2.1. Mechanical Properties of HDPE Fine Aggregate Concrete

Throughout the paper, HDPE incorporated concrete is denoted in an abbreviation form, such as 10% of HDPE inclusion as HDPE-10 and 100% of HDPE inclusion as HDPE-100, etc. and summarizes the mechanical performances of HDPE fine aggregate concrete. It was observed that the slump (workability) is decreased from 70 mm to 30 mm when HDPE is increased from 5% to 15% while keeping the w/c ratio a constant of 0.42

[10]. In another experiment, a constant slump of 90 mm is observed with the increase of w/c ratio as 0.45 for HDPE-0, 0.50 for HDPE-25 and HDPE-50, 0.55 for HDPE-75 and 0.6 for HDPE-100

[11]. These conditions have resulted in a decrease in the compressive strength by 40.2% when HDPE is increased from 0% to 50% and by 22.3% when HDPE is increased from 50% to 100%

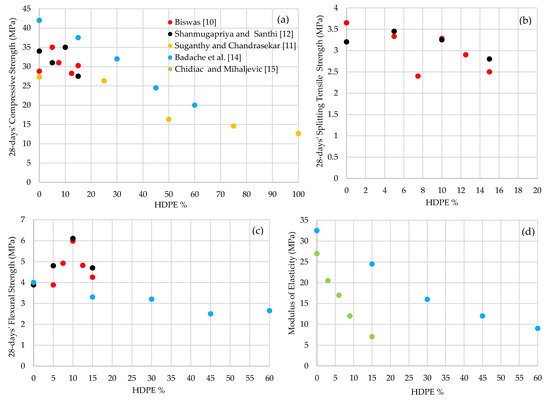

[11]. A decreasing trend in the compressive strength of HDPE fine aggregate concrete with the increase of HDPE percentage was observed. As illustrated in a, the 28-days’ compressive strength varied between 27.5 MPa to 42 MPa when HDPE is added from 0% to 20%

[10][12][13]. Shanmugapriya and Santhi

[12] observed a 3 MPa drop in compressive strength when HDPE is increased from 0% to 5%. Then the optimum compressive strength of 35 MPa was recorded at HDPE-10

[12]. Galupino et al.

[13] have also observed the optimum compressive strength of 38.6 MPa at HDPE-10. Biswas

[10] has obtained 35 MPa of compressive strength at HDPE-5 concrete but decreased by 19.3% when HDPE increased to 12.5%. Badache et al.

[14] have observed a decreasing trend in 28-days’ compressive strength with a drop of 52.4% and 57.8% when HDPE is increased from 0% to 50% and 50% to 100%, respectively.

Figure 2. 28-days’ (a) Compressive strength; (b) Splitting tensile strength; (c) Flexural strength and (d) Modulus of elasticity variation of HDPE fine aggregate concrete.

The 28-days’ splitting tensile strength also shows a decreasing trend with the increase of HDPE content from 0% to 15%, b. The HDPE-5 concrete shows the highest splitting tensile strength, 3.45 MPa, which is a 31.25% increase than the standard concrete of HDPE-0

[12]. However, a drop of 18.8% is observed with the increase of HDPE from 5% to 15%

[12]. In another study, it was observed a 8.7% and 27.9% of splitting tensile strength drop when HDPE is added from 0% to 5% and from 5% to 7.5%, respectively

[10]. There was a tensile strength gain of 26.8% when HDPE is increased from 7.5% to 10%, however, a drop of 23.8% was noted when HDPE is increased from 10% to 15%

[10].

Similar to compressive and splitting tensile strengths, the flexural strength also decreases with the increases of HDPE fine aggregate percentage, c. It is interesting to note that the flexural strength of concrete incorporated with HDPE up to 15% was higher than the standard concrete

[10][12]. The flexural strength has increased by 56.4% with the increase of HDPE from 0% to 10% and obtained the optimum flexural strength of 6.1 MPa at HDPE-10

[12]. Then, a slight strength drop of 1.4 MPa was observed at HDPE-15

[12]. A similar flexural strength development was observed by Biswas et al.

[10] when HDPE is increased from 0% to 15%. There was no change in flexural strength in HDPE-0 and HDPE-5 concretes, and then a 54.1% strength gain was noted with the increase of HDPE from 5% to 10% and obtained optimum flexural strength of 5.98 MPa at HDPE-10

[10]. A drop of 28.9% was observed, when HDPE is added from 10% to 15%

[10].

The modulus of elasticity is decreased with the increase of HDPE percentage, . According to d, there was a considerable elasticity modulus decrease, 74%, when HDPE content increases up to 15%

[14][15]. It is observed that the density of the HDPE fine aggregate concrete is decreased with the increase of recycled HDPE content, . The density of HDPE fine aggregate concrete has varied from 2165 kg/m

3 to 1825 kg/m

3, when HDPE increases from 0% to 15%

[15]. Badache et al.

[14] have observed a 20% density reduction with the increase of HDPE from 0% to 60% and obtained a density of 1760 kg/m3 at HDPE-60.

Table 1. Mix design and compressive strength properties of HDPE fine aggregate concrete.

| Reference |

Mix Design |

Mechanical Properties |

| Cement (kg/m3) |

HDPE % |

Sand % |

HDPE (kg/m3) |

Sand (kg/m3) |

Coarse Aggregates (kg/m3) |

Water (kg/m3) |

W/C Ratio |

Admixtures/Superplasticizer (w%) |

Compressive Strength (MPa) |

| 3 days |

7 days |

14 days |

28 days |

90 days |

120 days |

160 days |

180 days |

| [10] |

315 |

0 |

100 |

0 |

892.2 |

1285.5 |

132.3 |

0.42 |

- |

- |

17.77 |

23.09 |

28.8 |

- |

- |

- |

- |

| [13] |

- |

0 |

100 |

- |

- |

- |

- |

- |

- |

- |

29.65 |

33.49 |

34.2 |

- |

34.38 |

- |

- |

| [12] |

320 |

0 |

100 |

- |

848.6 |

1286.5 |

134.4 |

0.42 |

- |

- |

24 |

28 |

34 |

- |

- |

- |

- |

| [11] |

- |

0 |

100 |

- |

- |

- |

- |

0.45 |

- |

- |

15.55 |

24.75 |

27.26 |

- |

- |

- |

- |

| [15] |

118 kg |

0 |

100 |

- |

841 kg |

522 kg |

32 l |

- |

- |

19 |

- |

- |

- |

- |

- |

32.5 |

- |

| [14] |

400 |

0 |

100 |

- |

- |

- |

200 |

0.5 |

0.8 |

- |

34.5 |

- |

42 |

43 |

- |

- |

43 |

| [15] |

118 kg |

3 |

97 |

- |

816 kg |

522 kg |

30 l |

- |

- |

18.5 |

- |

- |

- |

- |

- |

25 |

- |

| [10] |

315 |

5 |

95 |

44.6 |

847.6 |

1285.5 |

132.3 |

0.42 |

- |

- |

23 |

27.8 |

35 |

- |

- |

- |

- |

| [13] |

- |

5 |

95 |

- |

- |

- |

- |

- |

- |

- |

15.69 |

18.41 |

28.57 |

- |

28.63 |

- |

- |

| [12] |

320 |

5 |

95 |

- |

806.2 |

1286.5 |

134.4 |

0.42 |

- |

- |

22 |

24.5 |

31 |

- |

- |

- |

- |

| [15] |

118 kg |

6 |

94 |

- |

790 kg |

522 kg |

30 l |

- |

- |

14 |

- |

- |

- |

- |

- |

19 |

- |

| [10] |

315 |

7.5 |

92.5 |

65.3 |

805.2 |

1285.5 |

132.3 |

0.42 |

- |

- |

21 |

25 |

31 |

- |

- |

- |

- |

| [15] |

118 kg |

9 |

91 |

- |

765 kg |

522 kg |

30 l |

- |

- |

12 |

- |

- |

- |

- |

- |

15.5 |

- |

| [10] |

315 |

10 |

90 |

84.8 |

762.8 |

1285.5 |

132.3 |

0.42 |

- |

- |

24.2 |

26.8 |

35.01 |

- |

- |

- |

- |

| [13] |

- |

10 |

90 |

- |

- |

- |

- |

- |

- |

- |

23.69 |

34.87 |

38.6 |

- |

38.89 |

- |

- |

| [12] |

320 |

10 |

90 |

- |

763.8 |

1286.5 |

134.4 |

0.42 |

- |

- |

24 |

27.5 |

35 |

- |

- |

- |

- |

| [10] |

315 |

12.5 |

87.5 |

103.2 |

722.3 |

1285.5 |

132.3 |

0.42 |

- |

- |

18.9 |

24 |

28.25 |

- |

- |

- |

- |

| [10] |

315 |

15 |

85 |

149.6 |

847.6 |

1156.86 |

132.3 |

0.42 |

- |

- |

22.9 |

25 |

30.25 |

- |

- |

- |

- |

| [13] |

- |

15 |

85 |

- |

- |

- |

- |

- |

- |

- |

23.76 |

27.48 |

20.89 |

- |

31.32 |

- |

- |

| [12] |

320 |

15 |

85 |

- |

721.3 |

1286.5 |

134.4 |

0.42 |

- |

- |

18 |

22 |

27.5 |

- |

- |

- |

- |

| [14] |

400 |

15 |

85 |

- |

- |

- |

200 |

0.5 |

0.7 |

- |

31.5 |

- |

37.5 |

39 |

- |

- |

40 |

| [15] |

118 kg |

15 |

85 |

- |

715 kg |

522 kg |

29 l |

- |

- |

6.5 |

- |

- |

- |

- |

- |

8.5 |

- |

| [11] |

- |

25 |

75 |

- |

- |

- |

- |

0.5 |

- |

- |

12.44 |

23.852 |

26.29 |

- |

- |

- |

- |

| [14] |

400 |

30 |

70 |

- |

- |

- |

200 |

0.5 |

0.6 |

- |

27.5 |

- |

32 |

36 |

- |

- |

36.5 |

| [14] |

400 |

45 |

55 |

- |

- |

- |

200 |

0.5 |

0.55 |

- |

23 |

- |

24.5 |

29.5 |

- |

- |

29 |

| [11] |

- |

50 |

50 |

- |

- |

- |

393.75 |

0.5 |

- |

- |

11.33 |

14.81 |

16.29 |

- |

- |

- |

- |

| [14] |

400 |

60 |

40 |

- |

- |

- |

200 |

0.5 |

0.5 |

- |

18.5 |

- |

20 |

25 |

- |

- |

26 |

| [11] |

- |

75 |

25 |

- |

- |

- |

433.125 |

0.55 |

- |

- |

9.55 |

13.18 |

14.59 |

- |

- |

- |

- |

| [11] |

- |

100 |

0 |

|

- |

- |

472.5 |

0.6 |

- |

- |

9.1 |

11.55 |

12.66 |

- |

- |

- |

- |

Table 2. Tensile strength, elastic modulus, density, and workability properties of HDPE fine aggregate concrete.

| Reference |

Mechanical Properties |

| Split Tensile Strength (MPa) |

Flexural Strength (MPa) |

Modulus of Elasticity (GPa) |

Density (Kg/m3) |

Slump (mm) |

| 7 days |

14 days |

28 days |

7 days |

14 days |

28 days |

90 days |

180 days |

| [10] |

2.1 |

2.72 |

3.65 |

2.92 |

3.28 |

3.88 |

- |

- |

- |

- |

- |

| [13] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [12] |

1.25 |

2.9 |

3.2 |

2.4 |

3.1 |

3.9 |

- |

- |

- |

- |

- |

| [11] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

90 |

| [15] |

- |

- |

- |

- |

- |

- |

- |

- |

27 |

2165 |

- |

| [14] |

- |

- |

- |

3.75 |

- |

4 |

4.15 |

4.75 |

32.5 |

2220 |

- |

| [15] |

- |

- |

- |

- |

- |

- |

- |

- |

20.5 |

2097 |

- |

| [10] |

1.28 |

2.75 |

3.33 |

2.15 |

3.1 |

3.88 |

- |

- |

- |

- |

70 |

| [13] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [12] |

1.25 |

2.85 |

3.45 |

2.5 |

3.8 |

4.8 |

- |

- |

- |

- |

- |

| [15] |

- |

- |

- |

- |

- |

- |

- |

- |

17 |

2022 |

- |

| [10] |

1.28 |

1.8 |

2.4 |

2.18 |

2.26 |

4.92 |

- |

- |

- |

- |

65 |

| [15] |

- |

- |

- |

- |

- |

- |

- |

- |

12 |

1930 |

- |

| [10] |

2.02 |

2.65 |

3.28 |

3.2 |

3.2 |

5.98 |

- |

- |

- |

- |

45 |

| [13] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [12] |

1.95 |

2.65 |

3.25 |

3.5 |

4.7 |

6.1 |

- |

- |

- |

- |

- |

| [10] |

1.88 |

2.38 |

2.9 |

2.28 |

2.27 |

4.82 |

- |

- |

- |

- |

40 |

| [10] |

1.35 |

2.01 |

2.5 |

3.27 |

3.15 |

4.25 |

- |

- |

- |

- |

30 |

| [13] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [12] |

1.8 |

2.3 |

2.8 |

2.2 |

3.6 |

4.7 |

- |

- |

- |

- |

- |

| [14] |

- |

- |

- |

3.25 |

- |

3.3 |

3.7 |

4.4 |

24.5 |

2120 |

- |

| [15] |

- |

- |

- |

- |

- |

- |

- |

- |

7 |

1825 |

- |

| [11] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

90 |

| [14] |

- |

- |

- |

2.9 |

- |

3.2 |

3.15 |

3.4 |

16 |

2000 |

- |

| [14] |

- |

- |

- |

2.5 |

- |

2.5 |

3 |

3.4 |

12 |

1890 |

- |

| [11] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

90 |

| [14] |

- |

- |

- |

2.35 |

- |

2.65 |

2.65 |

3 |

9 |

1760 |

- |

| [11] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

90 |

| [11] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

90 |

2.2. Durability Characteristics of HDPE Fine Aggregate Concrete

Water adsorption of HDPE fine aggregate concrete has increased from 5% to 10.4%, when recycled HDPE content increases from 0% to 15%

[15]. Similarly an increment of 5.5 kg/m

2/min has been observed in initial rate of adsorption (IRA) from 0.5 kg/m

2/min to 6.0 kg/m

2/min, with the increase of HDPE from 0% to 15%

[15]. It is observed that the chloride ion penetration is reduced and lies in the range of 2000–4000 Coulombs with the increase of HDPE content in concrete

[12]. For instance, when HDPE increased from 0% to 15% in concrete, the chloride permeability has reduced from 4250 to 2700 Coulombs which is a 36.5% reduction

[12].

After 28 days of curing, the Ultrasonic Pulse Velocity (UPV) test was performed on HDPE fine aggregate concrete and it is observed that the velocity has decreased from 3880 m/s to 2720 m/s, with the increase of HDPE from 0% to 60% in 15% intervals

[14]. Additionally, slight drops of 6 m/s, 41 m/s, 19 m/s, 118 m/s and 170 m/s were observed in UPV at HDPE-0, HDPE-15, HDPE-30, HDPE-45 and HDPE-60, respectively, over the curing period of 28 to 90 days

[14].

Thermal conductivity has dropped from 2 W/m·K to 1.14 W/m·K when HDPE increases from 0% to 60% at 7 days

[14]. Similar readings have been observed in thermal conductivity variation for 14, 28, 90 and 365 days which are slight drops of 0.8 W/m·K, 0.81 W/m·K, 0.76 W/m·K and 0.69 W/m·K, respectively, with the increase of HDPE percentage in concrete

[14]. It was also observed that thermal conductivity has dropped between 7 and 90 days, when HDPE is added from 0% to 60% in 15% intervals

[14]. These reductions are recorded to be by 11%, 5.2%, 6.7%, 3.8% and 10.5% for HDPE-0, HDPE-15, HDPE-30, HDPE-45 and HDPE-60, respectively

[14]. However, after 90 days, both standard and HDPE fine aggregate concretes have shown a stable conductivity as the decrease of thermal conductivity between 90 and 365 days are 2.8%, 3%, 0%, 4% and 1.9% for HDPE-0, HDPE-15, HDPE-30, HDPE-45 and HDPE-60 concrete, respectively

[14].

2.3. Mechanical Properties of HDPE Coarse Aggregate Concrete

The workability (slump) of HDPE coarse aggregate concrete has reduced from 61 mm to 55 mm, and to 28 mm, when HDPE is increased from 0% to 4% in 2% intervals while keeping the water/cement (W/C) ratio at 0.55,

[16]. HDPE-6 and HDPE-8 showed zero slump with the same W/C ratio of 0.55

[16]. Another experiment has recorded 55 mm and 13 mm slumps at HDPE-0 and HDPE-100 concretes

[17]. Both experiments have observed a reduction in the workability of the HDPE coarse aggregate concrete with the increase of HDPE. Philomina and D’Mello

[18] have observed that the slump has increased from 95 mm to 118 mm, an increase of 24.2%, when HDPE is added from 0% to 32%. Similarly, it has also observed an increment in the slump from 10 mm to 18 mm with the increase of HDPE from 0% to 30% in 10% intervals

[19].

Similar to HDPE fine aggregate concrete, the compressive strength of HDPE coarse aggregate concrete decreases with the increases of HDPE percentage, a. Lopez et al.

[20] observed compressive strength reduction from 11.6 MPa to 2.3 MPa when HDPE is added from 0% to 30%. Authors further noted that the variation of HDPE coarse aggregate size between ½′′ and ¾′′ has not made any significant impact on the compressive strength

[20]. Philomina and D’Mello

[18] reported a compressive strength reduction from 42.14 MPa to 30.98 MPa with the increase of HDPE from 0% to 32% in 8% intervals. Rahim et al.

[19] have observed that the 28-days’ compressive strength has dropped from 28.4 MPa to 18.24 MPa, when HDPE is added from 0% to 30% in 10% intervals, which is a drop from 28 MPa to 15.5 MPa by Habib et al.

[21], when HDPE is increased from 0% to 20% in 5% intervals and a drop of 15.9 MPa by Kodua

[16] with the increase of HDPE from 0% to 8% in 2% intervals. In another study, there is no compressive strength change noted up to 10% of HDPE incorporated in concrete, but afterwards, a little strength drop (i.e., from 26.54 MPa to 22.45 MPa) was observed when HDPE is added from 10% to 30%

[22]. Similarly, the compressive strength has decreased from 34 MPa to 28.5 MPa with the increase of HDPE from 0% to 10%, an increment of 5.5 MPa during 10% to 15% increase and again, a drop of 5.5 MPa, when HDPE is increased from 15% to 20%

[12]. It is identified that optimum 28-days’ compressive strength of 34 MPa is achieved at HDPE-15

[12]. However, Lopez et al.

[20] suggest that optimum 28-days’ compressive strength is obtained at HDPE-10.

Table 3. Mechanical properties of HDPE coarse aggregate concrete.

| eferences |

Mix Design |

Mechanical Properties |

| Cement (kg/m3) |

HDPE % |

Crushed Stone % |

HDPE (kg/m3) |

Crushed Stone (kg/m3) |

Sand (kg/m3) |

Water (kg/m3) |

W/C Ratio |

Admixtures/ Superplasticizer (w%) |

Compressive Strength (MPa) |

Split Tensile Strength (MPa) |

Flexural Strength (MPa) |

Density (kg/m3) |

Slump (mm) |

| 7 days |

14 days |

28 days |

56 days |

7 days |

14 days |

28 days |

7 days |

14 days |

28 days |

| [17] |

380 |

0 |

100 |

0 |

1045 |

665 |

190 |

0.5 |

- |

- |

- |

29.19 |

- |

- |

- |

- |

- |

- |

17.56 |

- |

55 |

| [22] |

- |

0 |

100 |

- |

- |

- |

- |

0.55 |

- |

21.32 |

23.68 |

26.54 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [12] |

320 |

0 |

100 |

0 |

1286.5 |

848.6 |

- |

- |

- |

24 |

28 |

34 |

- |

1.25 |

2.9 |

3.2 |

2.4 |

3.1 |

3.9 |

- |

- |

| [21] |

- |

0 |

100 |

- |

- |

- |

- |

0.5 |

- |

18.5 |

22 |

28 |

- |

3.2 |

3.6 |

4.5 |

- |

- |

6 |

2365.74 |

- |

| [18] |

- |

0 |

100 |

- |

- |

- |

- |

0.45 |

X |

23.71 |

30.5 |

42.14 |

43.61 |

2.87 |

3.3 |

3.9 |

- |

- |

4.56 |

2438.51 |

95 |

| [20] |

- |

0 |

100 |

- |

- |

- |

- |

- |

Y |

11.59 |

- |

- |

- |

- |

- |

- |

- |

- |

1.15 |

1855.23 |

- |

| [16] |

400 |

0 |

100 |

0 |

1200 |

800 |

- |

0.55 |

- |

13.9 |

19.5 |

30.6 |

- |

- |

- |

- |

- |

- |

4 |

- |

61 |

| [19] |

- |

0 |

100 |

- |

- |

- |

- |

0.55 |

- |

20.236 |

25.482 |

28.402 |

- |

- |

- |

- |

- |

- |

- |

- |

10 |

| [23] |

- |

0 |

100 |

- |

- |

- |

- |

0.4 |

- |

- |

- |

10000 Nm/kg |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [16] |

400 |

2 |

98 |

24 |

1176 |

800 |

- |

0.55 |

- |

12.6 |

16.1 |

19.8 |

- |

- |

- |

- |

- |

- |

5 |

- |

55 |

| [16] |

400 |

4 |

94 |

48 |

1152 |

800 |

- |

0.55 |

- |

12.5 |

14.1 |

18.5 |

- |

- |

- |

- |

- |

- |

3 |

- |

28 |

| [21] |

- |

5 |

95 |

- |

- |

- |

- |

0.5 |

- |

17 |

19 |

25 |

- |

2.8 |

3.4 |

4.2 |

- |

- |

5.7 |

2336.17 |

- |

| [16] |

400 |

6 |

94 |

72 |

1128 |

800 |

- |

0.55 |

- |

11.3 |

13.6 |

16.1 |

- |

- |

- |

- |

- |

- |

2.5 |

- |

0 |

| [18] |

- |

8 |

92 |

- |

- |

- |

- |

0.45 |

X |

22.5 |

26.3 |

40.23 |

45.32 |

2.64 |

3.56 |

4 |

- |

- |

4.28 |

2358.51 |

108 |

| [16] |

400 |

8 |

92 |

96 |

1104 |

800 |

- |

0.55 |

- |

9.4 |

10.3 |

14.7 |

- |

- |

- |

- |

- |

- |

2 |

- |

0 |

| [22] |

- |

10 |

90 |

- |

- |

- |

- |

- |

- |

18.24 |

22.35 |

25.64 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [12] |

320 |

10 |

90 |

128.68 |

1157.86 |

848.6 |

- |

- |

- |

22 |

24 |

28.5 |

- |

1.4 |

1.9 |

2.45 |

3.4 |

4 |

4.2 |

- |

- |

| [21] |

- |

10 |

90 |

- |

- |

- |

- |

0.5 |

- |

14 |

17 |

22 |

- |

2.6 |

3.1 |

3.8 |

- |

- |

5.2 |

2302.52 |

- |

| [20] |

- |

(1/2 ?) 10 |

90 |

- |

- |

- |

- |

- |

Y |

4.147 |

- |

- |

- |

- |

- |

- |

- |

- |

1.117 |

1506.79 |

- |

| - |

(3/4 ?) 10 |

90 |

- |

- |

- |

- |

- |

3.183 |

- |

- |

- |

- |

- |

- |

- |

- |

1.075 |

1466.88 |

- |

| [19] |

- |

10 |

90 |

- |

- |

- |

- |

0.55 |

- |

18.964 |

22.706 |

26.617 |

- |

- |

- |

- |

- |

- |

- |

- |

12.7 |

| [23] |

- |

10 |

90 |

- |

- |

- |

- |

0.4 |

- |

- |

- |

4500 Nm/kg |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [22] |

- |

15 |

85 |

- |

- |

- |

- |

- |

- |

17.23 |

20.49 |

23.37 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [12] |

320 |

15 |

85 |

192.99 |

1093.55 |

848.6 |

- |

- |

- |

24.5 |

26.5 |

34 |

- |

1.9 |

2.5 |

3.1 |

3.7 |

4.7 |

6.4 |

- |

- |

| [21] |

- |

15 |

85 |

- |

- |

- |

- |

0.5 |

- |

13 |

14 |

18.5 |

- |

2.5 |

2.9 |

3.5 |

- |

- |

5 |

2256.63 |

- |

| [23] |

- |

15 |

85 |

- |

- |

- |

- |

0.4 |

- |

- |

- |

3800 Nm/kg |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [18] |

- |

16 |

84 |

- |

- |

- |

- |

0.45 |

X |

21.18 |

24.73 |

37.66 |

43.86 |

1.96 |

2.92 |

3.82 |

- |

- |

3.98 |

2352.59 |

110 |

| [22] |

- |

20 |

80 |

- |

- |

- |

- |

- |

- |

15.67 |

19.13 |

22.45 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [12] |

320 |

20 |

80 |

257.31 |

1029.23 |

848.6 |

- |

- |

- |

21.5 |

23.5 |

28.5 |

- |

1.7 |

2.2 |

2.6 |

- |

- |

- |

- |

- |

| [21] |

- |

20 |

80 |

- |

- |

- |

- |

0.5 |

- |

11 |

13 |

15.5 |

- |

2.4 |

2.6 |

3.1 |

- |

- |

4.8 |

2221.96 |

- |

| [20] |

- |

(1/2 ?) 20 |

80 |

- |

- |

- |

- |

- |

Y |

3 |

- |

- |

- |

- |

- |

- |

- |

- |

0.85 |

1324.89 |

- |

| - |

(3/4 ?) 20 |

80 |

- |

- |

- |

- |

- |

2 |

- |

- |

- |

- |

- |

- |

- |

- |

0.72 |

1254.32 |

- |

| [19] |

- |

20 |

80 |

- |

- |

- |

- |

0.55 |

- |

14.161 |

18.298 |

22.997 |

- |

- |

- |

- |

- |

- |

- |

- |

15.3 |

| [23] |

- |

20 |

80 |

- |

- |

- |

- |

0.4 |

- |

- |

- |

3000 Nm/kg |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [18] |

- |

24 |

76 |

- |

- |

- |

- |

0.45 |

X |

16.66 |

22.91 |

35.54 |

42.28 |

1.74 |

2.88 |

3.76 |

- |

- |

3.73 |

2348.14 |

115 |

| [23] |

- |

25 |

75 |

- |

- |

- |

- |

0.4 |

- |

- |

- |

2200 Nm/kg |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| [20] |

- |

(1/2 ?) 30 |

70 |

- |

- |

- |

- |

- |

Y |

1.445 |

- |

- |

- |

- |

- |

- |

- |

- |

0.29 |

1079.13 |

- |

| - |

(3/4 ?) 30 |

70 |

- |

- |

- |

- |

- |

2.3 |

- |

- |

- |

- |

- |

- |

- |

- |

0.58 |

1179.51 |

- |

| [19] |

- |

30 |

70 |

- |

- |

- |

- |

0.55 |

- |

10.835 |

14.037 |

18.244 |

- |

- |

- |

- |

- |

- |

- |

- |

18 |

| [18] |

- |

32 |

68 |

- |

- |

- |

- |

0.45 |

X |

14.84 |

20.46 |

30.98 |

39.85 |

1.58 |

2.62 |

3.2 |

- |

- |

3.54 |

2311.11 |

118 |

| [17] |

380 |

60 |

40 |

172 |

412 |

665 |

190 |

0.5 |

- |

- |

- |

19.85 |

- |

- |

- |

- |

- |

- |

15.47 |

- |

- |

| [17] |

380 |

80 |

20 |

229 |

209 |

665 |

190 |

0.5 |

- |

- |

- |

13.37 |

- |

- |

- |

- |

- |

- |

12.56 |

- |

- |

| [17] |

380 |

100 |

0 |

286 |

0 |

665 |

190 |

0.5 |

- |

- |

- |

11.79 |

- |

- |

- |

- |

- |

- |

9.37 |

- |

13 |

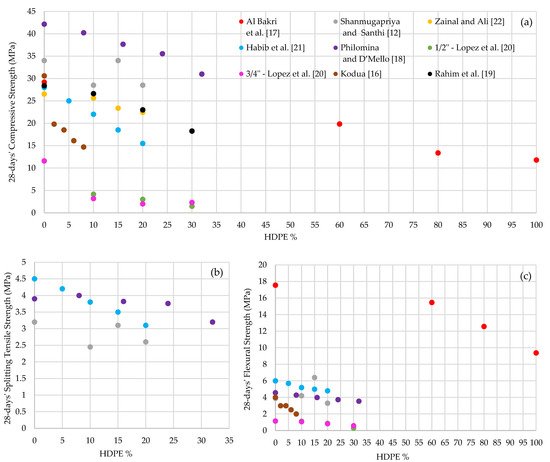

Figure 3. 28-days’ (a) Compressive strength; (b) Splitting tensile strength and (c) Flexural strength variations of HDPE coarse aggregate concrete.

The splitting tensile strength also shows a decreasing trend with the increment of HDPE content, b

[12][18][21]. A tensile strength reduction of 1.4 MPa (is observed at 28 days with the increase of HDPE from 0% to 20%

[21]. There is no tensile strength change recorded until HDPE is added up to 8%, but 0.8 MPa strength reduction was noted when HDPE increased to 32%

[18]. Shanmugapriya and Santhi

[12] noted the contradicted behavior illustrating a significant splitting tensile strength reduction of 23.4% when incorporated with 10% HDPE in concrete. However, tensile strength gain (26.5%) was observed with the increase of HDPE content from 10% to 15% and, again, a drop of 16.1% when HDPE increased from 15% to 20%

[12]. It is identified that HDPE-15 achieves the optimum 28-days’ splitting tensile strength.

Flexural strength or bending strength reduces with the increase of HDPE when incorporated as coarse aggregate in concrete c. Bakri et al.

[17] noted that the flexural strength decreased from 17.56 MPa to 15.47 MPa with the increase of HDPE content up to 60%. The flexural strength has dropped by 6.1 MPa when the HDPE is added from 60% to 100%

[17]. It has also been observed that the 28-days’ flexural strength of HDPE coarse aggregate concrete is dropped by 1.9 MPa (from 6 MPa to 4.1 MPa) when HDPE increases from 0% to 20% in 5% intervals

[21]. A 2 MPa flexural strength drop is observed with the increase of HDPE from 0% to 8%

[16][18][20]. Shanmugapriya and Santhi

[12] observed the opposite trend as a 2.5 MPa flexural strength gain obtained at 28 days for HDPE-15 concrete. The same experiment has achieved the optimum 28-days’ flexural strength of 6.4 MPa at HDPE-15, followed by a drop of 3.1 MPa, when HDPE is increased by another 5%

[12]. It is noted that the optimum 28-days’ flexural strength is attained in different HDPE percentages: for instance, 6.4 MPa at HDPE-15 (Shanmugapriya and Santhi)

[12], 4.28 MPa at HDPE-8 (Philomina and D’Mello)

[18] and 1.075 MPa at HDPE-10 (Lopez et al.)

[20].

The density of HDPE coarse aggregate concrete is decreased with the increase of HDPE content,

[18][20][21]. It is observed that there was a 5.2% reduction in density with the increase of HDPE from 0% to 32% and a 6.1% reduction during 0% to 20% of HDPE addition

[12][21]. The density of ½′′ HDPE coarse aggregate concrete matrix has reduced by 776.1 kg/m

3 and by 675.72 kg/m

3 in ¾′′ HDPE coarse aggregate concrete matrix only with the increase of HDPE from 0% to 30%

[20]. This reveals that a greater density drop could be achieved when the aggregate size is reduced from ¾′′ to ½′′ regardless of the HDPE inclusion percentage. Another notable observation is that the rate of reduction of dry density was 0.2% per volume percent of waste polymer added in HDPE coarse aggregate concrete

[23].

2.4. Durability Characteristics of HDPE Coarse Aggregate Concrete

Porosity and permeability of HDPE coarse aggregate concrete have increased with the increase of HDPE content

[20]. The HDPE-0 standard concrete displayed a porosity of 22.67 and increased it up to 36.21 when HDPE was added to 30%

[20]. The typical value of permeability of a pervious concrete ranges from 0.135 to 1.219 cm/s and all the HDPE coarse aggregate concretes display a higher permeability than the range specified

[20]. Permeability of ½′′ HDPE coarse aggregate concrete has increased by 5.28 cm/s, when the HDPE increases from 0% to 30% in 10% intervals

[20]. Similarly, the permeability was increased by 4.03 cm/s, when ¾′′ HDPE coarse aggregates are increased in the same range

[20]. It can be noted that the permeability of HDPE coarse aggregate concrete of this research study has exceeded the industry standards and varies between 0.135467 to 1.2192 cm/s

[20]. Moreover, the porosity of HDPE coarse aggregate concrete has increased by 65% and 59.7%, with the increase of HDPE from 0% to 30% for ½′′ and ¾′′ aggregate sizes, respectively. An extensive study carried out on sorptivity of HDPE coarse aggregate concrete results in a drop of 45.4% in sorptivity with the increase of HDPE from 0% to 32%

[18].

Water absorption rate of HDPE coarse aggregate concrete is increased by 34.7%, when the HDPE increase from 0% to 20%

[22]. In another experiment, a similar gain, 35.5% in water absorption was observed with the increase of HDPE content to 8%

[16]. However, Philomina and D’Mello

[18] have observed a 6.13% drop (from 4.4% to 4.13%) in water absorption rate of HDPE coarse aggregate concrete when HDPE is added from 0% to 32%

[18].

At direct UPV test, the pulse velocity of HDPE coarse aggregate concrete has increased from 4200 m/s to 4650 m/s, when HDPE is added from 0% to 16%

[18]. After reaching the maximum velocity, 4650 m/s at HDPE-16, a drop of 560 m/s was recorded with the increase of HDPE from 16% to 32%

[18]. The same experiment has performed an indirect UPV test for HDPE coarse aggregate concrete. Initially, the velocity is increased by 560 m/s, when HDPE increases from 0% to 8%

[18]. Then, an 830 m/s velocity drop during 8% to 16% HDPE addition is observed, followed by a 1030 m/s velocity gain with the increase of HDPE from 16% to 24% and, finally, a drop of 1860 m/s, when HDPE is added from 24% to 32%

[18]. The same study has carried out the rebound hammer test and have obtained rebound values at 56-days’ compressive strength

[18]. The 56-day rebound values have increased from 40 to 42 when HDPE is added from 0% to 8% and then have dropped from 42 to 36 with the increase of HDPE from 8% to 32%

[18]. Compressive strength obtained through rebound hammer test as well as through a destructive test show similar increments by 2.1 MPa and 1.71 MPa when HDPE increases from 0% to 8% and drops by 6.32 MPa and 5.47 MPa when HDPE is added from 8% to 32%, respectively

[18].

When considering the sulphate attack test, the compressive strength of HDPE coarse aggregate concrete (with the increase of HDPE from 0% to 32%) is increased when immersed with Na2SO4 apart from the standard concrete matrix (HDPE-0)

[18]. Compressive strength is observed to be dropped by 1.48 MPa in the standard concrete matrix (HDPE-0) after immersion in Na2SO4

[18]. Compressive strength is increased by 0.33 MPa, 0.51 MPa, 0.58 MPa and 1.63 MPa at HDPE-8, HDPE-16, HDPE-24 and HDPE-32 concretes, respectively

[18]. This has further displayed a 6.25% of weight loss due to a sulphate attack test in HDPE coarse aggregate concrete with the increase of HDPE from 0% to 32%

[18].

An acid attack test was carried out through a comparison of compressive strength values obtained after immersing HDPE coarse aggregate concrete mixes in both water and hydrochloric (HCl) acid after curing for 28 days

[18]. When the HDPE is increased from 0% to 32% in 8% intervals, the compressive strength has reduced by 12.21 MPa and 12.45 MPa after immersion in HCl acid and water, respectively. When comparing the compressive strength drop of each HDPE coarse aggregate concrete matrix: HDPE-0, HDPE-8, HDPE-16, HDPE-24 and HDPE-32 due to immersion in HCl acid is recorded to be 2.7%, 5.0%, 4.1%, 3.31% and 2.97%, respectively

[18]. The least compressive strength drop was recorded in HDPE-0 concrete matrix and, however, it can be observed that the compressive strength drop has reduced significantly with an increase of HDPE. The same experiment has observed an increase of 54.5% in weight loss percentage, with the increase of HDPE from 0% to 32%

[18]. According to Kodua

[16], when concrete mixes are immersed in nitric (HNO3) acid solution, compressive strength of HDPE coarse aggregate concrete is decreased by 53.9% with the increase of HDPE from 0% to 8%. An increase in weight loss of 34.1% was also observed, after immersing in HNO3, when HDPE is increased from 0% to 8%

[16]. Therefore, the effects imposed due to acids on HDPE coarse aggregate concrete are very minimal and can withstand the chemical reactions within the concrete

[18].