| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Alexandros I. Stefanakis | + 3623 word(s) | 3623 | 2020-11-10 09:24:04 | | | |

| 2 | Lily Guo | -120 word(s) | 3503 | 2020-11-11 04:40:59 | | | | |

| 3 | Lily Guo | Meta information modification | 3503 | 2020-11-11 06:49:14 | | |

Video Upload Options

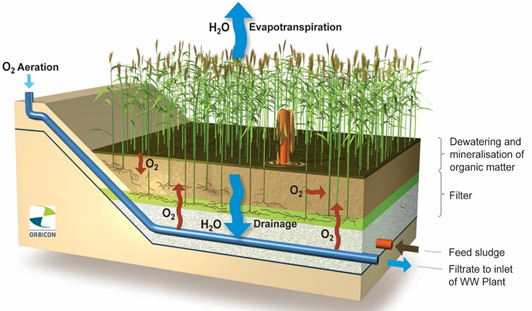

Sludge Treatment Reed Beds (STRB) represent a state-of-the-art nature-based solution to sludge treatment and management. It is an effective, economical (i.e., of low investment, operation and maintenance cost, and low energy consumption), environmentally friendly, and technically efficient technology. In STRBs, the sludge is applied to a growing stand of reeds under controlled conditions. The method relies on the exploitation of the transpiring and aerating capabilities of the reeds, which absorb moisture and nutrients from the sludge for their growth. Additionally, the sludge is dewatered by drainage through the underlying gravel layers, and evaporation from the sludge surface. In the long run, the sludge is oxidized and its organic matter content decreases. The final solids content of the dewatered sludge can build up to and exceed 40%, depending on the sludge loading rate and the climate. STRB operational life is usually at least 30 years and is divided into two or three operational phases of 8-12 years. At the end of each operational phase, the accumulated residual sludge is removed and recycled typically in agriculture and the STRB is emptied.

1. Introduction

Wastewater treatment processes typically result in the production of a by-product material, known as sewage sludge. Sewage sludge is produced at various points along the treatment train of wastewater treatment plants (WWTPs), namely in the primary sedimentation stage, the biological stage (e.g., aeration tanks), and the secondary sedimentation stage. Hence, depending on the treatment stage, sludge can be characterized as primary, secondary, biological, mixed (a mixture of primary and secondary sludge) or tertiary (from tertiary or advanced treatment stages)[1]. As any wastewater source, sludge can be originated from households, commercial and municipal areas, industrial facilities, agro-industries, surface runoff and stormwater. Sludge production is continuously increasing following a respective increase in the population numbers connected to centralized WWTPs and the adoption of stricter environmental legislation[2]. Typical sludge production in activated sludge plants, i.e., the most widely applied wastewater treatment method, is up to 2.5 kg per individual per day[1]. This means that, for example, for a population of 100,000 inhabitants, the generated sludge would reach 250 t/day. Municipal sludge was produced in the European Union (EU) at an annual rate of 8 million tons in 2016[3][4], a figure that is estimated to further increase and reach 13 million tons of dry solids (ds) this year[5].

Although the sludge volume represents a very small fraction (typically less than 1%) of the total wastewater volume that is treated at a WWTP, the overall cost for sludge management and handling could account for up to 50% of the total operation costs of the WWTP[1]. In addition, considering the circular approach based on which all waste should be viewed as a valuable resource rather than as waste[5], sustainable sludge management options are now required. Moreover, the target of eliminating landfilling or energy-consuming incineration means that alternative eco-friendly solutions are in focus[5].

Various technologies have been applied for sludge dewatering, such as mechanical treatment (i.e., decanters, centrifuges, and screw-presses) and simple sand drying beds in warmer climates, as have environmentally friendly solutions, such as sludge treatment reed beds (STRBs), also known as sludge treatment wetlands[1]. Sludge treatment in reed beds/constructed wetlands was developed in the late 1980s and today represents a cost-effective and easy-to-run nature-based solution for the dewatering and stabilization of sludge that can be applied at small and also at large scales[6][7][8] . Comparing STRBs with mechanical dewatering systems and sludge disposal, STRB technology typically has slightly higher investment costs but significantly lower operation costs. A life cycle cost analysis and comparison of STRB and mechanical systems for the dewatering of activated sludge of 550 t ds/year revealed that the STRB system is a cost-effective alternative[9][10]. As an eco-friendly wetland technology, STRBs do not require the use of polymer coagulants for the dewatering process, and due to the small amount of energy input needed, the absence of complex electro-mechanical equipment, and the use of natural materials and processes, STRBs as all treatment wetland systems are viewed as a green treatment technology with a minimal carbon footprint [1][11][12][13].

STRB technology is widely applied mostly for municipal sludge dewatering in Europe. For example, this technology has been used in Denmark for almost 30 years. Sewage sludge contains organic matter and nutrients; hence, it is widely used as a soil amendment, as a fertilizer in agriculture, and in other environmental applications (e.g., forestry and land reclamation)[8][14][15]. However, sewage sludge may also contain contaminants such as micropollutants, emerging contaminants, and trace elements (e.g., heavy metals and pathogenic microorganisms) that may have an adverse environmental impact[14][16][17]. There is limited study of the fate of various micropollutants and emerging contaminants in STRBs. STRBs have been found to be capable of removing some pharmaceuticals from domestic sludge (e.g., diclofenac[18] and antibiotics, i.e., ciprofloxacin and azithromycin[19]) and antibiotic-resistant genes[20][21], but generally, there is not sufficient information yet regarding the behaviour and performance of STRBs in the removal of such micropollutants in STRBs treating domestic and/or industrial sludge. STRBs are also much more efficient in the degradation of hazardous organic compounds, such as linear alkylbenzene sulfonate (LAS), nonylphenol polyethoxylates (NPE), di-(2-ethylhexyl)phthalate (DEHP), and certain polycyclic aromatic hydrocarbons (PAHs) than conventional methods[9][11][12]. These are important aspects for sludge reuse; for example, the Danish Environmental Protection Agency (DEPA) and the EU have regulated the contents of nutrients, heavy metals, and hazardous organic compounds in sludge spread on agricultural land (Table 1;[9][11].

Table 1. Regulatory limits in Denmark and the European Union (EU) for heavy metal and hazardous organic compound contents in sludge reused in agriculture[22][23].

|

Parameter |

EU |

|

Denmark |

|

|

Directive 86/278/EC [22] |

EC Working Document on Sludge, 3rd Draft[23] |

BEK No. 1001 of 27/06/2018 |

||

|

Metals |

mg/kg ds |

mg/kg ds |

mg/kg ds |

mg/kg TP ¹ |

|

Cadmium (Cd) |

20–40 |

10 |

0.8 |

100 |

|

Copper (Cu) |

1000–1750 |

1000 |

1000 |

- |

|

Nickel (Ni) |

300–400 |

300 |

30 |

2500 |

|

Lead (Pb) |

750–1500 |

750 |

120 |

10,000 |

|

Zinc (Zn) |

2500–4000 |

2500 |

4000 |

- |

|

Mercury (Hg) |

16–25 |

10 |

0.8 |

200 |

|

Chromium (Cr) |

- |

1000 |

100 |

- |

|

Organic compounds CONTAMINANTS |

mg/kg ds |

mg/kg ds |

mg/kg ds |

mg/kg TP |

|

LAS |

- |

2600 |

1300 |

- |

|

PAH |

- |

6 |

3 |

- |

|

NPE |

- |

50 |

10 |

- |

|

DEHP |

- |

100 |

50 |

- |

EC = European Council; ds = dry solids; LAS = linear alkylbenzene sulfonate; PAH = polycyclic aromatic hydrocarbons; NPE = nonylphenol polyethoxylates; DEHP = di-(2-ethylhexyl)phthalate; BEK = Bekendtgørelse; TP = Total phosphorous.

Generally, experience has shown that STRBs can treat most types of sludge with ds contents between 0.1 and 5% [1] Some sludge types, especially those of industrial, i.e., non-domestic, sources may, in general, be difficult to dewater and even unsuitable for an STRB system, e.g., sludge rich in oil and fat. Industrial sludge is considered a more difficult application and technically more challenging for effective dewatering, since it may contain heavy metals, nutrients, hazardous organic compounds, oil, and fats at much higher levels than typical sludge of domestic origin; thus, its treatment, dewatering, and/or disposal can be problematic considering the legal requirements. This is why the vast majority of STRB facilities worldwide are designed for the dewatering of domestic sludge.

On the other hand, there is an intensively increasing worldwide interest in the application of constructed wetlands (or reed beds) technology for industrial wastewater treatment[24], which also encompasses the reed bed system for sludge dewatering. Thus, over the last few years, there has also been a respective increase in research and development interest in the application of this green technology for industrial sludge dewatering. This gradual shift of research interest to industrial waste comes as a result of the proven high treatment efficiency of this natural treatment technology and the realization of the actual treatment capacity it possesses[13][25], as well as of the better understanding of its multiple environmental, technical, and economic benefits and the desire for sustainable options in the global water/wastewater industry.

However, as this tendency is relatively new, most of the available studies and reports in the international literature on STRBs deal with sludge from domestic WWTPs. The published literature on the feasibility and efficiency of industrial sludge treatment in STRB is very limited, and only very few case studies (mostly pilot projects) have been presented at international conferences or reported in journal articles and/or book chapters. This means that there is gap in the respective literature not only due to the small number of studies but also due to the fact that this information is scattered and not easily accessible.

2. Sludge Treatment Reed Bed System and Industrial Sludge

2.1. Description

STRBs are an established nature-based technology for sludge treatment. The concept of an STRB is similar to that of a vertical flow constructed wetland[1][26]. Most of these systems are found in Europe and the USA, e.g., in France, Denmark, Germany, Poland, and Sweden[27][28][29][30]. Almost 20% of the produced sludge in Denmark is treated in STRB systems [8,11], mostly in villages and small cities with populations of up to 10,000 inhabitants, though there are large-scale systems (serving over 100,000 inhabitants) as well. Lately, this sustainable technology has been introduced into various Mediterranean countries, such as in Greece, Italy, and Spain[30][31][32][33][34], as well as in China[35] and the Middle East[36], due to the favorable, i.e., warmer, climates.

An STRB is a concrete or trapezoidal earthen basin[37], the bottom of which is typically covered by a low-permeability sealing material, such as a high-density polyethylene (HDPE) geomembrane, to prevent leaching to the underground formations and the groundwater. The basin is filled with gravel and sand of different sizes and thicknesses[1], while on top of the substrate layer, local wetland plant species are planted, such as common reeds or cattails (Phragmites australis or Typha latifolia). A sludge distribution pipe network spreads the feed sludge across the surface of the bed, where sludge is dewatered through passive vertical drainage and evapotranspiration (Figure 1)[16][38][39]. A drainage pipe network is placed into a cobble (i.e., large stone) layer above the geomembrane and collects the drained water. The drainage network is connected to pipes that facilitate the passive aeration of the bed, which has been found to be beneficial for the dewatering performance of the system [1][40][41][42].

Figure 1. Schematic cross-section of a sludge treatment reed bed (STRB) system indicating the sludge layer, the porous media layer, the feeding pipes, and the drainage network (courtesy of Orbicon).

Vegetation and passive ventilation create favourable conditions for the conversion of degradable organic matter to a more stable humic form[33][43]. The dewatering process along with organic matter mineralization results in the reduction of the sludge volume, and the accumulated residual sludge is continuously incorporated into the filter media layer where the plants are established. As time passes, the depth of the mineralized residual sludge layer increases at an approximate accumulation rate of 10–15 cm/year, which depends on the quality of the feed sludge [1]. Typically, after 8 to 12 (even up to 20) years of continuous operation, the layer of the dewatered and also mineralized residual sludge is removed from the basins and then recycled as a fertilizer or as a soil conditioner [8][16][44][45][46]. There is a wide range of sludge types that can be dewatered in STRBs such as activated sludge, digested (anaerobic) sludge, and sludge from waterworks (WW). Experience has shown that STRBs can treat sludge of varying qualities, possessing a comparable or even higher dewatering capacity than conventional dewatering methods.

The effective dewatering and operation of an STRB depends on the quality of the feed sludge, the climatic characteristics, and proper design and construction[1]. The sludge loading rate (SLR; kg ds/m²/year) represents a key parameter in STRB design, and mostly depends on the sludge quality and the climate[1][44]. Usually, a first pilot testing phase is recommended before the implementation of a full-scale STRB to determine the dewatering ability and efficiency, especially when an industrial sludge is to be treated. A typical pilot study would consist of 3–12 beds, each with an area of up to 2 m² (or more). A typical testing period lasts 4–12 months, although there are pilot experiments operated for up to 3 years. Such a trial usually aims at identifying the suitability of the feed sludge for treatment in an STRB, the required number of beds, the optimum SLR and length of the feeding and resting periods, the dewatering efficiency (L/s/m²), the drained water quality, the residual sludge quality, and the plant growth. A pilot study will also provide the necessary guidance for potential modifications at the WWTP facility in order to decrease the content of any undesired materials in the raw sludge (e.g., heavy metals, fats and oil, etc.). However, there is not a unanimously and widely accepted STRB design, even for similar sludge types[1]. The number of beds in an STRB system varies between 1 and 24, the bed area between less than 100 and more than 3000 m², and the SLR between 30 and more than 100 kg ds/m²/year[1][9].

2.2. Operation

STRB operation is based on feeding cycles, where each cycle consists of loading and resting periods[1][11]. The loading period usually lasts a few days or even few weeks and is followed by a resting period without sludge applications to allow for sludge dewatering through drainage and evapotranspiration[1][11]. For example, the design developed by Orbicon for the Danish climatic conditions suggests a cycle of 1–2 weeks of loading and then 5–10 weeks of resting, i.e., without loads of new sludge [38,41], while for the temperate climate of Greece, the respective figures are 1 week of loading and 1–3 weeks of resting (varying between seasons)[1][32][33]. In general, the duration of the feeding and resting periods is decided according to the sludge quality, the climatic conditions (i.e., cold climates require prolonged resting periods), the seasonal variations, the age of the STRB, the ds levels in the feed sludge, and the depth of the residual sludge layer[9][11][44].

Although the operation of STRBs is relatively simple, their effective dewatering performance depends on the proper management of the feeding cycles to prevent overloading the beds. A properly managed STRB can reach 40% ds under colder climates (e.g., in Denmark)[47][45] or even higher in warmer climates (such as 60% in Greece [30,31]), figures that are higher compared to those for the energy-intensive mechanical dewatering methods. Due to the limited energy input required for the operation of STRBs, these systems are also much more energy efficient [43–45] and act as a carbon sink due to carbon fixation by the reed plants[1][48][41][49].

2.3. Industrial Sludge in STRB

The term “industrial sludge” is generally not clearly defined; however, it should be understood that it refers to sludge produced at the WWTPs of single industries and public WWTPs receiving not only municipal effluents but also effluents from industrial facilities, and sludge produced at the WWTPs of agro-industrial facilities, e.g., the food industry, aquaculture, dairy farms, olive mills, abattoirs, as well as sludge produced at water works (WW)[50] . The sludge produced in these facilities may include pollutants that are not present at all in the sludge derived from domestic wastewater, such as heavy metals, oil and fat, and hazardous organic compounds, or that are present at much higher concentrations, e.g., higher nutrient content (e.g., nitrate and phosphate) and higher oil and fat content. Hence, these sludge types are more difficult to manage due to their reduced dewaterability and the potential contamination of the residual sludge. In particular, sludge from WW, i.e., the purification facilities that produce potable water, is typically rich in iron and/or aluminium but has a low organic and oil and fat content. Sludge produced by the food industry, e.g., slaughterhouses, dairy farms, aquaculture farms, etc., has higher contents of organics (i.e., oil, fat, proteins, and carbohydrates), heavy metals, nutrients, and suspended solids. This means that these types of sludge represent an environmental hazard.

2.3.1. Organic Matter

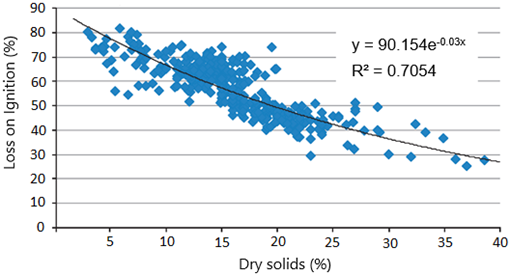

Insufficient sludge dewatering is often related to the feed sludge quality. The ratio between organic and inorganic matter is a commonly used parameter for assessing the sludge dewatering properties. The content of organic matter is usually expressed by determining the “loss on ignition” (LOI). The water retention capacity of sludge that has a high LOI, i.e., a high organic matter fraction, is much higher than that for a sludge with low LOI, i.e., sludge with a higher inorganic fraction, since the organic matter content highly affects the free water content. Thus, the higher the organic matter content, the lower the free water content and the higher the capillary water content[48], making dewatering more difficult[51]. The comparison of the organic matter content (expressed as LOI) in the feed sludge with the ds content in the residual sludge in a large number of STRBs revealed that higher organic matter content in the feed sludge results in lower ds content in the residual sludge (Figure 2).

Figure 2. Organic matter content (loss on ignition—LOI) in the feed sludge and dry solids content in the residual sludge—correlation in STRBs. Practical experiences indicate that a LOI higher than 65% significantly limits sludge dewatering.

2.3.2. Oil and Fats

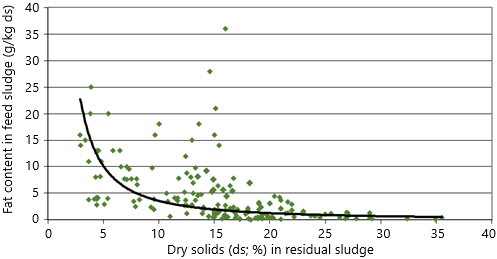

One visual way to evaluate the dewatering process in STRBs is the observation of cracks in the upper sludge layer during the resting period. Sludge with a high oil and fat content does not easily form cracks and openings during the resting period, which limits the natural aeration from the atmosphere on the bed surface. If such cracking is not observed, this probably implies insufficient sludge dewatering[51]. Therefore, a feed sludge with high fat and oil content should be considered during the design phase in order to avoid a negative impact on the ds content in the residual sludge (Figure 3). Experience has shown that a feed sludge with a fat content higher than 5000 mg/kg ds significantly affects the dewatering process and contributes to the creation of an anaerobic environment in the residual sludge layer, indicated by a black colour and unpleasant odour.

Figure 3. Correlation between fat and oil content in the feed sludge and dry solids content in the residual sludge [51].

2.3.3. Heavy Metals

The feed sludge can also contain high heavy metal content, depending on the industrial process generating the wastewater. Domestic sludge generally has low heavy metal content, even below the legal limits for sludge reuse . However, if industries are connected to a municipal WWTP, this may result in increased heavy metal concentrations in the influent wastewater and in the produced sludge, which sometimes can inhibit reed growth in the STRB, and its quality often exceeds the legal limits for reuse in agriculture (Table 1). The drying of reed plants due to high nickel content in the residual sludge has been reported at a Danish WWTP that receives wastewater from a heavy industry.

Experiences from Danish STRBs after 10 and 20 years of continuous operation showed that the heavy metal content in the residual sludge is generally below the Danish and EU limit concentrations[34]. Heavy metals are mainly bound to particles in the residual sludge and the gravel media, so their mobility out of the STRB through drainage is limited[41][52][53][54][54]. A research study in pilot STRBs indicated that the gravel substrate is the main heavy metal sink[55]. The accumulation in the residual sludge layer and also the plant uptake were very low, while less than 16% of the heavy metal mass left the bed through drainage.

2.3.4. Nutrients

The residual sludge from an STRB is considered a valuable fertilizer, due to its high nutrient, i.e., nitrogen and phosphorus, content[47][56]. Nitrification and denitrification are the main microbial processes that transform and reduce nitrogen during the operation period [41]. A small amount of nitrogen also leaves the system through drainage, mainly as nitrate, and, thus, returns to the WWTP inflow. In addition, it has been observed that the total phosphorous concentration tends to increase in the residual sludge[47][57], as a result of organic matter mineralization. A small fraction of phosphorous is subjected to interactions with iron and other constituents and is thus bound in the residual sludge matrix.

2.3.5. Hazardous Organic Compounds

Sludge may contain a range of hazardous organic compounds, e.g., polyaromatic hydrocarbons (PAHs), di-2-ethylhexyl-phthalates (DEHPs), nonylphenol/nonylphenol ethoxylates (NPEs), and linear alkyl benzene sulfonates (LASs), which originate from coal and tars, lubricating oil additives, and detergents. Sludge treatment in STRBs results in the mineralization of these compounds[6][11][12][54][49]. The long operation period of STRBs, which can exceed 10 years, provides adequate time for microbiological and abiotic processes to effectively mineralize and decrease the contents of most hazardous organic compounds. Even for a shorter period of 3–6 months, significant reductions have been observed. Such processes have not been detected in conventional mechanical dewatering methods, e.g., centrifugation[11][47][58].

A previous study on the mineralization of LAS and NPE in sludge treated in an STRB reported 98% LAS and 93% NPE degradation under aerobic conditions[11], indicating that limited oxygen availability affects the degradation of organic compounds. Oxygen inflow into the sludge significantly enhanced LAS and NPE mineralization; on the other hand, mineralization under anaerobic conditions was very limited. The same study reported 60% and 32% reductions of DEHP and PAH, respectively[11][14]. The organic compounds were not only mineralized in the upper parts but through the whole depth of the residual sludge layer. Trials with anaerobically digested sludge (representing sludge after mechanical treatment) indicated a partial degradation of LAS, NPE, DEHP, and PAH in the top sludge layer (0–20 cm), while below this depth, it was observed that these compounds were not degraded[11].

References

- Stefanakis, A.I.; Akratos, C.S.; Tsihrintzis, V.A. Vertical Flow Constructed Wetlands; Eco-Engineering Systems for Wastewater and Sludge Treatment, 1st ed; Elsevier: Amsterdam, The Netherlands, 2014.

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sust. Energ. Rev. 2008, 12, 116–140.

- Bianchini, A.; Bonfiglioli, L.; Pellegrini, M.; Saccani, C. Sewage sludge management in Europe: A critical analysis of data quality. Int. J. Environ. Waste Manag. 2016, 18, 226–238.

- EC (European Commission). Sewage Sludge. Available online: https://ec.europa.eu/environment/waste/sludge (accessed on 14 September 2020).

- Salado, R.; Vencovsky, D.; Daly, E.; Zamparutti, T.; Palfrey, R. Environmental, Economic and Social Impacts of the use of Sewage Sludge on Land; Part II: Report on Options and Impacts; Report by RPA; European Commission, DG Environment: Brussels, Belgium, 2010.

- Nielsen, S.; Willoughby, N. Sludge treatment and drying reed bed systems in Denmark. Water Environ. J. 2005, 19, 296–305.

- Uggetti, E.; Ferrer, I.; Llorens, E.; Garcia, J. Sludge treatment wetlands: A review on the state of the art. Bioresour. Technol. 2010, 101, 2905–2912.

- Brix, H. Sludge dewatering and mineralization in Sludge Treatment Reed Beds. Water 2017, 9, 160; doi:10.3390/w9030160.

- Nielsen, S. Economic assessment of sludge handling and environmental impact of sludge treatment in a reed bed system. Water Sci. Technol. 2015, 71, 1286–1292.

- Nielsen, S.; Larsen, J.D. Operational strategy, economic and environmental performance of sludge treatment reed bed systems—based on 28 years of experience. Water Sci. Technol. 2016, 74, 1793–1799.

- Nielsen, S. Mineralisation of hazardous organic compounds in a sludge reed bed and sludge storage. Water Sci. Technol. 2005, 51, 109–117.

- Boruszko, D. Changes of the content of heavy metals and PAH’s in sewage sludge treatment with Reed Bed Lagoons. J. Ecol. Eng. 2018, 19, 75–87.

- Stefanakis, A.I., 2019. The Role of Constructed Wetlands as Green Infrastructure for Sustainable Urban Water Management. Sustainability 11(24), 6981, https://doi.org/10.3390/su11246981.

- Olsson, L.; Larsen, J.D.; Ye, S.; Brix, H. Emissions of CO2 and CH4 from sludge treatment reed beds depend on system management and sludge loading. J. Environ. Manage. 2014, 141, 51–60.

- Mantovi, P.; Baldoni, G.; Toderi, G. Reuse of liquid, dewatered, and composted sewage sludge on agricultural land: Effects of long-term application on soil and crop. Water Res. 2005, 39, 289–296.

- Langergraber, G.; Dotro, G.; Nivala, J.; Rizzo, A.; Stein, O.R. Wetland Technology: Practical Information on the Design and Application of Treatment Wetlands, 1st ed.; IWA Publishing: London, UK, 2019.

- Stefanakis, A.I.; Becker, J.A. A review of emerging contaminants in water: Classification, sources, and potential risk. In: Impact of Water Pollution on Human Health and Environmental Sustainability; McKeown, A.E., Bugyi, G., Eds.; IGI Global: Hershey, PA, USA, 2015, pp. 55–80.

- Harrison, E.Z.; Oakes, S.R.; Hysell, M.; Hay, A. Organic chemicals in sewage sludges. Sci. Total Environ. 2006, 367, 481–497.

- Kołecka, K.; Gajewska, M.; Stepnowski, P.; Caban, M. Spatial distribution of pharmaceuticals in conventional wastewater treatment plant with Sludge Treatment Reed Beds technology. Sci. Total Environ. 2019, 647, 149–157.

- Wang, S.; Cui, Y.; Li, A.; Wang, D.; Zhang, W.; Chen, Z. Seasonal dynamics of bacterial communities associated with antibiotic removal and sludge stabilization in three different sludge treatment wetlands. J. Environ. Manage. 2019, 240, 231–237.

- Ma, J.; Cui, Y.; Li, A.; Zhang, W.; Ma, C.; Chen, Z. Occurrence and distribution of five antibiotic resistance genes during the loading period in sludge treatment wetlands. J. Environ. Manage. 2020, 274, 111190.

- European Union. Council Directive 86/278/EEC on the Protection of the Environment, and in Particular of the Soil, when Sewage Sludge is used in Agriculture; Off. J. Eur. Union 1986, L181, 6–12.

- European Commission-DG Environment. Working Document on Sludge; 3rd Draft; European Commission-DG Environment: Brussels, Belgium, 2000. Available online: http://ec.europa.eu/environment/waste/sludge/pdf/sludge_en.pdf (accessed on 13 July 2020).

- Stefanakis, A.I.; Tsihrintzis, V.A. Effect of various design and operation parameters on performance of pilot-scale Sludge Drying Reed Beds. Ecol. Eng. 2012, 38, 65–78.

- Nielsen, S. Sludge treatment reed bed facilities-organic load and operation problems. Water Sci. Technol. 2011, 63, 942–948.

- Stefanakis, A.I.; Tsihrintzis, V.A. Effects of loading, resting period, temperature, porous media, vegetation and aeration on performance of pilot-scale Vertical Flow Constructed Wetlands. Chem. Eng. J. 2012, 181–182, 416–430.

- Kołecka, K.; Obarska-Pempkowiak, H.; Gajewska, M. Polish experience in operation of sludge treatment reed beds. Ecol. Eng. 2018, 120, 405–410.

- Mennerich, A.; Niebuhr, L.; Ezzo, H. Full scale sludge treatment in reed beds in moderate climate—A case study. Water 2017, 9, 741.

- Kim, B.; Bel, T.; Bourdoncle, P.; Dimare, J.; Troesch, S.; Molle, P. Septage unit treatment by sludge treatment reed beds for easy management and reuse: Performance and design considerations. Water Sci. Technol. 2018, 77, 279–285.

- Stefanakis, A.I.; Akratos, C.S.; Melidis, P.; Tsihrintzis, V.A. Surplus activated sludge dewatering in pilot-scale Sludge Drying Reed Beds. J. Hazard Mater. 2009, 172, 1122–1130.

- Alexandros I. Stefanakis; Vassilios A. Tsihrintzis; Effect of various design and operation parameters on performance of pilot-scale Sludge Drying Reed Beds. Ecological Engineering 2012, 38, 65-78, 10.1016/j.ecoleng.2011.10.003.

- Uggetti, E.; Ferrer, I.; Carretero, J.; Garcia, J. Performance of sludge treatment wetlands using different plant species and porous media. J. Hazard Mater. 2012, 217–218, 263–270.

- Peruzzi, E.; Nielsen, S.; Macci, C.; Doni, S.; Iannelli, R.; Chiarugi, M.; Masciandaro, G. Organic matter stabilization in reed bed systems: Danish and Italian examples. Water Sci. Technol. 2013, 68, 1888–1894.

- Peruzzi, E.; Macci, C.; Doni, S.; Iannelli, R.; Masciandaro, G. Stabilization process in reed bed systems for sludge treatment. Ecol. Eng. 2017, 102, 381–389.

- Shanshan Hu; Xuanlou She; Xiandong Wei; Bo Hu; Chengxiao Hu; Yunqiu Qian; Yinghong Fang; Xirui Zhang; Safdar Bashir; Zhongbing Chen; et al. Surplus sludge treatment in two sludge treatment beds under subtropical condition in China. International Biodeterioration & Biodegradation 2017, 119, 377-386, 10.1016/j.ibiod.2016.11.005.

- Alexandros I. Stefanakis; Constructed Wetlands for Sustainable Wastewater Treatment in Hot and Arid Climates: Opportunities, Challenges and Case Studies in the Middle East. Water 2020, 12, 1665, 10.3390/w12061665.

- Enrica Uggetti; I. Ferrer; Javier Carretero; J. García; Performance of sludge treatment wetlands using different plant species and porous media. Journal of Hazardous Materials 2012, 2, 263-270, 10.1016/j.jhazmat.2012.03.027.

- Stefanakis, A.I. Constructed Wetlands: description and benefits of an eco-tech water treatment system. In Impact of Water Pollution on Human Health and Environmental Sustainability, 1st ed.; McKeown, A. & Bugyi, G., Eds.; IGI Global: Hershey, PA, USA, 2015; pp. 281-303.

- Meng, D.; Wu, J.; Xu, Z.; Xu, Y.; Li, H.; Jin, W.; Zhang, J. Effect of passive ventilation on the performance of unplanted sludge treatment wetlands: Heavy metal removal and microbial community variation. Environ. Sci. Pollut. Res. 2020, 27, 31665–31676. [

- Stefanakis, A.I. Constructed Wetlands: Description and benefits of an eco-tech water treatment system. In Impact of Water Pollution on Human Health and Environmental Sustainability, 1st ed.; McKeown, A., Bugyi, G., Eds.; IGI Global: Hershey, PA, USA, 2015; pp. 281–303.

- Nielsen, S. Sludge drying reed beds. Water Sci. Technol. 2003, 48, 101–108.

- Meng, D.; Wu, J.; Xu, Z.; Xu, Y.; Li, H.; Jin, W.; Zhang, J. Effect of passive ventilation on the performance of unplanted sludge treatment wetlands: Heavy metal removal and microbial community variation. Environ. Sci. Pollut. Res. 2020, 27, 31665–31676.

- Nielsen, S.; Peruzzi, E.; Macci, C.; Doni, S.; Masciandaro, G. Stabilisation and mineralisation of sludge in reed bed systems after 10–20 years of operation. Water Sci. Technol. 2014, 69, 539–545.

- Zhou, J.B.; Jiang, M.M.; Chen, B.; Chen, G.Q. Emergy evaluations for constructed wetland and conventional wastewater treatments. Commun. Nonlinear Sci. Numer Simul. 2009, 14, 1781–1789.

- Rosli, F.A.; Lee, K.E.; Goh, C.T.; Mokhtar, M.; Latif, M.T.; Hog, T.L.; Simon, N. The use of constructed wetlands in sequestrating carbon: An overview. Nat. Environ. Pollut. Technol. 2017, 16, 813–819.

- De Klein, J.J.M.; van der Werf, A.K. Balancing carbon sequestration and GHG emissions in a constructed wetland. Ecol. Eng. 2014, 66, 36–42.

- Nielsen, S.; Bruun, E.W. Sludge quality after 10–20 years of treatment in reed bed systems. Environ. Sci. Pollut. Res. 2015, 22, 12885–12891.

- Tuncal, T.; Uslu, O. A review of dehydrations of various industrial sludges. Drying Tech. 2014, 32, 1642–1654.

- Nielsen, S.; Bruun, E.W. Dewatering of industrial sludge in Sludge Treatment Reed Bed systems. In Constructed Wetlands for Industrial Wastewater Treatment, 1st ed.; Stefanakis, A.I., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2018; Volume 1, pp. 429–451.

- Kołecka, K.; Obarska-Pempkowiak, J. Potential fertilizing properties of sewage sludge treated in the sludge treatment reed beds (STRB). Water Sci. Technol. 2013, 68, 1412–1418.

- Federle, T.W; Itrich, N.R. Comprehensive approach for assessing the kinetics of Primary and Ultimate Biodegradation of Chemicals in activated sludge: Application to Liniear Alkylbenzene Sulfonate. Environ. Sci. Technol. 1997, 31, 1178–1184.

- Nielsen, S.; Peruzzi, E.; Macci, C.; Doni, S.; Masciandaro, G. Stabilisation and mineralisation of sludge in reed bed systems after 10–20 years of operation. Water Sci. Technol. 2014, 69, 539–545.

- Kołecka, K.; Nielsen, S.; Obarska-Pempkowiak, H. The speciation of selected heavy metals of sewage sludge stabilized in reed basins. In Proceedings of the 11th International IWA Specialist Group Conference on Wetland Systems for Water Pollution Control, Indore, India, 1–7 November 2008.

- Matamoros, V.; Nguyen, L.X.; Arias, C.A.; Nielsen, S.; Laugen, M.M.; Brix, H. Musk fragrances, DEHP and heavy metals in a 20 years old sludge treatment reed bed system. Water Res. 2012, 46, 3889–3896. [

- Stefanakis, A.I.; Tsihrintzis, V.A. Heavy metal fate in pilot-scale Sludge Drying Reed Beds under various design and operation conditions. J. Hazard. Mater. 2012, 213–214, 393–405.

- Kołecka, K.; Nielsen, S.; Obarska-Pempkowiak, H. The speciation of selected heavy metals of sewage sludge stabilized in reed basins. In Proceedings of the 11th International IWA Specialist Group Conference on Wetland Systems for Water Pollution Control, Indore, India, 1–7 November 2008.

- Matamoros, V.; Nguyen, L.X.; Arias, C.A.; Nielsen, S.; Laugen, M.M.; Brix, H. Musk fragrances, DEHP and heavy metals in a 20 years old sludge treatment reed bed system. Water Res. 2012, 46, 3889–3896

- Nielsen, S.; Bruun, E.W. Dewatering of industrial sludge in Sludge Treatment Reed Bed systems. In Constructed Wetlands for Industrial Wastewater Treatment, 1st ed.; Stefanakis, A.I., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2018; Volume 1, pp. 429–451. [G