| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Frank Van Eerdenburg | + 4493 word(s) | 4493 | 2021-07-29 11:40:29 | | | |

| 2 | Conner Chen | Meta information modification | 4493 | 2021-08-11 03:58:07 | | |

Video Upload Options

Lying is an important behavior of dairy cattle. Cows should spend more than 50% of a day lying as it has a high impact on their milk yield and animal welfare. The design, size, and flooring properties of the free stalls influence the time cows spend lying, the way they lie down, and their rising movements. The design of the free stalls should enable the cows to move and lie in positions as natural as possible. Cows should rest, with all parts of the body, on a clean, dry and soft bed, be able to stretch their front legs forward, lie on their sides with unobstructed space for their neck and head, and rest with their heads against their flanks without hindrance from a partition. When they stand, they should not be hindered by neck rails, partitions, or supports. A comfortable place for cows to lie down helps cows to stay healthy, improve welfare, and increase milk yield. Hence, the probability of a longer productive life for the cows increases and the number of replacements per year decreases.

1. The Free Stall

A free stall should be designed to provide the animals with a suitable, safe, and hygienic resting place, allowing normal behavior (e.g., normal lying down and raising movements), however, at the same time, defecation behaviors should be controlled. The design of the free stalls should enable the cows to move and lie in positions as natural as possible. Cows should be able to rest, with all parts of their body, on a clean, dry, and soft bed; be able to stretch their front legs forward; lie on their sides with unobstructed space for their neck and head; and rest with their heads against their flanks without hindrance from a partition. When they stand, they should not be hindered by neck rails, partitions, or supports [1]. Hence, when using a stall construction with several fixed restrictions, there is a risk that normal behavior during rest, lying down, and rising may be influenced or restricted too much [2]. Some design and management parameters may also have other effects than intended or even negative effects on other traits [3]. One example may be that larger stalls are positive for the lying time of the animals [4] but are also associated with more dirt in the stalls [5][6]. Consequences of design errors may be related to health, production, behavior, or hygiene. Dirty stalls and cows are associated with an increased incidence of infections of the udder, higher prevalence of lameness, and reduced milk quality [7][6][8][9][10][11][12][13][14][15][16][17][18][19][20]. Other conditions like the number of cows per stall, barn lay-out, previous experience with free stalls (early adaptation to the system), and the interactions between animals as well as with the farmer [21] should also be taken into consideration when designing a free stall based system.

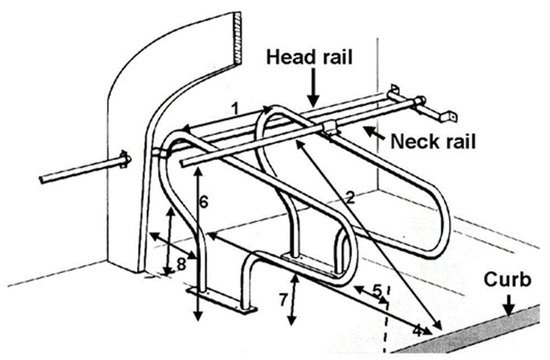

The major components of a free stall (see Figure 1) are the surface for lying (the free stall base including bedding materials), the stall components defining accessible space laterally in stall (the stall dividers), and the rails intended to define lengthwise space in the stall accessible for the cow (curb, head-, and neck rails, and brisket locator).

Figure 1. Schematic drawing of a free stall of a dairy barn. The numbered arrows indicate the dimensions as used by Irish and Merrill [22] (see Table 3).

2. The Surface for Lying (Free Stall Base)

2.1. Softness

The stall base can be made of different materials and construction, but has the main function of being a comfortable place for cows to rest or stand upon. Dependent on construction and type of divider, in many cases, it also functions as a basis for the fixation of stall parts. The general conclusion from the bedding preference literature, reviewed by Tucker and Weary [3], is that dairy cattle prefer softer surfaces. Preference testing provides information about cow choices, and these preferences provide insight into the features of the stall that are likely to be important to cows. Several experiments have shown that dairy cows have a preference for resting on soft surfaces [23][24][25][26][27][28][29][30][31][32][33][34][35][36][37][38] and there also seems to be a close relationship between softer stall bases, increased lying time [4][35], and improved stall cleanliness [20][33]. Reasons for preferring soft floorings may be found in improved comfort due to reduced contact pressure to protruding body parts when lying, improved friction when raising [39][40], but also reduced heat loss in cold climates [30][39]. In contrast, in a warmer climate, there have been discussion as to whether bedding materials with high thermal conductivity would be beneficial [41][42], and a preference for “cold” limestone over for instance “warm” wood shavings has also been found [43]. This illustrates that the choice of bedding could also be used as part of heat stress abatement strategies. Ortiz et al. showed that the use of forced cooling is preferred by the cows during warm periods [41]. A comfortable stall base in a free stall that allows for normal lying behavior is important to ensure that the cows choose to use the stall for rest, sleep, and rumination and also reduces the risk for cows to get lesions or other damage to their body [44][45][46]. If the flooring in free stalls is comfortable, the cows also produce more milk [47][48][49] because the mammary blood flow increases during lying by 25–50% [45], which is correlated with milk yield [46]. Lying costs less energy and is preferred over standing idle by cows. The time spent ruminating is also maximized when lying [48].

Cows drop down on one of their carpi when they are going to lie down [50]. The maximum load at each carpus is approximately 2 kN during rising or lying down movements [30][39]. Because there is not much subcutaneous fat in the knee, there is no cushioning of this force, resulting in a rather painful event for the cow if the floor is hard. Thus cows will become reluctant to lie down, resulting in reduced lying times. Flooring properties including the amount of bedding are important in this respect [51][4][52]. A quick test of the softness of the bedding is to let oneself drop quickly on the knees. This ‘knee test’ should preferably be executed by the farmer. If it hurts for the farmer, it will also hurt for the cow. This is usually a good way of convincing farmers to improve the bedding, however, the test is subjective. In order to provide a simple and objective method for measuring stall base softness, Nilsson [30] expressed softness as mm impact of a sphere (diameter = 100 mm) at 2 kN load, a method adapted to a sphere with the approximate diameter of a cow’s knee (diameter = 120 mm) by ADAS [49], and still used in standardized tests performed by DLG in Germany [53]. The method was also adapted to softer surfaces than mats (e.g., sand and straw) by Tucker et al. [52], known as the mixing bowl method. Recommended softness of a stall base is a minimum 16 mm impact of a 120 mm sphere at 2 kN load [54][39], preferably more than 20 mm. Ruud et al. [47] found increased softness to be associated with increased milk yield, reduced incidence of mastitis, and reduced number of involuntary removals in a survey in 232 free stall dairy herds. Cows housed on multilayer mats and mattresses in that study had 1.1% to 5.8% higher milk yields than concrete lying surfaces. This is similar to results of Calamari et al. [55]. Other studies have not found similar effects (e.g., Bewley et al. [56] and Fregonesi and Leaver [57]). The number of teat lesions dropped dramatically with flooring softness >8 mm impact, and the number of involuntary cullings dropped with increased softness, indicating a longer life span [47].

2.2. Friction

Cows should be able to lie down and stand up easily in the same way as they do on pasture, hence they should have sufficient grip in the stalls [58]. A bedding that is rough could, however, easily cause abrasion of the skin and lead to injured hocks (Figure 2) or other injuries [59]. Some abrasive materials, like sand, are not abrasive when applied in a thick layer (>10–15 cm) and even sawdust, which can be considered as soft and non-abrasive, becomes abrasive if there is only a thin layer (a few millimeters) present [60]. It is thus important to provide enough bedding material independent of the type [51][61]. Amount or depth of bedding is also a question regarding cost as well as management. When worn, concrete floors are a major risk factor for trampled teats due to insufficient grip [62]. Cows frequently stand in stalls for shorter periods, hence properties related to “standing stability” (firm and with good friction) are of importance. Such properties are not studied in detail in scientific studies known to us.

Figure 2. Abrasion of the hock of a dairy cow due to bad or insufficient bedding material in the free stalls.

2.3. Bedding Materials

A large variety of flooring materials are available and in use (see Table 1), however, the selection of bedding is often decided according to local availability. Bedding could be described according to the physical, chemical, and biological properties [63]. Bare concrete is too hard, and not recommended. It is even forbidden as the only stall flooring in some countries (e.g., in Norway) [64]. Most of the modern types of stall surfaces are soft enough to fulfill animal demands (e.g., rubber filled mattresses, waterbeds, and rubber mats that have a structure providing cushioning), whereas for some older products (i.e., compact rubber mats), the lying comfort is often at a non-acceptable level for use in a free stall. Acceptable softness could also be achieved by using loose bedding materials like sand, straw, or sawdust, when provided in a thick layer [61]. Cows clearly prefer lying surfaces with more bedding, and they spend more time lying down in well-bedded stalls than in those with little or no bedding [24][4][52][65][66], likely because this provides a softer lying surface [40]. Thin layers of sand may reduce the time spent lying with 2.33 h compared with a thick one [61].

Table 1. The table describes flooring types categorized according to typical softness, and illustrates plausible consequences of flooring softness for the dairy cows.

| Flooring Type | Softness 1 (mm Impact) |

Plausible Consequences |

|---|---|---|

| Concrete | 0 | Increased risk for teat lesions, mastitis and involuntary removal. Short resting time. Decreased milk yield |

| Compact rubber | 5–10 | Increased risk for mastitis and involuntary removal. Short resting time. Decreased milk yield |

| “Knob” mats | 10–15 | Increased risk for skin lesions. Somewhat short resting time and decreased milk yield |

| Softer structured rubber mats and multilayer mats | 16–30 | Normal resting time, udder health, milk yield, etc. |

| Rubber filled mattresses | 20–40 | |

| Water bed | >40 | |

| Sand | >40 | |

| Deep straw | >40 |

Bedding serves two purposes. First, it softens the floor in order to improve comfort and welfare of the cow. Second, it keeps the cow and the area they lie on clean. This is best achieved when bedding is dry, as also preferred by the cows [68]. The comfort of a stall will depend greatly on the type, amount, and quality of bedding in the stall [51][58]. Optimal bedding should provide adequate thermal insulation or cooling (depending on the temperature), an appropriate degree of softness, an appropriate degree of friction, a low risk of abrasion, and should be easy to maintain and clean [41][42][43][67][69].

Bedding should also be dry and clean in order to prevent the growth of bacteria [20]. Cows show a clear preference for dry bedding over wet material [66]. It is, therefore, important to cover soft cow mattresses with a layer of sawdust, straw, turf, ground limestone, etc., just to keep it dry and clean [65]. In this respect, the water holding capacity of the bedding material is important [63]. However, sand does not absorb water or liquids. It just drains to the bottom of the free stall and thus keeps the top layer dry. Whereas the top layer of an absorbing material will stay wet and needs to be replaced frequently. Adequate ventilation increases the evaporation of the moisture and thus contributes in keeping the bedding dry. A simple way of finding out in practice if the bedding is dry enough is when doing the knee test for softness, where one stays on the bedding for 10 s with all the weight on one knee. If the knee remains dry, the bedding can be considered as dry enough. In general, a regular (minimal twice a day) cleaning and refreshing of the bedding is required, however, this is also dependent on the stall design. Most bedding material used is made of organic compounds and is, therefore, a risk factor for the growth of bacteria unless dry [18][58][70][71][72][73]. A high bacterial count in the bedding can be a risk factor for the development of mastitis [9][12][15][74][75]. However, the major problem increasing the incidence of lameness, mastitis/SCC [6][15][16][18][19][76], and inducing a higher bacterial count in the bulk milk tank [18][20] is probably contamination of the bedding with manure.

The most used loose bedding materials are straw, sawdust, recycled manure solids, sand, and ground limestone [58]. Other loose materials in use are shredded paper, wood chips, horse manure, and other wastes of organic material. Sand and ground limestone are inorganic materials commonly associated with low bacterial counts in the bedding, given that the bedding is sufficiently clean [18][73][75]. One ideal bedding material for all farms does not exist, since every farm has its own characteristics according to location, management, size, etc., and availability of certain materials, like sand, or the type of farm, ultimately determine the choice of the farmer. Organic farms, for example, focus more on the nutrient content of the manure and thus straw is preferred over sand. Hence, it is normally more important to consider the traits of the selected bedding (e.g., soft, dry, and clean) than the choice of bedding per se.

Straw

Straw is one of the oldest bedding materials. It used to be a waste product of the agricultural division of a mixed farm, however, these days, straw can be rather expensive in certain areas due to competitive use. It provides a soft and dry bed for the cows when applied and maintained properly. Straw can be used long or chopped. Chopped straw is easier to apply, but contains more dust and can sometimes be abrasive. When used as the only bedding material, it should be applied in a thick layer of a minimum 15 cm, but preferably 30–40 cm [52][77][78].

Sawdust

Sawdust is used both as the only bedding material in deep litter beds or as a hygienical covering on other flooring materials. As for straw, if used as the only bedding material, sawdust needs to be applied in a thick layer of >15 cm (or >7 kg per stall) to act as a cushion [51][24][60][76]. The sawdust should be proper sawdust and not mixed with splinters. In order to keep the sawdust (or straw) on the free stall, a metal/plastic pipe or rubber strip of 15–30 cm height can be mounted on the rear curb of the free stall [79]. Sawdust should fill the bed up to the level of the retainer, otherwise cows may injure the dorsal sides of the point of their hocks quite easily [80].

Because sawdust has a high absorption capacity, it is often used to keep other bedding materials like rubber mats or mattresses dry. Sawdust is an organic material, and to keep bacterial count under control, it should be dry and clean. In a dry and cool environment, the growth rate of the bacteria is low, however, under common conditions, the bacteria numbers may reach their maximum within two days [16]. Hence, daily refilling of sawdust is recommended [20].

Daily change of the bedding in the rear part of the free stall will keep the bacterial count low [8], and a complete change of the bed should take place at least every week [70]. Manure and leaked milk should be removed at least twice a day. Storing larger amounts of bedding (e.g., in the front part of the free stall) is challenging, since bacteria will start growing from the moment it is in place and after some days, bacterial counts may be high, although the sawdust might still ‘look’ clean [15][16].

Recycled Manure Solids

Manure can be separated by compression, and the remaining solids can be used as bedding material in free stalls. It can be used after processing (drum composting) or immediately after compression. Drum composting reduces the number of E. coli bacteria. Further drying by blowing air reduces the moisture content, but has no influence on the number of bacteria [81][75]. The bacterial counts in the bedding are reflected in those on the teat ends and bulk milk [15][18]. It is, therefore, important to monitor the hygienic status and ventilation very closely. So far, no reports have been published about a higher incidence of mastitis or somatic cell count [81][75][82]. Advantages are the availability, and thus the use of thick layers in the stalls (>30 cm), which increases lying times, cow comfort, and welfare [52][75][80]. Disadvantages may be the high number of bacteria present in the bedding, and use in humid climates and/or poorly ventilated barns could lead to a high moisture content in bedding [15][18] as well as high air humidity.

Sand/Ground Limestone

Loose sand conforms to the shape of the body and when applied in a deep layer (>25 cm), it provides a good bedding material for the cows with high cow comfort and good udder health, however, the consumption of sand is high [80][83]. The amount of sand that has to be added on a daily basis ranges from 14–20 kg per stall [84]. The consumption of sand increases with filling level, however, proper maintenance is essential for good cow comfort. Drissler et al. [61] found that for every 1-cm decrease in sand bedding, cows spent 11 min less time lying down. In their trial, cows had access to free stalls with sand bedding that was 0, 3.5, 5.2, or 6.2 cm at the deepest point.

Sand bedding may also help to minimize stepped-on teat injuries. These teat injuries often occur during the rising of cows in stalls. In sand-bedded stalls, the claws move into the sand while the udder remains positioned on the sand surface, thereby lengthening the distance between the claw and the teats.

Because cows spill sand into the alleys, it also improves footing [61]. Therefore, the sand should not contain small stones. The sand should not be too fine either; after a while it will become hard like concrete [85]. On the other hand, large grains will be rough and can cause skin abrasions. Sand of good quality may reduce the number of hock lesions [18][63]. Instead of absorbing moisture, sand lets it filter easily to the bottom of the stall, thus keeping the upper (contact) level dry. Since sand and ground limestone are inorganic, they provide a poor environment for the growth of bacteria (if clean), which is reflected in the bacteria numbers found on the teats of the cows [15][75]. This advantage, combined with good cow cleanliness and that it also provides cooling during warm summer months, makes it a popular choice of many dairy producers (e.g., in the USA).

The major disadvantage of using sand as free stall bedding seems to be manure management. Sand can settle to the bottom of manure collection pits, storages, and spreaders, making removal difficult [86]. It is, therefore, not a good option in combination with slatted floors, which are common in various countries like the Netherlands and Norway. Sand is abrasive and can cause excessive wear on manure scrapers, pumps, and separators. To keep more bedding in the stall, a pipe/strip at the rear end of the stall or so called sand savers can be used [85].

Ground limestone is soft and inorganic and is often mixed with sawdust or wood shavings to improve the moisture absorption. When used pure, the pH of crushed limestone is relatively high (7.91). This resulted in a low growth rate of bacteria in a study by Janzen et al. [75], but this may also result in teats with a dry and irritated skin. ‘Sprinkling’ crushed limestone over the free stalls to reduce bacterial growth, however, does not result in a proper distribution through the bedding material and therefore does not have the desired effect on bacterial growth [75].

Rubber Mat

Rubber mats have been widely used for decades. The quality and comfort for the cows varies between the brands. In general, mats that get old tend to acquire very small fractures, which can become sources for bacterial infections (environmental mastitis) [14]. Care should be taken that the mats do not buckle. Most of the older types of mats are made of solid rubber and are rather firm, however, when applied with sufficient sawdust or sand on top (>5 cm), they can result in a moderately comfortable bed for the cows [79][87]. Rubber mats with rubber protrusions underneath (“knob mats”) provide better cushioning compared to compact rubber mats, and new and softer types are steadily being introduced into the market, many of these softer than 20 mm impact. Soft lying mats are equivalent to straw bedding in terms of resting time, but less favorable with respect to leg injuries located in the tarsal joints, according to Wechsler et al. [88].

Cow Mattress

Cow mattresses are a compromise between comfort for the cow and the amount of work and money spent by the farmer [89][90][91][92][93]. The original mattresses were big bags filled with straw, wood chips, corn stalks, ground cork, or rubber. They were comfortable for the cows when new, but after a period, dents tended to be created because of uneven load distribution [94][95][96][97]. Therefore, the modern mattresses have a structured base by a quilting procedure. Most mattresses these days are made of tubes of nylon fabric filled with ground rubber (e.g., from recycled car tires) or plastic foam. The tubes are placed parallel and a fabric covering is put on top [94]. Mattresses as well as the top layer are available in many different types, thickness, and qualities. If dents are formed after a few years of use, the cover can be removed, and the tubes reshuffled. The cover can be placed again, and the cows have a comfortable bed for another number of years. On top of a mattress, a layer of sawdust or other absorbing bedding material is needed to keep it dry and clean [20]. A thick layer of saw dust (7.5 kg per stall) improves lying comfort [67]. In general, both multilayer mats and rubber filled mattresses provide proper comfort for lying. However, bare mattresses result in more hock lesions than deep-bedded sand or sawdust [7][80][95].

Waterbed

Waterbeds are rubber bags filled with water. They are not heated. Lying comfort is good, however, during lying down or rising movements, the cow places most of her weight on the carpi, pushing the water away, which may be painful, depending on the base of the waterbed [40]. Dual waterbeds have a small chamber in the area of the carpi to avoid this problem [98]. When the cow leaves the stall, the water mattress regains its rounded shape and all liquids on the top of it, like leaked milk, will run down onto the alley. Bedding should be used to absorb the remaining humidity. In this way, it may prevent bacterial growth and thus mammary infections. Normally, cows need a few days to get used to the feeling of the waterbed when entering the free stalls, and some cows prefer sand and certain mattresses over waterbeds [99][100].

3. Space—In General

The dimensions of free stalls are of importance for animals, as resting behavior and preference is influenced by stall size [51][87][101]. Size appeared to be more important than softness of the bedding for cows [102]. In a stall that is too small, a comfortable resting position is impossible (Figure 3) [51][103][104]. In the last decades, the body size of the dairy cows has increased substantially. However, the dimensions of the free stalls have not been adjusted accordingly on many farms; this is particularly a problem in older barns [103]. An overview of some of the recommended dimensions is presented in Table 2. The importance is well illustrated by Tucker et al. who investigated the effects of stall dimensions [101], neck rail position [5], and brisket board [104] on preference and stall usage. Therefore, stall size should match the size of the cows (Table 3). The basis for Table 3 is not well documented by the authors [22], however, it is commonly used and should preferably be updated in a scientific study. However, to base the design on the mean size of the cows in the herd means that the space will be too small for the bigger cows [31]. Free stall dimensions have to be selected based on the 20% largest cows of the herd. Since body size varies between breeds, it is obvious that stall size also has to be adapted to the breed; the same stall size will not work for both Jersey and Holstein Friesian. A uniform size of the herd is a prerequisite to offer the optimal stall size for as many animals as possible. It is also suggested that less attractive stalls (usually in the end of rows) should be 10% wider than other stalls, so “big” individuals could choose these ones [105]. To determine if the dimensions for free stalls are right, a careful look at the cows (behavior, posture, cleanliness, condition, bruises, hairless patches, and injuries) and the cleanliness and shininess of dividers and neck rails (meaning not clean or shiny) may confirm that the chosen dimensions are good [62][106][107]. Finally, one should be careful to assess single stall design parameters isolated from the others. A restrictive stall front design is associated with a higher need for lateral space [103]. The location of this lateral lunge space depends on the length of the free stall. It should be placed in such a way that the cow has an easy, natural access [83].

Figure 3. A free stall that is too short and narrow. The neck rail is shiny, indicating a restricted position. Furthermore, there is no lunge space due to the front wall and, finally, not enough (clean) bedding material.

Table 2. Recommended free stall design for dairy cattle. All measures in meters.

| NFA 1 (550 kg) |

Norw. Rec. 2 (550–650 kg) |

CIGR 3 (550 kg) |

Anderson 4 1st Lact (700 kg) |

McFarland 5 (550 kg) |

|

|---|---|---|---|---|---|

| Free stall length–wall | 2.40 | 2.60–2.70 | 2.39 | 2.74–3.04 | 2.34–2.49 |

| Free stall length–free | 2.10 | 2.40–2.50 | 2.06 | 2.43–2.74 | 2.03–2.19 |

| Free stall Width | 1.14 6 | 1.14–1.19 6 | 1.12 | 1.21 6 | 1.03–1.09 6 |

| Neck rail–height | 1.10 | 1.10–1.15 | “Not to low” | 1.22 | 1.07–1.17 |

| Neck rail–diagonal | - | 2.0–2.1 | - | - | - |

| Neck rail–horizontal | 1.6–1.7 | - | - | 1.73 | 1.58–1.63 |

| Upper head rail height | 0.8–0.9 | 0.95 | >0.73 | 0.86–1.02 | - |

| Lower head rail height | <0.2 | <0.1 | - | Absent | - |

| Brisket board height | 0.10 | 0.07–0.10 | - | 0.10 | 0.10–0.15 |

| Brisket board length | 1.70–1.80 | 1.80–1.90 | 1.63 | 1.78 | 1.58–1.63 |

| Rear curb height | 0.15–0.25 | 0.20–0.30 | 0.15–0.20 | 0.20 | 0.30 |

Table 3. Minimum free stall dimensions in relation to cow size. After Irish and Merrill [22].

| Dimension and Location | Animal Dimension |

|---|---|

| 1. Width (center to center of partitions) | Twice hip width |

| 2. Distance rear of curb to neck rail | Body length (rear of pin bones to brisket) or 210 cm (mean) |

| 3. Distance rear curb to open front | 1–1¼ body length |

| 4. Distance rear curb to closed front | 1–1⅓ body length |

| 5. Clearance rear of curb to rear of partition | At paunch height, ½ hip width or less |

| 6. Height stall bed to neck rail | ¾–4/5 shoulder height |

| 7. Clearance beneath side rails for legs and to block hips | ¾ hip width |

| 8. Clearance between rails for head (lunge) space | Hip width |

References

- Van Erp-van der Kooij, E.; Almalik, O.; Cavestany, D.; Roelofs, J.; Van Eerdenburg, F. Lying postures of dairy cows in cubicles and on pasture. Animals 2019, 9, 183.

- Bernardi, F.; Fregonesi, J.; Winckler, C.; Veira, D.M.; von Keyserlingk, M.A.G.; Weary, D.M. The stall-design paradox: Neck rails increase lameness but improve udder and stall hygiene. J. Dairy Sci. 2009, 92, 3074–3080.

- Tucker, C.B.; Weary, D.M. Stall design: Enhancing cow comfort. Adv. Dairy Technol. 2001, 13, 155–167.

- McPherson, S.E.; Vasseur, E. Graduate Student Literature Review: The effects of bedding, stall length, and manger wall height on common outcome measures of dairy cow welfare in stall-based housing systems. J. Dairy Sci. 2020, 103, 10940–10950.

- Tucker, C.B.; Weary, D.M.; Fraser, D. Influence of neck-rail placement on free-stall preference, use, and cleanliness. J. Dairy Sci. 2005, 88, 2730–2737.

- Robles, I.; Zambelis, A.; Kelton, D.F.; Barkema, H.W.; Keefe, G.P.; Roy, J.P.; Von Keyserlingk, M.A.G.; De Vries, T.J. Associations of freestall design and cleanliness with cow lying behavior, hygiene, lameness, and risk of high somatic cell count. J. Dairy Sci. 2021, 104, 2231–2242.

- Cook, N.B.; Hess, J.P.; Foy, M.R.; Bennett, T.B.; Brotzman, R.L. Management characteristics, lameness, and body injuries of dairy cattle housed in high-performance dairy herds in Wisconsin. J. Dairy Sci. 2016, 99, 5879–5891.

- Dodd, F.H.; Higgs, T.M.; Bramley, A.J. Cubicle management and coliform mastitis. Vet. Rec. 1984, 114, 522–523.

- Hogan, J.S.; Smith, K.L. Bacteria counts in sawdust bedding. J. Dairy Sci. 1997, 80, 1600–1605.

- Grommers, F.J. Mastitis in dairy cows with special reference to direct and indirect effects of climatological factors. In Energy Metabolism in Farm Animals; Verstegen, M.W.A., Henken, A.M., Eds.; M. Nijhoff: Dordrecht, The Netherlands, 1987; pp. 337–351.

- Matos, J.S.; White, D.G.; Harmon, R.J.; Langlois, B.E. Isolation of Staphylococcus aureus from sites other than the mammary gland. J. Dairy Sci. 1991, 74, 1544–1549.

- Rendos, J.J.; Eberhart, R.J.; Kesler, E.M. Microbial populations of teat ends of dairy cows, and bedding materials. J. Dairy Sci. 1975, 58, 1492–1500.

- Roberson, J.R.; Fox, L.K.; Hancock, D.D.; Gay, J.M.; Besser, T.E. Ecology of Staphylococcus aureus isolated from various sites on the farm. J. Dairy Sci. 1994, 77, 3354–3364.

- Schukken, Y.H.; Grommers, F.J.; van de Geer, D.; Erb, H.N.; Brand, A. Risk factors for clinical mastitis in herds with a low bulk milk somatic cell count. 2. Risk factors for Escherichia coli and Staphylococcus aureus. J. Dairy Sci. 1991, 74, 826–832.

- Zdanowicz, M.; Shelford, J.A.; Tucker, C.B.; Weary, D.M.; Von Keyserlingk, M.A.G. Bacterial populations on teat ends of dairy cows housed in free stalls and bedded with either sand or sawdust. J. Dairy Sci. 2004, 87, 1694–1701.

- Zehner, M.M.; Farnsworth, R.J.; Appleman, R.D.; Larntz, K.; Springer, J.A. Growth of environmental mastitis pathogens in various bedding materials. J. Dairy Sci. 1986, 69, 1932–1941.

- Kristula, M.A.; Rogers, W.; Hogan, J.S.; Sabo, M. Comparison of bacteria populations in clean and recycled sand used for bedding in dairy facilities. J. Dairy Sci. 2005, 88, 4317–4325.

- Van Gastelen, S.; Westerlaan, B.; Houwers, D.J.; van Eerdenburg, F.J.C.M. A study on cow comfort and risk for lameness and mastitis in relation to different types of bedding materials. J. Dairy Sci. 2011, 94, 4878–4888.

- Devries, T.J.; Aarnoudse, M.G.; Barkema, H.W.; Leslie, K.E.; von Keyserlingk, M.A. Associations of dairy cow behavior, barn hygiene, cow hygiene, and risk of elevated somatic cell count. J. Dairy Sci. 2012, 95, 5730–5739.

- Robles, I.; Kelton, D.F.; Barkema, H.W.; Keefe, G.P.; Roy, J.P.; Von Keyserlingk, M.A.G.; DeVries, T.J. Bacterial concentrations in bedding and their association with dairycow hygiene and milk quality. Animal 2020, 14, 1052–1066.

- Hemsworth, P.H.; Coleman, G.J. Human-Livestock Inter-actions: The Stockperson and the Productivity and Welfare of Intensively-Farmed Animals; CAB International: Oxon, UK, 1998.

- Irish, W.W.; Merrill, W.G. Design parameters for freestalls. In Proceedings of the Dairy Freestall Housing Symposium, Harrisburg, PA, USA, 15–16 January 1986; pp. 45–52.

- Fregonesi, J.A.; von Keyserlingk, M.A.G.; Weary, D. Cow preferences and usage of free stalls compared with an open pack area. J. Dairy Sci. 2009, 92, 5479–5502.

- Tucker, C.B.; Weary, D.M.; Fraser, D. Effects of three types of free-stall surfaces on preferences and stall usage by dairy cows. J. Dairy Sci. 2003, 86, 521–529.

- Von Keyserlingk, M.A.G.; Weary, D. Improving the welfare of dairy cattle: Implications of freestall housing on behavior and health. In Proceedings of the Western Dairy Management Conference, Reno, NV, USA, 11–13 March 2000; pp. 43–52.

- Wander, J.F.W. Zur Einrichtung von Liegeboxenställen für Milchkühe (Freestalls for dairy cows). Bauen. Auf. dem. Lande 1974, 5, 138–141.

- Natzke, R.P.; Everett, R.W. Cow preference for free stall surface material. J. Dairy Sci. 1982, 65, 146–153.

- Irps, H. Results of research projects into flooring preferences of dairy cattle. In Farm animal Housing and Welfare; Baxter, G., Mac Cormack, J.A.C., Eds.; Martinus Nijhof: The Hague, The Netherlands, 1983; pp. 200–215.

- Gebremedhin, K.G.; Cramer, C.O.; Larsen, H.J. Preference of dairy cattle for stall options in free stall housing. Trans. ASAE 1985, 28, 1637–1640.

- Nilsson, C. Floors in Animal Houses; University of Agricultural Sciences: Lund, Sweden, 1988.

- Cermak, J. Cow comfort and lameness. Bov. Pract. 1988, 23, 79–83.

- Colam-Ainsworth, P.; Lunn, G.A.; Thomas, R.C.; Eddy, R.G. Behaviour of cows in cubicles and its possible relationship with laminitis in replacement dairy heifers. Vet. Rec. 1989, 125, 573–575.

- Herlin, A. Comparison of lying area surfaces for dairy cows by preference, hygiene and lying down behaviour. Swed. J. Agric. Res. 1997, 27, 189–196.

- Krohn, C.C.; Munksgaard, L. Behaviour of dairy cows kept in extensive (loose housing pasture) or intensive (tie stall) environments. 2. lying and lying-down behaviour. Appl. Anim. Behav. Sci. 1993, 37, 1–16.

- Rushen, J.; De Passille, A.M.B.; Haley, D.B.; Manninen, E.; Saloniemi, H. Using behavioural indicators and injury scores to assess the effect of stall flooring on cow comfort. In Proceedings of the 6th International Symposium of Livestock Environment, Louisville, KY, USA, 21–23 May 2001; pp. 716–723.

- Manninen, E.; Passille, A.M.; Rushen, J.; Norring, M.; Saloniemi, H. Preferences of dairy cows kept in unheated buildings for different kind of cubicle flooring. Appl. Anim. Behav. Sci. 2002, 75, 281–292.

- O’Connell, J.M.; Meaney, W.J. Comparison of shredded newspaper and sawdust as bedding for dairy cows: Behavioural, clinical and economic parameters. Irish Vet. J. 1997, 50, 167–170.

- Jensen, P.; Recén, B.; Ekesbo, I. Preference of loose housed dairy cows for two different cubicle floor coverings. Swed. J. Agric. Res. 1988, 18, 141–146.

- Hansen, K.; Strøm, J.S.; Sigurdson, S. Lejebelægninger i Sengebåse Til Køer (Cubicle Mats for Dairy Cows); Danish Ministry of Food, Agriculture and Fishery: Copenhagen, Denmark, 1999; Volume 12, p. 8.

- Fulwider, W.K.; Palmer, R.W. Use of impact testing to predict softness, cow preference, and hardening over time of stall bases. J. Dairy Sci. 2004, 87, 3080–3088.

- Ortiz, X.A.; Smith, J.F.; Rojano, F.; Choi, C.Y.; Bruer, J.; Steele, T.; Schuring, N.; Allen, J.; Collier, R.J. Evaluation of conductive cooling of lactating dairy cows under controlled environmental conditions. J. Dairy Sci. 2015, 98, 1759–1771.

- Kadzere, C.T.; Murphy, M.R.; Silanikove, N.; Maltz, E. Heat stress in lactating dairy cows: A review. Livest. Prod. Sci. 2002, 77, 59–91.

- Cummins, K. Bedding plays role in heat abatement. Dairy Herd Manag. 1998, 35, 20.

- Fulwider, W.K.; Grandin, T.; Garrick, D.J.; Engle, T.E.; Lamm, W.D.; Dalsted, N.L.; Rollin, B.E. Influence of free-stall base on tarsal joint lesions and hygiene in dairy cows. J. Dairy Sci. 2007, 90, 3559–3566.

- Metcalf, J.A.; Roberts, S.J.; Sutton, J.D. Variations in blood flow to and from the bovine mammary gland measured using transit time ultrasound and dye dilution. Res. Vet. Sci. 1992, 53, 59–63.

- Prosser, C.G.; Davis, S.R.; Farr, V.C.; Lacasse, P. Regulation of blood flow in the mammary microvasculature. J. Dairy Sci. 1996, 79, 1184–1197.

- Ruud, L.E.; Bøe, K.E.; Østerås, O. Associations of soft flooring materials in free stalls with milk yield, clinical mastitis, teat lesions, and removal of dairy cows. J. Dairy Sci. 2010, 93, 1578–1586.

- Norgaard, P.; Rorbech, N.; Christensen, P.M. Effect of slope of cubicle floor on lying and ruminating behavior in cattle tied in experimental box stalls. In Proceedings of the Fifth International Dairy Housing Conference, Fort Worth, TX, USA, 29–31 January 2003; pp. 282–287.

- Dumelow, J. Testing cubicle mats for dairy cows. Agric. Eng. 1995, 50, 17–21.

- Phillips, C. Cattle Behaviour and Welfare; Blackwell Science: Oxford, UK, 2002.

- Tucker, C.B.; Weary, D.; Rushen, J.; De Passille, A.M. Designing better environments for dairy cattle to rest. Adv. Dairy Technol. 2004, 16, 39–53.

- Tucker, C.B.; Weary, D.M.; von Keyserlingk, M.A.G.; Beauchemin, K.A. Cow comfort in tie stalls: Increased depth of shavings or straw bedding increases lying time. J. Dairy Sci. 2009, 92, 2684–2690.

- D.L.G. Test Reports for Prefabricated Mats and Mattresses. Available online: www.dlg.org/stall.html (accessed on 16 November 2017).

- Ruud, L.E.; Stokke, T.; Boe, K.E.; Hettasch, T.; Skjolberg, P.O. Hus for Storfe—Norske Anbefalinger (Cattle Housing—Norwegian Recommendations), 4th ed.; Norwegian Cattle Health Services: Ås, Norway, 2015; p. 128.

- Calamari, L.; Calegari, F.; Stefanini, L. Effect of different free stall surfaces on behavioural, productive and metabolic parameters in dairy cows. Appl. Anim. Behav. Sci. 2009, 120, 9–17.

- Bewley, J.; Palmer, R.W.; Jackson-Smith, D.B. A comparison of free-stall barns used by modernized Wisconsin dairies. J. Dairy Sci. 2001, 84, 528–541.

- Fregonesi, J.A.; Leaver, J.D. Behaviour, performance and health indicators of welfare for dairy cows housed in strawyard or cubicle systems. Livest. Prod. Sci. 2001, 68, 205–216.

- Van Eerdenburg, F.J.C.M. Lying area design and barn climate getting it right. In Proceedings of the Cow Longevity Conference, Tumba, Sweden, 28–29 August 2013; pp. 74–99.

- Vokey, F.J.; Guard, C.L.; Erb, H.N.; Galton, D.M. Effects of alley and stall surfaces on indices of claw and leg health in dairy cattle housed in a free-stall barn. J. Dairy Sci. 2001, 84, 2686–2699.

- Kielland, C.; Ruud, L.E.; Zanella, A.J.; Østerås, O. Prevalence and risk factors for skin lesions on legs of dairy cattle housed in freestalls in Norway. J. Dairy Sci. 2009, 92, 5487–5496.

- Drissler, M.; Gaworski, M.; Tucker, C.B.; Weary, D.M. Freestall maintenance: Effects on lying behavior of dairy cattle. J. Dairy Sci. 2005, 88, 2381–2387.

- Ruud, L.E.; Bøe, K.E.; Østerås, O. Risk factors for dirty dairy cows in Norwegian freestall systems. J. Dairy Sci. 2010, 93, 5216–5224.

- Ferraz, P.F.P.; Ferraz, G.A.S.; Leso, L.; Klopcic, M.; Barbari, M.; Rossi, G. Properties of conventional and alternative bedding materials for dairy cattle. J. Dairy Sci. 2020, 103, 8661–8674.

- LMD. Forskrift Om Hold Av Storfe (Regulations on Keeping Cattle). Available online: https://lovdata.no/dokument/SF/forskrift/2004-04-22-665 (accessed on 16 November 2020).

- Reich, L.J.; Weary, D.M.; Veira, D.M.; Von Keyserlingk, M.A.G. Effects of sawdust bedding dry matter on lying behavior of dairy cows: A dose-dependent response. J. Dairy Sci. 2010, 93, 1561–1565.

- Nilsson, C. Walking and lying surfaces in livestock houses. In Farm Animals and the Environment; Phillips, C.P.D., Ed.; CABI: Wallingford, UK, 1992; pp. 93–110.

- Tucker, C.B.; Weary, D.M. Bedding on geotextile mattresses: How much is needed to improve cow comfort? J. Dairy Sci. 2004, 87, 2889–2895.

- Nordlund, K.; Cook, N.B. A flowchart for evaluating dairy cow freestalls. Bov. Pract. 2003, 37, 89–96.

- Fregonesi, J.A.; Veira, D.M.; von Keyserlingk, M.A.G.; Weary, D.M. Effects of bedding quality on lying behavior of dairy cows. J. Dairy Sci. 2007, 91, 5468–5472.

- Hogan, J.S.; Smith, K.L.; Schoenberger, P.S.; Todhunter, D.A. Bacteriological counts in organic and inorganic beddings. J. Dairy Sci. 1987, 70 (Suppl. 1), 129.

- Rowbotham, R.F.; Ruegg, P.L. Associations of selected bedding types with incidence rates of subclinical and clinical mastitis in primiparous Holstein dairy cows. J. Dairy Sci. 2016, 99, 4707–4717.

- Rowbotham, R.F.; Ruegg, P.L. Association of bedding types with management practices and indicators of milk quality on larger Wisconsin dairy farms. J. Dairy Sci. 2015, 98, 7865–7885.

- Rowbotham, R.F.; Ruegg, P.L. Bacterial counts on teat skin and in new sand, recycled sand, and recycled manure solids used as bedding in freestalls. J. Dairy Sci. 2016, 99, 1–15.

- Hogan, J.S.; Smith, K.L.; Hoblet, K.H.; Todhunter, D.A.; Schoenberger, P.S.; Hueston, W.D.; Pritchard, D.E.; Bowman, G.L.; Heider, L.E.; Brockett, B.L.; et al. Bacterial counts in bedding materials used on nine commercial dairies. J. Dairy Sci. 1989, 72, 250–258.

- Janzen, J.J.; Bishop, J.R.; Bodine, A.B.; Caldwell, C.A.; Johnson, D.W. Composted dairy waste solids and crushed limestone as bedding in free stalls. J. Dairy Sci. 1982, 65, 1025–1028.

- Chapinal, N.; Barrientos, A.K.; von Keyserlingk, M.A.; Galo, E.; Weary, D.M. Herd-level risk factors for lameness in freestall farms in the northeastern United States and California. J. Dairy Sci. 2013, 96, 318–328.

- Norring, M. The Effects of Stall Surfaces and Milk Yield on the Lying Behavior of Dairy Cow; University of Helsinki: Helsinki, Finland, 2011.

- Norring, M.; Manninen, E.; de Passille, A.M.; Rushen, J.; Munksgaard, L.; Saloniemi, H. Effects of sand and straw bedding on the lying behavior, cleanliness, and hoof and hock injuries of dairy cows. J. Dairy Sci. 2008, 91, 570–576.

- Mowbray, L.; Vittie, T.; Weary, D.M. Hock lesions and free stall design: Effects of stall surface. In Proceedings of the Fifth International Dairy Housing Conference, Fort Worth, TX, USA, 29 January 2003; pp. 288–295.

- Weary, D.M.; Taszkun, I. Hock lesions and free-stall design. J. Dairy Sci. 2000, 83, 697–702.

- Husfeldt, A.W.; Endres, M.I. Association between stall surface and some animal welfare measurements in freestall dairy herds using recycled manure solids for bedding. J. Dairy Sci. 2012, 95, 5626–5634.

- Husfeldt, A.W.; Endres, M.I.; Salfer, J.A.; Janni, K.A. Management and characteristics of recycled manure solids used for bedding in Midwest freestall dairy herds. J. Dairy Sci. 2012, 95, 2195–2203.

- Bickert, W.G.; Smith, J.F. Freestall Barn Design and Management for Cow Comfort; Report number: 2; Kansas Agricultural Experiment Station Research Reports: Kansas City, MO, USA, 1998.

- Bernard, J.K.; Bray, D.R.; West, J.W. Bacterial concentrations and sand usage in free stalls with fresh or recycled sand. In Proceedings of the Fifth International Dairy Housing Conference, Fort Worth, TX, USA, 29 January 2003; pp. 1–8.

- Norell, R.J.; Deaton, P.C.; Packham, J.H.; Parkinson, S.C. Cow preference between conventional sand bedded free stalls and free stalls with sand savers. J. Dairy Sci. 2004, 87, 388.

- McFarland, D.F.; Graves, R.E. A case study with dairy cattle: Freestalls. In Proceedings of the Animal Behavior and the Design of Livestock and Poultry Systems, Indianapolis, IN, USA, 19–21 April 1995; pp. 277–293.

- Tucker, C.; Weary, D. Cow comfort and free-stall design. In Proceedings of the Ontario Dairy Symposium, Toronto, ON, Canada, 20–21 March 2001; pp. 76–83.

- Wechsler, B.; Schaub, J.; Friedli, K.; Hauser, R. Behaviour and leg injuries in dairy cows kept in cubicle systems with straw bedding or soft lying mats. Appl. Anim. Beh. Sci. 2000, 69, 189–197.

- Chaplin, S.J.; Tierney, G.; Stockwell, C.; Logue, D.N.; Kelly, M. An evaluation of mattresses and mats in two diary units. Appl. Anim. Behav. Sci. 2000, 66, 263–272.

- Livesey, C.T.; Marsh, C.; Metcalf, J.A.; Laven, R.A. Hock injuries in cattle kept in straw yards or cubicles with rubber mats or mattresses. Vet. Rec. 2002, 150, 677–679.

- Bowell, V.A.; Rennie, L.J.; Tierney, G.; Lawrence, A.B.; Haskell, M.J. Relationships between building design, management system and dairy cow welfare. Anim. Welf. 2003, 12, 547–552.

- Wagner-Storch, A.M.; Palmer, R.W.; Kammel, D.W. Factors affecting stall use for different freestall bases. J. Dairy Sci. 2003, 86, 2253–2266.

- Palmer, R.W. Cow comfort issues in freestall barns. In Proceedings of the 7th Western Dairy Management Conference, Reno, NV, USA, 9–11 March 2005; pp. 141–156.

- House, H.K. Rubber filled cow mattress update. In Proceedings of the Fourth International Dairy Housing Conference, St. Louis, MO, USA, 28–30 January 1998.

- Adams, A.E.; Lombard, J.E.; Fossler, C.P.; I.N., R.M.; Kopral, C.A. Associations between housing and management practices and the prevalence of lameness, hock lesions, and thin cows on US dairy operations. J. Dairy Sci. 2017, 100, 1–18.

- Bickert, W.G. Free stall design and management: Michigan experiences. In Proceedings of the American Society of Agricultural Engineers, Chicago, IL, USA, 16–17 December 1991; p. 914566.

- McFarland, D. Experiences with free stall design in Pennsylvania. In Proceedings of the American Society of Agricultural Engineers, Chicago, IL, USA, 16–17 December 1991; p. 914568.

- Wadsworth Jones, B. The impact of Dual Chamber Cow Waterbeds as a Freestall Base; Tarleton State University: Lexington, KY, USA, 2014.

- Palmer, R.W.; Wagner-Storch, A.M. Cow preference for different freestall bases in pens with different stocking rates. In Proceedings of the Fifth International Dairy Housing Conference, Fort Worth, TX, USA, 29–31 January 2003.

- Sonck, B.; Daelemans, J.; Langenakens, J. Preference test for free stall surface material for dairy cows. In Proceedings of the ASAE-CSAE-SCGR Annual International Meeting, Toronto, ON, Canada, 18–21 July 1999; p. 10.

- Tucker, C.B.; Weary, D.M.; Fraser, D. Free-stall dimensions: Effects on preference and stall usage. J. Dairy Sci. 2004, 87, 1208–1216.

- Shewbridge Carter, L.; Rutter, S.M.; Ball, D.; Gibbons, J.; Haskell, M. Dairy cow trade-off preference for 2 different lying qualities: Lying surface and lying space. J. Dairy Sci. 2021, 104, 862–873.

- Dirksen, N.; Gygax, L.; Traulsen, I.; Wechsler, B.; Burla, J.-B. Body size in relation to cubicle dimensions affects lying behavior and joint lesions in dairy cows. J. Dairy Sci. 2020, 103, 9407–9417.

- Tucker, C.B.; Zdanowicz, M.; Weary, D. Brisket boards reduce freestall use. J. Dairy Sci. 2006, 89, 2603–2607.

- Anonimus. Indretning af Stalde til Kvaeg—Danske Anbefalinger (Cattle Housing—Danish Recommendations); Danish Extension Service: Aarhus, Denmark, 2010; p. 184.

- Hulsen, J. Cow Signals; Roodbont, Agricultuiral Publishers: Zutphen, The Netherlands, 2014.

- Ruud, L.E.; Kielland, C.; Østerås, O.; Bøe, K.E. Free-stall cleanliness is affected by stall design. Livest. Sci. 2011, 135, 265–273.

- NFA. Norwegian Food Authorithies: Veileder til forskrift Om Hold Av Storfe (Guidelines to the Regulations on Keeping Cattle). Available online: https://lovdata.no/dokument/SF/forskrift/2004-04-22-665 (accessed on 16 November 2020).

- CIGR. The Design of Dairy Cow Housing. Report of the CIGR Section II Working Group 14 on Cattle Housing; Farm Buildings Research Team; ADAS Bridgets Dairy Research Centre: Winchester, UK, 1994.

- Anderson, N.G. Cow behaviour to Judge Free-Stall and Tie-Stall Barns; OMAFRA: Guelph, ON, Canada, 2008; pp. 1–10.

- McFarland, D.F. Freestall design: Cow recommended refinements. In Proceedings of the Animal Behaviour and the Design of Livestock and Poultry Systems, Indianapolis, IN, USA, 19–21 April 2003; pp. 131–138.