 08:03:15 | | | |

| 2 | Vicky Zhou | Meta information modification | 1979 | 2021-06-15 05:21:55 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Bikiaris, D. Poly(lactic Acid). Encyclopedia. Available online: https://encyclopedia.pub/entry/10809 (accessed on 08 February 2026).

Bikiaris D. Poly(lactic Acid). Encyclopedia. Available at: https://encyclopedia.pub/entry/10809. Accessed February 08, 2026.

Bikiaris, Dimitrios. "Poly(lactic Acid)" Encyclopedia, https://encyclopedia.pub/entry/10809 (accessed February 08, 2026).

Bikiaris, D. (2021, June 13). Poly(lactic Acid). In Encyclopedia. https://encyclopedia.pub/entry/10809

Bikiaris, Dimitrios. "Poly(lactic Acid)." Encyclopedia. Web. 13 June, 2021.

Copy Citation

Poly(lactic Acid) is one of the most promising polymers used in these applicationsand is properly called “polymer of the 21st century “. It is the only one, synthesized on a greater scale that is concurrently: biocompatible, biodegradable and biobased. PLA is an aliphatic biobased polyester derived from lactic acid (2-hydroxypropionic acid), which is mostly derived from animal or plant sources such as cellulose, starch, corn, fish waste and kitchen waste.

poly(lactic acid)

synthesis

melt polycondensation

ring opening polymerization

catalysts

solid state polymerization

chain extension

applications

1. Introduction

It has been estimated that until today, global polymers’ total production has reached about 9 billion tons [1]. From these plastics, only 9–10% is recycled and reused, another small amount (12%) is incinerated, while the biggest percentage (78–79%) is accumulated in environment (oceans, lakes, rivers and landfills). Consecutively, they pose serious problems—mostly, for their disposal, environmental contamination, toxicity to the ecosystem and human health. Despite the fact that plastic pollution has become the biggest public enemy today, plastic materials, due to their benefits and advantages over other already used materials, are present almost everywhere in human life. It is reported that their total global production topped 359 million tons in 2018 [2].

Most of them are used as packaging materials, about 35–45 percent of global plastics production, including many single use plastics (SUPs), such as straws, cutlery, cups, bags, packaging films and bottles. Due to their lightness, they cannot be easily recycled, thus contributing to the environmental pollution. The large presence of plastic waste in the natural habitat has a significant effect on the ecosystem due to their huge concentration, widespread distribution, and non-biodegradable properties. Most of them end up in oceans (about 13 Mts per year) where they degrade to microplastics with diameters <5 mm. These microplastics pose a big threat to aquatic and land living organisms [3], while it has been reported that they can pass into the human body via drinking water or the food chain [4][5] with unknown consequences for human health. Plastic islands and microplastics spotted in the aquatic ecosystem are significant evidence of plastic pollution in the environment [6]. Furthermore, environmental carbon dioxide emissions, as well as depletion of fossil resources, are two serious problems concerning the polymers industry.

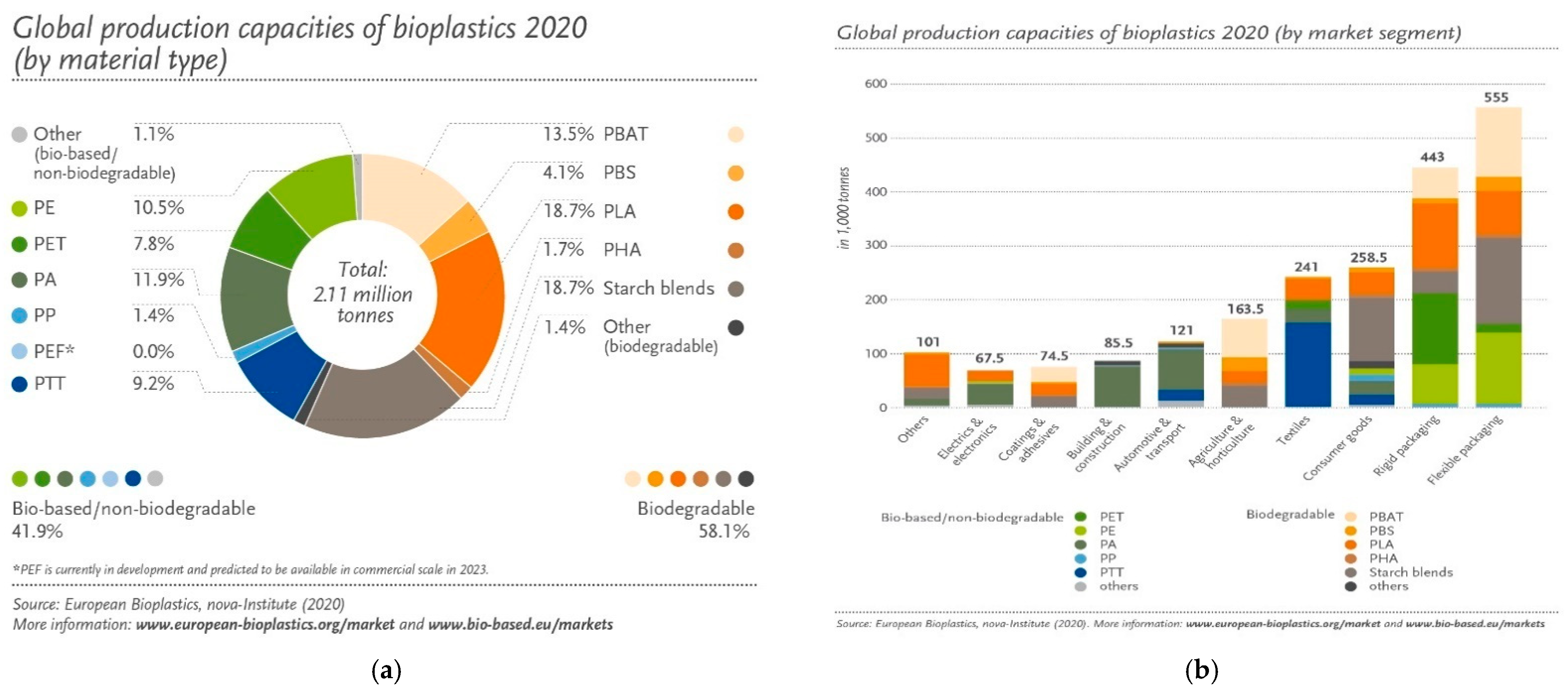

One solution in combating these problems is to use renewable resources for polymer production (biobased polymers). The worldwide interest in biobased polymers has accelerated in recent years [7]. However, as demand is rising, and with more sophisticated biopolymers such as polyethylene, polypropylene, polyamides, poly(ethylene terephtalate) (PET), furanoate and vanillate polyesters as well as many other aliphatic polyesters [1][2][3][4][5][6], the bioplastics market is continuously growing and diversifying. European Bioplastics in cooperation with the nova-Institute compiled the latest market data of global bioplastics production, which is set to increase from around 2.11 million tons in 2020 to approximately 2.87 million tons in 2025 (Figure 1) [8]. Nevertheless, the research community still focuses on biobased and biodegradable polymers such as PLA, poly(glycolic acid) (PGA) and their PLA-co-PGA copolymers, poly(hydroxyalkanoates) (PHAs) such as poly(hydroxy butyrate) (PHB) and poly(hydroxy valerate) (PHV) and their copolymers, succinate derived polyesters, polycaprolactone (PCL) and others. Biodegradable plastics account for almost 60 percent (over 1.2 million tons) of the global bioplastics especially due to PLA and PHA’s significant growth rates. PHA production increased from 5.3 million tons to 17.0 million tons between years 2013 and 2020, while PLA global production was around 190,000 tons in 2019 (Figure 1), with new investments in the US and in Europe announced every year [6][9].

Figure 1. (a) Global production of bioplastics 2020 (by material type); (b) global production capacities of bioplastics 2020 (by market segment) (https://www.european-bioplastics.org/market, accessed on 27 April 2021) [8].

Figure 1. (a) Global production of bioplastics 2020 (by material type); (b) global production capacities of bioplastics 2020 (by market segment) (https://www.european-bioplastics.org/market, accessed on 27 April 2021) [8].The development of biodegradable polymers is showcased as one of the most effective innovations in the polymer industry for addressing environmental issues [10]. For this reason, biodegradable polymers are used in various applications, from biomedicine, additive technologies, film, fibers [11], packaging [12][13], automotive to agriculture [14].

PLA is one of the most promising polymers used in these applications [15] and is properly called “polymer of the 21st century “. It is the only one, synthesized on a greater scale that is concurrently: biocompatible, biodegradable and biobased [16]. PLA is an aliphatic biobased polyester derived from lactic acid (2-hydroxypropionic acid) [9][17][18][19], which is mostly derived from animal or plant sources such as cellulose, starch, corn, fish waste and kitchen waste [20]. Carothers in 1932 was the first to synthesize PLA with low molecular weight, while DuPont in 1954 patented a product with a higher molecular weight [17]. PLA exhibits good mechanical strength, biocompatibility, biodegradability and mainly high compostability, [21] constituting it an ideal alternative to the traditional petroleum-based polymers. In addition, it is expected to be widely used in many fields, such as food packaging industry, automotive and medical applications. Today it seems to be the friendliest environmental polymer with ever increasing applications and demands for larger production.

Derived from biomass, PLA is a conventional bioplastic that can be made in a process of three steps including fermentation, separation and polymerization. PLA is a biodegradable polyester polymerized from monomers derived from renewable sugarcane, cornstarch and other abundant natural resources [17]. An intensive large-scale process from recombinant corn which shrinks production costs has been implemented by NatureWorks Co. (Blair, NE, USA) [14]. The typical method for synthesizing PLA is the ring opening polymerization (ROP) of lactide monomer, a process which uses several kind of catalysts such as zinc, tin, lead and aluminum, initiators such as sec-, -n and tert-butyl lithium, and solvents such as diphenyl ether, chloroform and toluene [14]. The molecular weights of the polymer fabricated by the ring opening polymerization can be controlled by the residence time, catalyst type, consternation and temperature. The sequence and ratio of L- and D-lactic acid units in the final polymer could also be controlled [17]. PLA and its degradation products, mostly H2O and CO2, are neither carcinogenic nor toxic to the human body, hence making it a perfect polymer for biomedical applications including clips, sutures, and drug delivery systems (DDS). In addition, PLA can be formulated by several techniques such as melt extrusion, film casting, blow molding, and fiber spinning due to its greater thermal processability in comparison to other known biomaterials [22].

2. PLA Applications

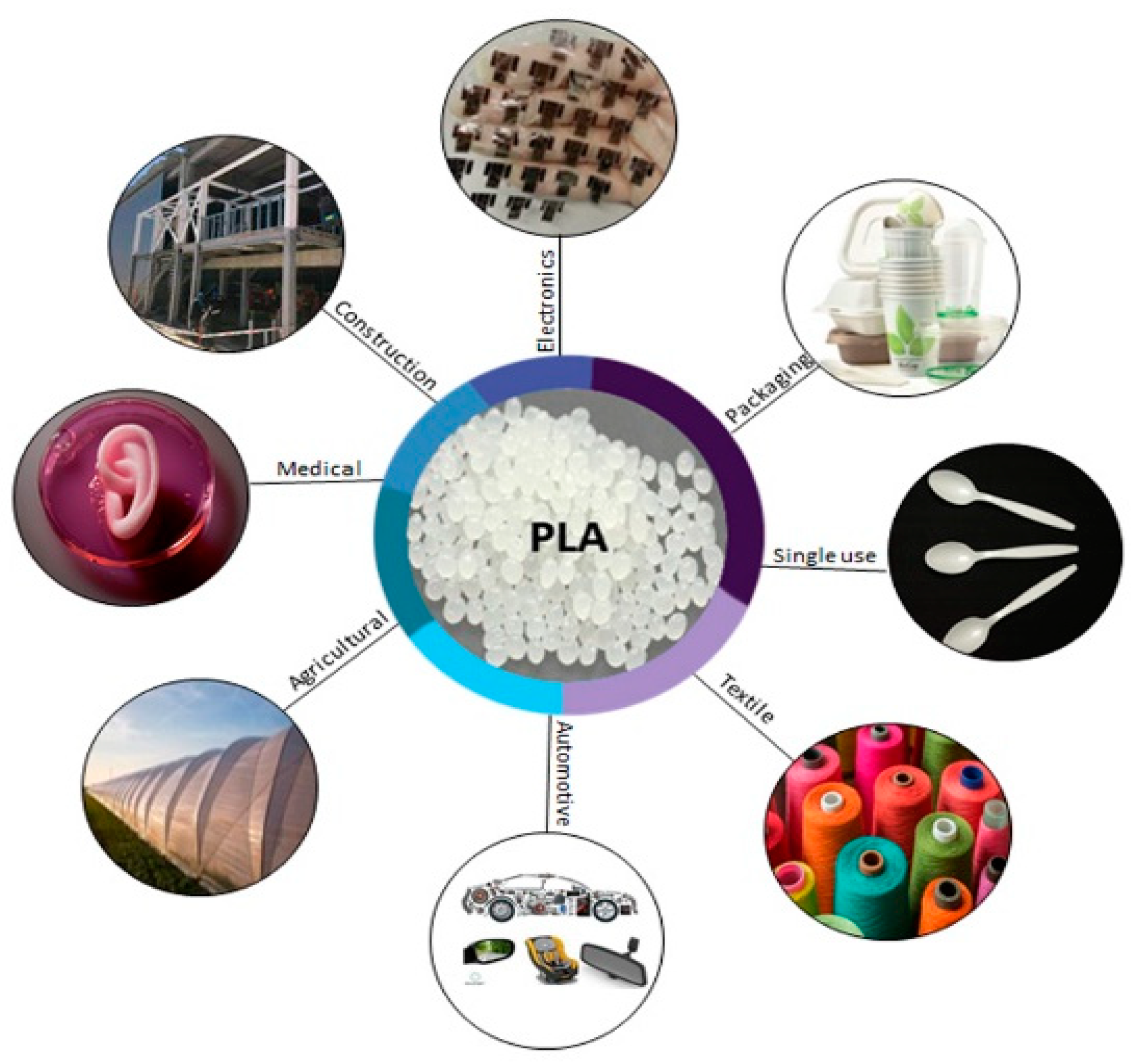

The global PLA market extent was priced at USD 525.47 million in 2020 and is estimated to expand at a consecutive annual growth rate (CAGR) of 18.1% from 2021 to 2028 [23]. The request for the product mostly originates from the end-use industries, such as biomedicine, automotive, construction, agriculture, single used items and food packaging, mostly for replacing petroleum based plastics (Figure 2) [24]. The global PLA market consists of six regions: Asia Pacific, Europe, Latin America, North America, Middle East and Africa. Asia Pacific is anticipated to be the fastest-growing regional market from 2021 to 2028, owing to constant development of the automotive as well as packaging industry. PLA demand is going to be increased a lot in countries of Asia Pacific such as Malaysia, China, India, Vietnam, Thailand, Singapore, South Korea, and Japan owing to high adoption rate by the automobile manufacturers. North American countries such as the U.S and Canada are estimated to witness a significant regional market growth in PLA. This can be explained based on consumers’ preferences in these countries for packaged foods, including frozen and ready-to-eat meals. In addition, it is anticipated that Mexico and Latin American countries will exhibit a remarkable growth in PLA market due to rising automotive production and electronic products respectively. Europe is the largest PLA market followed by North America and Asia Pacific. Poland, Russia, France, Spain, the UK, and Germany have emerged as the main market consumers of PLA due to the continuous development of their transportation sector. Moreover, Middle East and Africa are estimated to witness a substantial growth in the textile industry. Simultaneously, the fact that less carbon emissions are formed by PLA in comparison with conventional plastics is considerably boosting its demand across the globe [25].

Figure 2. PLA applications in end-use industries and its’ global market consumption.

Figure 2. PLA applications in end-use industries and its’ global market consumption.The predicted global growth of PLA market lifted the competition among the leading companies in terms of LA and PLA production, the product quality and technology advancements used in the manufacturing process [26]. Corbion Purac is the leading producer of LA in global industrial scale, with a total of over 200,000 metric ton LA capacities. 140,000 tons of LA plant are located in Thailand (next to the PLA plant under Total Corbion joint venture) plus multiple plants around the globe. The second largest LA plant is Cargill’s in the USA (next to the NatureWorks PLA plant under the joint venture between PTT Public Company Limited and Cargill). Jindan in China is owner of a ~100,000 tons LA plant since the beginning of this century. In Belgium, Galactic owns a LA plant and is converting its 40,000 tons in China to 80,000 tons with BBCA (by 2020). Several other companies such as Golden Corn and Baisheng are constructing new LA plants by genetically engineered strains [9].

3. Conclusions

In the last two decades, PLA has gained tremendous interests and attention due to the ever-increasing alarming issues such as resource sustainability and environment pollution caused by plastic wastes. Currently, crude oil is used both as the energy source for transportation and as the material source for chemical and plastic industries. However, the development of the petroleum industry has caused serious environmental issues, such as greenhouse gas emissions and global warming, which require immediate and drastic solutions. To resolve these issues, bio-degradable and bio-based plastics have been developed as a promising alternative to conventional plastics. In comparison to most other bio-based and bio-degradable plastics, PLA is by far the most important and promising one for rigid applications.

Its upper price as related with conventional petrochemical polymers was one of the biggest drawbacks that confined its usage in the previous years. Today, new synthesizing methods such as ring opening polymerization (ROP), with different catalysts such as Sn and Zn, have led to a significant decrease in its price than in former years. Supplementary academic and industrial attention should be paid to the development of new PLA preparing methods, which would be less costly and more complex than those of the other polymerization routes.

PLA would be one of the most promising candidates for numerous industrial purposes. Its multiple desirable properties such as low cost, renewability, excellent biocompatibility, great materials assets, transparency and thermoplasticity open up many fields of application. Furthermore, since its discovery in 1932 by Carothers at DuPont, the alarming environmental issues mentioned above force us toward more extensive use of PLA. Nevertheless, PLA exhibits numerous limitations such as low heat stability, water barrier properties, oxygen permeability and mechanical properties. For these reasons, remarkable efforts have been made to enhance the performance of PLA by increasing its molecular weight via solid state and chain extending techniques. The type of used chain extender and pre-crystallization, catalyst, temperature and time in SSP are the most critical factors to produce high molecular weight PLA.

In the biomedical fields, PLA composites provide great solutions such as bone tissue engineering, the treatment of blood vessels, and organs and skin regeneration. PLA in the form of micro- and nano-particles loaded with different drugs can be used for tumor therapy and drug delivery applications. In terms of materials, PLA is a very reliable substance for constructions, automotive industry, packaging, agriculture, textiles, electronics along with single use items.

The current scope of the PLA industry is a great indication of the dominant position of PLA among other bioplastics. In addition, the ever-growing number of pilot projects announced or under construction, the numerous products and applications of PLA in bio-degradable and/or bio-based polymer markets, and the number of polymer companies and converters involved in PLA proves its significance.

To conclude, with all things considered, the protection of the environment is more critical nowadays than ever. In an attempt to totally replace petroleum-based plastics with biobased polymers, PLA seems as one of the most dominant succorers for this achievement. However, researchers and companies are forced to overcome the numerous challenges and limitations that are presented in its monomer and polymer synthesis as well as in its applications.

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made—Supplementary Information. Sci. Adv. 2017, 3, 19–24.

- Chinthapalli, R.; Skoczinski, P.; Carus, M.; Baltus, W.; De Guzman, D.; Käb, H.; Raschka, A.; Ravenstijn, J. Biobased building blocks and polymers—Global capacities, production and trends, 2018–2023. Ind. Biotechnol. 2019, 15, 237–241.

- Pappa, A.; Papadimitriou-Tsantarliotou, A.; Kaloyianni, M.; Kastrinaki, G.; Dailianis, S.; Lambropoulou, D.A.; Christodoulou, E.; Kyzas, G.Z.; Bikiaris, D.N. Insights into the toxicity of biomaterials microparticles with a combination of cellular and oxidative biomarkers. J. Hazard. Mater. 2021, 413, 125335.

- Toussaint, B.; Raffael, B.; Angers-Loustau, A.; Gilliland, D.; Kestens, V.; Petrillo, M.; Rio-Echevarria, I.M.; van den Eede, G. Review of micro- and nanoplastic contamination in the food chain. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2019, 36, 639–673.

- Zhang, Q.; Xu, E.G.; Li, J.; Chen, Q.; Ma, L.; Zeng, E.Y.; Shi, H. A review of microplastics in table salt, drinking water, and air: Direct human exposure. Environ. Sci. Technol. 2020, 54, 3740–3751.

- Ganesh Saratale, R.; Cho, S.K.; Dattatraya Saratale, G.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Naresh Bharagava, R.; Kumar, G.; Su Kim, D.; Mulla, S.I.; et al. A comprehensive overview and recent advances on polyhydroxyalkanoates (PHA) production using various organic waste streams. Bioresour. Technol. 2021, 325, 124685.

- Babu, R.P.; O’Connor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8.

- Market—European Bioplastics e. 2019. Available online: (accessed on 27 April 2021).

- Jem, K.J.; Tan, B. The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv. Ind. Eng. Polym. Res. 2020, 3, 60–70.

- Nakajima, H.; Dijkstra, P.; Loos, K. The recent developments in biobased polymers toward general and engineering applications: Polymers that are upgraded from biodegradable polymers, analogous to petroleum-derived polymers, and newly developed. Polymers 2017, 9, 523.

- Höhnemann, T.; Steinmann, M.; Schindler, S.; Hoss, M.; König, S.; Ota, A.; Dauner, M.; Buchmeiser, M.R. Poly(Ethylene furanoate) along its life-cycle from a polycondensation approach to high-performance yarn and its recyclate. Materials 2021, 14, 1044.

- Loos, K.; Zhang, R.; Pereira, I.; Agostinho, B.; Hu, H.; Maniar, D.; Sbirrazzuoli, N.; Silvestre, A.J.D.; Guigo, N.; Sousa, A.F. A Perspective on PEF Synthesis, Properties, and End-Life. Front. Chem. 2020, 8, 1–18.

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Martínez, B.M.; Alonso, R.; Agostinis, L.; et al. Bio-based packaging: Materials, modifications, industrial applications and sustainability. Polymers 2020, 12, 1588.

- Achmad, F.; Yamane, K.; Quan, S.; Kokugan, T. Synthesis of polylactic acid by direct polycondensation under vacuum without catalysts, solvents and initiators. Chem. Eng. J. 2009, 151, 342–350.

- Maharana, T.; Mohanty, B.; Negi, Y.S. Melt-solid polycondensation of lactic acid and its biodegradability. Prog. Polym. Sci. 2009, 34, 99–124.

- Pretula, J.; Slomkowski, S.; Penczek, S. Polylactides—Methods of synthesis and characterization. Adv. Drug Deliv. Rev. 2016, 107, 3–16.

- Hamad, K.; Kaseem, M.; Yang, H.W.; Deri, F.; Ko, Y.G. Properties and medical applications of polylactic acid: A review. Express Polym. Lett. 2015, 9, 435–455.

- DeStefano, V.; Khan, S.; Tabada, A. Applications of PLA in modern medicine. Eng. Regen. 2020, 1, 76–87.

- Luo, F.; Fortenberry, A.; Ren, J.; Qiang, Z. Recent progress in enhancing poly(lactic acid) stereocomplex formation for material property improvement. Front. Chem. 2020, 8, 688.

- Jin, F.L.; Hu, R.R.; Park, S.J. Improvement of thermal behaviors of biodegradable poly(lactic acid) polymer: A review. Compos. Part B Eng. 2019, 164, 287–296.

- Zaaba, N.F.; Jaafar, M. A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. Polym. Eng. Sci. 2020, 60, 2061–2075.

- Ren, J. Biodegradable Poly(Lactic Acid): Synthesis, Modification, Processing; Springer: Heidelberg, Germany; Dordrecht, The Netherlands; London, UK; New York, NY, USA; Beijing, China, 2010; ISBN 9787302236016.

- Polylactic Acid Market Size Share and Trends. Available online: (accessed on 17 April 2021).

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392.

- MRFR. Polylactic Acid Market Size, Trends, Industry Growth and Research Report—Forecast to 2027; MRFR: Pune, India, 2021; 138p.

- Bioplastics & Biopolymers Market by Type (Non-Biodegradable/Bio-Based, Biodegradable), End-Use Industry (Packaging, Consumer Goods, Automotive & Transportation, Textiles, Agriculture & Horticulture), Region—Global Forecast to 2025 COVID-19 Speak to Analyst. 2020, 6454.

More

Information

Subjects:

Polymer Science

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

4.6K

Revisions:

2 times

(View History)

Update Date:

15 Jun 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No