Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Qian Chen | + 1784 word(s) | 1784 | 2021-08-14 12:14:24 | | | |

| 2 | Vicky Zhou | Meta information modification | 1784 | 2021-08-24 04:23:44 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Chen, Q. Graphene/Tourmaline-Composite-Modified Asphalt. Encyclopedia. Available online: https://encyclopedia.pub/entry/13487 (accessed on 08 February 2026).

Chen Q. Graphene/Tourmaline-Composite-Modified Asphalt. Encyclopedia. Available at: https://encyclopedia.pub/entry/13487. Accessed February 08, 2026.

Chen, Qian. "Graphene/Tourmaline-Composite-Modified Asphalt" Encyclopedia, https://encyclopedia.pub/entry/13487 (accessed February 08, 2026).

Chen, Q. (2021, August 24). Graphene/Tourmaline-Composite-Modified Asphalt. In Encyclopedia. https://encyclopedia.pub/entry/13487

Chen, Qian. "Graphene/Tourmaline-Composite-Modified Asphalt." Encyclopedia. Web. 24 August, 2021.

Copy Citation

In graphene/tourmaline-composite-modified asphalt, graphene can be used to further improve the road performance and emission reduction effect of tourmaline-modified asphalt. The temperature susceptibility, high temperature, anti-aging properties and rheological performance of the graphene/tourmaline-composite-modified asphalt are better than those of the tourmaline-modified asphalt and base asphalt. The asphalt fume reduction rate of graphene/tourmaline-composite-modified asphalt is higher than that of tourmaline-modified asphalt. With the increase of graphene content, the emission reduction performance increases gradually, and the enhancement effect of graphene on tourmaline performance is more obvious.

road materials

modified asphalt

tourmaline

asphalt fume pollution

emission reduction effect

graphene

1. Introduction

With the vigorous development of highway transportation, people put forward higher requirements for the service performance and quality of pavement [1][2][3]. Various kinds of asphalt modifiers have been widely studied and applied to improve the service quality and durability of asphalt pavement. At present, asphalt modifiers can be divided into inorganic material modifiers and polymer modifiers. Most polymer modified asphalts need to be prepared at higher temperatures, which has the disadvantages of high cost, complex equipment and preparation process [4][5]. Inorganic material modifiers can not only improve the interface between asphalt and mineral aggregate and asphalt pavement performance, but also has the characteristics of simple production process, low price, excellent performance and rich reserves. It has been more and more favored by pavement researchers [6][7][8][9][10][11].

Tourmaline is a kind of silicate mineral with piezoelectric and thermoelectric properties. It is widely used in air purification, water purification, cooling coatings and other environmental protection fields [12][13][14][15]. In recent years, some researchers have applied it to prepare modified asphalt and modified asphalt mixtures. Wang et al. studied the road performance of tourmaline-modified asphalt and its mixture as well as its effects of emission reduction, flame retardancy and smoke suppression. It was found that tourmaline can effectively improve the pavement performance of asphalt and has certain environmental effects [16][17][18]. Tourmaline can adsorb the asphalt smoke pollutants generated when the asphalt is heated, and the adsorption rate can reach more than 50%. Moreover, it can also purify automobile exhaust, and has the most obvious purification effect on NOx, with a purification rate of 85.7%. In addition, compared with ordinary asphalt mixture, tourmaline-modified asphalt mixture is difficult to be ignited, and the amount of smoke generated during combustion is small, which has significant flame retardant and smoke suppression functions [19][20]. Wu et al. studied the high temperature performance of tourmaline-modified asphalt mortar and determined the influence of the tourmaline content and mesh number on the high temperature performance of tourmaline-modified asphalt [21]. Ding et al. found that tourmaline powder can significantly improve the fatigue life of base asphalt mixture and SBS modified asphalt mixture and enhance the high temperature rutting resistance of asphalt pavement [22].

The performance optimization of tourmaline for asphalt mainly comes from its piezoelectric and thermoelectric properties. Wang et al. found that graphene can enhance the piezoelectric and thermoelectric properties of tourmaline [16]. At the same time, graphene has the advantages of a large specific surface area, high surface energy and an excellent interface effect. At present, the application of graphene in the performance enhancement of asphalt and the composite-modified asphalt preparation have been explored and studied [23][24][25][26][27][28][29]. Su et al. improved the surface activity of polyacrylonitrile (PAN) by covalent grafting of aminated graphene and further prepared graphene fiber asphalt. The results of a dynamic shear rheological (DSR) test showed that the viscoelasticity and permanent deformation resistance of the asphalt were significantly improved [30]. Guo et al. found that the addition of graphene can improve the elastic recovery and deformation resistance of rubber asphalt and improve its rheological properties [31]. To sum up, the current research mainly focuses on the performance evaluation of modified asphalt with only tourmaline and the modified asphalt mixture. There is a lack of studies on the performance enhancement of tourmaline-modified asphalt and the preparation of tourmaline-composite-modified asphalt. The advantages of graphene make it obtain excellent application effects in enhancing the activity of asphalt modifiers and the performance of modified asphalt. However, there are few studies on the performance evaluation of graphene-reinforced tourmaline-modified asphalt and the preparation of graphene/tourmaline-composite-modified asphalt.

2. Road Performance and Emission Reduction Effect of Graphene/Tourmaline-Composite-Modified Asphalt

2.1. Optimization of Modified Asphalt Preparation Process Parameters

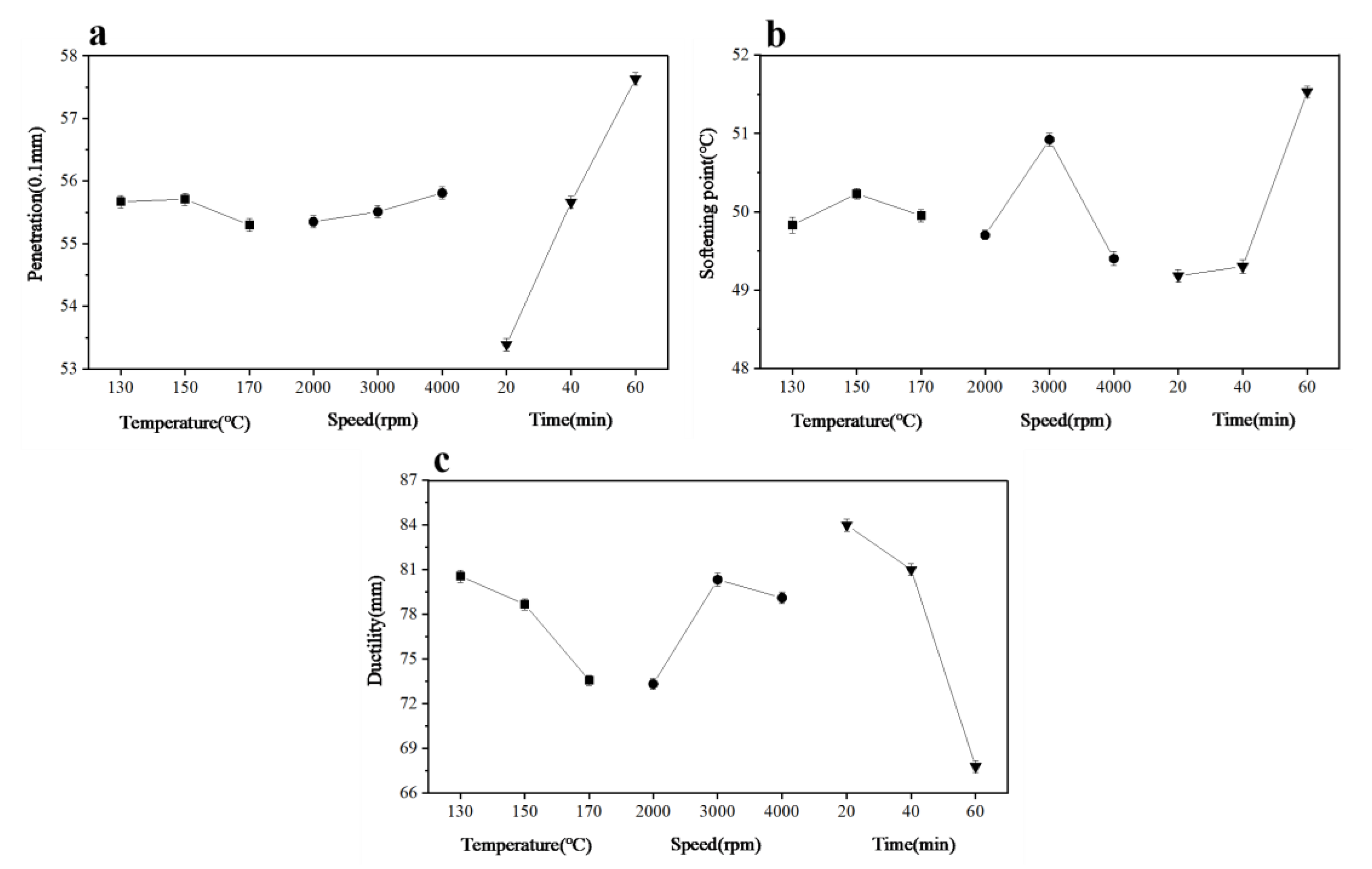

According to the orthogonal test scheme, graphene/tourmaline-composite-modified asphalt was prepared by using different process parameters. The penetration, softening point and 10 °C ductility of the asphalts were tested. The variance analysis and range analysis results of the orthogonal test are shown in Table 1 and Table 2, respectively. The change trend of the asphalt’s performance index mean value with factor levels are shown in Figure 1.

Figure 1. The change trend of asphalt performance index mean value with factor level: (a) Penetration; (b) Softening point; and (c) Ductility.

Table 1. Orthogonal test variance analysis for modified asphalt preparation process optimization.

| Index | Factor | Si2 | fi | Si2/fi | Fi | Sig. |

|---|---|---|---|---|---|---|

| Penetration | Temperature | 0.304 | 2 | 0.152 | 0.123 | 0.890 |

| speed | 0.322 | 2 | 0.161 | 0.130 | 0.885 | |

| Time | 27.094 | 2 | 13.547 | 10.950 | 0.084 | |

| Error | 2.474 | 2 | 1.237 | / | / | |

| Sum | 30.195 | 8 | F0.05(2, 2) = 19; F0.1(2, 2) = 9 | |||

| Softening point | Temperature | 0.254 | 2 | 0.127 | 1.309 | 0.433 |

| speed | 3.871 | 2 | 1.935 | 19.963 | 0.048 | |

| Time | 10.524 | 2 | 5.262 | 54.278 | 0.018 | |

| Error | 0.194 | 2 | 0.097 | / | / | |

| Sum | 14.842 | 8 | F0.05(2, 2) = 19; F0.1(2, 2) = 9 | |||

| Ductility | Temperature | 78.691 | 2 | 39.346 | 127.480 | 0.008 |

| speed | 83.877 | 2 | 41.938 | 135.880 | 0.001 | |

| Time | 446.988 | 2 | 223.494 | 724.120 | 0.007 | |

| Error | 0.617 | 2 | 0.309 | / | / | |

| Sum | 610.173 | 8 | F0.05(2, 2) = 19; F0.1(2, 2) = 9 | |||

Table 2. Orthogonal test range analysis for modified asphalt preparation process optimization.

| Factor | 25 °C Penetration/(0.1 mm) | Softening Point/°C | 10 °C Ductility/mm | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| k1 | k2 | k3 | Range | k1 | k2 | k3 | Range | k1 | k2 | k3 | Range | |

| Temperature | 55.67 | 55.71 | 55.30 | 0.41 | 49.83 | 50.23 | 49.95 | 0.40 | 80.56 | 78.67 | 73.57 | 6.99 |

| Speed | 55.35 | 55.51 | 55.81 | 0.46 | 49.70 | 50.92 | 49.40 | 1.52 | 73.33 | 80.33 | 79.11 | 7.00 |

| Time | 53.39 | 55.66 | 57.63 | 4.24 | 49.18 | 49.30 | 51.53 | 2.35 | 84.00 | 81.00 | 67.78 | 16.22 |

Note: k is the comprehensive average of the data at certain level.

2.2. Micromorphology and Modifier Dispersion of Modified Asphalt

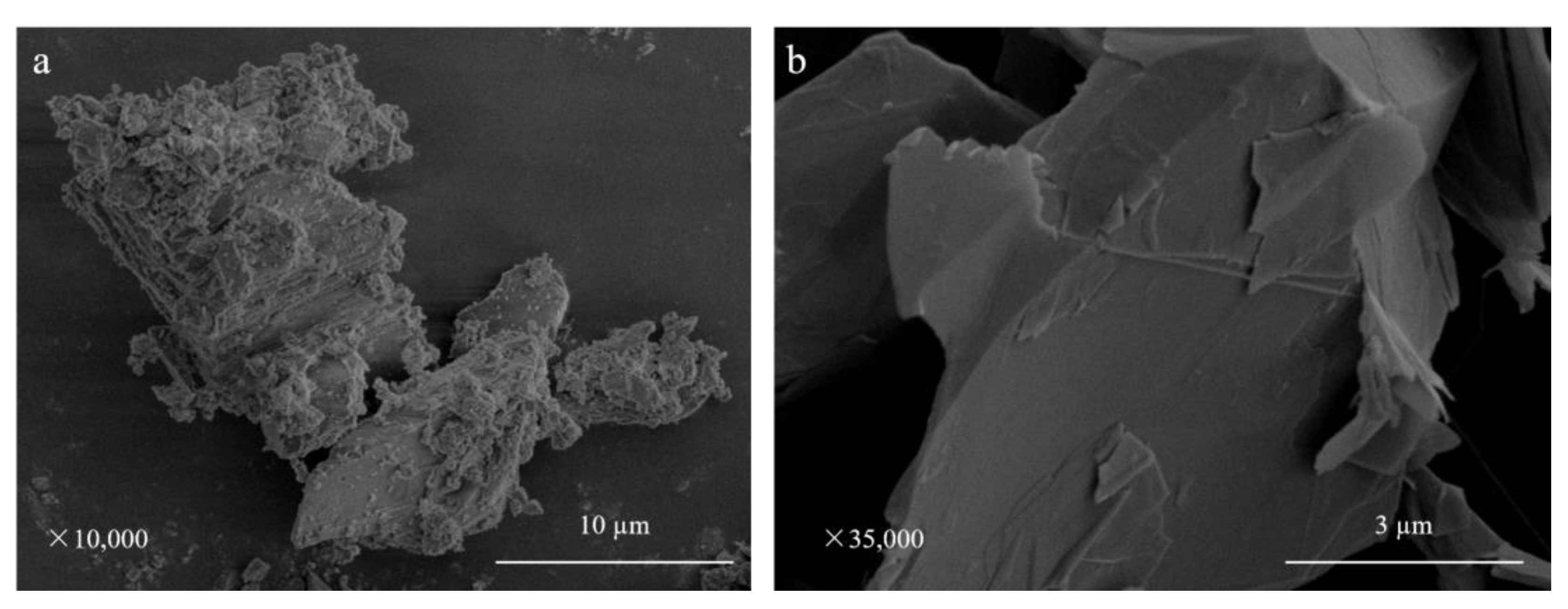

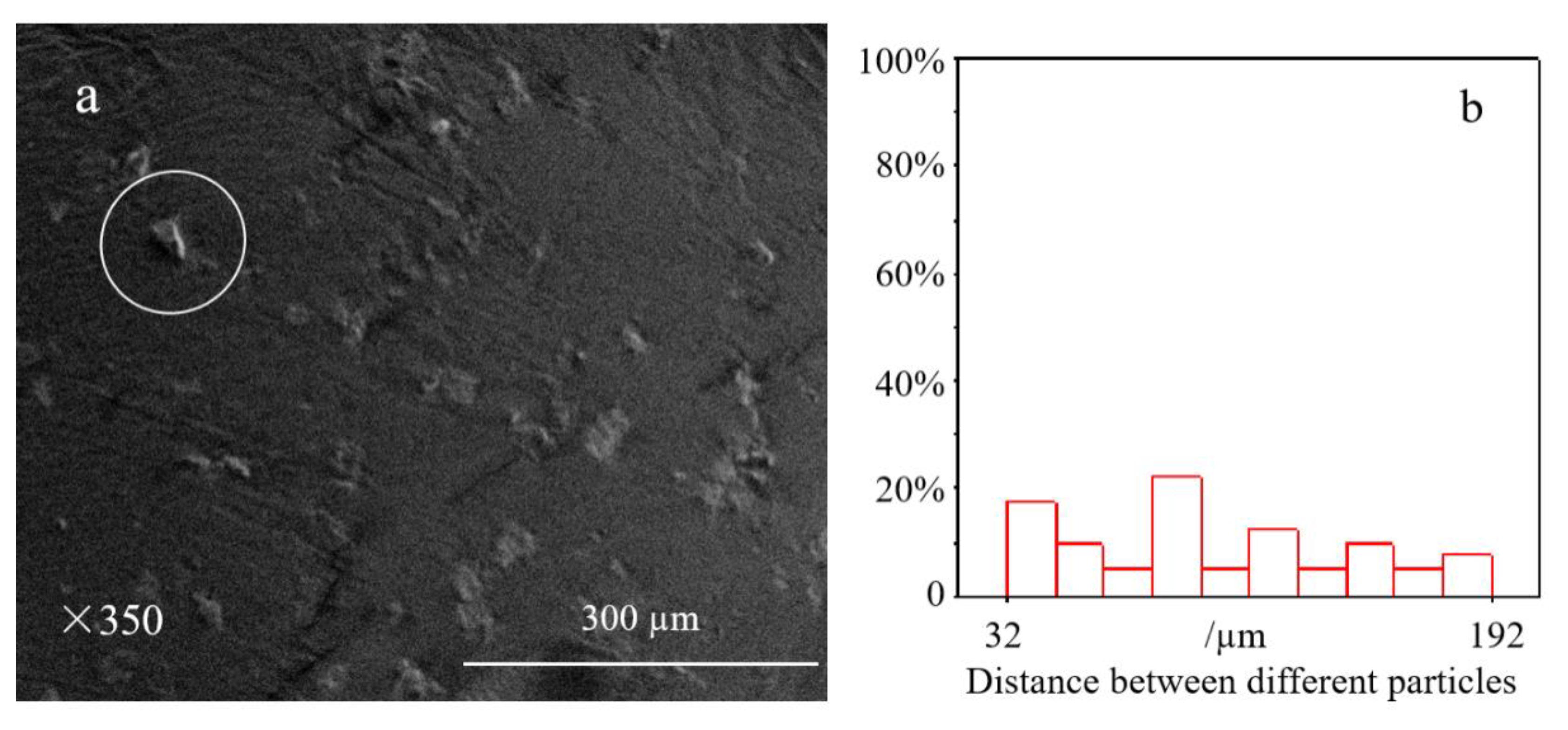

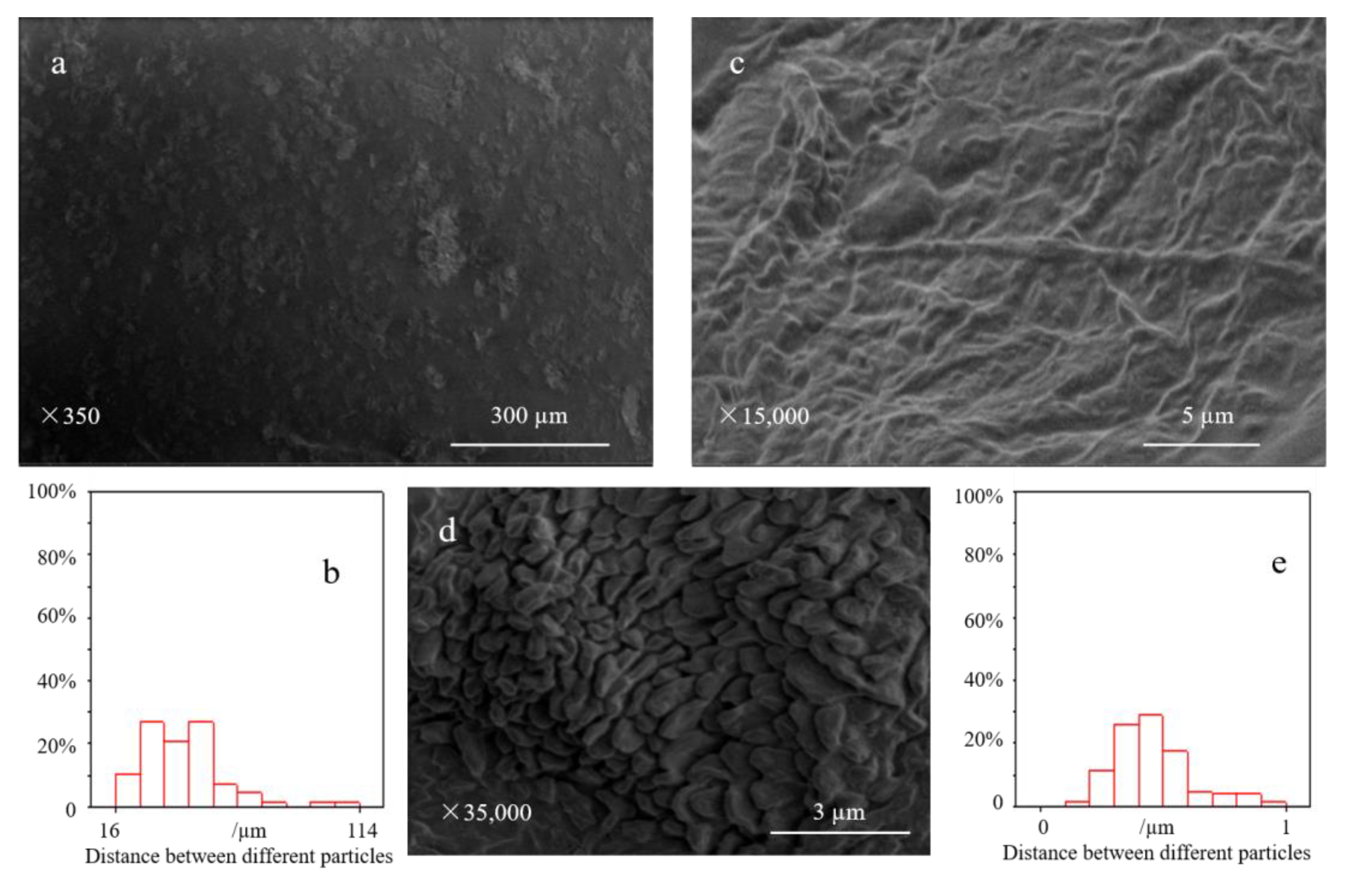

An SEM test was used to determine the micromorphology and dispersion of graphene/tourmaline in the composite-modified asphalt. The SEM images of raw materials are shown in Figure 2, and the SEM images of the graphene/tourmaline-composite-modified asphalt are shown in Figure 3 and Figure 4.

Figure 2. SEM images: (a) Tourmaline (×10,000); (b) Graphene (×35,000).

Figure 3. (a) SEM image and (b) particle size distribution of modified asphalt with 10 wt% G1.5/T100.

Figure 3. (a) SEM image and (b) particle size distribution of modified asphalt with 10 wt% G1.5/T100. Figure 4. SEM images and particle size distributions of modified asphalt with 30 wt% G1.5/T100: (a) SEM (×350); (b) Particle size distribution (×350); (c) SEM (×15,000); (d) SEM (×35,000); (e) Particle size distribution (×35,000).

Figure 4. SEM images and particle size distributions of modified asphalt with 30 wt% G1.5/T100: (a) SEM (×350); (b) Particle size distribution (×350); (c) SEM (×15,000); (d) SEM (×35,000); (e) Particle size distribution (×35,000).2.3. Basic Performance

Different graphene/tourmaline-composite-modified asphalts were prepared according to the optimum preparation parameters. The temperature susceptibility, high temperature and anti-aging properties of graphene/tourmaline-composite-modified asphalt have been studied. The enhancement effect of graphene on the performance of tourmaline-modified asphalt was confirmed.

2.3.1. Temperature Susceptibility Performance

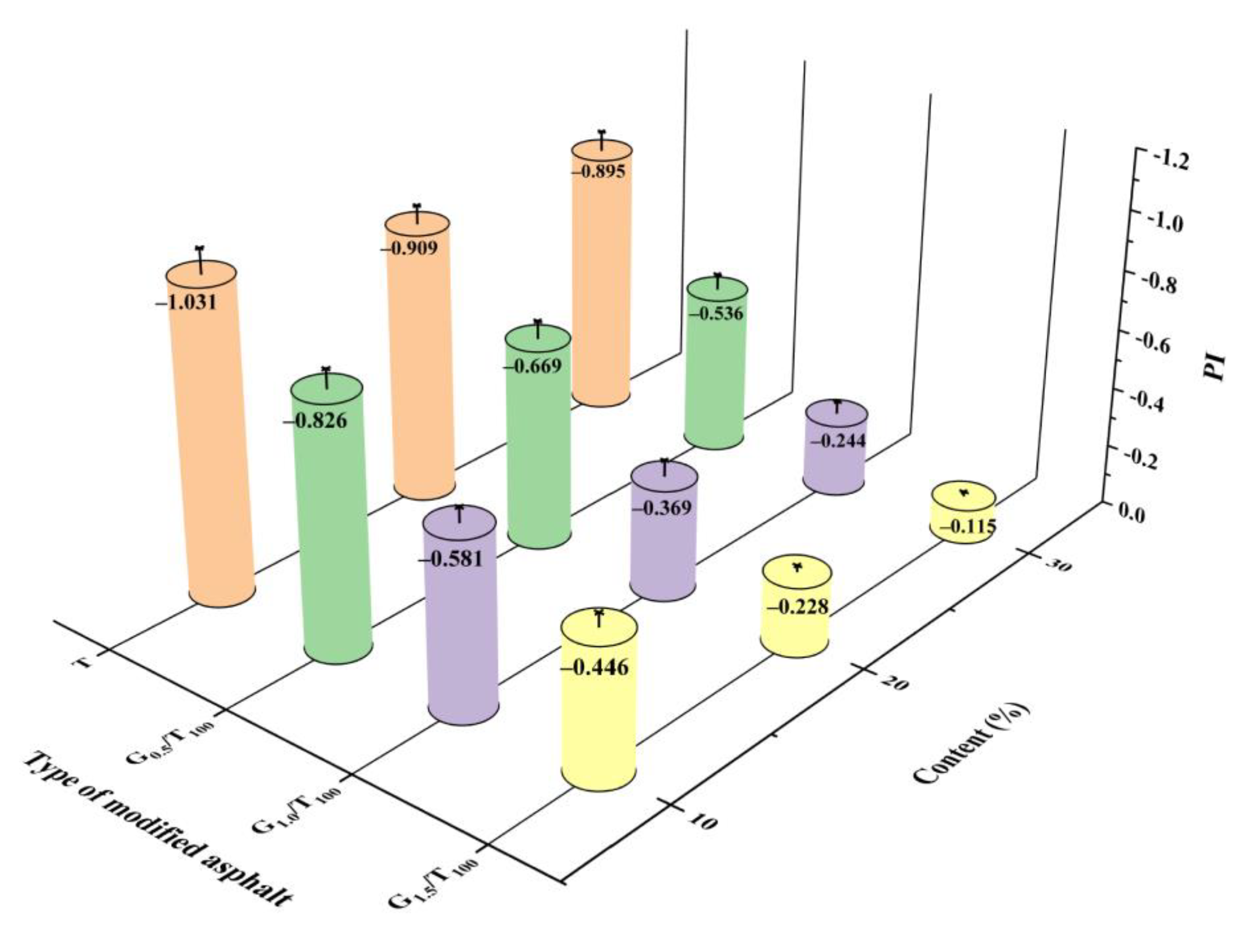

The penetration of each modified asphalt was tested at 15 °C, 25 °C and 30 °C. The penetration index was calculated. The influence of the content of the graphene/tourmaline composite powder on the temperature susceptibility performance of asphalt was analyzed. The results are shown in Figure 5.

2.3.2. High Temperature Performance

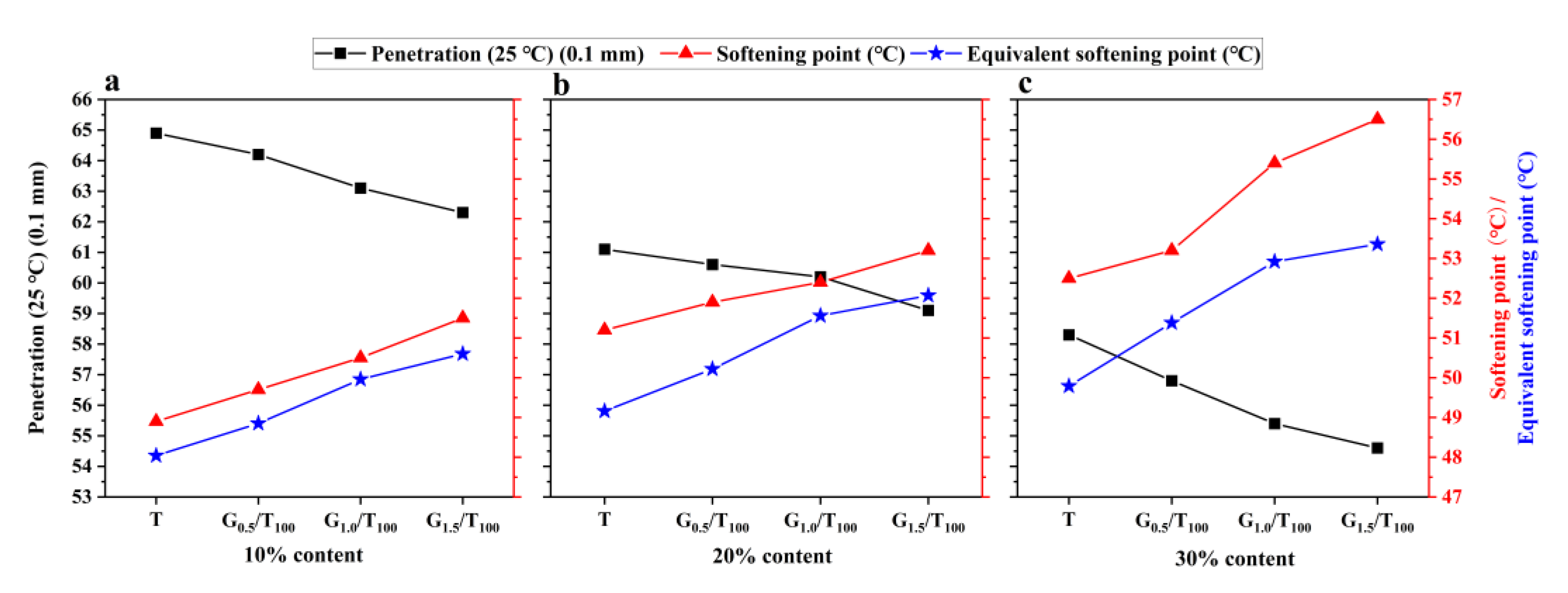

To study the influence of the content of graphene/tourmaline composite powder on the high temperature performance of asphalt, the penetration and softening point of each asphalt were tested, and the equivalent softening point was calculated. The results are shown in Figure 6.

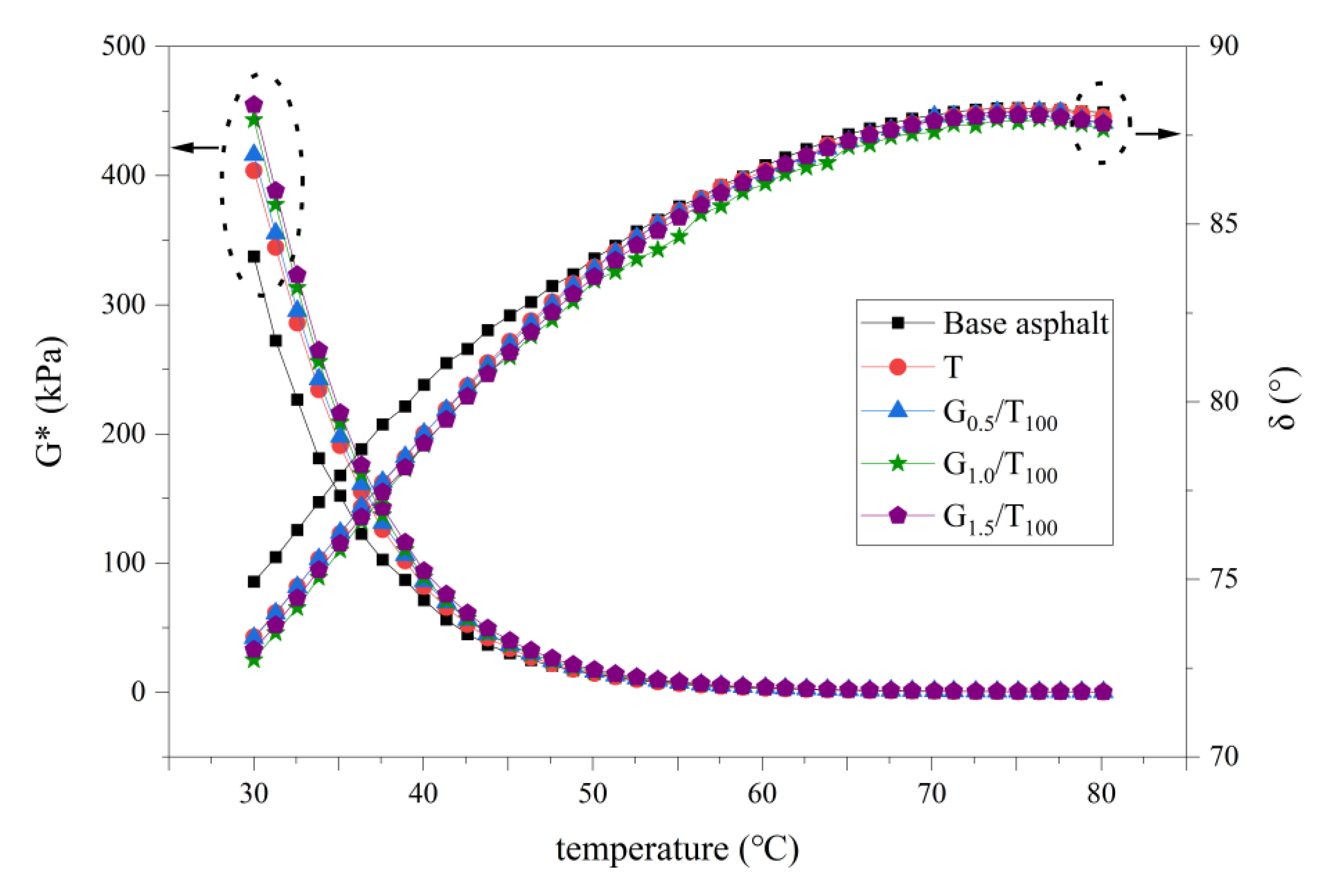

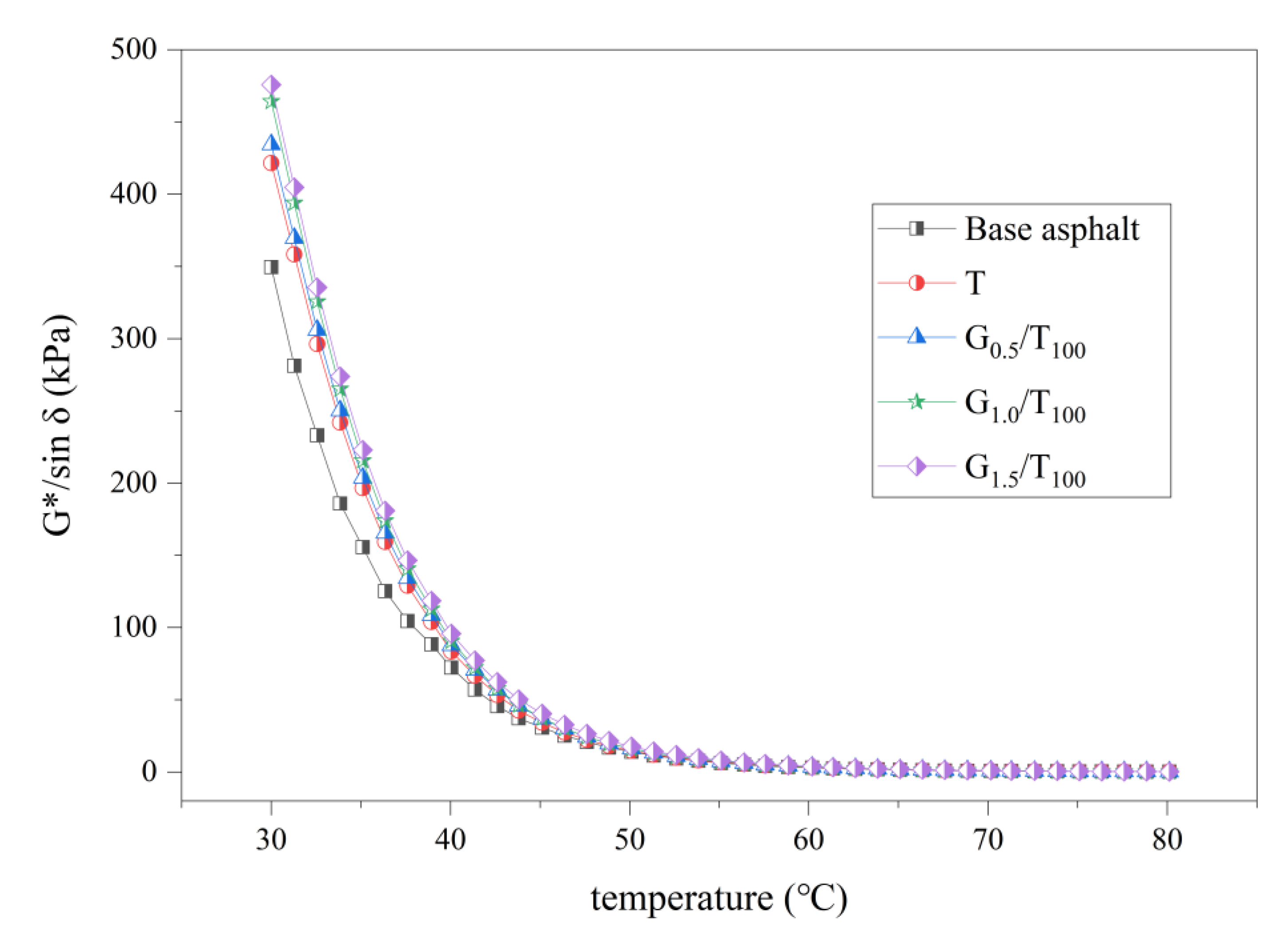

2.3.3. Rheological Performance

As a typical viscoelastic material, the performance of asphalt is strongly dependent on temperature. In the process of pavement use, asphalt needs to bear a certain temperature load coupling effect. Through the temperature scanning test, the rheological performance of graphene/tourmaline-composite-modified asphalts are tested, and the results are shown in Figure 7 and Figure 8.

Figure 8. Rutting factor (G*/sin δ) of different graphene/tourmaline-composite-modified asphalts.

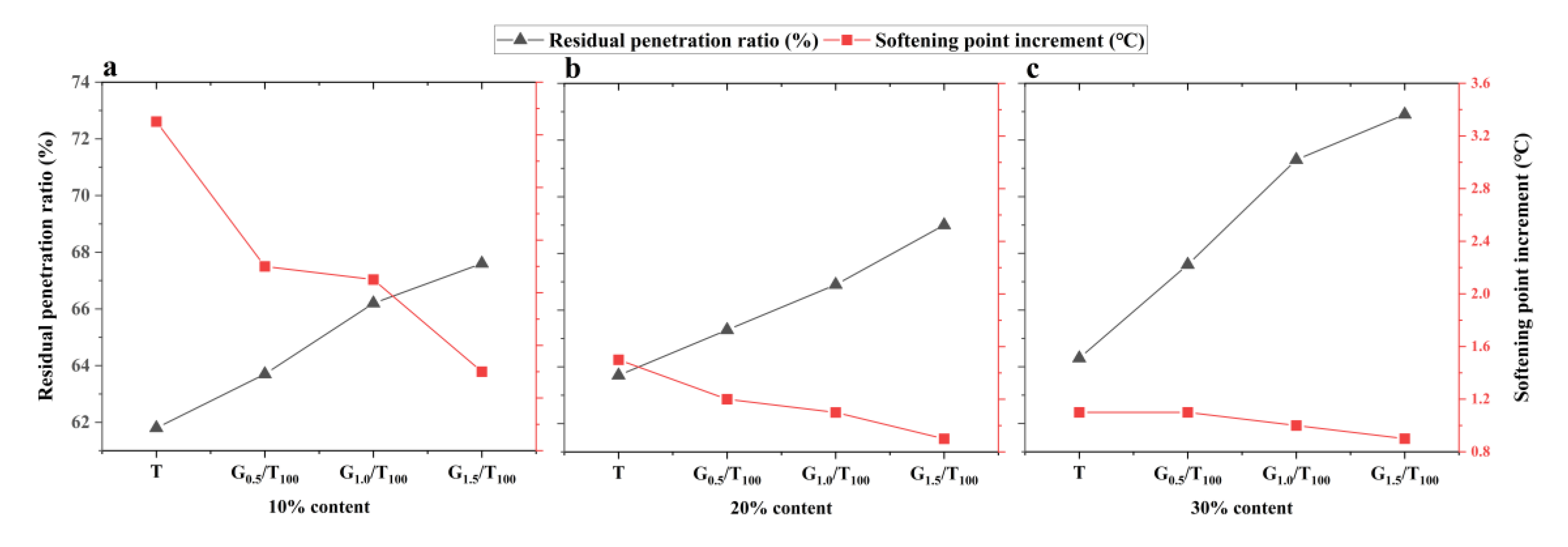

2.3.4. Anti-Aging Performance

The asphalt was aged by RTFOT. The penetration and softening point of the asphalt after aging were measured. The residual penetration ratio and softening point increment were calculated respectively. The effects content of graphene/tourmaline composite powder on the asphalt anti-aging performance were studied. The results are shown in Figure 9.

2.4. The Emission Reduction Effect of Hot Mixing

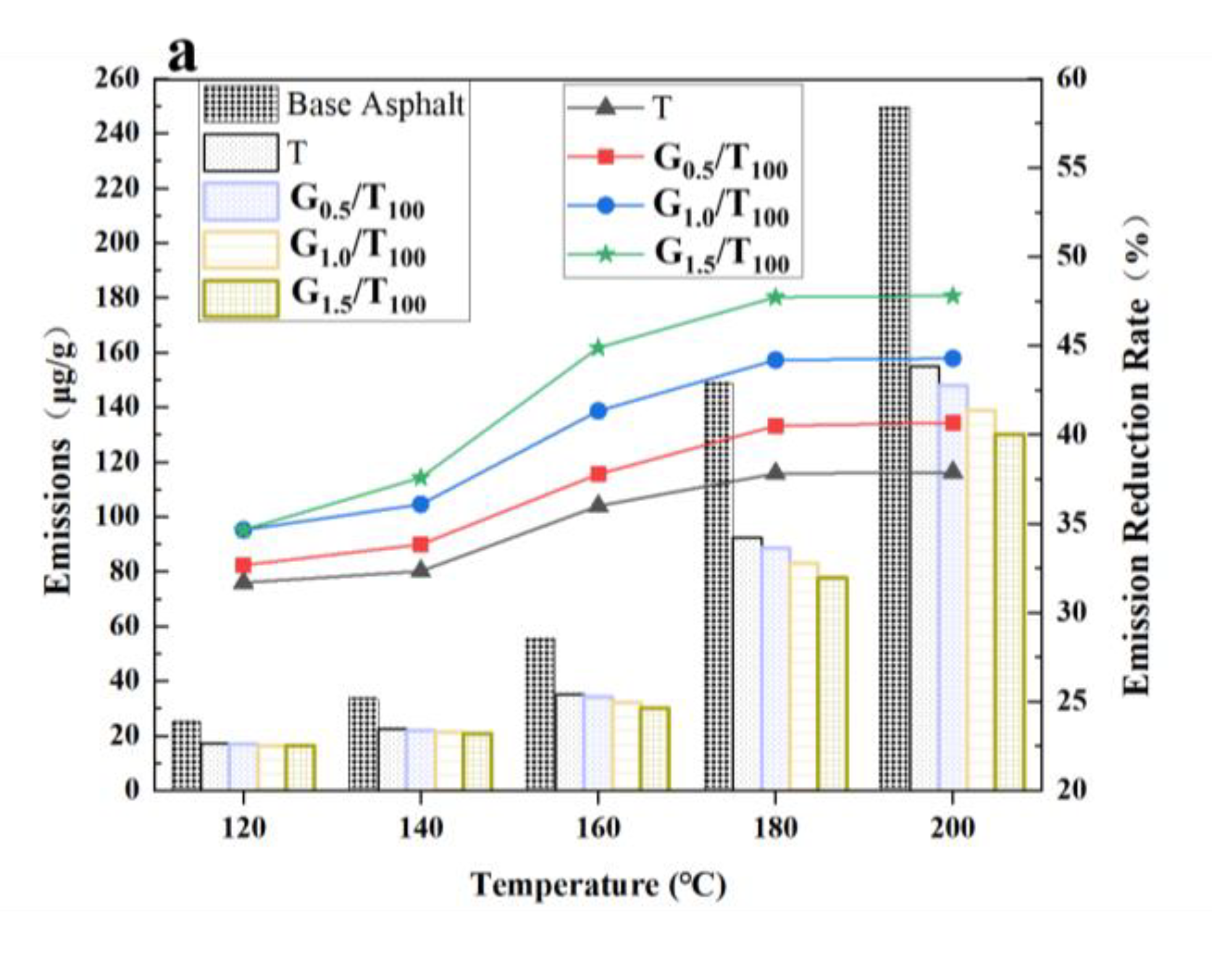

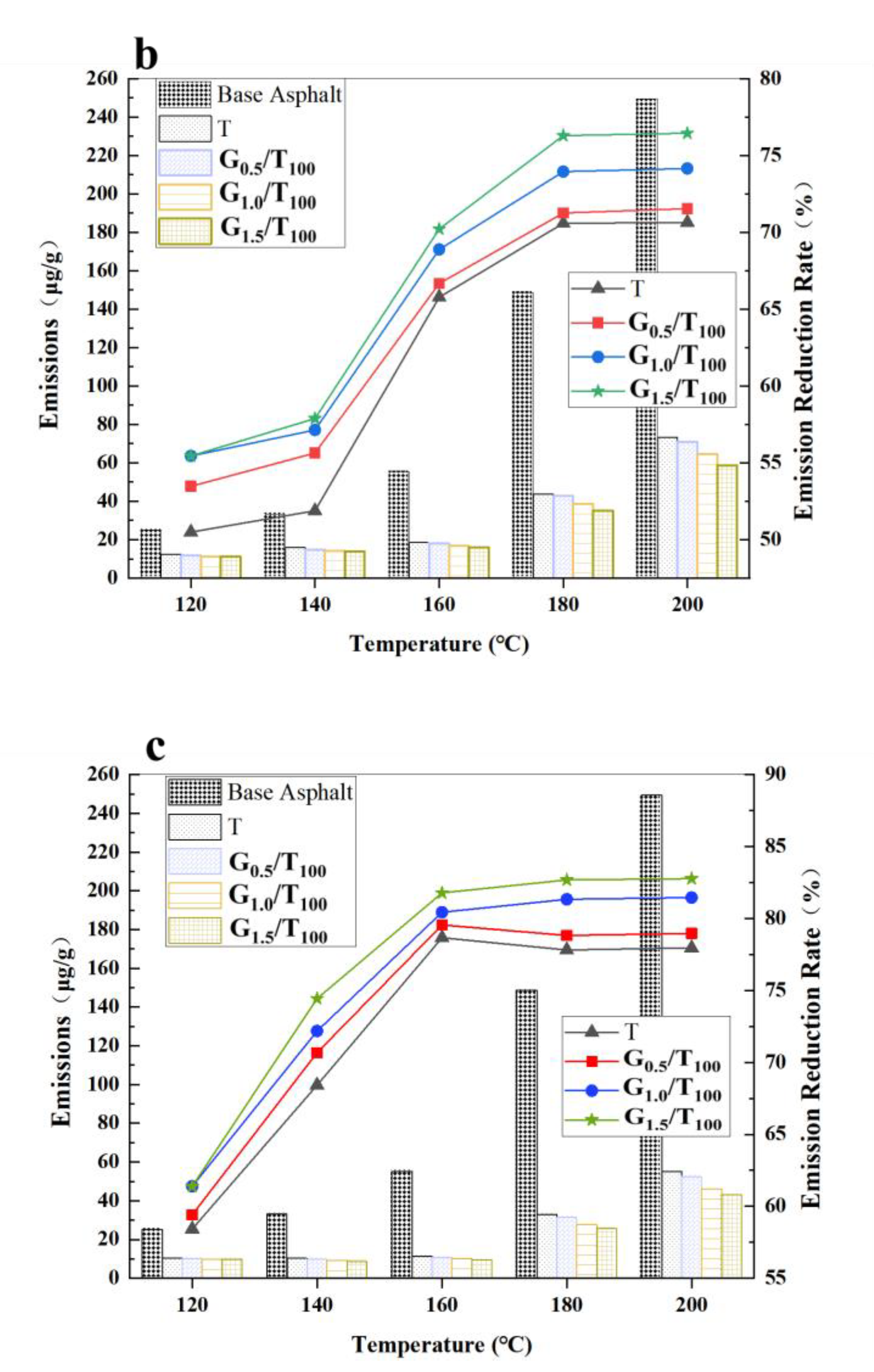

2.4.1. Analysis of Asphalt Fume Emission Reduction Effect

Graphene/tourmaline-composite-modified asphalts were prepared. The emission reduction effect of graphene/tourmaline-composite-modified asphalt during its heating was tested. The asphalt fume emission and emission reduction rate at different temperatures are shown in Figure 10.

Figure 10. Asphalt fume emission reduction effect: (a) Emission reduction effect at 10% content; (b) Emission reduction effect at 20% content; and (c) Emission reduction effect at 30% content.

Figure 10. Asphalt fume emission reduction effect: (a) Emission reduction effect at 10% content; (b) Emission reduction effect at 20% content; and (c) Emission reduction effect at 30% content.2.4.2. Analysis of NOX and COX Emission Reduction Effect

A graphene/tourmaline-composite-modified asphalt mixture was prepared. The emission reduction effects of NOX and COX in the mixing process of asphalt mixture with different contents of graphene/tourmaline composites were tested. The test results are shown in Table 3.

Table 3. Test results of pollutant emissions during the mixing process of graphene/tourmaline-modified asphalt mixture.

| Mixture Type | Content/wt% | NOx | COx | ||

|---|---|---|---|---|---|

| Concentration/ppm | Emission Reduction Rate/% | Concentration/ppm | Emission Reduction Rate/% | ||

| Base Asphalt | -- | 92.75 | -- | 87.89 | -- |

| Tourmaline-modified asphalt | 10 | 60.62 | 34.64 | 56.91 | 35.25 |

| 20 | 32.58 | 64.87 | 21.65 | 75.37 | |

| 30 | 28.46 | 69.32 | 18.50 | 78.95 | |

| G0.5/T100-modified asphalt | 10 | 60.32 | 34.97 | 56.24 | 36.01 |

| 20 | 32.25 | 65.23 | 21.00 | 76.11 | |

| 30 | 27.66 | 70.18 | 17.95 | 79.58 | |

| G1.0/T100-modified asphalt | 10 | 59.17 | 36.21 | 54.50 | 37.99 |

| 20 | 29.83 | 67.84 | 19.46 | 77.86 | |

| 30 | 25.68 | 72.31 | 16.73 | 80.97 | |

| G1.5/T100-modified asphalt | 10 | 59.71 | 35.62 | 55.41 | 36.95 |

| 20 | 30.63 | 66.98 | 20.31 | 76.89 | |

| 30 | 26.57 | 71.35 | 17.61 | 79.96 | |

3. Conclusions

The basic performances, rheological performance and emission reduction effect of graphene/tourmaline-composite-modified asphalt were studied. The micromorphology and dispersion of graphene/tourmaline in the composite modified asphalt were clarified. In addition, the mechanisms of the modifier strengthening asphalt’s performance was determined. The details are as follows.

-

The basic properties of graphene/tourmaline-composite-modified asphalt are better than those of tourmaline-modified asphalt and base asphalt, and the improvement effect is more obvious with the increase of graphene content. Compared with tourmaline-modified asphalt, the temperature susceptibility performance, high temperature stability and anti-aging performance of graphene/tourmaline-composite-modified asphalt increased by 87%, 8% and 58%, respectively.

-

Graphene/tourmaline composites do not change the viscoelastic performance of asphalt. It improves the rutting resistance of asphalt. Compared with base asphalt, the rutting factor of composite modified asphalt is increased by 19 to 20%.

-

The asphalt fume reduction effect of graphene/tourmaline-composite-modified asphalt is better than that of tourmaline-modified asphalt. With the increase of graphene content, the emission reduction performance is improved. The asphalt fume reduction rate of the composite modified asphalt can reach 83%.

-

The emission reduction effect of NOX and COX in the mixing process of graphene/tourmaline-composite-modified asphalt mixture is better than that of tourmaline-modified asphalt mixture, and the emission reduction rates can reach 70% and 80%, respectively.

-

Compared with tourmaline-modified asphalt, the glass transition temperature of graphene/tourmaline-composite-modified asphalt decreased, and the heat absorption and heat release were higher. The thermal stability and anti-aging properties are improved.

Due to the high price of graphene, the cost of graphene/tourmaline composites is higher than the typical asphalt modifiers. The cost of graphene/tourmaline composites will limit their further promotion and application in the road field. Future research should focus on the reduction of material costs. In order to further improve the research, more testing and analysis methods of asphalt road performance should be added in the future. In addition, the components of asphalt fumes are complex and diverse. Therefore, the adsorption performance and its mechanism of each component of the modifier should be focused on.

Information

Subjects:

Chemistry, Inorganic & Nuclear

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.5K

Revisions:

2 times

(View History)

Update Date:

24 Aug 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No