1000/1000

Hot

Most Recent

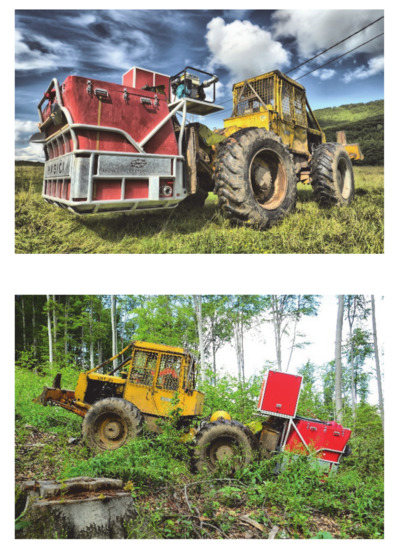

The presented article presents an innovative solution of a fire-fighting adapter based on the basic hypothesis: to provide sufficient technical support in difficult terrain conditions for water transport logistics in order to quickly prevent the spread and destruction of forest fire. At present, when forest fires begin, it is often quite complicated to provide sufficient technical support for the quick prevention and elimination of fires. This fact is largely eliminated by the designed fire-fighting adapter. The mentioned fire-fighting adapter can be used as a fire-fighting mobile device with a base machine of a forest wheeled skidder (LKT), part of the long-distance transport of water in difficult terrain (lake system), a water tank in difficult terrain with the possibility of filling the Bambi bag with a helicopter, part of the long-distance transport of water in the case of a difficult water source without a forest access road network, and a mobile device for emergency transportation of materials in difficult terrain. In addition to the use for fighting forest fires, the fire adapter can also be used to provide for transport of water for forest nurseries (irrigation), freshly planted areas in the event of prolonged drought, the filling of watering-places for forest animals and filling puddles in the dry season. When designing the supporting frame, we used and imitated the evolutionary approach of nature in the form of generative design. The presented paper deals with the use of modern composite materials in the design of superstructures for base machines, which gradually acquire meaning. The main reason for the increasing use of fiberglass is to achieve higher strength and safer weight reduction. This adapter is designed for forest wheel tractors that reach 40% slope availability, areable to work on the stand area, overcome obstacles and are available in sufficient quantities in all Slovak forest areas.

With regard to forest protection, forest fires are the most drastic form of forest destruction. They have an enormous impact on all forest ecosystems, especially the plants and animals living there. From a technical point of view, a forest fire is a sudden, partly or very uncontrolled extraordinary event limited in time and place. This fact has a negative impact on all social functions of forests (productive and non-productive). It is a complex physical and chemical effect, which are based on non-stationary processes (changing in place and time) burning, gas exchange and heat transfer.

Elimination of forest fires on any scale combines several phenomena. Firstly, sufficient forces and resources for its localization and liquidation. Secondly, the availability of the site and sufficient extinguishing agent (water) in connection with the availability of water resources themselves. Not one area of this vicious circle cannot be prepared in advance. However, making the forest accessible with the preservation, revitalization and construction of the forest road network and water resources should be part of the construction of the forest. All this in accordance with the preservation of production and increasingly presented non-production functions of the forest. [1].

It is necessary to look at safety construction from the point of view that it is not just a question of designing and dimensioning machinery, but the creation of a comprehensive system of filling defined objectives. This means that for adapters, which are used as attachments to forestry machinery, it is necessary to approach the design from two perspectives. The first is the purpose for which the adapters are designed (operational characteristics) and the second is the impact on the operator or other employees working nearby. The task of designers who deal with technical (operational) parameters is to ensure the highest possible efficiency of the machine with the adapter. The role of engineers who deal with security, is to minimize the hazards arising throughout the life of the machine [2][3].

Design and development of pumping appliances (CAS) for fire-fighting in inaccessible forest fire areas are subject to high costs from the point of view of development, and also have limited possibilities of mass production (piece production). The last question is utilization of such a one-purpose machine, mainly the number of uses in relation to the working life of the machine. This is the basic problem which invites alternative solutions.

Based on concept IV, we approached the technical solution of the fire-fighting adapter for the LKT, specifically the selection of adequate construction materials based on requirements for their strength and minimum weight. The basic condition for the design of the adapter was the use of the reserves of the capacity weight of the base machine with emphasis on:

The design of the fire-fighting adapter must be adapted to the parameters of LKT base machine. The LKT will be carried on the inclinable rear log arch. The fire-fighting adapter must also be able to be transported by other means, so it can be dismantled. The proposed fire-fighting body with its equipment will meet the criteria for forest fire interventions and the monitoring of forest areas.

The basic technical parameters for the fire-fighting adapter on LKT will be:

Because the proposed fire-fighting body is to be used in the complicated terrain of mountain forests, its weight must be monitored in its design. Weight is a basic condition for ensuring good stability of the whole machine with an adapter. By reducing the weight, we could achieve better stability of the base machine. Stability, in the case of increased slope navigation or maneuvering on a slope could be increased by placing the adapter on the floor. In this case, it was necessary to use the floating position of the rear LKT shield. In order to increase the capacity weight of the base machine, but also to ensure maximum handling, a four-member operator was therefore applied for the lightweight construction of tanks of composite materials (fiberglass). [4] We came to these conclusions on the basis of an analysis of the mechanical properties of materials that could be used in the design of the tank.

On the Testometric M500-100CT tensile-strength testing machine we determined the basic strength properties (breaking strength Rm, yield point Rp0.2 and max. force at break of the sample Fm) and deformation characteristics (elongation A and reduction of area Z) of material samples of steel and fiberglass. We tested EN10028 P275N steel plates and fiberglass made of chopped strand mat M534 cured with polyester resin AROPOL M105 TB. Based on the measured values (Table 1), we can conclude that, in both materials, approximately the same maximum force Fm required for tearing samples was achieved at break of the sample. The breaking strength Rm of the steel was almost twice higher than that of the composite material. The yield point Rp0.2, which is characteristic of the plastic deformation zone, is identical for the composite to the achieved breaking strength Rm. Composites, such as amorphous materials, have low to zero plasticity. The steel samples had an Rp0.2 value higher than the composite material samples. The deformation characteristics of the composite sample cannot be determined for the reason already mentioned. A significant reduction of the area and elongation of the steel samples confirms the excellent plastic properties.

Table 1. Resulting values of the static tensile test.

| Test | Fm(1) [N] | Rm(2) [N/mm2] | Rp0.2(3) [N/mm2] | Z(4) [%] | A(5) [%] |

|---|---|---|---|---|---|

| EN10028 P275N Steel | |||||

| 1 | 15,130 | 403,467 | 293,067 | 69,760 | 26,250 |

| 2 | 15,690 | 418,400 | 309,067 | 66,000 | 28,750 |

| 3 | 15,650 | 417,333 | 307,215 | 72,093 | 31,875 |

| fiberglass | |||||

| 1 | 16,360 | 218,133 | - | - | - |

| 2 | 14,340 | 191,200 | - | - | - |

| 3 | 16,210 | 216,133 | - | - | - |

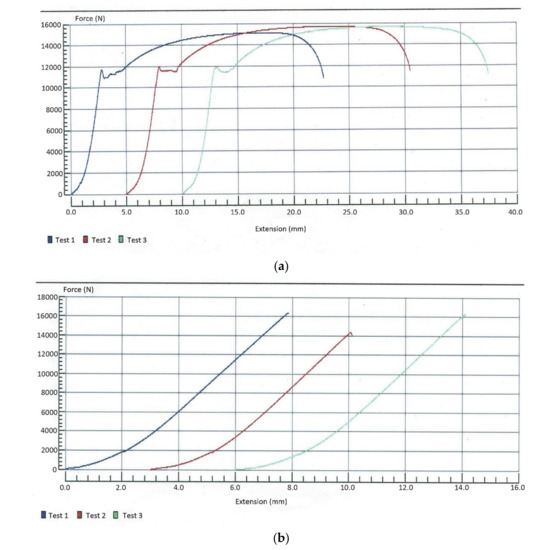

The stress-strain diagram of the steel sample is shown in Figure 1a and the composite material is shown in Figure 1b.

Figure 1. Stress-strain diagram: (a) steel sample; (b) composite material (fiberglass).

According to [4], when monitoring the weights, a significant difference is evident between the weight of the steel and fiberglass water tanks. The weight of fiberglass tanks is 82% lower compared to steel tanks. This fact and the analysis undertaken favor fiberglass for making these types of tanks.

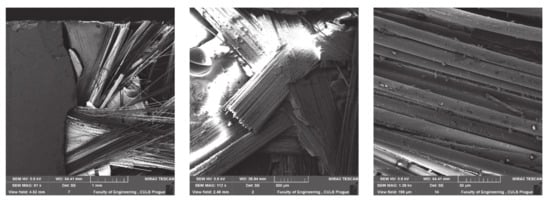

According to [5], the type of resin used, the type of reinforcement, the proportional share of glass fibers in the total volume, and their arrangement give the properties of the fiberglass. Strength increases with increasing fiber content and their arrangement in one direction. Good interaction of the glass fibres with the matrix in the form of epoxy was proved on the base of the conclusions of mechanical testing and the subsequent results of the electron microscopy [6]. As early as in the design stage, the individual components were dimensioned to withstand many times greater loads and stresses than were envisaged for operational conditions [7]. Analysis was needed to assess the suitability of the material proposed by the tank in terms of its strength and possible material savings in its production. SEM analysis of the samples was performed at the Faculty of Engineering, Czech University of Life Sciences Prague by the MIRA3 TESCAN analyzer. The microstructure of the fibers of the composite used is shown in Figure 2. For this reason, the water tank does not exceed 130 kg. In the future we may also see the possibility of producing composite water tanks using natural fibers, to which various authors currently devote their research [8][9][10][11][12][13][14][15][16]. The replacement of synthetic fibers with natural ones has a lot of benefits which can be rationalized also by means of an ecological equilibrium [8].

Figure 2. SEM images of the composite.

Good interaction of the glass fibres with the matrix in the form of epoxy was proved on the base of the conclusions of mechanical testing and the subsequent results of the electron microscopy [6].

As early as in the design stage, the individual components were dimensioned to withstand many times greater loads and stresses than were envisaged for operational conditions [7].

Replacing of the synthetic fibres with natural ones has a lot of benefits which can be rationalized also by means of an ecological equilibrium [8].

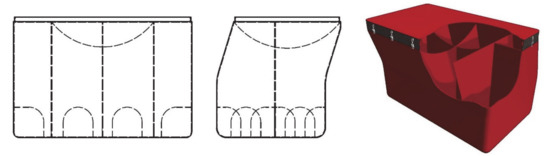

For reason of transport safety, and prevention of vertical and horizontal movement of water in the water tank during transport, as shown in Figure 3, we considered the construction of internal wave-breaks. These breakwaters are part of the construction of the water tank itself, thereby increasing its overall strength. To simplify this, maintenance has been undertaken to construct a removable lid.

Figure 3. The water tank construction with built-in wave-breaks.

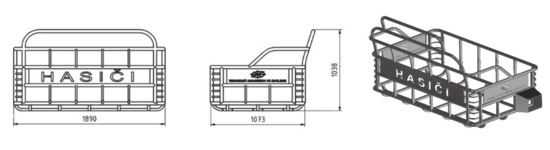

Requirements for the transportation of the tank in the forest terrain, and the possibility of its damage, required the construction of the protective frame (Figure 4), which performs a protective function during transport, but also when manipulating the water tank outside of transportation. In addition, in an emergency, it can serve as an improvised trailer for transporting materials in difficult terrain. In this case, the composite tank is removed from the protective steel frame.

Figure 4. The protective frame construction of the tank for transporting water.

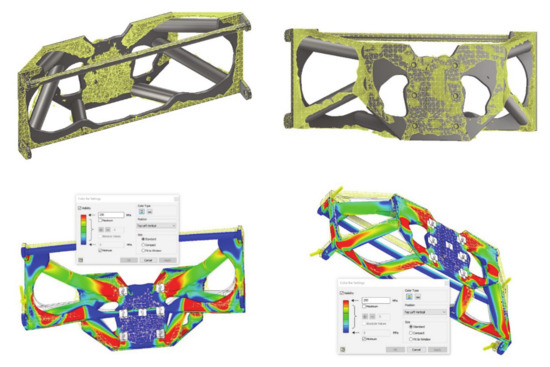

Scheme supporting fire-fighting frame adapters were processed in Autodesk Inventor using the Shape Generator. This tool represents a new form of computer-aided structural design that provides capabilities beyond classical optimization. It is based on a generative design and simulates the natural evolutionary approach. Using a generic design does not result in one solution but a potentially large number [17]. The created structure is discontinuous and cannot fulfill its function in the generated state. The built-in algorithm detracts from the generated shape until completion of a specified criterion of weight loss. When replacing such a shape with a real construction, we will not directly arrive at an acceptable design (Figure 5).

Figure 5. Replacement of the generated shape by a real construction—the maximum stress was significantly above the stress displayed.

To adjust the input form design, we therefore decided to reinforce the structure based on the results of regular stress analysis. We designed and applied several reinforcements (Figure 6) and performed a stress analysis (Figure 7). Due to the above-mentioned complex theoretical assumptions, we calculated a load of 50 kN, while the weight of the complete body, including the full tank is less than 2400 kg. This compensates for the fact that even if the device is not designed for dynamic driving, dynamic effects may occur.

Figure 6. Modifying the supporting frame.

Figure 7. FEA analysis: (a) for slope gradient 0 %; (b) for slope gradient of 20%-driving uphill.

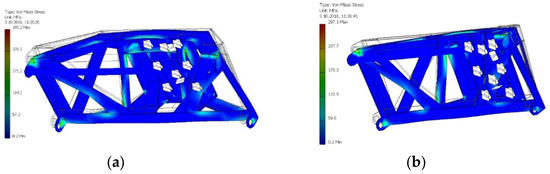

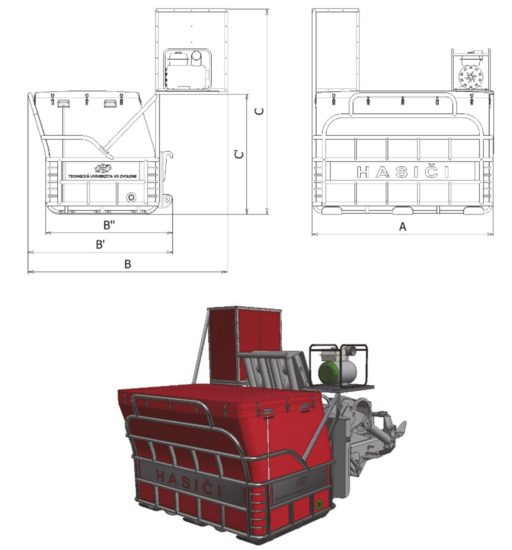

The basic essence of the technical solution of the fire-fighting adapter is to ensure sufficient water transport with the necessary firefighting equipment for firefighting purposes in conditions of mountain forests. The resulting technical solution of the fire-fighting adapter (Figure 8) is adapted to the parameters of the base machine LKT, on which the adapter is supported (Figure 9), respectively, semi-mounted (floating position) on the rear LKT shield. The adapter can be removed and transported by other means of transport to the place of intervention.

Figure 8. The design of the fire-fighting adapter. A = 1390 mm, B = 2082 mm, B′ = 1510 mm, B″ = 1325 mm, C = 2140 mm C′ = 1252 mm.

Figure 9. Fire-fighting adapter.

Additional equipment of the fire-fighting adapter according to the demands of accepted practice:

This equipment is intended to ensure an autonomous capacity to refill the tank of the fire-fighting adapter from the nearest natural water source, as well as to manage the intervention itself in complicated terrain.

In addition to the use for fighting forest fires, the fire adapter can also be used to provide for transport of water for forest nurseries (irrigation), freshly planted areas in the event of prolonged drought, filling of watering-places for forest animals and filling puddles in the dry season.