| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Magdalena Ramirez-Peña | + 13377 word(s) | 13377 | 2020-08-20 18:44:03 |

Video Upload Options

The supply chain is currently taking on a very important role in organizations seeking

to improve the competitiveness and profitability of the company. Its transversal character mainly places it in an unbeatable position to achieve this role. This article, through a study of each of the key enabling technologies of Industry 4.0, aims to obtain a general overview of the current state of the art in shipbuilding adapted to these technologies. To do so, a systematic review of what the scientific community says is carried out, dividing each of the technologies into di erent categories. In addition, the global vision of countries interested in each of the enabling technologies is also studied. Both studies present a general vision to the companies of the concerns of the scientific community, thus encouraging research on the subject that is focused on the sustainability of the

shipbuilding supply chain.

1. Introduction

The existing flow of materials and information within an organization is defined as Supply Chain and it goes from the suppliers of raw materials to the consumer of the final product [1]. In addition, the Council of Supply Chain Management Professionals also assigns it the role of integrator between all actors involved. The evolution of the Supply Chain has reached the point where it is considered a strategic concept within the business model of companies [2]. This strategic tool with a multidisciplinary and transversal character, affects the three strategic levels that are distinguished in the organizations. The first strategic level considers where the organization is framed and the market in which it competes. The second strategic level defines how it will compete and the functional strategy as put into practice within each area that makes up the company [3].

Based on this transversality, which is assigned to the Supply Chain, the models that can be most interesting to follow are studied. The techniques and practices provided by Lean Manufacturing are fully applicable to the Supply Chain as it is considered a network of small businesses that even become a network of small independent companies that must be coordinated in the best possible way. A Lean Supply Chain develops collaborative relationships based on mutual trust between suppliers, develops programs to be able to give them technical support, establishes open door policies and promotes participation from the first stages working as a team in the search for solutions [4].

The agile contribution to the Supply Chain allows it to respond to the continuous changes that exist in the market by establishing new competencies. It is based on a dynamic structure management providing information visibility [5]. There is also the supply chain defined as a combination of both paradigms known as leagile [6]. Most studies focus on studying the supply chain from a financial risk aspect, which has led to new studies from a social perspective, hence creating a new model [7]. In addition, it is known at the outset how many interruptions a Supply Chain will be subjected to, and knowing this, the most appropriate approach would be to try to prevent and properly manage the changes in status that the supply chain may be subjected to. Resilience offers this contribution [8].

Special mention is made of sustainability. Sustainability, green, there are different terms that refer to this concept but although there are nuances, the objective is the same. It must be understood that the Sustainable Supply Chain contemplates the creation of economic, environmental and social considerations. In other words, integrating the environment into the management of the Supply Chain [9].

For the shipbuilding sector, sustainability has a very important weight. To be able to integrate the environmental dimension in all the operations carried out within a shipyard has been a matter of vital importance in the last years. Therefore, one of the advantages of such integration in the Supply Chain would give the company a certain competitive advantage, for example with regard to improving energy efficiency [10,11].

Considering also that, the efforts lately are directed to its adaptation to the requirements marked by the Industry 4.0 not to be left behind in the market being this the only way to survive in a so competitive market in a sector. That is why it is proposed to improve management by using a tool as useful in this sense as the systematic review for companies. For companies, used to using business articles, the contribution provided by a scientific study is beneficial for decision making [12].

The origin of the term Industry 4.0 is located in Germany where Kagermann, Lukas and Wahlster base their industrialization proposal on nine high technologies in addition to establishing strategies for their implementation, which was later known as Key Enabling Technologies (KETs) [13,14]. Some authors have varied these technologies, adapting them as best suits their sector. In the shipbuilding, there have been few contributions and differences with respect to overall [15]. In our study, those described in a conceptual model developed specifically for shipbuilding will be considered [16]. These studies have even allowed defining an index that allows evaluating the state of maturity in the implantation in the company [17]. These technologies will affect the development of new products and services, the business models carried out by organizations and Supply Chain, creating competitive advantage and cost reduction. In order to generate benefits for all stakeholders, Supply Chain 4.0 could define itself as the transformation of the traditional supply chain using enabling technologies [18–20]. This is not the only new dimension of Supply Chain 4.0, it must also be supported by other new dimensions such as those related to management and capacity supports, process performance requirements and strategic results. This makes the concept of Supply Chain 4.0 an evolution of the traditional concept which, despite being in its initial period, is in the process of development [18]. This development of Supply Chain 4.0 can be considered as a transformation that includes the incorporation of technologies in addition to the human and environmental dimensions, placing sustainability at the centre of improving the company [19]. Furthermore, Industry 4.0 itself helps industries to incorporate actions for the protection and control of the environment converting supply chains into Sustainable Supply Chains 4.0. The purpose of these sustainable supply chains 4.0 is to plan and project the supply chain itself taking into account environmental and social concerns besides profits [20].

Therefore, this study aims to give an overview of the state of the art in shipbuilding adaptation for Industry 4.0. Firstly, it provides an analysis of the interest of countries around the world in key enabling technologies for industry 4.0. Secondly, it provides a review of studies focusing on making the supply chain sustainable by trying to encourage greater concern about this issue.

2. Materials and Methods

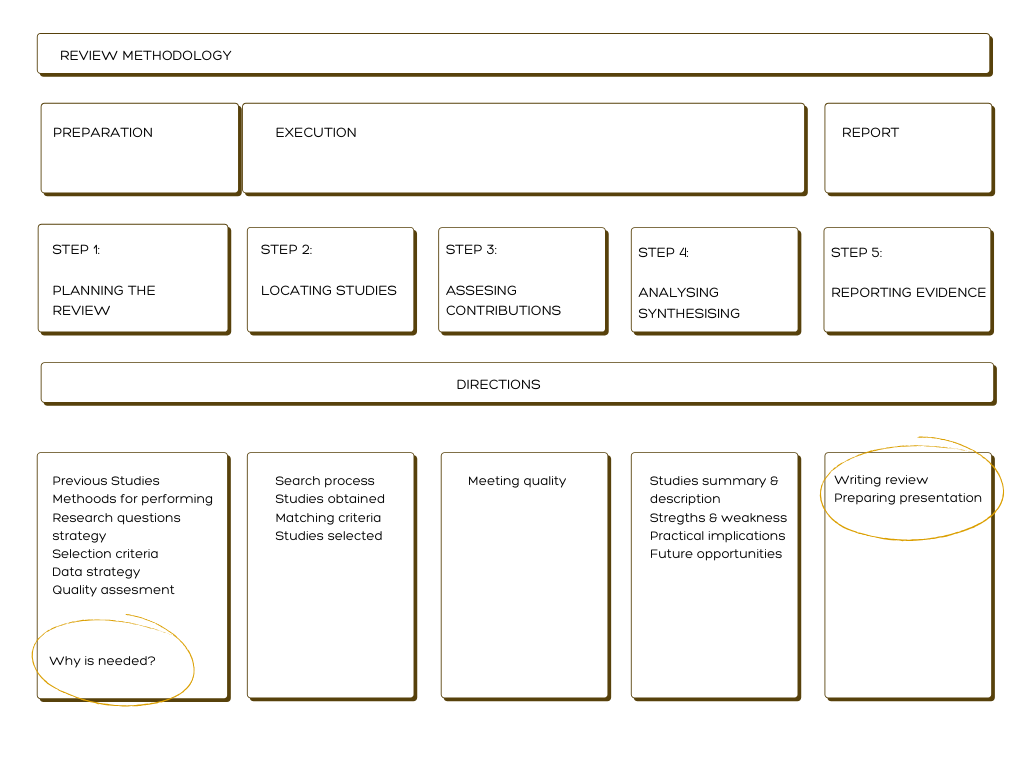

In order to carry out the proposed study, the article aims to follow a systematic review. This systematic review procedure is a tool for both advanced management scholarships and studies carried out in organizations that wish to improve their management practice. In this way, the management accomplished by companies becomes enriched by the contribution of the scientific community that goes beyond those consulted by companies, usually, journals more focused on business. This enrichment provides a clear, scientific and replicable process, it does not provide answers, it provides what is known and not known about the question –both equally important-. The five steps of the systematic review are planning the review, locating studies, assessing contributions, analyzing and synthesizing information, and reporting evidence. These steps will allow getting to know the state of the art of the studied proposal. [12].

There are different possibilities to frame a systematic review as PICO (Patient, Intervention, Comparison, Outcomes), SPICE (Stakeholder, Phenomenon of Interest Comparison Evaluation) and CIMO (Context, Intervention, Mechanism, Outcomes). The CIMO logic (Context, Intervention, Mechanism, Results) is adopted to developing the set of proposition of the research sections as being appropriate to the field of management [21]. Where we could define: Context: Shipbuilding, Intervention: Each of the KETs, Mechanisms: Categories into which the impact on the supply chain has been divided, Outcomes: effects of these interventions. Figure 1 shows the methodology followed in the article based on the reviewed literature for the systematic review [12,22].

During the preparation of the review, the need for it is identified through proposed research questions, not answered by previous studies. Subsequently, the search strategy is defined, the selection criteria for data extraction and quality assessment are established. The checklist of Preferred Information Items for Systematic Reviews and Meta-Analyses (PRISMA) [22] is used to provide for the accuracy of the review process.

sustainability; supply chain; shipbuilding; key enabling technologies; industry 4.0

Figure 1. Methodology Review. Adapted from [12,22]

Regarding the search strategy, different databases were evaluated. Starting by carrying out the search with the same argument in several databases and evaluating the answers obtained in each of them until reaching the conclusion that the Scopus database offers a greater number of contributions including those provided by the rest of the databases and the possibility of classification with different criteria including impact criteria [23]. No a priori exclusion criteria are made with respect to the time horizon of the publications since the search arguments already mark recent studies. The established search arguments allow the intersection of Marine AND each of the twelve industry 4.0 enabling technologies for the shipbuilding sector [16]. The term shipbuilding was logically the first search argument although a number of items were not generated that would allow it to be considered an appropriate indicator. Therefore, "Shipbuilding" was not considered as a search argument, it was preferable to establish exclusion criteria, extending the search term to "Marine" given in this extension, included the publications generated with Shipbuilding.

It is decided that only articles from peer-reviewed journals will be accepted, with the inclusion of a book chapter being an exception. It is the co-authors who decide whether publications are accepted or not, and they debate until agreement is reached. Most of the indexed journals used, have a high impact factor, between the first two quartiles, considered through the Journal Citation Report (JCR), an appropriate tool for the area in which the study is framed.

Each of the elements studied is collected to be classified according to the context, the intervention and the mechanism and result relationship. In this way, categories are established that allow the content of each topic to be analysed (see Appendix A). In addition, it was decided to carry out a study that would allow us to know which countries are studying which technology that would allow us to identify the development of each technology at a global level.

3. Results

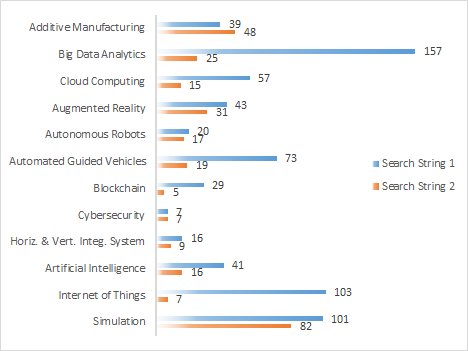

As a first contact and applying the search strategy limited to the "Supply Chain" AND each of the twelve enabling technologies with their most common nomenclatures shown in Figure 2 as "Search String 1", 680 publications are obtained. However, when the term "Marine" is included in the search string, the number of publications decreases considerably to the number of 284 publications shown in Figure 2 as "Search String 2", which we will study next.

The second search string was therefore the term "Marine" with each of the KET's and filtering with the term "Shipbuilding". "Supply Chain" being understood as a transversal and driving factor of the shipbuilding industry. At this point it can be stated that many of the publications related to shipbuilding, are made associated to the object of research directly without any relation with the term shipbuilding.

Figure 2. Search String Comparison

3.1. An overview of the results

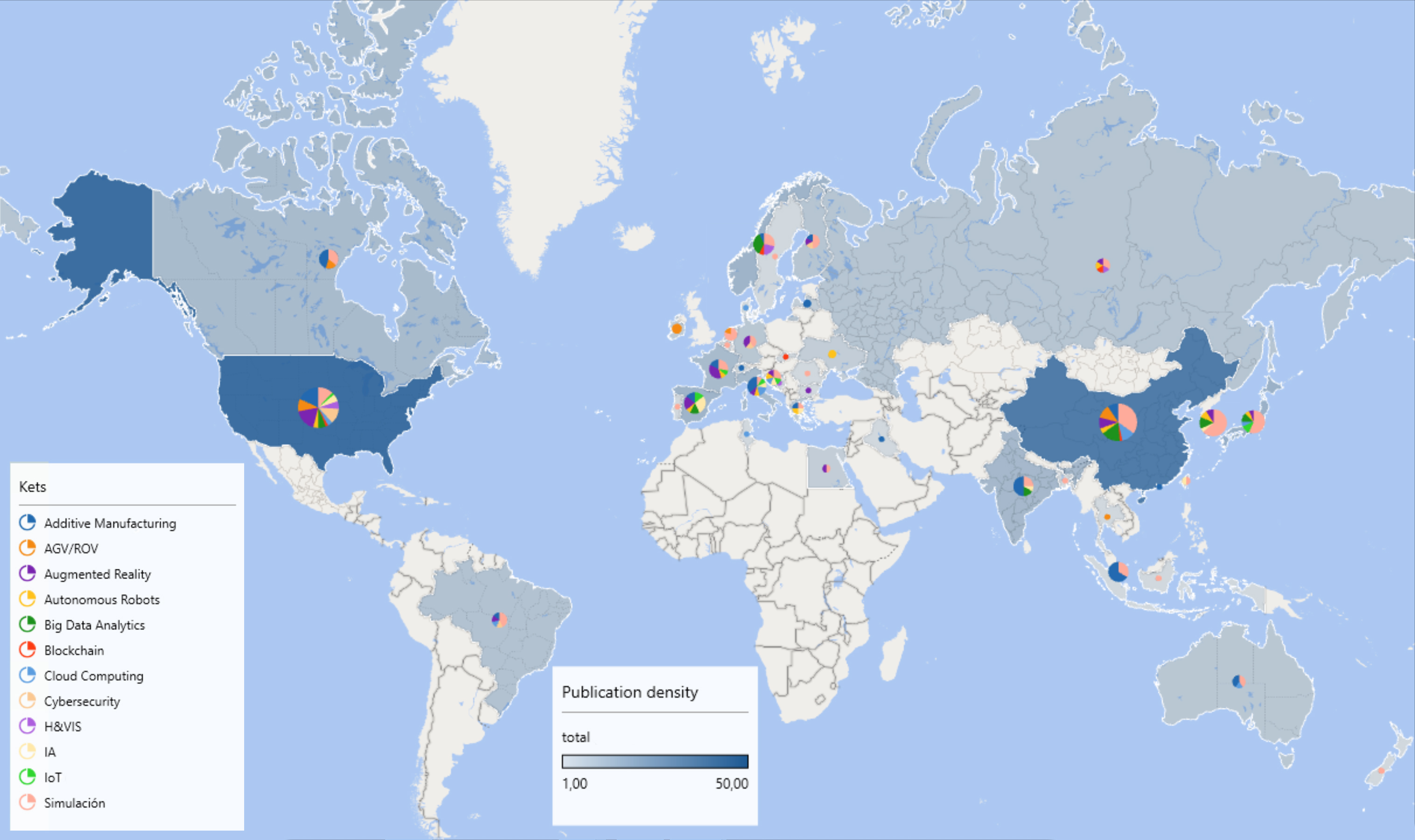

Regarding the country study, Figure 3 shows the distribution of each of the publications grouped by technology. As can be seen, the trend is that these technologies are being studied globally in a general way, however, it is possible to make a breakdown of this.

The United States is the only country with publications on all enabling technologies, with the highest number on additive manufacturing (9/50). China shows more interest in simulation (15/43) followed by Big Data (7/43). This behavior is the same for South Korea (Simulation: 14/22, Big Data: 3/22). Both have no publications are found in Cybersecurity, Horizontal and Vertical Integration Systems or Internet of Things. In the same way England and Japan also show the highest number of publications in simulation, however Norway does it in Big Data and Spain in Artificial Intelligence. India, Singapore and Canada are also opting for additive manufacturing along with Italy while France is doing so in augmented reality. The rest of the contributing countries present few publications in each of the technologies, highlighting the Netherlands that present 4/5 in simulation and on the other hand the Internet of things is only of interest to Croatia outside of the countries with the highest number of publications.

Figure 3. Worldwide Distribution of Technology Studies

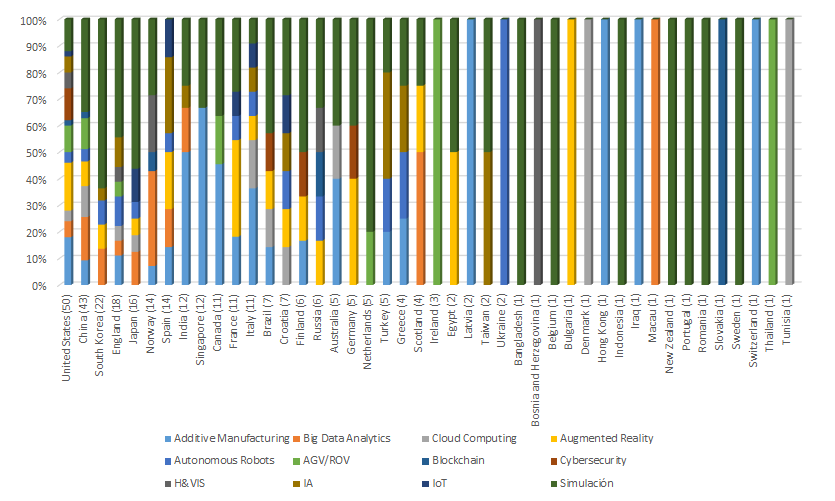

Figure 4 shows the technologies studied by the different countries, as well as the number of publications provided. As stated above, the United States is the only country that studies all the technologies, being also the one with the highest number of publications. Of the 44 countries that make up the study, 18 focus on a single technology. Most of the studies deal with simulation. However, 11 of these countries have a different interest in technologies such as Cloud Computing, Automated Guided Vehicles, Augmented Reality or Autonomous Robots.

Figure 4. Countries Classification according to the KETs studied

3.2. Analysis of the key enabling technologies

In order to carry out our study and as previously indicated in the methodology, the values of the surveys to be confronted are divided into two groups, on the one hand to experts of the sector, and on the other hand to the scientific community. For this second group, using the scientific database, asking to provide with the publications up to the moment of each of the KET's associated to the shipbuilding supply chain.

Additive manufacturing has been one of the most disruptive manufacturing technologies provided in the context of Industry 4.0. Additive manufacturing could be classified according to the material used, the way it is provided and the method used to induce consolidation. Based on this, the largest number of published papers are in the general technology group. Firstly, the application of technology for metal [24], for composite materials [25] and the simulation of processes for marine components with the intention of inserting the simulation of additive manufacturing in the large scale shipbuilding environment [26]. Also included are studies on how additive manufacturing benefits the shipbuilding supply chain [27]. Other studies focus on the manufacture of parts using direct laser forming technique for the blades of a turbine or X-band a horn with 3D printing [28] and even the refurbishment of parts outlining the benefits of laser cladding technology for in-situ marine crankshaft repairs [29]. There also articles that study the improvement of the properties of manufactured parts, on the elasticity of naval steels [30] on corrosion [31] even going as far as redesigning them for application in additive manufacturing [32].

Big Data and Analytics enables real-time decision making through stored data and its evaluation. Key to promoting operational excellence by adding value to the company. Applied to shipbuilding, publications can be grouped into four groups. In the first group are those aimed at improving processes and systems. One of the most important system improved are navigation systems, where finding solutions based on ship performance, monitoring and navigation data that improve navigation strategies [33]. Also there are processes improved focused to correlate the sound of the arc with the quality of the welding [34] or studying how the adoption of Big Data Analytics increases the production and productivity of the company, and helps it to have more control of its processes [35]. The second group is focused on its potential application motivated by growing concern about climate change [36] and to analyze the optimization of energy consumption through the transfer of energy that exists in the hull, the propeller and the main engine coming to demonstrate the efficiency reduction of energy consumption and CO2 emissions [37]. The third group focuses on the improvement of intelligent systems as is the case of a tool to analyze data obtained through IoT [38]. Moreover, other publications show guidance for implementation [39] and sector analysis [40].

Cloud Computing improves reaction times and allows to improve production systems through data based services. There are three different groups, one of which aims to improve ship behaviour in service analyzing stress, fatigue, fracture [41], their maintenance [42] and on improving the safety of ship operations developing a method of accident analysis with a bridge simulator [43]. The second group focuses on improving data management improving the detection, identification and ship tracking [44] and their application on ship routing [45]. The third one concerns environmental efficiency through marine engine failure detection to reduce marine pollution [46] and sustainable development [47].

The general application of Augmented Reality is to provide workers with information to improve decision-making and work procedures in real time. Applied to shipbuilding, three groups can be distinguished, the first one based on a general assessment of the technology applying augmented reality techniques for learning and daily management of the marine hydraulic system [48], of its impact on the sector considering how it can be applied in order to provide useful and attractive interfaces that allow workers to obtain information about their tasks and to interact with certain elements around them [49] and as a training tool [50]. A second group focuses on application to simulated naval environments [51], specifically in the fields of navigation alleviating cognitive load problems for ships [52], safety [53] and maintenance work [51]. A last group aims at improving the efficiency of systems such as the development of a methodology to match images to different fields of view of the camera and display device by means of coordinate conversion [54].

Autonomous and collaborative robots are born with the intention of tackling complex tasks and work as a team with the humans. The main activity in shipbuilding is automated welding describing the welding robots used in the prefabrication of sub-assemblies in production lines as well as a new high-speed welding process that uses two wires in the welding torch, allowing productivity to be at least doubled [55], in this case rail running mobile welding robot for the double hull ship structure [56] can be considered one of the complex tasks mentioned. In addition, there are cleaning and inspection tasks solving the huge environmental and financial problem for the marine industry of marine growth on ships [57] and those corresponding to dimensional control in particular the difficulty of measuring marine propellers [58]. The improvement of systems efficiency through simulation is again present in this technology [59], as well as the study of the technology from a general perspective.

Regarding to autonomous vehicles, it could be divided into two initial categories, one focused on improving the systems and the other on the applications derived from their use. In the first group, a distinction is made between surface vehicles. In this case, studying the propulsion topologies of ships in mechanical, electrical and hybrid, propulsion and energy supply systems and demonstrating that hybrid architectures with advanced control strategies can reduce fuel consumption and emissions, improve noise, maintainability, manoeuvrability and comfort [60] and underwater vehicles, integrating the obstacle detection and analysis capabilities [61]. Within the applications of their use, there are autonomous vehicles dedicated to Inspection-Maintenance-Repair, so they are called IMR vehicles. Therefore, their use can be more focused on inspection incorporating the Smart Loop Management System (STMS)[62], others on maintenance [63] and on repair which allows engineers and marine operators to assess the risks associated with certain tasks, such as pipeline repair or the installation of hoses, in real time using ROV (Remotely Operated Vehicle) simulation technology. A very useful system to give a quick response [64].

The Blockchain technology allows the division into three groups, one formed by applications of its use in the sector saving the industry from intermediaries, and rebuilding all business models [65]. A second group is made up of publications aimed at strengthening security where it is stated that the Blockchain technology allows to extract the information of the contract directly, guaranteeing the reliability of the system, it also guarantees its authenticity and security building a more ecological environment [66]. The last group is devoted to the search for energy efficiency studied from the perspective of cryptocurrences, due to the algorithms used developing an increase of energy consumption, being necessary to develop new algorithms [67].

With respect to the category of horizontal and vertical integration systems, the majority of publications address vertical integration. These publications aimed at the development of new products such as the developments carried out for the aero-derivative gas turbine [68]. Also it is used as an indicator of productivity in the sector developing strategies that allow it to improve costs, quality indices, flexibility and delivery time, among others [69], and are valued as an alternative in management by supporting efforts aligned with the supply chain and commercial strategy [70]. Other publications consider it to be positive compared to the transfer of information to foreign shipyards in such a positive way in an increasingly globalized world [71] and compare it to the alternatives of outsourcing [72].

The groups in which we divide Cybersecurity technology are focused on reducing environmental risks, so essential today that optical communications and quantum encryption are included to ensure the operations of the safest ships and to guarantee the safety of the oceans [73]. A second group studies the safety of the systems on- board by developing virtual laboratories to characterize and identify security events in maritime control systems [74]. Of course, there is a group aimed at supporting other technologies as is the case with IoT. Considering that as more devices are brought online, safety must be a major concern for users and operators. It is established that embedded applications should be built on a secure platform that can extend security features to the applications it houses [75]. And a group aimed at general considerations of the implementation of the same [76].

Artificial intelligence is present in different aspects in the shipbuilding sector although it was foreseeable that most of the publications would be on the development of improvements to navigation and control systems as algorithms that help route planning to avoid ship collisions [77]. In general, the applications that the use of the technology could have in the sector from the design stages by studying the main dimensions, hull shape selection, stability or propulsion, through the use of artificial neural networks [78]. It also has a group of publications focused on decision support [79], energy efficiency and even process optimization [80] such as the formation of certain parts of the hull by heating or mechanical forming by developing an automatic line heat forming process based on the intensive application of numerical simulation and artificial intelligence [81].

The Industrial Internet of Things (IoT) that allows field devices to communicating with each other and with the control systems with real-time responses establishes three groups. The first group includes the linkage it has with other technologies as explained above with Cybersecurity [82]. The second group includes the use of technology to support the design stage of vessels allowing for increased performance and value of the ship although there are challenges to be considered in ensuring that relevant, accurate and reliable data are articulated to stakeholders [83]. The third group is composed of publications that reflect the integration of processes and systems [84].

Within Simulation, we distinguish depending on the type in, simulation by finite elements, simulation of discrete events, SPH, CFD. In the six established groups, we find studies with the different types of simulation previously identified. The first group contains the new propulsion systems in which electronic propulsion systems are established [85] or on the effects that the hydrodynamic efficiency of the propellers has [86]. Both are physical simulations. The second group studies the ship structure and services with respect to crack propagation behaviour [87] or residual stress analysis [88], finite element simulations. There are publications focused on spill prevention [89] and risk analysis due to high pressure of fuel gas in tanks [90]. The third group is dedicated to welding which is so important in the shipbuilding sector [91], both from the perspective of different positions [92] and deformations in assembly [93].

The following group [94] covers the study of navigation systems and a fifth group [95] covers the supply chain. The sixth group includes planning [96], production control [97] and optimisation [98]. Finally, an important number of publications are dedicated to the previous stages of shipbuilding such as ship design as a tool for optimization [99] and analysis [100].

3.3. Evaluation of the key enabling technologies according to some basic categories

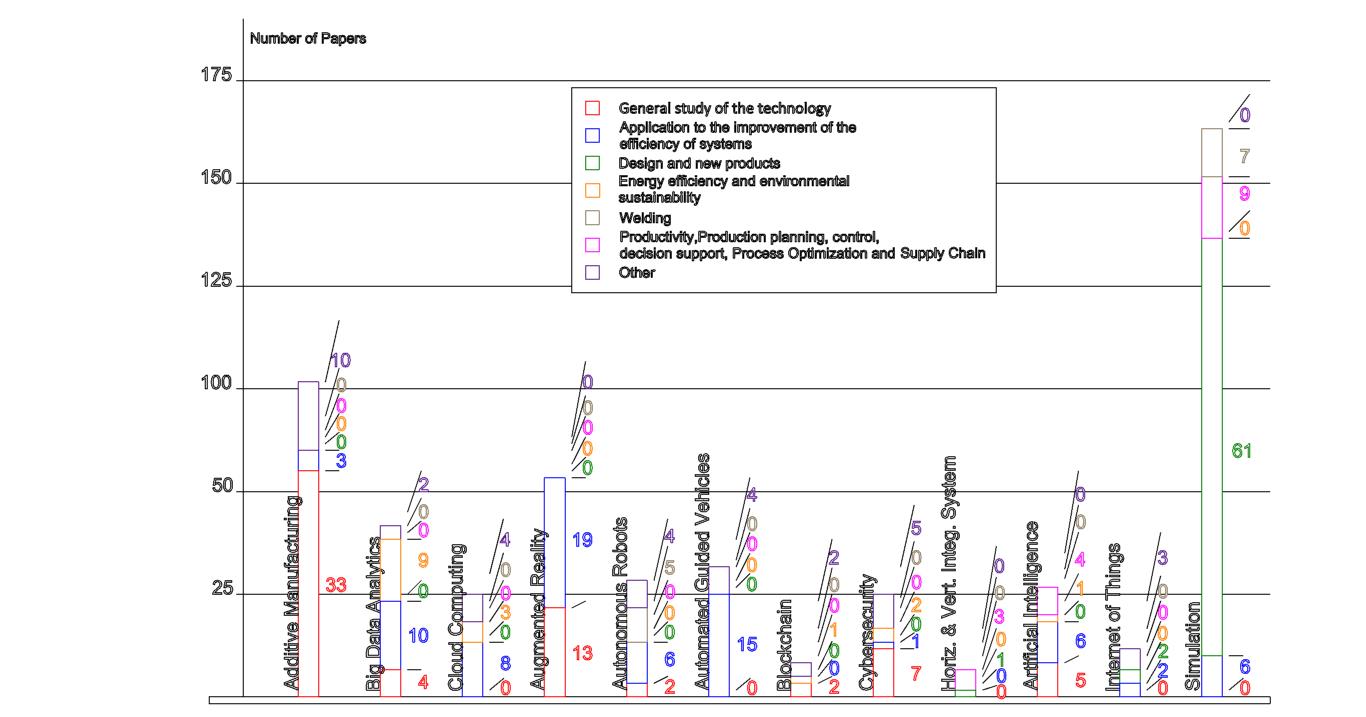

From the twelve industry 4.0 enabling technologies specific to the shipbuilding sector, the categories that are common to most of them are identified. One of the common categories focuses on the general study of technology in its application to the sector (66 studies). Another common approach with a larger number of articles focuses on the application of systems improvement and efficiency, especially for navigation systems (66 studies). Another category discussed was dedicated to design, including within this category both tasks aimed at ship design and the design of new related products (64 studies). and the other grouping subjects ranging from productivity, production control, decision support, process optimisation and the supply chain (16 studies). There is a specific category dedicated to one of the most relevant activities in the sector as it is the welding distributed in only two technologies: Autonomous Robots and Simulation. (12 studies). This leaves other non-common categories with less than 10 studies (44 studies).

Finally, it is followed by two categories with the same number of studies, one dedicated to studying the effects on energy efficiency and environmental sustainability (16 studies). This is the indicator offered by the study of the trend followed by the scientific community in its approach to supply chain sustainability. It can be seen that less than 6% of publications are of concern to researchers in the sector.

Not all KET's address the category of environment, called Energy Efficiency and Environmental Sustainability. Only five of the twelve KET's deal with studies related to Sustainability. The weight falls on Big Data Analytics with a total of 9 of the 16 articles counted, the rest being distributed among Cloud Computing, Blockchain, Cybersecurity and Artificial Intelligence. It is very striking that the rest of the technologies do not present any interest in this field when it should concern all technologies completely for being one of the key points of the 4.0 industry. Figure 5 shows the seven categories addressed by each KET.

Figure 5. KETs' concerns distributed in the six basic categories

This therefore highlights the lack of integration of the environment into supply chain management, i.e. the economic, environmental and social considerations necessary for the understanding of a Sustainable Supply Chain are not taken into account. There is still a long way to go to implement sustainable practices and techniques for a sector for which it carries considerable weight, such as Shipbuilding. Information that should be taken into account both by the interested scientific community and by the companies of the sector, which besides being an imperative need, could be reversed as a competitive advantage.

4. Conclusions

The supply chain has been considered today as a strategic tool because of its transversality, affecting all levels within an organization. Using it also as a trainer to make the company more sustainable, is one of the tasks that the study has carried out. Sustainability should be studied as a basic requirement in all sectors but it is more important for the shipbuilding industry. Such sustainability, carried out through the Supply Chain, will make the techniques and practices used applicable to different companies, thus contributing to extend an appropriate and extensible sustainability network. Industry 4.0 brings to the industry the need to implement new technologies that allows the industry to be updated improving sustainability and benefits. This transformation also affects the Supply Chain in which, in addition to using new technologies, it considers the human and environmental dimensions. This is why the supply chain is now considered Sustainable Supply Chain 4.0.

Firstly, the enabling technologies of the industry 4.0 adapted to the shipbuilding sector have been studied. Studies of each one of them belonging to the sector have been located and have been grouped by categories, giving a clear vision of which technologies are being studied for the longest time and which, it could be interpreted, as the sector has not yet shown enough interest. Additionally, it has been studied at a global level, which countries are researching these technologies and which are not, providing a clear vision of the major powers such as the United States and Asia, which are choosing to advance in technologies such as Additive Manufacturing and Simulation, which are experiencing a peak.

The proposed categories have been measured in the literature and could serve as a starting point to study the implementation of Supply Chain model practices in shipbuilding. However, the approach of the research method carried out, allows to have a general vision of what the scientific community is studying and which are the reference places to be available to the companies that decide to consult and improve their practices. One of the proposed categories is related to the environment, sustainability and energy efficiency as a key point for the advancement of technologies and coincides with one of the lines of interest of the industry 4.0. However, it has been detected that not all KETs show concern in their research for this key category in which one should emphasize above all, the Big Data Analysis which presents studies focused on climate change and emissions reductions. Cloud Computing follows with concern on the subject, presenting articles focused on engine failure detection to reduce marine pollution and to reduce energy costs. Blockchain also shows interest in developing new algorithms that take into account this dimension. Cybersecurity contemplates the security of ships, thus guaranteeing the oceans in the same way that Artificial Intelligence does.

With regard to Simulation technology, is important to add that although no direct reference is made, its indirect involvement with sustainability should be acknowledged. Moreover, it should also be noted that additive manufacturing does not have any articles either, despite the fact that it is considered to be a clean technology in its own right, it is an intrinsic property of the technology itself. However, this means that there is not enough attention to the subject and companies should provide the means to expand research in this area, so that they can implement sustainable policies at all levels, taking advantage of the transversality offered by the supply chain.

Author Contributions: M.R.-P. and M.B. conceptualized the paper. M.B. and F.J.A.F. approved the experimental procedure; M.R.-P. and J.S. analyzed the data; M.R.-P. wrote the paper; M.B. and J.S. revised the paper; F.J.A.F. supervised the paper.

Funding: “This research received no external funding”

Acknowledgments: Navantia S.A. S.M.E. and University of Cadiz (UCA) supported this work.

Conflicts of Interest: “The authors declare no conflict of interest.”

Appendix A

|

KET |

Interventions |

Author(s) |

|

Additive Manufacturing |

Improvement techniques for the minimization of defects |

[1] |

|

|

General study of the technology |

[2,3,12–21,4,22–24,5–11] |

|

|

Parts manufacturing and repair |

[25–34] |

|

|

Parts property improvement |

[35–43] |

|

|

Redesign for application in additive manufacturing |

[44–46] |

|

Big Data Analytics |

Process and system improvement |

[47–56] |

|

|

Environmental studies |

[57–65] |

|

|

Smart Systems |

[66,67] |

|

|

General study of the technology |

[67–70] |

|

Cloud Computing |

Performance improvement in service |

[71–74] |

|

|

Control system improvement |

[75–82] |

|

|

Energetic efficiency and environmental sustainability |

[81–83] |

|

Augmented Reality |

Learning and the influence of technology on the sector |

[69,84,93–95,85–92] |

|

|

Simulated naval environments applied to navigation, safety and maintenance |

[96,97,106–111,98–105] |

|

|

Application to the improvement of the efficiency of systems, mainly navigation |

[112–114] |

|

Autonomous Robots |

Welding |

[115–119] |

|

|

General study of the technology |

[69,92] |

|

|

Improvement of system efficiency |

[120,121] |

|

|

Cleaning, inspection and maintenance work |

[122–125] |

|

|

Unmanned vehicles |

[126–129] |

|

Automated Guided Vehicle |

System improvement |

[130–134] |

|

Repairs, maintenance and inspection |

[135–144] |

|

|

|

Vehicle systems improvement |

[145–148] |

|

Blockchain |

Applications of its use |

[149,150] |

|

|

Strengthening Security |

[151,152] |

|

|

Energetic efficiency |

[153] |

|

Cybersecurity |

General considerations in the implementation of the technology |

[152,154–159] |

|

|

Environmental risk reduction |

[160,161] |

|

|

Improving the safety of on-board systems |

[162] |

|

Horiz. & Vertical Integration System |

New product development |

[163] |

|

Impact on productivity |

[164–166] |

|

|

|

Alternatives Study |

[167] |

|

|

Encouraging Transfer |

[168] |

|

|

Outsourcing Comparison |

[169–171] |

|

Artificial Intelligence |

Navigation and control systems improvement |

[172–177] |

|

|

General study of the technology |

[69,178–181] |

|

|

Decision Support |

[182,183] |

|

|

Energy efficiency |

[62] |

|

|

Process optimization |

[184,185] |

|

Internet of Things |

Linking to other technologies |

[84,181,186] |

|

|

Support to the design of ships |

[180,187] |

|

|

Process and system integration |

[92,188] |

|

Simulation |

New propulsion systems |

[189–191] |

|

|

Structure and services ship study |

[192,193,202–211,194,212–221,195,222–231,196,232–240,197–201] |

|

|

Welding |

[116,241–246] |

|

|

Navigation systems study |

[247–249] |

|

|

Supply Chain |

[250–252] |

|

|

Production planning and control |

[253–258] |

|

|

Design |

[67,259,268,269,260–267] |

References

1. Oliver R, Webber MD. Supply-chain management: logistics catches up with strategy. London: Allen & Hamilton, Inc.; 1982.

2. SCM Definitions and Glossary of Terms [Internet]. [cited 2020 Jun 1]. Available from: https://cscmp.org/imis0/CSCMP/Educate/SCM_Definitions_and_Glossary_of_Terms/CSCMP/Educate/SCM_Definitions_and_Glossary_of_Terms.aspx?hkey=60879588-f65f-4ab5-8c4b-6878815ef921

3. Porter M, Porter M, Kramer M, Kramer M. Strategy and Society: The Link Between Competitive Advantage and Corporate Social Responsibility (HBR OnPoint Enhanced Edition). Havard Bus Rev. 2007;(December).

4. Martínez-Jurado PJ, Moyano-Fuentes J. Lean management, supply chain management and sustainability: A literature review. J Clean Prod [Internet]. 2014;85:134–50. Available from: http://dx.doi.org/10.1016/j.jclepro.2013.09.042

5. Christopher M. The Agile Supply Chain Competing in Volatile Markets. Ind Mark Manag. 2000;29(1):37–44.

6. Aravind Raj S, Jayakrishna K, Vimal KEK. Modelling the metrics of leagile supply chain and leagility evaluation. Int J Agil Syst Manag. 2018;11(2):179–202.

7. Cunha L, Ceryno P, Leiras A. Social supply chain risk management: A taxonomy, a framework and a research agenda. Vol. 220, Journal of Cleaner Production. Elsevier Ltd; 2019. p. 1101–10.

8. Carvalho H, Duarte S, Machado VC. Lean, agile, resilient and green: Divergencies and synergies. Int J Lean Six Sigma. 2011;2(2):151–79.

9. Srivastava SK. Green supply-chain management: A state-of-the-art literature review. Int J Manag Rev. 2007;9(1):53–80.

10. Mello MH, Strandhagen JO. Supply chain management in the shipbuilding industry: Challenges and perspectives. Proc Inst Mech Eng Part M J Eng Marit Environ. 2011;225(3):261–70.

11. Xie G, Yue W, Wang S. Energy efficiency decision and selection of main engines in a sustainable shipbuilding supply chain. Transp Res Part D [Internet]. 2017;53:290–305. Available from: http://dx.doi.org/10.1016/j.trd.2017.04.022

12. Briner RB, Denyer D, Rousseau D. Systematic Review and Evidence Synthesis as a Practice and Scholarship Tool. In: Press OU, editor. The Oxford Handbook of Evedence-Based Management. New York: Oxford University Press; 2012. p. 112–29.

13. Kagermann, Henning, Lukas W-D, Wahlster W. Industrie 4 0 Mit dem Internet der Dinge auf dem Weg zur vierten industriellen Revolution 2.pdf [Internet]. Meinung. 2011. Available from: http://www.wolfgang-wahlster.de/wordpress/wp-content/uploads/Industrie_4_0_Mit_dem_Internet_der_Dinge_auf_dem_Weg_zur_vierten_industriellen_Revolution_2.pdf

14. Kagermann H, Wahlster W, Helbig J. Securing the future of German manufacturing industry: Recommendations for implementing the strategic initiative INDUSTRIE 4.0. Final Rep Ind 40 Work Gr. 2013;(April):1–84.

15. Criado García-Legaz A, Merino Rego C. Una visión del astillero 4.0 de navantia. Revista General de Marina. 2018;275(Apoyo Logístico 4.0):249–81.

16. Ramírez-Peña M, Sánchez Sotano AJ, Pérez-Fernández V, Abad Fraga FJ., Moises B. Achieving a sustainable shipbuilding supply chain under I4.0 perspective. J Clean Prod. 2020;244:2019.

17. Ramirez-Peña M, Abad Fraga FJ, Sánchez Sotano AJ, Batista M. Shipbuilding 4.0 Index Approaching Supply Chain. Materials (Basel). 2019;12(24):4129.

18. Frederico GF, Garza-Reyes JA, Anosike A, Kumar V. Supply Chain 4.0: concepts, maturity and research agenda. Supply Chain Manag. 2019;25(2):262–82.

19. Dossou PE. Impact of Sustainability on the supply chain 4.0 performance. Procedia Manuf. 2018;17:452–9.

20. Daú G, Scavarda A, Scavarda LF, Portugal VJT. The healthcare sustainable supply chain 4.0: The circular economy transition conceptual framework with the corporate social responsibility mirror. Sustain. 2019;11(12).

21. Denyer D, Tranfield D, Aken JE Van, Denyer D, Tranfield D, Aken JE Van. Developing Design Propositions through Research Synthesis. Organ Stud. 2008;29(393).

22. Moher D, Liberati A, Tetzlaff J, Altman DG, Group TP. Preferred Reporting Items for Systematic Reviews and Meta-Analyses : The PRISMA Statement. PLoS Med. 2009;6(7).

23. Aghaei Chadegani A, Salehi H, Md Yunus MM, Farhadi H, Fooladi M, Farhadi M, et al. A comparison between two main academic literature collections: Web of science and scopus databases. Asian Soc Sci. 2013;9(5):18–26.

24. Duda T, Raghavan LV. 3D Metal Printing Technology. In: IFAC-PapersOnLine [Internet]. Elsevier B.V.; 2016. p. 103–10. Available from: http://dx.doi.org/10.1016/j.ifacol.2016.11.111

25. Lu Z, Cao J, Song Z, Li D, Lu B. Research progress of ceramic matrix composite parts based on additive manufacturing technology. Virtual Phys Prototyp [Internet]. 2019;14(4):333–48. Available from: https://doi.org/10.1080/17452759.2019.1607759

26. Fisher CR, Vail CE. Computational Simulation of an Additively Manufactured Marine Component. J Mater Eng Perform [Internet]. 2019;28(2):627–32. Available from: https://doi.org/10.1007/s11665-018-3603-4

27. Grace R. U.S. Marines: Seeking a Few Good Co-Creators: Leveraging open-source product development, the Marines are using digital technology and 3D printing to enhance their supply chain. In: Plastics Engineering. 2019. p. 18–23.

28. Lu ZL, Zhang AF, Tong ZQ, Yang XH, Li DC, Lu BH. Fabricating the steam turbine blade by direct laser forming. Mater Manuf Process. 2011;26(7):879–85.

29. Torims T, Pikurs G, Ratkus A, Logins A, Vilcans J, Sklariks S. Development of technological equipment to laboratory test in-situ laser cladding for marine engine crankshaft renovation. In: 25th DAAAM International Symposium on Intelligent Manufacturing and Automation, DAAAM [Internet]. Elsevier B.V.; 2015. p. 559–68. Available from: http://dx.doi.org/10.1016/j.proeng.2015.01.405

30. Wu W, Tor SB, Merchant AA. Tensile properties of ASTM A131 EH36 shipbuilding steel processed by selective laser melting. In: Proceedings of the International Conference on Progress in Additive Manufacturing. 2018. p. 684–9.

31. Xing X, Duan X, Jiang T, Wang J, Jiang F. Ultrasonic peening treatment used to improve stress corrosion resistance of AlSi10Mg components fabricated using selective laser melting. Metals (Basel). 2019;9(1).

32. Turner AJ, Al Rifaie M, Mian A, Srinivasan R. Low-Velocity Impact Behavior of Sandwich Structures with Additively Manufactured Polymer Lattice Cores. J Mater Eng Perform [Internet]. 2018;27(5):2505–12. Available from: https://doi.org/10.1007/s11665-018-3322-x

33. Perera LP, Mo B. Machine intelligence for energy efficient ships: A big data solution. In: Proceedings of 3rd International Conference on Maritime Technology and Engineering, MARTECH 2016. 2016. p. 143–50.

34. Sumesh A, Rameshkumar K, Mohandas K, Babu RS. Use of machine learning algorithms for weld quality monitoring using acoustic signature. In: Procedia Computer Science [Internet]. Elsevier Masson SAS; 2015. p. 316–22. Available from: http://dx.doi.org/10.1016/j.procs.2015.04.042

35. Wang H, Osen OL, Li G, Li W, Dai HN, Zeng W. Big data and industrial Internet of Things for the maritime industry in Northwestern Norway. In: IEEE Region 10 Annual International Conference, Proceedings/TENCON. 2016.

36. Xu G, Shi Y, Sun X, Shen W. Internet of things in marine environment monitoring: A review. Sensors (Switzerland). 2019;19(7):1–21.

37. Yan X, Wang K, Yuan Y, Jiang X, Negenborn RR. Energy-efficient shipping: An application of big data analysis for optimizing engine speed of inland ships considering multiple environmental factors. Ocean Eng. 2018;169:457–68.

38. Muthuramalingam S, Bharathi A, Rakesh kumar S, Gayathri N, Sathiyaraj R, Balamurugan B. Iot based intelligent transportation system (iot-its) for global perspective: a case study. Intell Syst Ref Libr. 2019;154:279–300.

39. Morais D, Waldie M, Roberts P, David P. How to implement tech in shipbuilding: Charting the course to success. SNAME Marit Conv SMC 2018. 2018;2020.

40. Nikolopoulos L, Boulougouris E. A methodology for the holistic, simulation driven ship design optimization under uncertainty. In: Conference: International Marine Design Conference. 2018. p. 227–44.

41. Ayyub BM, Stambaugh KA, McAllister TA, De Souza GF, Webb D. Structural life expectancy of marine vessels: Ultimate strength, corrosion, fatigue, fracture, and systems. ASCE-ASME J Risk Uncertain Eng Syst Part B Mech Eng. 2015;1(1):011001/1-13.

42. Mihanović L, Ristov P, Belamarić G. Use of new information technologies in the maintenance of ship systems. Sci J Marit Res. 2016;30(1):38–44.

43. Nishizaki C, Itoh H, Yoshimura K, Hikida K, Mitomo N. Development of a method for marine accident analysis with bridge simulator. In: Proceedings of 2011 6th International Conference on System of Systems Engineering: SoSE in Cloud Computing, Smart Grid, and Cyber Security, SoSE 2011. 2011. p. 31–6.

44. Bannister NP, Neyland DL. Maritime domain awareness with commercially accessible electro-optical sensors in space. Int J Remote Sens. 2015;36(1):211–43.

45. Zhang S kai, Shi G you, Liu Z jiang, Zhao Z wei, Wu Z lin. Data-driven based automatic maritime routing from massive AIS trajectories in the face of disparity. Ocean Eng [Internet]. 2018;155(1550):240–50. Available from: https://doi.org/10.1016/j.oceaneng.2018.02.060

46. Carbone R, Montella R, Narducci F, Petrosino A. DeepNautilus: A Deep Learning Based System for Nautical Engines’ Live Vibration Processing. In: Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics). Springer Verlag; 2019. p. 120–31.

47. Ju D, Shen B. Sustainable development of marine economy guided by knowledge cloud services. In: 2nd International Conference on Networking and Distributed Computing, ICNDC 2011. 2011. p. 235–9.

48. He C, Jia X, Liu D, Liu Y. Study of augmented reality technology applied in the field of marine engineering. WIT Trans Modelling Simul. 2014;60:585–92.

49. Blanco-Novoa O, Fernandez-Carames TM, Fraga-Lamas P, Vilar-Montesinos MA. A Practical Evaluation of Commercial Industrial Augmented Reality Systems in an Industry 4.0 Shipyard. IEEE Access. 2018;6(c):8201–18.

50. Rowen A, Grabowski M, Rancy JP, Crane A. Impacts of Wearable Augmented Reality Displays on operator performance, Situation Awareness, and communication in safety-critical systems. Appl Ergon. 2019 Oct 1;80:17–27.

51. Shang L, Chen J, Gao Q, Hu F. Research of virtual simulation experiment platform for marine auxiliary machinery based on VR/AR. In: ACM International Conference Proceeding Series. 2019. p. 2020.

52. Morgère JC, Diguet JP, Laurent J. Electronic navigational chart generator for a marine mobile augmented reality system. 2014 Ocean - St John’s, Ocean 2014. 2015;

53. Grabowski M, Rowen A, Rancy JP. Evaluation of wearable immersive augmented reality technology in safety-critical systems. Saf Sci. 2018 Mar 1;103:23–32.

54. Lee JM, Lee KH, Kim DS, Nam BW, Li R. Study on alignment of navigational information through transparent window. In: Towards Green Marine Technology and Transport. 2015. p. 741–4.

55. Rooks B. Robot welding in shipbuilding. In: Industrial Robot. 1997. p. 413–7.

56. Kim J, Lee K-Y, Kim T, Lee D, Lee S, Lim C, et al. Rail Running Mobile Welding Robot ‘RRX3’ for Double Hull Ship Structure. In: 17th World Congress The International Federation of Automatic Control [Internet]. IFAC; 2008. p. 4292–7. Available from: http://dx.doi.org/10.3182/20080706-5-KR-1001.00722

57. Larsen KR. Autonomous robot cleans ship hulls and inspects for corrosion. Mater Perform. 2009;48(1):17–9.

58. Cavada J, Fadón F. Robotic solutions applied to production and measurement of marine propellers. In: ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis ESDA2012. Nantes; 2012. p. 1–7.

59. Zhang Y, Hu M, Chen WH, Chen C, Zheng S. Structure synthesis & simulation analysis of the repeated foldable waste disposal robot of the marine. In: 2016 IEEE International Conference on Robotics and Biomimetics, ROBIO 2016. 2016. p. 242–7.

60. Geertsma RD, Negenborn RR, Visser K, Hopman JJ. Design and control of hybrid power and propulsion systems for smart ships: A review of developments. Appl Energy [Internet]. 2017;194:30–54. Available from: http://dx.doi.org/10.1016/j.apenergy.2017.02.060

61. Sivčev S, Rossi M, Coleman J, Omerdić E, Dooly G, Toal D. Collision detection for underwater ROV manipulator systems. Sensors (Switzerland). 2018;18(4).

62. Trslic P, Rossi M, Sivcev S, Dooly G, Coleman J, Omerdic E, et al. Long term, inspection class ROV deployment approach for remote monitoring and inspection. In: OCEANS 2018 MTS/IEEE Charleston, OCEAN 2018. 2019.

63. Fahrni L, Thies PR, Johanning L, Cowles J. Scope and feasibility of autonomous robotic subsea intervention systems for offshore inspection, maintenance and repair. In: Advances in Renewable Energies Offshore - Proceedings of the 3rd International Conference on Renewable Energies Offshore, RENEW 2018. 2019. p. 771–8.

64. Steinke DM, Nicoll RS, Roy AR. Real-time finite element analysis of a remotely operated pipeline repair system. In: Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering - OMAE. 2013.

65. Gausdal AH, Czachorowski K V., Solesvik MZ. Applying Blockchain technology: Evidence from Norwegian companies. Sustain. 2018;10(6):1–16.

66. Yang Z, Xie W, Huang L, Wei Z. Marine data security based on blockchain technology. In: IOP Conference Series: Materials Science and Engineering. 2018.

67. Koštál K, Krupa T, Gembec M, Vereš I, Ries M, Kotuliak I. On transition between PoW and PoS. In: International Symposium Electronics in Marine. 2018. p. 207–10.

68. Sy A A, Moritz RR. Rolls-royce power generation current products and new product plans. In: Proceedings of the ASME Turbo Expo. 2001. p. 1–8.

69. Lamb T, Hellesoy A. A shipbuilding productivity predictor. J Sh Prod. 2002;18(2):79–85.

70. Haartveit DEG, Semini M., Alfnes E. Integration alternatives for ship designers and shipyards. In: IFIP Advances in Information and Communication Technology [Internet]. 2012. p. 620–7. Available from: http://www.scopus.com/inward/record.url?eid=2-s2.0-84870715085&partnerID=tZOtx3y1

71. Grabot B, Vallespir B, Gomes S, Bouras A, Kiritsis D. Advances in Production Management Systems: Innovative and Knowledge-Based Production Management in a Global-Local World: IFIP WG 5.7 International Conference, APMS 2014, Ajaccio, France, September 20-24, 2014, Proceedings, Part I. IFIP Adv Inf Commun Technol. 2014;438(PART 1):2020.

72. Sergio E, Senada S. The make-or-buy decision in the Croatian shipbuilding industry: A transaction cost economics approach. South East Eur J Econ Bus. 2009;4(1):81–105.

73. McGillivary P. Why maritime cybersecurity is an ocean policy priority and how it can be addressed. Mar Technol Soc J. 2018;52(5):44–57.

74. Selvam N, Scott R, Dewitt C. Use of a Cybersecurity Laboratory in Support of the Virtual Vessel Concept to Increase Safety Onboard Marine and Offshore Assets. In: Proceedings of the Annual Offshore Technology Conference. 2017. p. 2299–306.

75. Chen J. How to choose the right computing platform for IIoT. ECN Electron Compon News. 2017;61(3):18–20.

76. Silverajan B, Vistiaho P. Enabling cybersecurity incident reporting and coordinated handling for maritime sector. In: Proceedings - 2019 14th Asia Joint Conference on Information Security, AsiaJCIS 2019. IEEE; 2019. p. 88–95.

77. Tsou MC, Kao SL, Su CM. Decision support from genetic algorithms for ship collision avoidance route planning and alerts. J Navig. 2010;63(1):167–82.

78. de Góngora R. Practical use cases of artificial intelligence in the shipdesign stage. In: RINA, Royal Institution of Naval Architects - 19th International Conference on Computer Applications in Shipbuilding, ICCAS 2019. 2019. p. 2020.

79. Cebi S, Celik M. Ship machinery installation based on fuzzy information axiom: The case of compressed air system. In: 8th International FLINS Conference. 2008. p. 1093–8.

80. Park SW, Roh M Il, Oh MJ, Kim SH, Lee WJ, Kim I Il, et al. Estimation model of energy efficiency operational indicator using public data based on big data technology. In: Proceedings of the International Offshore and Polar Engineering Conference. 2018. p. 894–7.

81. Grela JS, Otero J, Guijarro-Berdiñas B, Rego-Fernández D. Optimizing the ship constructions by automatic line heating forming process based in numerical simulation and artificial intelligence. Mar 2015 - Comput Methods Mar Eng VI. 2015;218–29.

82. Mikulić A, Parunov J. A review of artificial intelligence applications in ship structures. In: Trends in the Analysis and Design of Marine Structures - Proceedings of the 7th International Conference on Marine Structures, MARSTRUCT 2019. 2019. p. 515–23.

83. Sullivan Brendan P, Monica R, Claudio S, Rossella L, Lucia R, Sergio T. Lincoln integrated solution supporting the design of specialized connected vessels. In: Proceedings of the Summer School Francesco Turco. 2018. p. 250–6.

84. Hiekata K. Advanced Information Systems for Ship Design, Construction and Operation. J Japan Soc Precis Eng. 2017;83(1):26–9.

85. Ericsen T. The ship power electronic revolution: Issues and answers. In: Record of Conference Papers - Annual Petroleum and Chemical Industry Conference. 2008.

86. Ghassemi H, Yamasaki H, Ikehata M. An investigation of wake model and its effect on the hydrodynamic performance of propellers by using a surface panel method. Nihon Zosen Gakkai Ronbunshu/Journal Soc Nav Archit Japan. 1995;178:83–91.

87. Okawa T, Sumi Y. A computational approach for fatigue crack propagation in ship structures under random sequence of clustered loading. J Mar Sci Technol. 2008;13(4):416–27.

88. Liu B, Villavicencio R, Guedes Soares C. Experimental and numerical analysis of residual stresses and strains induced during cold bending of thick steel plates. Mar Struct [Internet]. 2018;57(September 2017):121–32. Available from: http://dx.doi.org/10.1016/j.marstruc.2017.10.005

89. Lee D, Choi J, Park BJ, Kang HJ, Lim S. Study of damage safety assessment for a ship carrying radioactive waste. Int J Nav Archit Ocean Eng. 2012;4(2):141–50.

90. Yoon JY, Park SI, Lee JB, Kwon S, Hwang Y. A preliminary investigation on the risk arising from the use of HP FGS system in LNGC by analyzing risk contributors comparatively. Proc Int Conf Offshore Mech Arct Eng - OMAE. 2016;3:2020.

91. Lee J, Choi W, Kang M, Chung H. Variation simulation and diagnosis model of compliant block assembly considering welding deformation. J Sh Prod Des. 2019;35(3):263–72.

92. Song L, MaoM Y, Xiang Z, Chen Z, Bin L. A simulation on the effect of welding sequences for T-joints under single V groove. Manuf Technol. 2018;18(3):504–9.

93. Lee J, Choi W, Kang M, Chung H. Tolerance analysis and diagnosis model of compliant block assembly considering welding deformation. Trans - Soc Nav Archit Mar Eng. 2016;124:154–64.

94. Tarovik O V., Topaj A, Bakharev AA, Kosorotov A V., Krestyantsev AB, Kondratenko AA. Multidisciplinary approach to design and analysis of arctic marine transport systems. In: Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering - OMAE. 2017. p. 1–10.

95. Woo JH, Kim Y, Jeong YK, Shin JG. A research on simulation framework for the advancement of supplying management competency. J Sh Prod Des. 2017;33(1):60–79.

96. Özkök M, Helvacioğlu H. Simulation-based modeling of block assembly area at shipyards. In: Safety of Sea Transportation - Proceedings of the International Conference on Marine Navigation and Safety of Sea Transportation, TRANSNAV 2017. 2017. p. 165–70.

97. Karpowicz AS, Simone V. An application of computer simulation methods in ship production process. Comput Ind. 1987;9(1):37–51.

98. Munitic A, Dvornik J, Simundic S. Computing simulation model of shipbuilding organization process. In: Simulation Series. 2003. p. 191–4.

99. Vasconcellos JM. Optimization procedure as decision tool for ship design. In: International Maritime Conference 2010, Pacific 2010. 2010. p. 340–9.

100. Ferguson SW. Towards a marine digital twin, predictive engineering analytics for ship design. In: RINA, Royal Institution of Naval Architects - International Conference on Computer Applications in Shipbuilding, ICCAS 2017. 2017. p. 104–7.

101. Kim TB, Yue S, Zhang Z, Jones E, Jones JR, Lee PD. Additive manufactured porous titanium structures: Through-process quantification of pore and strut networks. J Mater Process Technol [Internet]. 2014;214(11):2706–15. Available from: http://dx.doi.org/10.1016/j.jmatprotec.2014.05.006

102. Kumar M, Ramakrishnan R, Omarbekova A. 3D printed polycarbonate reinforced acrylonitrile–butadiene–styrene composites: Composition effects on mechanical properties, micro-structure and void formation study. J Mech Sci Technol. 2019;33(11):5219–26.

103. Gonzales MAC, Kujala P. 3D printing miniature marine structures models for structural analysis purpose: Is it possible? Proc Int Conf Offshore Mech Arct Eng - OMAE. 2019;3:95772.

104. Ermakova A, Mehmanparast A, Ganguly S. A review of present status and challenges of using additive manufacturing technology for offshore wind applications. Procedia Struct Integr [Internet]. 2019;17:29–36. Available from: https://doi.org/10.1016/j.prostr.2019.08.005

105. Wang JJ, Zhang M, Tan X, Jing W, Liu EJ, Tor SB, et al. Impact and fatigue characteristics of additively manufactured steel materials: A review. Proc Int Conf Prog Addit Manuf. 2018;2018-May(Dmd):487–92.

106. Wistance W, Lee J. Additive manufacturing metal 3D printing for the marine and offshore sector - Paving the path from lab into the field. Offshore Technol Conf Asia 2018, OTCA 2018. 2018;1987:1–12.

107. Kostidi E, Nikitakos N. Exploring the potential of 3D printing of the spare parts supply chain in the maritime industry. Saf Sea Transp - Proc Int Conf Mar Navig Saf Sea Transp TRANSNAV 2017. 2017;(June):171–8.

108. Cuoghi F. From racetrack to orbit, an additive revolution. Reinf Plast [Internet]. 2016;60(4):231–6. Available from: http://dx.doi.org/10.1016/j.repl.2015.10.010

109. Jaiganesh V, Christopher AA, Mugilan E. Manufacturing of PMMA Cam Shaft by Rapid Prototyping. In: 12Th Global Congress on Manufacturing and Management, GCMM2014 [Internet]. Elsevier B.V.; 2014. p. 2127–35. Available from: http://dx.doi.org/10.1016/j.proeng.2014.12.456

110. Cilia T, Bertetta D, Gualeni P, Tani G, Viviani M. Additive manufacturing application to a ship propeller model for experimental activity in the cavitation tunnel. J Sh Prod Des. 2019;35(4):364–73.

111. De Moraes CC, Santiago RC. AUV Scaled Model Prototyping using 3D Printing Techniques. AUV 2018 - 2018 IEEE/OES Auton Underw Veh Work Proc. 2018;2020.

112. Husser NA, Onas AS. An investigation of turbulence stimulation on 3D printed model propellers. SNAME Marit Conv SMC 2018. 2018;2020.

113. Chen C, Liu L, Xu J. Application of metal additive manufacturing in shipbuilding and construction of marine engineering. Sh Build China. 2016;57(3):215–25.

114. Fu Y, Cao XA, Li Z. Printability of magnesium potassium phosphate cement with different mixing proportion for repairing concrete structures in severe environment. Key Eng Mater. 2016;711(1):989–95.

115. Yuan S, Shen F, Chua CK, Zhou K. Polymeric composites for powder-based additive manufacturing: Materials and applications. Prog Polym Sci [Internet]. 2019;91:141–68. Available from: https://doi.org/10.1016/j.progpolymsci.2018.11.001

116. Sarathchandra DT, Kanmani Subbu S, Venkaiah N. Functionally graded materials and processing techniques: An art of review. Mater Today Proc [Internet]. 2018;5(10):21328–34. Available from: https://doi.org/10.1016/j.matpr.2018.06.536

117. Srivastava M, Rathee S, Maheshwari S, Noor Siddiquee A, Kundra TK. A Review on Recent Progress in Solid State Friction Based Metal Additive Manufacturing: Friction Stir Additive Techniques. Crit Rev Solid State Mater Sci [Internet]. 2019;44(5):345–77. Available from: https://doi.org/10.1080/10408436.2018.1490250

118. Jha SK. Emerging technologies: Impact on shipbuilding. Marit Aff. 2016;12(2):78–88.

119. Jovanovic VM, Bilgen O, Arcaute K, Audette MA, Dean AW. Active duty training for support of navy’s additive manufacturing strategy. ASEE Annu Conf Expo Conf Proc. 2017;2017-June.

120. Wu W, Tor SB, Leong KF, Chua CK, Merchant AA. State of the art review on selective laser melting of stainless steel for future applications in the marine industry. In: Proceedings of the International Conference on Progress in Additive Manufacturing. 2016. p. 475–81.

121. Toy YC, Mahouti P, Güneş F, Belen MA. Design and manufactering of an X-band horn antenna using 3-D printing technology. Proc 8th Int Conf Recent Adv Sp Technol RAST 2017. 2017;195–8.

122. Giovannelli A. Development of turbomachines for renewable energy systems and energy-saving applications. Energy Procedia [Internet]. 2018;153:10–5. Available from: https://doi.org/10.1016/j.egypro.2018.10.069

123. Casas AM, Torims T, Gutierrez Rubert SC. Additive manufacturing as a technique for in situ repair and renovation of marine crankshaft journals. Key Eng Mater. 2019;799 KEM:263–9.

124. Queguineur A, Rückert G, Cortial F, Hascoët JY. Evaluation of wire arc additive manufacturing for large-sized components in naval applications. Weld World. 2018;62(2):259–66.

125. Jadayil WA, Serhan D. The Effect of Heat Treatment and Alloying of Ni – Ti Alloy with Copper [Internet]. Springer International Publishing; 2019. 413–420 p. Available from: http://dx.doi.org/10.1007/978-3-030-05861-6_38

126. Ding D, Pan Z, van Duin S, Li H, Shen C. Fabricating superior NiAl bronze components through wire arc additive manufacturing. Materials (Basel). 2016;9(8).

127. Asghar A, Stowe R, Allan WDE, LaViolette M, Alexander D, Ingram G. S-duct diffuser offset-to-length ratio effect on aerodynamic performance of propulsion-system inlet of high speed aircraft. Proc ASME Turbo Expo. 2018;1:1–15.

128. Kopperstad K, Lemu HG. Design and performance study of additive manufactured thrusters for remotely operated underwater vehicle. Proc Int Offshore Polar Eng Conf. 2018;2018-June:379–86.

129. Mohammadi M, Asgari H. Achieving low surface roughness AlSi10Mg_200C parts using direct metal laser sintering. Addit Manuf [Internet]. 2018;20:23–32. Available from: http://dx.doi.org/10.1016/j.addma.2017.12.012

130. Wu W, Tor SB, Chua CK, Leong KF, Merchant A. Investigation on processing of ASTM A131 Eh36 high tensile strength steel using selective laser melting. Virtual Phys Prototyp. 2015;10(4):187–93.

131. Ebrahimi A, Kenny S, Mohammadi M. On bending performance of additively manufactured Steel Catenary Riser (SCR): Effect of welding residual stress on bending strain capacity. Proc Int Conf Offshore Mech Arct Eng - OMAE. 2018;5:1–8.

132. Valentin TM, Landauer AK, Morales LC, DuBois EM, Shukla S, Liu M, et al. Alginate-graphene oxide hydrogels with enhanced ionic tunability and chemomechanical stability for light-directed 3D printing. Carbon N Y [Internet]. 2019;143:447–56. Available from: https://doi.org/10.1016/j.carbon.2018.11.006

133. Ebrahimi A, Mohammadi M. Numerical tools to investigate mechanical and fatigue properties of additively manufactured MS1-H13 hybrid steels. Addit Manuf [Internet]. 2018;23(May):381–93. Available from: https://doi.org/10.1016/j.addma.2018.07.009

134. Jing W, Wang J, Tan X, Liu E, Tor S. Mechanical properties and fracture analysis of additively manufactured EH 36 steel parts by laser engineered net shaping process. Proc Int Conf Prog Addit Manuf. 2018;2018-May:498–504.

135. Arias-González F, del Val J, Comesaña R, Lusquiños F, Quintero F, Riveiro A, et al. Processing of pure Ti by rapid prototyping based on laser cladding. 8th Iberoam Opt Meet 11th Lat Am Meet Opt Lasers, Appl. 2013;8785:878546.

136. Rinoj G, Idapalapati S, Feih S. Failure mode analysis of kagome lattice structures. Proc Int Conf Prog Addit Manuf. 2016;Part F1290:91–6.

137. Staiano G, Gloria A, Ausanio G, Lanzotti A, Pensa C, Martorelli M. Experimental study on hydrodynamic performances of naval propellers to adopt new additive manufacturing processes. Int J Interact Des Manuf [Internet]. 2018;12(1):1–14. Available from: https://doi.org/10.1007/s12008-016-0344-1

138. Sumesh A, Rameshkumar K, Mohandas K, Babu RS. Use of machine learning algorithms for weld quality monitoring using acoustic signature. Procedia Comput Sci [Internet]. 2015;50:316–22. Available from: http://dx.doi.org/10.1016/j.procs.2015.04.042

139. Perera LP, Mo B. Marine Engine Operating Regions under Principal Component Analysis to evaluate Ship Performance and Navigation Behavior. IFAC-PapersOnLine [Internet]. 2016;49(23):512–7. Available from: http://dx.doi.org/10.1016/j.ifacol.2016.10.487

140. Dominguez AG. “Smart Ships”: Mobile Applications, Cloud and Bigdata on Marine Traffic for Increased Safety and Optimized Costs Operations. Proc - 2nd Int Conf Artif Intell Model Simulation, AIMS 2014. 2014;303–8.

141. Park SW, Roh M Il, Oh MJ, Kim SH. Association analysis of piping materials of an offshore structure using big data technology. J Sh Prod Des. 2019;35(3):220–30.

142. Jia S, Ma L, Zhang S. Big data prototype practice for unmanned surface vehicle. ACM Int Conf Proceeding Ser. 2018;43–7.

143. Tang G, Cao Q, Li X. Analysis of vessel behaviors in costal waterways using big AIS data. 2019 IEEE 4th Int Conf Cloud Comput Big Data Anal ICCCBDA 2019. 2019;290–4.

144. An J, Qiao T, Yang X, Hong H, Cheng D, Bai X. Design of a Visual Analysis Platform for Sea Route Based on AIS Data. 2019 2nd Int Conf Artif Intell Big Data, ICAIBD 2019. 2019;102–6.

145. Nishizaki C, Terayama M, Okazaki T, Shoji R. Development of Navigation Support System to Predict New Course of Ship. World Autom Congr Proc. 2018;2018-June:131–5.

146. Zaman I, Pazouki K, Norman R, Younessi S, Coleman S. Challenges and opportunities of big data analytics for upcoming regulations and future transformation of the shipping industry. Procedia Eng [Internet]. 2017;194:537–44. Available from: http://dx.doi.org/10.1016/j.proeng.2017.08.182

147. Kim K Il, Lee KM. Dynamic programming-based vessel speed adjustment for energy saving and emission reduction. Energies. 2018;11(5).

148. Anan T, Higuchi H, Hamada N. New artificial intelligence technology improving fuel efficiency and reducing CO2 emissions of ships through use of operational big data. Fujitsu Sci Tech J. 2017;53(6):23–8.

149. Zhou CH, Huang HX, Zhou L, Sui ZY, Wen YQ, Xiao CS. Main engine power estimation method for the inland ship based on big data. Dalian Haishi Daxue Xuebao/Journal Dalian Marit Univ. 2019;45(2):44–9.

150. Wang G, Hu K. To establish ship performance assessment scheme in a dynamically challenging environment. PRADS 2016 - Proc 13th Int Symp Pract Des Ships Other Float Struct. 2016;2020.

151. Hamedifar H, Spitzenberger C, Stahl C, Brown A, Nilberg B, Demay V, et al. Terminal and transportation risk assessment for LNG export in North America. Pet Abstr. 2015;55(41):112–3.

152. Wang H, Karlsen A, Engelseth P. Big data for the Norwegian maritime industry. In: Network Security and Communication Engineering - Proceedings of the 2014 International Conference on Network Security and Communication Engineering, NSCE 2014. 2015. p. 399–402.

153. Casals-Torrens P, Bosch R, Diaz-Gonzalez F, Nicolas-Apruzzese J, Fuses V. Challenges in the formation of marine engineers. goals and opportunities in the education and training of marine technology. In: AGA 2018 - 19th Annual General Assembly (AGA) of the International Association of Maritime Universities (IAMU). International Center for Numerical Methods in Engineering; 2018. p. 61–70.

154. Huang Y, Guo C, Sun J, Huo Y. Cloud Model Based Intelligent Control for Marine Hydraulic Steering Gear System. Lect Notes Electr Eng. 2018;458:647–54.

155. Montella R, Ruggieri M, Kosta S. A fast, secure, reliable, and resilient data transfer framework for pervasive IoT applications. In: INFOCOM 2018 - IEEE Conference on Computer Communications Workshops. Institute of Electrical and Electronics Engineers Inc.; 2018. p. 710–5.

156. Cui K, Sun W, Sun W. Joint computation offloading and resource management for USVs cluster of fog-cloud computing architecture. In: Proceedings - 2019 IEEE International Conference on Smart Internet of Things, SmartIoT 2019. Institute of Electrical and Electronics Engineers Inc.; 2019. p. 92–9.

157. Xu Y, Liu P, Penesis I, He G. Deployment of Batch Mode Scientific Workflow on a Computation-as-a-Service Private Cloud. In: 5th International Conference on Soft Computing and Machine Intelligence, ISCMI 2018. Institute of Electrical and Electronics Engineers Inc.; 2018. p. 123–8.

158. Aguilar E, Radeva P. Class-Conditional Data Augmentation. In: Vento M, Percannella G, editors. 18th International Conference, CAIP 2019 [Internet]. Salerno: Springer; 2019. p. 182–92. Available from: http://dx.doi.org/10.1007/978-3-030-29891-3_17

159. Riahi M, Krichen S. A multi-objective decision support framework for virtual machine placement in cloud data centers: a real case study. J Supercomput. 2018 Jul 1;74(7):2984–3015.

160. Kim H, Lee SS, Park JH, Lee JG. A model for a simulation-based shipbuilding system in a shipyard manufacturing process. Int J Comput Integr Manuf. 2005;18(6):427–41.

161. Jia X. Application research of augmented reality technology in marine engineering. Energy Educ Sci Technol Part A Energy Sci Res. 2014;32(6):8791–8.

162. Snyder J. A new reality in navigation. Vol. 109, Marine Log. 2004. p. 31–4.

163. Luis CEM, Mellado RC, Díaz BA. PBL methodologies with embedded augmented reality in higher maritime education: Augmented project definitions for chemistry practices. In: Procedia Computer Science. Elsevier B.V.; 2013. p. 402–5.

164. Zhang N, Liu Y, Luo W, Shen Z, Guo C. Virtual reality based marine engineering English learning environment simulation research. In: 2015 12th International Computer Conference on Wavelet Active Media Technology and Information Processing, ICCWAMTIP 2015. Institute of Electrical and Electronics Engineers Inc.; 2016. p. 228–32.

165. Luis CEM, Marrero AMG. Real object mapping technologies applied to marine engineering learning process within a CBL methodology. In: Procedia Computer Science. Elsevier B.V.; 2013. p. 406–10.

166. Mahdi IM, Mohamedien MA, Ibrahim HMH, Khalil MAEM. Proposed management system of marine works based on bim approach (Technology). J Eng Appl Sci. 2019 Dec 1;66(6):771–90.

167. Rowen A, Grabowski M, Rancy JP. Through the Looking Glass(es): Impacts of Wearable Augmented Reality Displays on Operators in a Safety-Critical System. In: IEEE Transactions on Human-Machine Systems. IEEE; 2019. p. 652–60.

168. Piciarelli C, Vernier M, Zanier M, Foresti GL. An augmented reality system for technical staff training. In: Proceedings - IEEE 16th International Conference on Industrial Informatics, INDIN 2018. Institute of Electrical and Electronics Engineers Inc.; 2018. p. 899–904.

169. Kai AT. Driving transformation in the age of experience. In: RINA, Royal Institution of Naval Architects - International Conference on Computer Applications in Shipbuilding, ICCAS 2017. Royal Institution of Naval Architects; 2017. p. 20–3.

170. Dos Santos Brito CJ, Almeida MWS, Vieira-E-Silva ALB, Teixeira JMXN, Teichrieb V. Screen space rendering solution for multiphase SPH simulation. In: Proceedings - 19th Symposium on Virtual and Augmented Reality, SVR 2017. Institute of Electrical and Electronics Engineers Inc.; 2017. p. 309–18.

171. Bakalov I. A contemporary concept in troubleshooting and fixing malfunctions using an engine room simulator in augmented reality environment. Univers J Mech Eng. 2019 Mar 1;7(2):33–6.

172. Moulis G. Pluridisciplinary development of an innovative system demonstrator using augmented Reality for 360° awareness of French navy ships. In: Proceedings of the 16th Ergo’IA “Ergonomie Et Informatique Avancée” Conference on - Ergo’IA ’18 [Internet]. New York, New York, USA: ACM Press; 2018 [cited 2020 Jun 10]. p. 1–10. Available from: http://dl.acm.org/citation.cfm?doid=3317326.3317331

173. Popov AN, Kondratiev AI, Smirnov IO. The algorithm for fast forecasting of the collision danger degree with ships and surface objects in the e-navigation area. In: AGA 2018 - 19th Annual General Assembly (AGA) of the International Association of Maritime Universities (IAMU). International Center for Numerical Methods in Engineering; 2018. p. 442–9.

174. Kim JH, Lee KH, Lee JM, Lee G. A study on 3D design model-based-visualization system to support pipe maintenance. In: Proceedings of the International Offshore and Polar Engineering Conference. 2011. p. 142–6.

175. Discenzo FM, Chung D, Chen SL, Behringer R, Sundareswaran V, Carnahan D, et al. Augmented reality supports real-time diagnosis and repair of shipboard systems. In: IFAC Proceedings Volumes (IFAC-PapersOnline). IFAC Secretariat; 2004. p. 233–8.

176. Aromaa S, Aaltonen I, Kaasinen E, Elo J, Parkkinen I. Use of wearable and augmented reality technologies in industrial maintenance work. In: AcademicMindtrek 2016 - Proceedings of the 20th International Academic Mindtrek Conference. Association for Computing Machinery, Inc; 2016. p. 235–42.

177. Vasilijević A, Borović B, Vukić Z. Primjene proširene stvarnosti u pomorstvu. Brodogradnja. 2011;62(2):136–42.

178. Von Lukas UF. Virtual and augmented reality for the maritime sector- Applications and requirements. In: IFAC Proceedings Volumes (IFAC-PapersOnline). 2010. p. 196–200.

179. Grabowski M. Research on wearable, immersive augmented reality (WIAR) adoption in maritime navigation. J Navig. 2015;68(3):453–64.

180. von Lukas UF, Quarles J, Kaklis P, Dolereit T. Underwater mixed environments. Lect Notes Comput Sci (including Subser Lect Notes Artif Intell Lect Notes Bioinformatics). 2015;8844:56–76.

181. Morikawa K, Ando T. Reduction of piping management person-hours through use of AR technology at shipbuilding sites. Fujitsu Sci Tech J. 2019;55(1):20–6.

182. Butkiewicz T. Designing augmented reality marine navigation AIDS using virtual reality. In: OCEANS 2017 - Anchorage. Institute of Electrical and Electronics Engineers Inc.; 2017. p. 1–9.

183. Morgere JC, Diguet JP, Laurent J. Mobile Augmented Reality System for Marine Navigation Assistance. In: Proceedings - 2014 International Conference on Embedded and Ubiquitous Computing, EUC 2014. 2014. p. 287–92.

184. Kazasidis M, Chionopoulos S, Pantelis D. Experimental investigation of FCAW-G weldments of HSLA AH40-FCA (fatigue crack arrester) steel, used in marine applications. 18th Int Conf Ships Shipp Res NAV 2015. 2015;417–26.

185. Çevik B, Koç M. The effects of welding speed on the microstructure and mechanical properties of marine-grade aluminium (AA5754) alloy joined using MIG welding. Kov Mater. 2019;57(5):307–16.

186. Bragagna R. Automazione e robotka nella fabbricae di strutture saldate per il settore navale. Riv Ital della Saldatura. 2010 Jan;62(1):37–41.

187. Mišković N, Nad D, Vukić Z. Guidance of laboratory marine platforms. In: MIPRO 2010 - 33rd International Convention on Information and Communication Technology, Electronics and Microelectronics, Proceedings. 2010. p. 583–8.

188. Serebrenniy V V., Lapin D V., Mokaeva AA. Concept of multifunctional modular mobile robotic complex for marine vessels maintenance. In: AIP Conference Proceedings. American Institute of Physics Inc.; 2019.

189. Automated construction system for labour saving. Sh Boat Int. 2007;(NOV./DEC.):40.

190. Kwon Y, Park S, Lee J. PID compensating model for design of ship’s autopilot. In: International Conference on Control, Automation and Systems. IEEE Computer Society; 2016. p. 1337–9.

191. Blintsov V, Aloba LT. Control automation of maritime unmanned complex with a group of autonomous underwater vehicles. EUREKA, Phys Eng. 2019;2019(4):54–62.

192. Blintsov V, Klochkov O. Generalized method of designing unmanned remotely operated complexes based on the system approach. EUREKA, Phys Eng. 2019;2019(2):43–51.

193. Pandey J, Hasegawa K. Fuzzy waypoint guidance controller for underactuated catamaran wave adaptive modular vessel. In: Studies in Computational Intelligence. Springer Verlag; 2018. p. 393–413.

194. Zhuang J yuan, Zhang L, Zhao S qi, Cao J, Wang B, Sun H bing. Radar-based collision avoidance for unmanned surface vehicles. China Ocean Eng. 2016;30(6):867–83.

195. Ji X, Zhuang JY, Su YM. Marine radar target detection for USV. In: Advanced Materials Research. Trans Tech Publications Ltd; 2014. p. 863–9.

196. Miao R, Pang S, Jiang D. Development of an Inexpensive Decentralized Autonomous Aquatic Craft Swarm System for Ocean Exploration. J Mar Sci Appl. 2019;18(3):343–52.